Fiber optic cables are a must-have in modern telecommunications and data transfer systems. Fiber optics can transmit information over long distances with negligible signal loss, making them very popular. They have changed the way we share and access information globally. This manual covers everything about fiber optic cables, how they work, where they are used, and what is new in this area of technology. If you work with these things for a living or just love playing around with gadgets like me – read on! My intention is that by the time I finish writing this guide, someone who has not been introduced to any kind of wiring before will be able to tell an optical cable from a coaxial one without much struggle. What I want at the end of my guide is the different types of fibers used today, how each type works/its construction process, etc. Why use fiber optics instead of copper wires? What makes them better than other materials currently available in terms of cost efficiency or performance? Latest trends that may shape future development within this field.

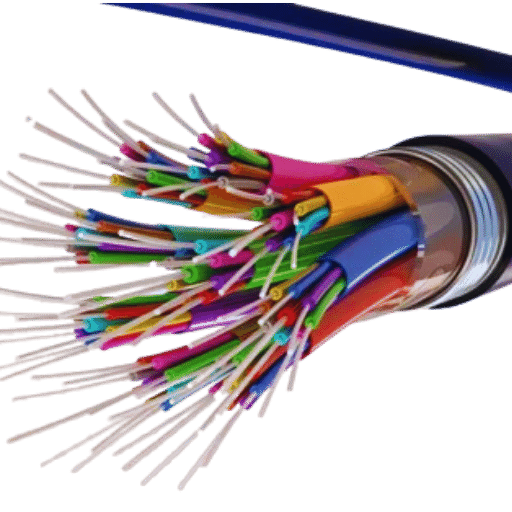

A fiber optic cable is a cable that uses thin fibers of glass or plastic to transmit data as light signals. These cables work based on the principle of light refraction, which allows them to carry information across long distances, unlike regular copper wires, which use electrical signals. The cables have three parts – core, cladding, and protective outer coating. Light signals travel through the core which is made from highly purified glass or plastic. Cladding surrounds this inner layer with a lower refractive index than that of the core so that when light enters, it reflects back into the core where it continues its path through till the required destination point is reached, thus ensuring no data loss occurs during the transmission process hence making these types of cables very efficient for high-speed and long-distance data transfers.

The rule of the passage of light in fiber optic cables is based on refraction and total internal reflection. What happens is that when light enters the fiber optic core at a specific angle, it gets refracted and then imprisoned by the core-cladding interface. On the other hand, cladding has a lower refractive index than that of core; hence, it aids continuous reflection within the core. This process, known as total internal reflection, enables signals to move over long distances without much attenuation taking place. The critical angle, which refers to the introduction angle of light, plays an important role in ensuring effective transmission is achieved at all times. Moreover, advancement in fiber optics technology has led to different types of fibers being produced, like single-mode and multi-mode fibers, which are meant to enhance transmission efficiency for various applications ranging from telecommunication to medical imaging, among others.

Fiber optic cables can be divided into two major categories: Single-Mode Fiber (SMF) and Multi-Mode Fiber (MMF).

Single-Mode Fiber (SMF):

Multi-Mode Fiber (MMF):

Selection of these types of fiber optic cables depends on specific network design requirements that balance distance with bandwidth and cost among other considerations. Each type has unique strengths that make them appropriate for different applications within modern communication infrastructure.

Single-mode optical fibers are built in such a way that they transmit light directly down the fiber. They have small core diameters, about 8-10 micrometers, which means only one propagation mode of light is supported. Consequently, single-mode fibers can achieve low attenuation and high bandwidth, thereby making them perfect for long-distance transmissions. Singlemode fibers are extensively used in many applications such as telecommunication networks, internet connections, and cable television, where it is necessary to transfer huge amounts of data at high speed over large distances. With this design, signal loss and dispersion in single-mode fibers are minimized so as to ensure fast and reliable data transmission.

Multimode fiber-optic cables usually have larger core diameters, usually ranging between 50 and 62.5 micrometers; this allows several light modes to travel simultaneously through the cable. As a result, more data can be transmitted over shorter distances than single-mode fibers. On the other hand, multi-mode fibers suffer from higher attenuation and modal distortion that restrict their usable range. Here are some key characteristics of multimode fibers:

The use of multimode fiber-optic cables is widespread in local area networks (LANs), data centers, short-distance data communication systems among others because they are cheap and easy-to-install. They facilitate high-speed data transfer within buildings or campuses where long-range connectivity is not required.

