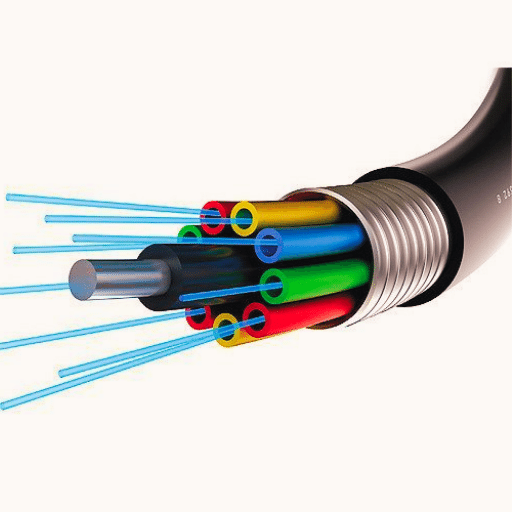

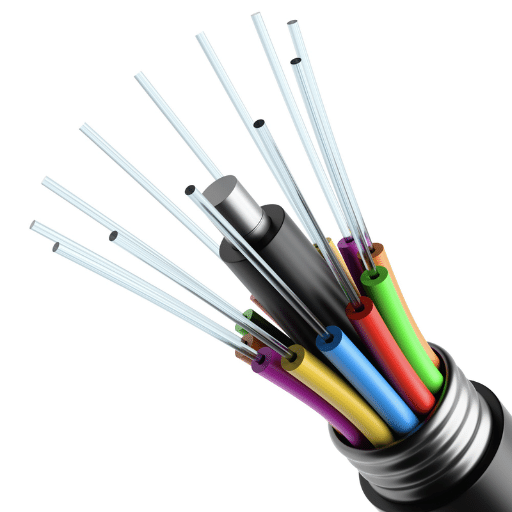

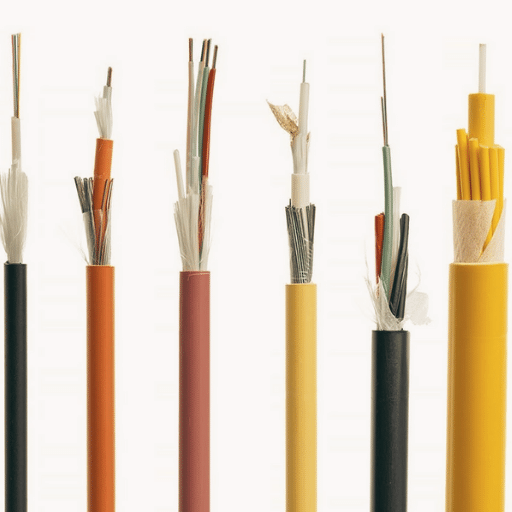

Fiber Optic Cable is a cable composed of fragile glass or plastic fibers bundled together and coated in a protective covering. These fibers can transmit information using light, which travels through the strands at incredibly high speeds. The result is fast and reliable communication capable of handling large amounts of data over long distances. In comparison to traditional copper cables, which use electrical signals to transmit data, Fiber Optic Cable is more efficient and has the potential to operate at much higher bandwidths.

Fiber Optic Cable is an essential tool for modern communication systems, as it provides a fast and reliable means of transmitting information over long distances. The speed and bandwidth capabilities of Fiber Optic Cable make it ideal for use in telecommunications, data centers, and other applications that require high-speed, reliable data transmission. Because Fiber Optic Cable can transmit data over long distances without losing signal strength or quality, it has become an increasingly popular choice for connecting global networks. As the world becomes more connected, the importance of Fiber Optic Cable in facilitating this connectivity is only set to grow.

The Types of Cable Damage range from physical damage caused by rodents or animals to environmental factors such as humidity and temperature changes. Physical damage often occurs when rodents or other animals bite or chew through the cable’s outer coating, causing significant damage to the glass fibers inside. Water exposure can also cause damage to Fiber Optic Cable, leading to signal loss or attenuation. Aging and thermal damage occur over time due to exposure to high temperatures, leading to signal loss and degradation. Bending and fracture damage can also occur when the cable is bent at sharp angles or subjected to temperature changes. It is crucial to prevent these types of damage to maintain data transmission reliability.

Several factors contribute to Fiber Optic Cable Damage. Common Causes include improper installation, excessive bending, mechanical stress, and inadequate cable protection. Improper installation can weaken the cable’s protective coating or cause awkward positioning, leading to damage if not addressed. Excessive bending can also cause Fiber Optic Cable damage, as the fibers inside are fragile and easily breakable. Mechanical stress can also damage the cable, such as high tension and twisting. Finally, inadequate cable protection, such as insufficient shielding and inadequate enclosures, can expose Fiber Optic Cable to excessive environmental factors that can result in damage. Therefore, it is essential to ensure proper installation, maintain adequate tension, avoid high-stress movements, and use appropriate shielding and enclosures to prevent Fiber Optic Cable damage.

Repairing a damaged fiber optic cable requires specific equipment and materials, including a fiber optic cable tester, a fiber optic cleaner, fiber optic connectors, a splicing machine, fiber optic strippers, polishing pads, and a fusion splicer. Each tool and material serves a unique purpose in the repair process, and the proper equipment is necessary to ensure a successful repair.

The first step in repairing a fiber optic cable is identifying the location and extent of the damage. This requires using a fiber optic cable tester to determine the location of the break or cut in the cable. Once the damage is identified, isolating the affected area and protecting the surrounding fiber optic cables is essential.

