In modern telecommunications and data transmission systems, fiber-optic trunking cables are of great importance as they offer fast connections and reliability. Several optical fibers are contained in these cables, which are enveloped by a protective covering to ensure that information is transmitted over long distances with minimal loss of signal power. Knowing all about fiber optic trunking involves looking at their makeup and different types as well as what governs their operation, among other things. This article will serve as an inclusive guide to fiber optic trunking cables; it will explain how they work, where they can be applied best, why we need them, and what new technologies have been developed around this area of communication so far. By reading this piece, people may begin appreciating these cords’ significance to our digital infrastructure, which guarantees uninterrupted connectivity for enterprises and homes alike during the era of the Internet.

A trunk cable is a type of fiber optic cable that can carry large amounts of data at once through a telecommunications system. It acts as the “backbone” or main line of communication within a network, connecting different areas together while preserving signal quality over long distances. The purpose of this cable is to bridge gaps between many user devices and/or network sections without losing any strength in the signals being sent along it so that information can travel quickly. They are designed with wide bandwidth capabilities for increased efficiency when transmitting data, which prevents loss or disruption during transmission due to weak signals caused by distance traveled or external factors such as noise interference, etcetera.

Several primary components work together in a trunk cable system to ensure that data is transferred effectively. Here are the main elements:

This set works as an entire system designed specifically for use with telecommunications systems relying heavily upon robustness and reliability offered by such components when working together in unison, forming larger parts necessary but not limited to trunking out large amounts of communication over long distances.

In various sectors, for example, data centers, telecommunications, and enterprise networking, fiber optic trunk cables are used. Commonly referred to as the backbone of the internet, these cables are employed in long-distance communication. Fiber optic technology has several advantages which include the following:

Overall, these functionalities brought about by the integration of fibre-optic trunks into network infrastructures increase efficiency and speed while still ensuring scalability and a safety net for current and upcoming communication requirements.

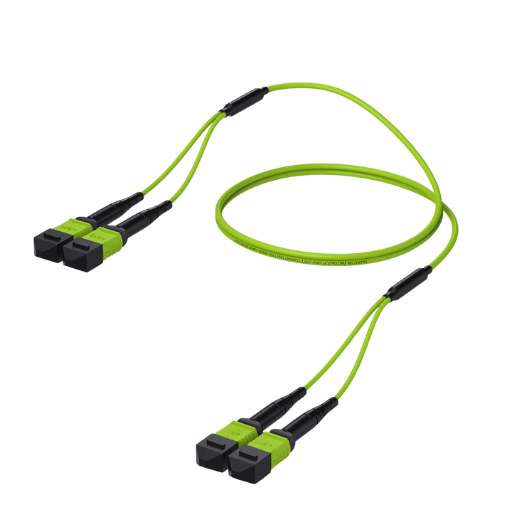

When deciding on multimode or single-mode fiber optic trunk cables, it is important to know what each of them does best.

In conclusion, if you’re wondering whether to use multi-mode versus single-mode trunks, then ask yourself how far apart things are going be from each other because while more expensive, they offer greater ranges in terms of speed, but the cost per distance becomes higher with such options too so think about your needs!

Connector compatibility with fiber optic systems is an important factor to consider since it directly affects network performance and reliability. Using connectors that are compatible with each other helps ensure optimal signal transmission by reducing insertion loss and return loss, which can deteriorate signal quality, leading to data loss. Additionally, having the right connectors can protect the fiber from physical damage due to its delicate nature.

Moreover, using standard connectors like SC, LC, or ST enhances interconnectivity between various components or equipment within a network, thus making it easier to maintain and upgrade, especially in data centers where many parts may require frequent replacement or reconfiguration. Therefore, the appropriate selection of these points not only improves system-wide efficiency but also safeguards the integrity of fiber optic installations in general terms.

High-density cable assemblies are meant to save space in areas where there is not much room, like data centers and telecommunications hubs. Normally, they have more fibers per unit area than regular ones, which means that you can connect with more devices and transfer data faster. In order to fit everything into such a tiny space, these cables use small connectors and advanced wiring methods without losing signal quality or making installation hard. With this type of wiring, it is easy to grow your network because high-density cable assemblies allow for scalability, which allows them to be expanded as needed without wasting any resources.

