What is a Fiber Pigtail and Its Types?

A Fiber Pigtail is a single, short, usually tight-buffered, optical fiber that has an optical connector pre-installed on one end and a length of exposed fiber at the other end. This sensitive end is fusion spliced onto another single fiber (or fiber bundle), providing a robust and reliable link between the fiber and the device it’s connected to.

There are several types of fiber pigtails, each with their unique characteristics and applications. The most common styles include:

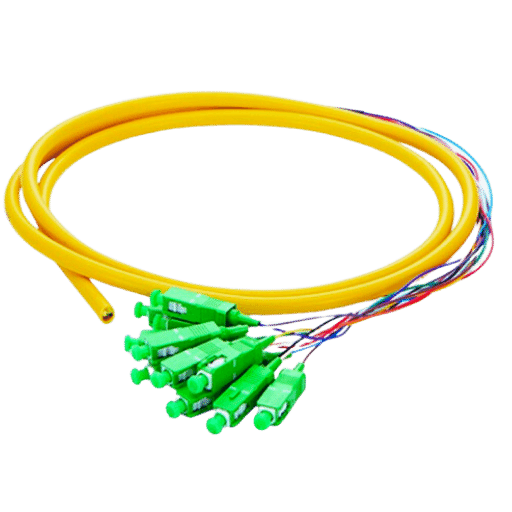

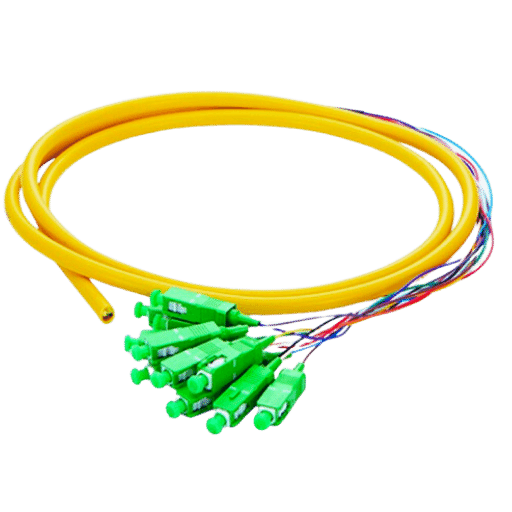

- Single-mode Fiber Pigtails: These are designed for long-distance data transmission. They use 9/125um glass fiber and are often color-coded yellow.

- Multimode Fiber Pigtails: Ideal for short-distance transmissions, these use larger diameters (50 or 62.5/125um) and are typically color-coded orange or aqua.

- Polarization Maintaining (PM) Fiber Pigtails: These are designed to maintain the polarization of the light wave transmitted through them. They are commonly used in fiber amplifiers, fiber lasers, and other high-speed communication devices.

Each type serves different applications and environments, and the specific requirements of your network should determine the choice of fiber pigtail.

Understanding the Basics of Fiber Pigtail

Understanding the basics of Fiber Pigtail involves recognizing a few key components:

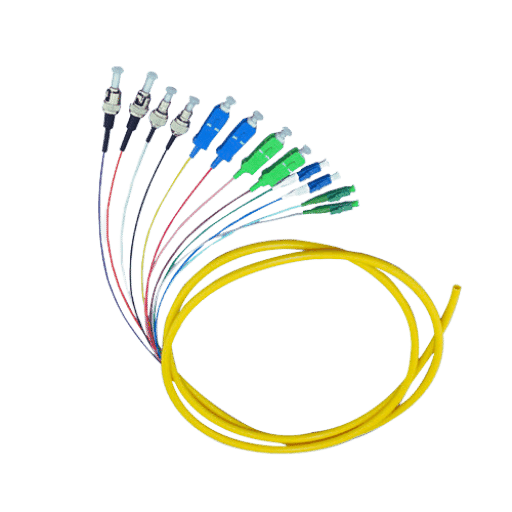

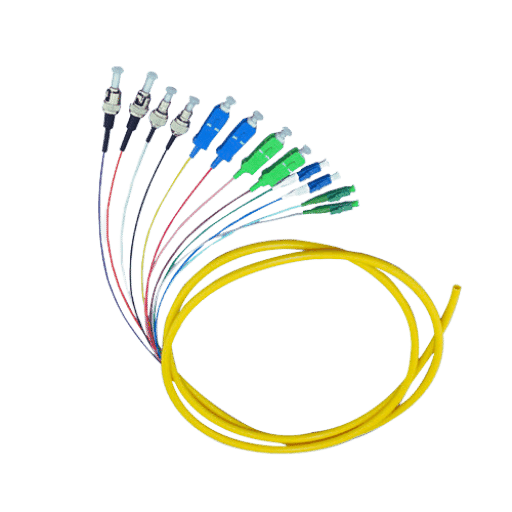

- Optical Connector: This is the pre-installed end of the fiber pigtail. It’s the component that gets plugged into the optical device or panel. Different types of connectors exist, like SC, LC, FC, ST, and E2000, each serving other purposes and environments.

- Core and Cladding: The body is the thin glass center of the fiber where the light propagates. Surrounding the body is another layer of glass known as the cladding. Their combined structure enables total internal reflection, allowing light to travel down the fiber.

- Buffer Coating: This is a plastic coating that protects the fiber from damage and moisture. In fiber pigtails, this coating is usually tight-buffered, meaning it’s directly in contact with the cladding.

- Splice: This refers to the junction where the exposed end of the fiber pigtail is joined to another fiber. Fusion splicing, which uses heat to fuse the threads, is the most common method as it provides a high-quality, reliable splice.

- Transmission Modes: Fiber pigtails can be single-mode or multimode. Single-mode fibers transmit one signal per fiber and are used for long-distance transmission. In contrast, multimode fibers transmit multiple light rays or modes simultaneously and are used for short distances.

Understanding these components can help you make an informed decision when choosing a fiber pigtail for your network.

Types of Fiber Pigtail Connectors

The selection of Fiber Pigtail Connectors is vast, each designed for specific applications and environments. Here are some common types:

- SC Connector Stands for “Subscriber Connector” or “Square Connector”. Known for its push-pull design, it’s often used in datacom and telecom applications.

- LC Connector: “Lucent Connector” or “Little Connector” is designed for high-density applications. It’s a small form-factor connector that uses a 1.25mm ferrule, half the size of the SC.

- FC Connector: “Ferrule Connector” or “Fiber Channel,” known for its screw-on design, is primarily used in telecom and measurement equipment.

- ST Connector: The “Straight Tip” connector uses a bayonet mount and a long cylindrical ferrule to hold the fiber. They are used mainly in multimode fiber applications such as LANs.

- E2000 Connector: This is a high-performance fiber connector with a spring-loaded shutter used to protect the ferrule from dust and scratches.

Understanding the differences among these connectors can assist in selecting the most suitable Fiber Pigtail for your particular network setup.

Differences Between Single Mode and Multimode Fiber Pigtails

Single Mode and Multimode Fiber Pigtails differ significantly in their design and functionality, each suited to different types of applications:

- Transmission Distance: Single Mode Fiber Pigtails are designed for long-distance transmission due to their ability to prevent signal degradation over large spans. At the same time, Multimode Fiber Pigtails are primarily used for short distances.

- Core Diameter: Single Mode Fiber Pigtails have a smaller core diameter, typically 9 microns, which allows only one mode of light to propagate. On the other hand, Multimode Fiber Pigtails have a larger core diameter, ranging from 50 to 62.5 microns, enabling multiple light modes to bear simultaneously.

- Cost: Single Mode Fiber Pigtails, due to their sophisticated design for long-distance transmission, tend to be costlier than Multimode Fiber Pigtails.

- Data Rate and Bandwidth: Single Mode Fiber Pigtails offer a higher data transfer rate over longer distances, making them ideal for telecommunication and cable TV networks. Conversely, Multimode Fiber Pigtails, with their multiple transmission paths, provide high bandwidth over short distances, perfect for data and audio/visual applications in LAN networks.

- Color Codes: Single Mode Fiber Pigtails are usually color-coded yellow, while Multimode Fiber Pigtails are typically orange or aqua.

Understanding these differences can be crucial when determining which type of fiber pigtail will best serve the specific requirements of your network.