Armored fiber optic cables are manufactured for better protection in difficult conditions. In these, there is an extra layer of protection that is usually made of steel which guards the optical fibers against mechanical harm, rodent bites and any other external hazards. This feature makes them suitable for use in industrial settings, underground ducts and places with a lot of movement or possible human interference.

Unlike armored ones, unarmored fiber optic cables lack an outermost protective cover and are, therefore, better suited for controlled environments where physical dangers are few. They are generally light weight, more flexible to work with and easier to install thus can be used indoors such as office buildings or data centers.

There are several differences between the two types:

The choice between using either an armored or an unarmoured fiber optic cable largely depends on the specific needs of the installation environment, including the required level of protection against potential physical damage.

Compared to traditional copper cables, fiber optic cables have many advantages. One of the main ones is that they have a much higher bandwidth. So, data can be transmitted at higher rates and larger amounts. Therefore, these cables are suitable for high-speed internet connections and sending large volumes of data.

The other important thing is that fiber optic cables don’t react with electromagnetic interference (EMI). It’s different from copper wires, which are affected by electromagnetic noise. In the process of transmitting information through fiber optics use light that doesn’t respond to EMI. That’s why this approach has better signal quality and fewer transmission errors.

Fiber optics are also secure since they cannot be easily eavesdropped on without detection thus minimizing chances for data breaches. Furthermore, they are tougher than other types of wires so their resistance against such things as water or extreme temperatures makes them more reliable in long-term use with reduced maintenance costs.

To conclude; wider bandwidths decreased signal losses immunity against EMI enhanced safety features and greater resilience among others are what make up for these benefits associated with fibre-optic communication systems over other alternatives available currently in the market which has led their widespread adoption globally today.

Distinct advantages and disadvantages of fiber optic cables and copper cables can be brought out by different technical parameters when they are compared.

Bandwidth and Data Transmission Rates:

Signal Loss and Distance:

Electromagnetic Interference (EMI):

Security:

Durability and Environmental Resistance:

Cost:

In conclusion, Fiber optic cables may be expensive at first but they offer better bandwidths, low signal losses, EMI immunity enhanced security features and durability hence becoming most preferred for modern communication networks while copper cable still remains viable cost-effective solution for less demanding applications over short distances.

Due to their high performance, fiber optic cables are used in various sectors. These areas are:

These uses show how versatile and indispensable fiber-optic cables can be in enabling advanced technological solutions across different fields.

The success of a fiber optic installation project depends on careful preparation and planning. It is necessary to consider the following:

These steps pave way for easy installation process leading into good performance and reliability of network connection provided by optic fibers.

Initial Planning and Assessment:

Design and Layout:

Required Permits and Approvals:

Selection of Components:

Preparation of Installation Site:

Team Training:

Cable Installation:

Splicing and Termination:

Testing and Validation:

Documentation and Reporting:

The above steps will result in an organized and efficient fiber optic cable installation process, which in turn enhances network performance as well as its general reliability.

These mistakes are capable of greatly affecting how well a fiber-optic network performs or its reliability. Such problems can be mitigated effectively by remaining watchful for them and employing good practices thus ensuring strong and efficient installations.

To guarantee the durability and dependability of fiber optic cables, it is imperative to perform routine maintenance on them. Physical harm should be looked into, cable connections verified while also ensuring that there isn’t extreme flexing or straining of these wires during regular checkups. Optic Time Domain Reflectometer (OTDR) measurements ought to be used for tests so as to identify signal loss or points of failure along the entire length of a cable. Such inspections and tests carried out on a regular basis help in the early detection and resolution of potential problems that could lead to major disruptions in the network besides maintaining its best performance levels.

Cleaning fiber optic connectors is very important if you want to maintain your fiber optic network. Dust, oil, and moisture are all contaminants that can block light transmissions and degrade signals. The steps below show how to clean them properly:

Dry Cleaning:

Wet Cleaning:

Automated Cleaners:

Technical Parameters:

The mentioned methodologies coupled with adherence towards given technical parameters would help avoid signal degradation risks while keeping high transmission quality across fibre optic networks intact.

Connector Damage:

Dirty Connectors:

Incorrect Mating of Connectors:

Dealing with these common problems is what will keep fiber optic networks efficient and reliable. These include regular inspection periods, cleaning procedures and taking care when connecting.

As the demand for higher bandwidth and faster internet speed keeps growing, fiber optic technology is rapidly evolving to meet these needs. Below are some of the critical changes:

Dense Wavelength Division Multiplexing (DWDM)

Bend-insensitive Fiber

Integration with 5G Networks

Photonic Integrated Circuits (PICs)

These advances are pushing forward fiber-optics evolution towards making them stronger, scalable and able to handle future data demand spikes. There’s still much room left for creativity within this field since breakthrough after breakthrough promises ever-greater speeds and reliability in communication systems required by our modern world.