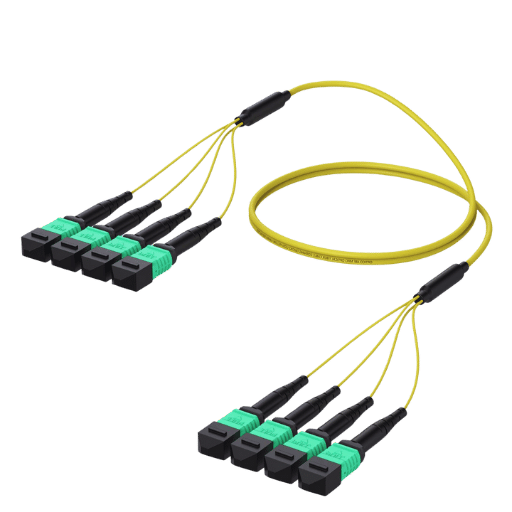

When choosing between a 24-strand and a 12-strand trunk cable, it is important to look at the needs of your network infrastructure. For higher capacity applications, the 24-strand cable can be useful because it is able to make more connections per cable which allows for wider data transmission capabilities. This makes it most suitable for use in data centers and enterprise environments where there are high bandwidth requirements. On the other hand, if you have smaller networks or less demanding applications, then using a 12-strand trunk cable might be better as they offer compactness that can simplify installation while still giving good performance levels. Both options usually come with high-quality fiber types like single mode or multimode so that flexibility in deploying them is achieved alongside compatibility with existing systems.

Optical fiber cables are categorized into OM3 and OS2 depending on their characteristics which ensures they meet specific performance requirements as well as application needs. OM3 is a multi-mode fiber that supports data rates of up to 10 Gbps for distances up to 300 meters which makes it ideal for high bandwidth applications in local area networks (LANs). It can use laser-based light sources, hence enabling efficient transmission of data within shorter distances, such as enterprise networks and data centers.

On the contrary, OS2 is a single-mode optical fiber designed for long-haul communication with the capability of supporting data rates from 1 Gbps to 100 Gbps over distances that may exceed 10 kilometers. This feature has made it more suitable than any other category when it comes to wide area networks (WANs) or telecommunications, where signal attenuation should be kept minimal at all costs. Moreover, these types of fibers are commonly used where there is a need for connectivity between two points far apart, thus ensuring greater reliability through enhanced transmit distance abilities.

Other classifications of fibers include OM1 and OM2 which are older multi-mode variants having lower bandwidth capacities as well as shorter reach compared to OM3. Consequently, what distinguishes among these groups lies upon the network requirements such as distance, bandwidth and type of application involved so that network performance can be optimized accordingly.

In order to guarantee good contacts for effective network operation, precise termination methods must be followed, and high-quality connectors must be used. Correctly removing the cable ends, not exposing them to too much moisture as well and checking that the connections are good help in reducing signal loss. Additionally, routine inspection using industry-standard test equipment helps to find problems before they affect the network. Cleaning up connections and keeping records about every installation and testing procedure done so far ensures reliability over time while at the same time improving the performance of networks.

Customization and design options are necessary to meet specific operational needs when building network infrastructure. Among the factors to consider are the types of cables to be used, like Ethernet, fiber optic, or coaxial, depending on bandwidth requirements and distance coverage. Also, whether star, mesh, or hybrid, network topology greatly influences performance optimization as well as reliability enhancement. Scalability is achieved by using modular components that allow organizations to adjust their systems to meet changing demands over time. Additionally, integrating more advanced technologies such as Power over Ethernet (PoE) can simplify installations through the reduction of separate power supplies needed, hence promoting efficiency in layout design. Organizations should maintain real-time control through the adoption of software solutions for monitoring and managing the networks, thus ensuring continuous relevance of customized designs according to current needs.