Benefits of Using Different Fiber Types in Pigtails

Single Mode Fiber Pigtails provide several significant benefits:

- Long Distance Transmission: Their capacity to maintain signal integrity over long distances is unmatched, making them an ideal choice for telecommunications and CATV networks.

- High Data Rate: The design of these fibers allows for higher data transfer rates, ensuring efficient and reliable data transmission.

- Decreased Signal Interference: The single light mode propagation minimizes the risk of signal interference and dispersion, enhancing the overall network performance.

Conversely, Multimode Fiber Pigtails offer their unique advantages:

- Cost-Effective: These fibers are generally less expensive to produce and install, making them a cost-effective solution for short-distance transmissions.

- High Bandwidth Short Distance Transmissions: With their ability to carry multiple light modes, these fibers can provide high bandwidth over short distances, suitable for data and audio/visual applications in LAN networks.

- Versatility: The larger core diameter reduces the need for precision when aligning connections, making these fibers a versatile option for various network configurations.

The decision to use either Single Mode Fiber Pigtails or Multimode Fiber Pigtails should be made with careful consideration of the specific requirements and constraints of your network application.

Standard Fiber Count Configurations in Pigtails

Pigtails come in various fiber count configurations, each catering to different bandwidth and application requirements.

The Single Fiber Pigtail is the most rudimentary configuration, often used for simple point-to-point connections.

4 Fiber Pigtails are commonly used for bi-directional transmissions, which require separate fibers for transmitting and receiving data.

6 Fiber Pigtails are ideal for applications requiring redundancy, with additional fibers acting as backup in case of a primary fiber failure.

12 Fiber Pigtails are typically used in high-density network environments such as data centers, offering substantial capacity for data transfer.

Lastly, 24 Fiber Pigtails are used in large-scale operations requiring extensive bandwidth, such as wide area networks and metropolitan area networks. The choice of fiber count is dictated by the specific needs of the network, including factors such as transmission distance, data rate, and redundancy requirements.

How to Splice Fiber Pigtails?

Step-by-Step Guide to Fusion Splicing Fiber Pigtails

Fusion splicing is a commonly used method for joining two optical fibers end-to-end, creating a single long thread. Here is a step-by-step guide to fusion splicing fiber pigtails:

- Strip the Fiber: Begin by stripping the protective coating from the end of each line using a fiber optic stripper. This exposes the delicate glass fiber.

- Clean the Fiber: Clean the exposed fiber with a lint-free wipe soaked in isopropyl alcohol to remove any residues.

- Cleave the Fiber: Using a fiber cleaver, create a clean, flat end-face on each fiber. This ensures optimal alignment and minimal signal loss during fusion.

- Place Fibers in the Fusion Splicer: Position each fiber in the splicer’s holding fixture. The fusion splicer automatically aligns the threads using a combination of image and light detection.

- Fusion Splice: Initiate the fusion splice. The splicer uses an electric arc to melt the fibers, fusing them. Allow the splice to cool.

- Inspect the Splice: Examine the splice using the splicer’s magnification features. Look for a uniform line indicating a successful fusion.

- Protect the Splice: Finally, slide a heat-shrink splice protector over the splice and apply heat to secure it.

Follow these steps carefully to ensure a successful fusion splice. Incorrect splicing can lead to increased signal loss and potential failure of the fiber network.

Advantages and Disadvantages of Mechanical Splicing for Fiber Pigtails

Mechanical splicing for fiber pigtails presents its unique sets of advantages and disadvantages.

Advantages of Mechanical Splicing:

- Speed: Compared to fusion splicing, mechanical splicing is a faster process, making it a preferable choice when restoration speed is of utmost importance.

- Ease of Use: Mechanical splices are generally easier to implement and do not require expensive equipment or extensive training.

- Cost-Effective: The initial investment for mechanical splicing equipment is lower than for fusion splicing, making it a more budget-friendly option.

Disadvantages of Mechanical Splicing:

- Higher Insertion Loss: Mechanical splicing tends to have higher insertion loss compared to fusion splicing. This may result in reduced signal quality.

- Back Reflection Issues: Mechanical splices can cause back reflection problems, which can interfere with certain types of equipment.

