For different systems, inline couplers ensure connectivity and efficiency, e.g., in fiber optic networks and other places. With the increasing need for better-performing and more reliable products, the search for excellence in the best inline coupler alternatives is now very important in optimizing activities and minimizing downtime. This blog post will consider how advanced technology is transforming the capabilities of inline couplers by extensively analyzing their characteristics, advantages, and applications. If you are looking at enhancing system efficiency, increasing durability, or streamlining maintenance, this guide will give you the insights needed to make informed decisions. Be prepared to unlock the potential of customized inline coupler solutions that adequately address today’s dynamic environments.

An inline coupler is a tool used to link up two stretches of a system, usually cables, pipes, or hoses, in an effective and safe mode. It allows for a smooth flow of signals, fluids, or any other media while maintaining the system’s integrity. These devices are reliable in design, minimizing chances of leakage or energy loss and maintaining uniformity in performance. They are easy to install; thus, they find common use in such industries as telecommunications, hydraulics, and mechanical systems so as to ensure that there is no disruption during operations.

In many technical and industrial systems, in-line couplers are an important part. They join various parts like pipes, cables, or hoses within a system so that they can still operate despite being subject to extreme conditions. These current inline couplers are characterized by their precision in design, high strength and ability to work under different pressures as well as flow rates. Hydraulic systems’ couplers, for instance, are made such that they stay sealed even when pressure exceeds 3000 psi.

An example of a major improvement in modern designs is the use of new materials like stainless steel and advanced polymeric composites that have extended the life span of these devices through resistance to corrosion. In addition, the application of quick-connecting types has been facilitated by their simplicity in usage and the absence of delays caused during maintenance operations. O-rings or gaskets form part of integrated sealing mechanisms in addition to other measures that prevent any leakage that may interfere with optimal performance.

Industries such as telecommunications and fluid dynamics are heavily reliant on these tools for their functionality. A good example is telecommunication, where fiber optic inline couplers facilitate smooth data transfer with very minimal signal loss, enabling high-speed connectivity over long distances. In the same way, mechanical systems give room for expansion or contraction due to temperature variations and other mechanical stresses, thus ensuring system stability. These attributes underscore the importance of inline couplers in modern infrastructure and technology.

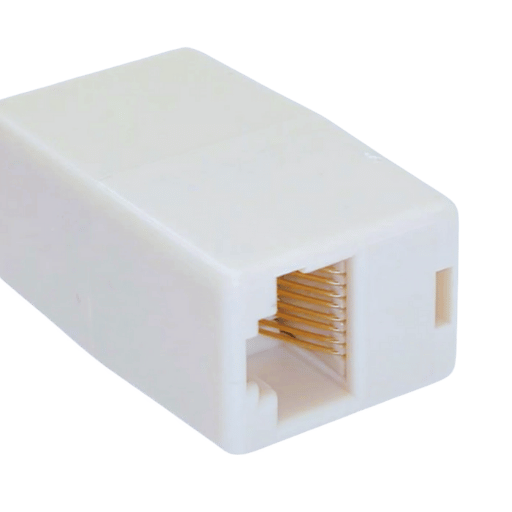

For the connection of an inline coupler to an Ethernet cable, make sure that both Ethernet cables have RJ45 connectors because, without them, they will be incompatible with a coupler. Insert one end of the first Ethernet cable into one side of the in-line coupler and press it down until you hear a click sound. Consequently, take the second Ethernet cable and plug it into the other side of the coupler using the same technique. At this point, both cables are tightly fixed; hence, they form a bridge allowing for extended network connectivity without additional equipment. For better performance, please ensure that connections are tight.

Compatibility with Ethernet Standards

Durable Construction

Ease of Installation

Signal Integrity Preservation

Compact and Lightweight Design

Cost-Effectiveness

Universal Application

These combined features make an inline coupler that offers the most stable, efficient, and long-term network solutions possible.

Compare CAT5e, CAT6, and CAT6a when you want to choose an RJ45 inline coupler. Your requirement would decide the option to go for:

CAT5e

CAT6

CAT6a

Once you know what RJ45 inline coupler works alongside the cable you are using and the scope of your network you can make your pick.