Fusion splicing can repair the damage if the fiber optic cable has been cut. Fusion splicing involves aligning the two broken fiber ends and fusing them with an electric arc. Excess fibers are removed once connected, and the splice is protected with a heat shrink sleeve.

In the case of a broken fiber optic cable, mechanical splicing can be used to repair the damage. Mechanical splicing involves aligning the two broken fiber ends and securing them with an adhesive or automatic clamp. The splice is then protected with a heat shrink sleeve.

Splicing fiber optic cables combines two to create a single, longer line. This technique is commonly used to repair damaged fiber optic cables and to extend the reach of a fiber optic network. Splicing fiber optic cables requires a fusion splicer machine and a proper understanding of fiber optic cable splicing techniques. A successful splice creates minimal signal loss and ensures a reliable cable connection.

Preventive measures can significantly reduce the need for costly repairs in the future. Regularly inspecting the cables for signs of wear and tear, such as cracks or bends, can help to identify potential problems before they occur. Additionally, ensuring that the wires are installed in a location that provides adequate ventilation and protection from extreme temperatures will help to extend their lifespan. In situations where the cables must be installed in harsh environmental conditions, protective ducts can be used to shield them from the elements.

Regular inspection and testing ensure that fiber optic cables function as intended. Inspections can detect damage or defects early on, preventing further harm to the cable. Testing can also determine the cable’s performance, including its ability to transmit data efficiently and at the intended speed. This helps to prevent slow transmission speeds and data loss. Proper testing is critical during the installation and initial deployment of fiber optic cables and during routine maintenance.

Protecting fiber optic cables from physical damage is essential, as they are very delicate and can easily be damaged if not handled correctly. One way to protect cables is by using ducting or conduits. Another protective measure is to install lines in a location that is not susceptible to traffic or other hazards. It’s also essential to properly ground fiber optic cables to prevent them from becoming electrified due to power surges or lightning strikes.

Proper installation techniques ensure the longevity and optimal performance of fiber optic cables. The installation process should adhere to industry-specific regulations and guidelines. The correct tools and equipment are essential when handling the lines and their connectors. Stressing the wires during installation can damage the fibers, resulting in signal loss. Ensuring that the lines are appropriately supported and avoiding over-bending or kinking will also help to prevent damage.

Timely repairs are a fundamental aspect of fiber optic cable maintenance. Any delay in repairing damaged or faulty cables can result in various complications that may lead to more significant issues. For instance, if a line is not repaired immediately, it can cause signal disruption, resulting in data loss and reduced network performance. Furthermore, if the problem continues, it could lead to permanent damage, making repairs even more complicated and costly. Thus, conducting regular checks and taking immediate action when an issue arises is vital to prevent more extensive damage.

Fiber optic cables require specialized knowledge and equipment to repair effectively. Repairs that involve crucial components like attenuators, splicers, and couplers should be left to trained and certified professionals with years of experience in the field. Fixing these complicated issues without professional assistance can further damage the cables and result in costly repairs. By involving experts, you can be assured that the job will be done effectively and within a shorter time frame. Professional assistance also includes the best cleaning solutions, testing equipment, and accurate diagnoses of issues, ensuring that all repairs are conducted with precision and care.

Maintaining fiber optic cables is crucial due to the benefits it offers. For instance, regular cleaning and inspection help keep the wires functioning optimally, which improves their performance and extends their lifespan. In addition, proper maintenance helps detect and repair issues early, reducing the likelihood of costly repairs. Regular maintenance, such as cleaning and inspection, also reduces the potential for contamination, which can negatively affect signal quality. Maintaining fiber optic cables can help prevent downtime and revenue loss, leading to greater productivity and profitability.

A: Fiber optic cables transmit data as light pulses through the optical fibers. The light is transmitted through the core thread, surrounded by a cladding layer that reflects the lightwaves into the body, allowing it to travel long distances with minimal signal loss.

A: Repairing a broken fiber optic cable requires specialized tools and expertise. The damaged section of the line needs to be cut out, and the two ends of the fiber optic cable need to be spliced back together using a fusion splicer.

A: A fusion splicer is a tool to join two fiber optic cables by fusing the glass fibers at their ends. This creates a continuous connection and ensures the signal can pass through the splice without any loss or interference.

A: To repair a fiber optic cable, you will need tools such as a fiber optic stripper, fiber optic cutter, fiber cleaver, OTDR (Optical Time Domain Reflectometer), and a chopper. These tools are used to prepare the cable ends, clean the stripped fiber, splice the cable, and verify the quality of the splice.

A: No, you should never use a regular cutter to cut a fiber optic cable. Fiber optic cables are delicate and require special tools, such as a fiber optic cutter, designed to make clean cuts without damaging the fibers.

A: Clean the stripped thread using a lint-free wipe and a fiber optic cleaning solution before splicing the fiber. This removes any dust or contaminants that could affect the quality of the splice.

A: If you accidentally damage a fiber optic cable, the first step is to isolate the damaged section by cutting the cord on either side of the damaged area. Then, you can use a fusion splicer to join the two line ends back together.

A: To prevent damage to fiber optic cables, it is essential to handle them carefully, avoid bending or pulling them too tightly, and protect them from exposure to extreme temperatures or moisture. Regular inspections and maintenance can also help identify and address any potential issues before they cause damage.