- Less Durable: Mechanical splices are typically not as robust or permanent as fusion splices, potentially necessitating more frequent maintenance or replacement.

Best Practices for Waterproofing Fiber Pigtails

To ensure the longevity and functionality of fiber pigtails, it is essential to implement waterproofing practices. Here are the best practices for waterproofing fiber pigtails:

- Use of Waterproof Enclosures: The first line of defense against water damage is to use waterproof enclosures. These are specially designed to prevent water ingress and protect the delicate fiber components from harsh environmental conditions.

- Proper Sealing: It is vital to seal all closures and entry points properly correctly. Silicone sealants or waterproof tapes are recommended for this purpose.

- Regular Inspections: Regularly inspect your fiber pigtails for signs of water damage, such as discoloration or corrosion. Early detection can save you from expensive repairs and network downtime.

- Use Outdoor-rated Cables: If the fiber pigtails are to be used outdoors, opt for outdoor-rated cables. These cables have additional layers of protection against water, UV radiation, and other environmental hazards.

- Keep a Maintenance Schedule: Establish a routine maintenance schedule to check and reapply waterproofing methods as necessary. Regular maintenance will ensure that your waterproofing efforts remain effective over time.

Dealing with Armored Fiber Pigtails: Tips and Techniques

Working with armored fiber pigtails requires specific techniques to maintain and optimize their performance:

- Understanding the Structure: Armored fiber pigtails are built with an extra protective layer made from steel or other metals to provide added protection against physical damage. Be mindful of this structure during installation and maintenance.

- Proper Handling: Despite the armor, these pigtails cannot withstand sharp bending or twisting. Handle with care to prevent fiber breakage.

- Use of Armored Fiber Patch Panels: When integrating armored fiber pigtails into a network, utilizing armored fiber patch panels can provide an additional layer of protection and ensure easy cable management.

- Regular Inspections: Just like any other fiber component, conduct regular inspections to detect any signs of damage or wear that could impact performance.

- Professional Installation: Given their unique structure, engaging a professional for installation can prevent potential damages and ensure the armored fiber pigtails function optimally.

- Proper Storage: When not in use, armored fiber pigtails should be coiled and stored in a clean and dry environment to prevent any potential damage.

Remember, while armored fiber pigtails offer superior protection, they still require careful handling and regular maintenance to ensure their longevity and efficiency.

Understanding Bare Fiber Splicing in Pigtails

Bare fiber splicing in pigtails is a vital process in fiber optics, connecting optical fibers to maintain signal integrity. It can be done through fusion or mechanical splicing, each with its advantages. Proper fiber preparation is crucial for optimal alignment and performance.

Fiber Pigtail Installation and Usage

How to Properly Install and Secure Fiber Pigtail Assemblies

- Preparation: Gather all necessary tools and equipment to ensure a smooth installation process. This includes fiber pigtails, connectors, a fusion splicer, and a fiber cleaver.

- Cleaning: Before installation, clean the fiber pigtail ends with a quality fiber cleaner to remove any dust or debris.

- Stripping: Use a fiber stripping tool to remove the outer jacket of the fiber pigtail, exposing the optical fiber.

- Cleaving: Utilize a fiber cleaver to achieve a precise, clean cut at the end of the fiber. This step is critical for a successful fusion splice.

- Splicing: Following the stripping and cleaving process, proceed to join the fibers using a fusion splicer. This device will align and fuse the thread ends together.

- Securing the Connection: Once the splice is completed, protect the splice point using heat shrink tubing or a splice sleeve to secure the connection.

- Testing: Finally, test the newly installed fiber pigtail assembly using an optical power meter to ensure the splice provides a clear signal path.

Remember, each step in the installation process is crucial, and skipping or rushing through steps can lead to poor performance or even damage to the fiber pigtail assemblies. It’s recommended always to follow the manufacturer’s instructions and seek professional assistance if needed.

Utilizing Fiber Pigtails in Splice Trays for Optimal Performance

Fiber pigtails can be efficiently utilized in splice trays for optimal performance. The primary concern is maintaining a clean environment and avoiding excessive bends or pressure on the fibers. Organize the pigtails within the tray to prevent tangling and crisscrossing of fibers.