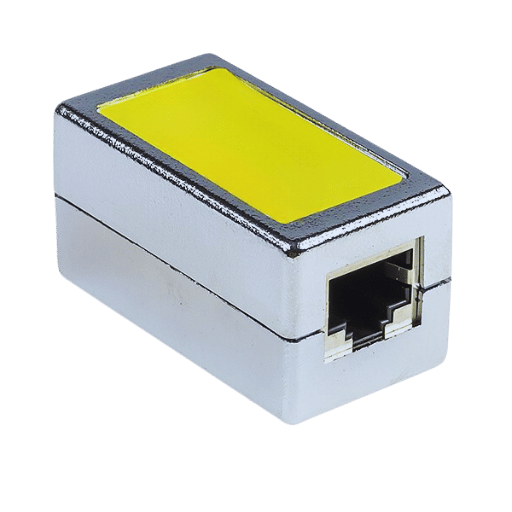

When one is deciding on whether to use shielded or unshielded RJ45 inline couplers, one must be mindful of their individual applications and performance characteristics. Shielded couplers incorporate a conductive shield which helps in reducing electromagnetic interference (EMI) and crosstalk. This feature is especially useful when there are many electrical devices and machines present, as well as in industrial settings where the amount of interference is high. For instance, in data centers or manufacturing plants with a crucial need for stable and reliable connections, the commonly used solution is shielded couplers.

Unshielded couplers, on the other side, do not have such shields and instead work best with environments that don’t produce lots of EMI. They cost less to purchase and install making them perfect choices for places like homes or offices where typical interferences prevail. However, they may be unreliable maintaining connection integrity within noisy electromagnetic environments.

In terms of technical performance, shielded couplers guard CAT6a and CAT7 cables that usually operate at higher frequencies and data rates better than others. Tests showed that under these conditions shielded couplers performed well in preventing data loss as well as maintaining signal quality. On the other hand unshielded ones are fine for lower-category cables or situations where there is hardly any interference such as home applications.

An effective shielded coupler is grounded correctly for its operational purposes. This means that lack of proper grounding would result to amplified interference which in turn defeats the purpose of shielding. When selecting the appropriate coupler type, one must carefully consider the network environment so as to ensure that it matches both cable standard and surrounding conditions for better performance and sustainable use.

A network junction box may be significantly flexible for networking configurations, hence allowing a user to easily link two Ethernet cables. This is particularly handy when you need to make the cable longer or change it so that it fits a layout without any need to buy new ones or make any changes. This device is also important in that it maintains proper alignment between paired wires, ensuring minimal signal degradation and enhancing proper data transmission. Moreover, this plug-and-play equipment is highly recommended as an efficient and ready-to-use solution for residential and commercial networking tasks.

Check RJ45 cables and its Coupler

Adjust Connectors

The Placement of The First Cable

Place The Second Cable According To The Connector’s Placement

Check The Connection

With the aid of this technique a better installation can be achieved with no compromise on the pre existing quality standards and network connections.

Use of Faulty or Poor-quality Cabling

Lack of Proper Alignment of Connectors

Not Taking into Account Cable Category Specifications

Neglecting Environmental Factors

Skirting Thorough Connection Testing

Over-Bending or Tight Looping of Cables

Ignoring Signal Loss over Longer Distances

If users follow these mistakes, they can have an efficient and high-performance network connection while maintaining both cables and coupler’s lifespan.

The tools and materials required for a smooth and effective installation of an RJ45 coupler include:

Ethernet Cables (Cat 5e, Cat 6, or higher)

Cable Stripper and Crimping Tool

RJ45 Connectors

Network Cable Tester

Screwdriver and Mounting Accessories (if applicable)

Wire Cutters

Tape Labelling and Permanent Marker

One way to ensure an installation of professional-grade quality is by using these appropriate tools which will address issues such as signal loss or misconfigurations.