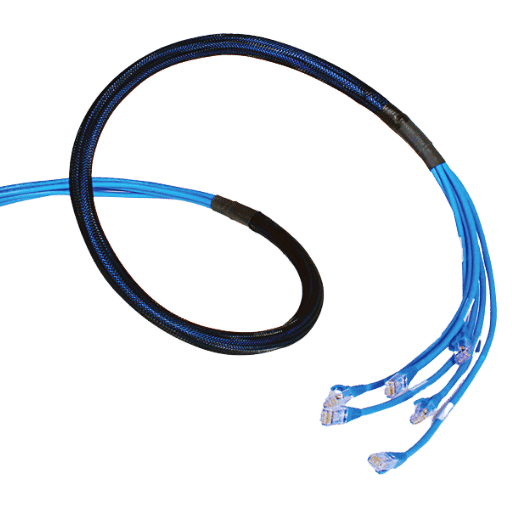

Connector housings, patch panels and cable management systems are among the crucial accessories of trunk cables. Connectivity is ensured by connectors like RJ45 or LC duplex which also guarantee signal integrity. Patch panels enable orderly connection that, in turn, facilitates efficiency in cable arrangement as well as network reconfiguration options. Cable ties together with raceway systems foster tidiness while labeling systems promote identification accuracy during troubleshooting procedures, hence making them easier, too. Such accessories serve to enhance not only functionality but also the reliability of the network infrastructure on all levels.

To maintain network performance and reliability, correct trunk cable replacement is crucial. Compatibility, performance specifications, and environmental conditions are some of the main factors that should be considered. To ensure that integration into the current infrastructure does not cause any disruptions, among other things, size and pin configuration in terms of the original specification have to match, for instance, with replacement connectors.

By taking into account all these details carefully organizations can ensure not only restoration but also sustainability where new components contribute towards long-term grounding and efficiency within network systems.

Sustaining performance and keeping up with changing technological needs are the two main reasons why we should maintain and improve our trunk cable systems. Conducting regular checks is important because it helps us identify areas that could compromise the entire system if not attended to; this can be achieved by looking for signs of weakness like worn-out spots or physical damages caused by environmental factors among others. Another thing that should be done during maintenance is testing everything using appropriate tools such as cable testers so as to detect problems like signal loss early enough before they become serious.

When upgrading, one should bear in mind both present and future bandwidth demands; therefore, going for cables that can support higher data rates than what we expect would be necessary. For instance, this may involve installing higher category cables like cat6a or cat7 which have power over Ethernet capabilities that are required by some advanced technologies. On top of scalability, planning well how different parts will relate with each other through good cable management practices, including proper labeling and routing, among others, saves time when doing expansion or any other changes later on. Not only do these measures enhance reliability, but they also ensure the optimal functioning of the whole network at large.

A: Fiber-optic trunk cables are made for connecting different networking devices together and creating fast communication channels between them. They have several optical fibers in a single cable thus enabling continuous signal transmission that enhances quick data transfer.

A: A release cable helps in deploying and connecting trunk assemblies by acting as an intermediary component. It allows easy installation and maintenance through rapid cable release which reduces the time taken during fixing.

A: Time is saved during MTP® trunk cables installation because they come already terminated, therefore, fewer terminations are done on-site. This simplifies deployment significantly hence enabling businesses to establish their networks fast.

A: Low insertion loss within these types of cables means better performance since it reduces signal deterioration. Thus higher bandwidths are achieved with reliable long distance data communication being possible.

A: Yes, fiber optic trunks can work for both overhead and underground applications. They can withstand harsh external conditions due to their design as well as having strong jackets thereby ensuring that signals remain stable regardless of the environment where they are deployed.

A: Customized trunk assemblies provide tailored solutions which exactly fit into a specific building’s requirements for its infrastructure. These modifications improve efficiency, minimize installation time and save space utilization.

A: When used in relation to fiber optic trunk cables, the word “plenum” refers to those cables that comply with particular fire safety codes and can be used in spaces where air is circulated within buildings. They contain a special fire-resistant jacket which gives off little smoke or toxic gases when it burns.

A: Yes, many fiber optic trunk cables are made proudly in America thereby ensuring good manufacturing practices and supporting local businesses. This often results into more reliable products that perform better.

A: “12 fiber” when talking about fiber optic trunks denotes an assembly with twelve individual strands or cores of optical fibers. Such an arrangement allows for multiple data channels within one cable, thus increasing throughput capacity for data transmission over a network.

A: Buffers found in trunks act as protective coverings around fragile glass threads making up each strand; these buffers protect them from physical harm as well as environmental factors that may lead to wear and tear affecting performance levels exhibited by such connections.