The growths in fiber optics technology make way for some revolutionary applications across different sectors:

Quantum Communication:

Enhanced Telemedicine:

Virtual and Augmented Reality (VR/AR):

Smart City Infrastructure:

Industrial Automation:

The advanced optical fiber technology is expected to impact the world’s communication infrastructure greatly. No other cables can provide as much bandwidth as those made of fiber optics, which allows for quicker data transmission over longer distances with less signal loss. This improvement in technology serves the increasing need for high-speed internet that can be used both in urban and rural areas without interruption. Fiber optics can also scale to meet future data needs more easily than any other solution currently available, making it an ideal choice for expanding networks that will not become obsolete tomorrow. Moreover, apart from these benefits mentioned above, fiber optic systems offer better security capabilities, which is so important nowadays when everything gets connected with everything else around us via electronic devices like smartphones or computers – this alone should be enough reason to replace old copper wires wherever possible! What’s more, this change will create stronger communication channels, which are vital components necessary for economic development and reducing disparities between developed nations and underdeveloped ones.

A: A fiber optic cable, or optical fiber cable, comprises multiple strands of fibers within a protective covering. Each fiber strand transmits data as light signals, enabling fast and reliable long-distance data transmission.

A: Various cable types can be found in a fiber-optic network like single mode fiber, multimode cable, duplex fiber, bulk fiber optic cable, and patch cables. The choice depends on specific purposes served by each type with respect to use-case scenarios as well as required transmission capabilities for data.

A: Single-mode fibers have smaller cores, which allow them to transmit information over greater distances at higher speeds with lower signal loss than their multimode counterparts can achieve. On the other hand, Multimode fibers (e.g., OM3) have larger cores that may cause signal distortion if used for too long. Due to this characteristic, they are often employed when shorter link lengths are involved.

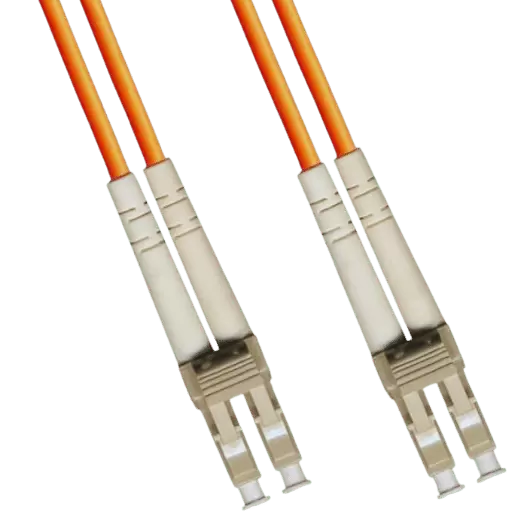

A: Duplex fiber patch cables consist of two separate strands of fibers that allow for simultaneous bidirectional communication between connected devices. These types of cables are typically used in high-throughput applications such as those found in data centers and other areas where large amounts of data need to be transferred quickly; this is possible because they provide an independent pathway for both upstream and downstream traffic.

A: A patch cord or simply put “fiber patch” is more flexible compared with standard cables hence it’s commonly used when connecting different network devices together like switch ports or servers within racks whereas standard cords would not easily bend back onto themselves making them unsuitable for such short distance connections made inside cabinets/racks where space might be limited.

A: This helps you see each individual fiber within a bundle, which simplifies connection management and maintenance. Every color represents one particular fiber allowing for quick troubleshooting and installation.

A: The cable jacket protects the fiber strands from physical damage, moisture, and other environmental hazards. It also guards against internal fibers thus ensuring data transmission reliability over long periods.

A: OFNR is an abbreviation for Optical Fiber Non-Conductive Riser; it’s used for vertical runs between floors in non-plenum areas with buildings. These types of cables are employed for risers within structures so as to comply with fire safety regulations.

A: They can tolerate severe weather conditions including exposure to UV rays or extreme temperatures plus they should be waterproof among other things like that. Conversely indoor fibers have less physical protection than their outdoor counterparts since they’re meant to be installed inside buildings only but not exposed outside walls.

A: It uses light signals to transmit data through strands of optical fiber cables. With this method, you can achieve faster speeds with more bandwidth than traditional electrical cable internet services which makes it ideal for reliable high-speed connections.