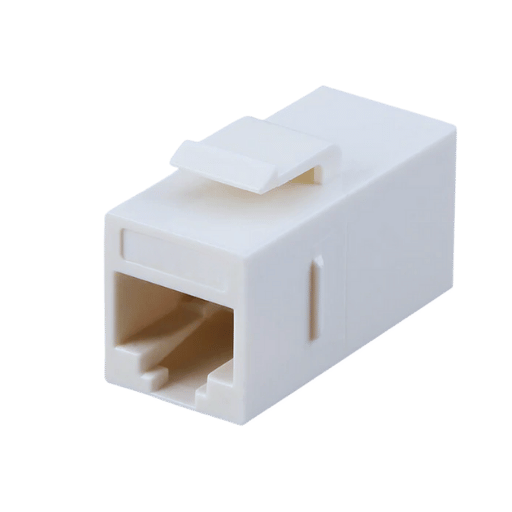

In other words, inline couplers can be combined with keystone jacks in network installations. To create structured cabling systems, patch panels or wall plates usually house keystone jacks which are used to terminate raw cable ends. On the other hand, inline couplers join two pre-terminated cables together. Nonetheless, their integration is a network specific design and requirement as they can both exist within one system.

Installation Built Around Convenience

Change of Form While Retaining Function

Affordability and Low Expenditure Requirements

Continuity and Clarity of the Signal

Utilization of Patch C8cap LS LSOH Couplers Patch Panels or Cables Cabling Connections

Space-saving Structure

Ability to Last Long

Keystone couplers help in network installation and maintenance in an adapted and effective manner owing to these benefits.

Cat6a RJ45 inline couplers are highly dependent on transmitting high-speed data, including apps requiring 10Gbps. They are tailor-made to accommodate the bandwidth and reduced crosstalk associated with Cat6a cabling. Upon correct installation, these maintain a good signal quality and reduce data loss, hence allowing their use in demanding places such as enterprise networks and data centers. Nonetheless, it’s vital for the couplers selected to conform to industry standards, ensuring that they have been tested for compatibility with Cat6a specifications in order to achieve maximum performance.

The durability of RJ45 couplers designed for Cat7, Cat6, and Cat5e cables is determined by the material used, its build quality, and compliance with industry standards to a large extent. Typically, premium quality couplers will have robust enclosures made from tough plastic or metal that are resistant to mechanical stresses, environmental influences, and wearing off over time. For instance, cat 7 couplers often incorporate shieldings so as to decrease electromagnetic interference (EMI) and enhance their long life span in high-performing applications, thus making them well-suited for demanding environments.

Testing data from manufacturers reveals that Cat7 couplers are engineered to handle frequency levels up to 600 MHz, surpassing the requirements of Cat6 (250 MHz) and Cat5e (100 MHz). This enhanced capacity ensures optimal performance while preserving structural integrity during high-frequency operations. Additionally many Cat6 and Cat7 couplers go through severe testing such as plug cycle tests where thousands of insertions and removals validate the connector’s durability hence ensuring its reliability in environments prone to frequent changes in equipment.

The couplers for older standards, such as Cat5e, are often cheaper and tailored for meeting required performance levels without the more advanced shielding characteristic of newer categories. Proper installation and handling practices like avoiding too much curvature or exposure to high temperatures will also see all types of couplers last longer.

In conclusion, it is worth noting that any of the three couplers mentioned above (Cat7, Cat6, and Cat5e) come with different degrees of toughness; however, selection should be based on network performance requirements and environmental conditions so as to enhance reliability and lifespan maximally.

The presence of electromagnetic interference (EMI) in the world necessitates the use of shielded inline couplers to guarantee data integrity. These couplers have a layer of conductive metal, which helps to cut down on loss and prevent noise from entering the system, ensuring that it remains stable and dependable. They are best suited for EMI rich environments such as industrial installations or places with dense electronic equipment concentration. Shielded cables must be used with properly grounded shielded couplers, and all other components on the network should also be properly grounded for optimum performance.

A: Modular inline couplers serve the primary purpose of joining two patch cables or extending an existing patch cable. As mentioned above, modular inline couplers are designed to extend Ethernet cables without complex wiring or tools. These couplers are available for purchase in all categories: cat5, cat6, and cat7, and are easily used with common interfaces such as RJ45 (8P8C) connectors. These are designed for temporary use or computerized devices that are not connected to a modem/router through an ethernet cable but need direct access to ethernet through the devices.

A: Regarding ethernet cabling, a cat6 RJ45 inline coupler is precise for use with cat6 cables but is general enough to correlate with cat5e or cat7 cables, too. Plug a high-category coupler (along the lines of Cat7) into a low-category one (such as Cat6), and this will turn the connection into this “Frankenstein.” However, all is not lost – even though these connectors will nullify the high-speed Prez connectors far more meaningfully than an ordinary device designed for a certain category.