Practical Tips for Handling 1 Fiber vs. 12 Fiber Pigtails

Whether handling a single or 12-fiber pigtail, the careful management of fibers is crucial. For single-fiber pigtails, ensure a clean and dust-free environment. For 12 fiber pigtails, the importance of organization and gentle handling is amplified due to the higher number of fibers.

Choosing the Right Connector Type for Your Fiber Pigtail Applications

The choice of connector type for your fiber pigtail depends on your specific application. SC connectors are widely used for their excellent performance, while LC connectors are preferred for their compact design and high-density connectivity.

Comparing Advantages of SC and LC Connectors in Fiber Pigtails

SC and LC connectors, two common types used in fiber pigtails, have distinct advantages:

SC Connectors

- Performance: SC connectors are known for their excellent performance and low insertion loss.

- Durability: They have a robust and durable design that withstands repeated use.

- Ease of Use: The push-pull design of SC connectors makes them easy to connect and disconnect.

LC Connectors

- Size: LC connectors are more miniature, making them ideal for high-density applications.

- Reduced Backreflection: LC connectors are known for their reduced backreflection, which improves signal quality.

- Versatility: They are versatile and can be used for both single-mode and multimode fibers.

Common Issues and Maintenance of Fiber Pigtails

Identifying Potential Problems with Fiber Pigtail Splices

Identifying potential problems with fiber pigtail splices and addressing them promptly ensures the longevity and efficiency of your fiber optic network. Here are some common issues to be aware of:

- Poor Alignment: Improper alignment of fibers can lead to high insertion loss, affecting the performance of the connection.

- Dirty Fiber Ends: Dirt or dust on the ends of the fibers can cause scattering or absorption of the light, reducing the signal strength.

- Cracked Fibers: Cracked or damaged fibers can result in signal loss and reduced network performance.

- Inferior Splice Quality: Poorly made splices may lead to high loss and reflection, which can affect the quality of data transmission.

- Improper Fiber Handling: Mishandling fibers during the splicing process can lead to mechanical stress, causing signal loss and potential damage to the threads.

- Moisture Exposure: Exposure to moisture can cause degradation of the splice, affecting the longevity and reliability of the connection.

Regular maintenance checks and careful handling of fiber pigtails can help mitigate these issues and ensure the optimal performance of your fiber optic network.

Ensuring Proper Cleaning and Care for Fiber Patch Cords and Pigtails

Proper cleaning and care are essential for maintaining the performance of fiber patch cords and pigtails. Contamination from dust, oils, or other particulates can degrade signal quality. Use isopropyl alcohol and lint-free wipes for cleaning, and permanently cap the connectors when not in use.

Addressing Signal Loss and Quality Issues in Single-Mode Fiber Pigtails

Bends, kinks, or poor-quality connectors can cause a signal loss in single-mode fiber pigtails. Regular inspection and testing can help identify these issues. If signal loss is determined, consider replacing the faulty components or re-splicing the fiber.

Effective Troubleshooting for Multimode Fiber Pigtail Connections

Effective troubleshooting of multimode fiber pigtail connections involves a systematic approach. Here are some common steps to consider:

- Visual Inspection: Check for noticeable signs of damage, such as cracks or bends in the fiber or dirt on the connectors.

- Cleaning: Use appropriate cleaning methods to remove any dust or debris from the connectors, ensuring a clean signal path.

- Testing: Use fiber optic testing tools to measure signal loss and identify any problematic areas.

- Replacement: If problems persist, it may be necessary to replace components or even the entire pigtail.

- Documentation: Keep detailed records of any issues and resolution steps taken, creating a valuable resource for future troubleshooting.

Maximizing Lifespan and Performance of Fiber Optic Pigtail Cables

To maximize the lifespan and performance of fiber optic pigtail cables, ensure proper installation and handling, regular cleaning, and environmental control. Avoid excessive bending or pulling, and keep the wires away from corrosive substances and extreme temperatures. Regular testing can help identify any performance issues early on.