A: To install the wall plate, simply follow these steps. 1: Pick your desired location and cut a hole in the wall plate. 2: Run your Ethernet cable to this location. 3: Strip the cable jacket and arrange the wires either of the T568A or T568B standard. 4: Punch down the wires with the punch-down tool onto the back of the RJ45 keystone jack. 5: Place the keystone jack into the wall plate. 6: Fix the wall plate to the wall. This method does not require a multitude of tools or punch-down gear, which is beneficial for DIY hobbyists.

A: Many waterproof RJ45 couplers provide an easy means of connecting cable ends, which protects the loose ends of the cables, especially when the ends are soldered together. Additionally, they provide interference-free, moisture-proof, salt spray, durable, and reliable force for low temperatures. The following are some advantages Waterproof RJ45 Couplers provide: 1. Because of their robust nature, the connection is protected from moisture, dust, or any type of corrosion. 2. There are reliable Ethernet connections that can be set for outdoor environments, such as security cameras and outdoor Wi-Fi access points. 3. Numerous waterproof couplers are PoE compatible making the transfer of power along with data unbanded. 4. A variety of materials, such as ABS plastic and metal, are used to make their strong, durable bodies. 5. A number of brands offer IP67 or IP68-rated waterproof inline couplers that are specially built to secure the connection points from immersion in water.

A: Yes, as it is, almost all of the cat6 inline couplers can work with PoE systems, including those under power over ethernet. Cat6 couplers are useful tools as they can perform under pue standards of 100 W. They were purposely designed for standard couplers with high PoE specifications, but be careful when using specific couplers. Always ensure that the team you coordinate with is rated. They are recommended for safe and trusted operations. When you use Poe, take note that every link in your system, be it cables, couplers, or connectors, is Poe compliant. Doing this will minimize worrying about problems that may arise or damage to equipment.

A: In order to keep the connection secure while employing an inline coupler and RJ45 plug, it is suggested to take the following directives: 1. Use well-made, verified, and professional-grade RJ45 plugs and patch cables. 2. Confirm that the category of the coupler being used is appropriate for the network being used (for example, Cat6). 3. To ensure better connectivity and corrosion resistance, consider purchasing couplers with gold-plated contacts. 4. Secure your couplers with a simple snap-in retaining clip, as it is very easy to attach, making the hold strong and secure. 5. While connecting, ensure that the RJ45 plug is pushed into the coupler until there is an audible click. 6. If using in an environment with high vibrations, consider using lockable RJ45 plugs and couplers for extra protection. 7. Keep on checking connections and cleaning them so that there are no performance issues.

A: In networking, keystone jacks and inline couplers perform differently even though they serve in the same field. Keystone Jack: Has a pentagon shape, which is commonly used with other items as part of the plate or installed on the patch panel. A wall jack box is about this size: The cable has to be connected directly to the jack, very much like a wall outlet. These are used where a physical transfer is needed to be permanent. Different standards, such as Cat5e and Cat6, may be used, which are unshielded, twisted pairs, Jacks, and shielded, twisted types if required. Inline Coupler: An inline coupler connects two patch cables or is used to lengthen some existing cable;- No termination of cable to the jack is needed. Finally, such installations are more appropriate for temporary arrangements or situations when quick fitting is required. Couplers are also standardized categories, but unlike jacks, they can be modular or fixed. Couplers are used along with RJ45 (8P8C) plugs and sockets in Ethernet networks, similar to Jacks; only structured cable systems tend towards keystone jacks because they are less restrictive in their type of location.

1. Title: Dynamic Meteorology-induced Emissions Coupler (MetEmis) development in the Community Multiscale Air Quality (CMAQ): CMAQ-MetEmis

2. Title: Inline integration of offset MMF-capillary-MMF structure as a portable and compact fiber-optic surface-enhanced Raman scattering microfluidic chip

3. Title: An ultra-sensitive nanofiber coupler refractometer

4. Title: Inline Fiber-optic Refractometry using Sensitive Resonance Positions of Single-mode Fibre to Planar Polymer Waveguide Couplers

6. Ethernet