The Future of Fiber Pigtails and Emerging Technologies

Fiber pigtail technology is evolving to meet the demands of next-generation networks and innovations. Advancements in splicing and connectors streamline installation and boost performance. Single-mode fiber pigtails are preferred for long-haul applications, while multimode pigtails remain cost-effective for short distances. Beyond telecommunications, fiber pigtails have potential in environmental sensing, health monitoring, and industrial automation. The industry faces challenges in balancing performance, cost, and ease of use, but these present opportunities for innovation.

Frequently Asked Questions

Q: What are the different types of fiber pigtails?

A: There are several types of fiber pigtails, including single mode, multimode, SC, LC, FC, armored, waterproof, and more.

Q: How does a fiber pigtail differ from a fiber cable?

A: A fiber pigtail is a single, short, terminated optical fiber, whereas a fiber cable consists of multiple fibers bundled together within a sheath.

Q: What is the difference between a fiber pigtail and a fiber optic cable?

A: A fiber pigtail is a single, short, terminated optical fiber typically used for splicing or connecting to a patch panel, whereas a fiber optic cable consists of multiple fibers bundled together within a protective jacket for long-distance transmission.

Q: What is single-mode fiber?

A: Single-mode fiber is a type of optical fiber that allows only one mode of light to propagate. It is designed for long-distance, high-speed transmission with a smaller core size compared to multimode fiber.

Q: What is involved in fiber optic pigtail splicing?

A: Fiber optic pigtail splicing is the process of joining or connecting the fiber pigtail to another optical fiber using fusion splicing or mechanical splicing techniques.

Q: What are the specifications of a fiber pigtail?

A: Fiber pigtail specifications include fiber type (single mode or multimode), connector type (SC, LC, FC), cable length, and jacket material (armored or waterproof).

Q: What are the common types of connectors used in fiber pigtails?

A: Common connector types used in fiber pigtails include SC, LC, and FC connectors, which are widely used in fiber optic communication systems.

Q: Are fiber optic pigtails available with connectors on both ends?

A: Yes, fiber optic pigtails are available with connectors on one end (pigtail) or with connectors on both ends (patch cord).

Q: What is the purpose of a fiber splice tray in relation to fiber pigtails?

A: A fiber splice tray is used to organize and protect the spliced or terminated fiber pigtails, providing secure and reliable housing for fiber optic connections.

Q: What are the differences between single-mode fiber and multimode fiber in the context of fiber pigtails?

A: Single-mode fiber is designed for long-distance, high-speed transmission with a smaller core size, while multimode fiber is used for shorter distances with a larger core size. Different types of fiber pigtails are available for these specific applications.

Recommended Reading: Everything You Need to Know About Fiber Connector Types

References

- Optcore: What is Fiber Pigtail? A Complete Guide for Beginners: This beginner-friendly guide introduces the basics of fiber pigtail, including its definition and applications.

- Foppex: Understanding Fiber Pigtail: A Comprehensive Guide: A thorough guide that explores the world of fiber pigtails, covering their definition, significance, usage, types, and installation process.

- QSFPTek: Fiber Optic Pigtail Introduction and Installation Guide: This post provides fundamental information about fiber optic pigtails, including details on various pigtail connector types and classifications.

- VCelink: Fiber Connector Types: The Ultimate Guide: This guide provides an overview of different fiber connector types, which are crucial to understanding fiber pigtails.

- FS Community: Fiber Optic Pigtail: What Is It and How to Splice It?: This blog post discusses fiber optic pigtail and provides a guide to splicing it, offering practical advice for users.

- TrueFiber: What is a Fiber Optic Pigtail, and What Is It Used For?: This blog post explains what a fiber optic pigtail is and its uses, particularly in single-mode applications.

- FiberSavvy: Fiber-Optic Pigtails: This article delves into the different characteristics and uses of fiber pigtails within a fiber network.

- Version: An Ultimate Guide for Selection of Fiber Optic Cables and Connectors: This guide helps users choose the best fiber optic cables and connectors for their needs, which is essential when dealing with fiber pigtails.

- Hardware Secrets: Fiber Optic Cables – A Comprehensive Guide: This comprehensive guide discusses everything you need to know about fiber optic cables, their connector types, prices, uses, and more.

- Fibconet: Fiber Optic Pigtail Meaning: What is it, and how do you choose it? This post explains what a fiber optic pigtail is and provides guidance on how to choose the right one, offering valuable insights for users.