What is an LC Connector and How Does it Work?

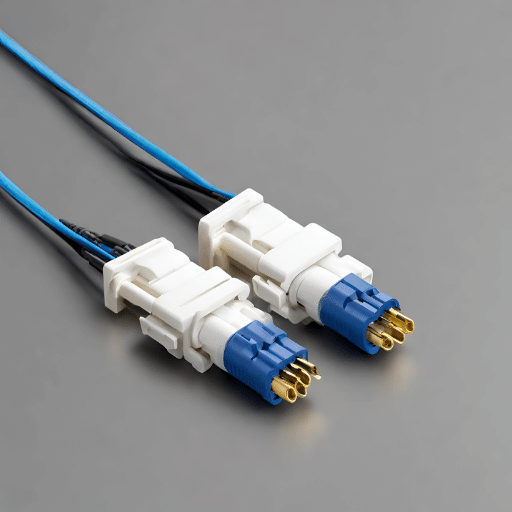

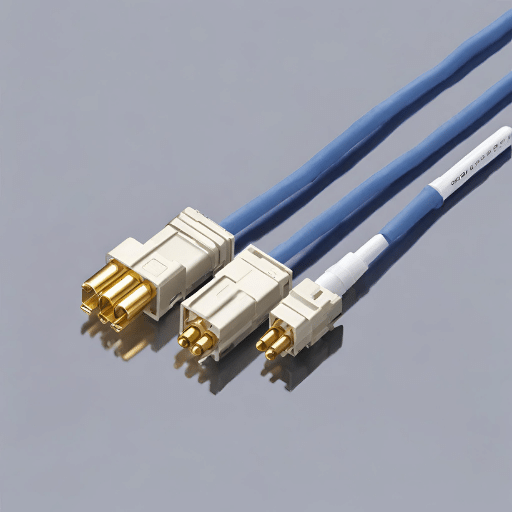

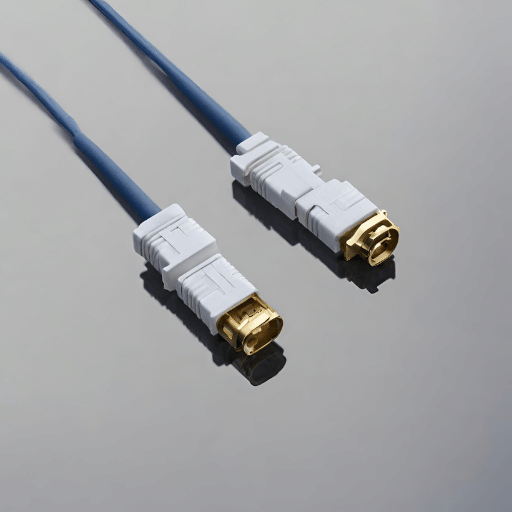

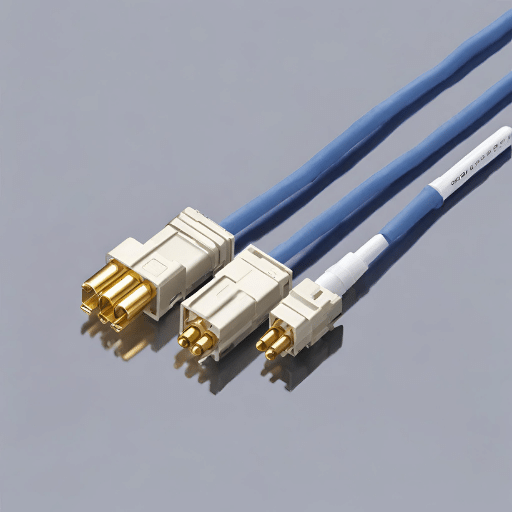

An LC connector, short for Lucent Connector, is a small form-factor fiber optic connector used in optical communications. Lucent Technologies developed it and has gained significant popularity due to its compact size and reliable performance. The LC connector utilizes a ceramic ferrule to align the fiber and employs a retaining tab mechanism (similar to a phone or RJ45 connector) for easy connection and disconnection. It is designed to hold a single thread and typically comes in pairs for bidirectional data transmission. It’s essential to ensure that the LC connector is clean and undamaged to maintain optimal signal quality.

Understanding the Basics of LC Connector

- Compact Design: LC connectors are tight and have a small form factor, making them ideal for high-density applications.

- Bidirectional Transmission: Typically used in pairs, LC connectors enable bidirectional data transmission.

- Retaining Tab Mechanism: With a design similar to RJ45 and telephone jacks, LC connectors are easy to connect and disconnect thanks to their retaining tab mechanism.

- Ceramic Ferrule: The use of a ceramic ferrule ensures precise alignment of the fiber, promoting high-quality signal transmission.

- Maintenance: Ensuring the cleanliness and integrity of the LC connector is crucial for optimal performance and signal quality.

- Wide Usage: Due to their reliable performance, LC connectors see widespread use in telecommunication networks, data processing networks, and cable television networks, among others.

- Compatibility: LC connectors are compatible with both single-mode and multimode fibers, offering versatility in diverse applications.

- Standardization: The LC connector meets the standards set by TIA/EIA-604-10, ensuring its quality and performance.

Advantages of LC Connector in Fiber Optic Systems

The LC Connector offers several significant advantages in fiber optic systems:

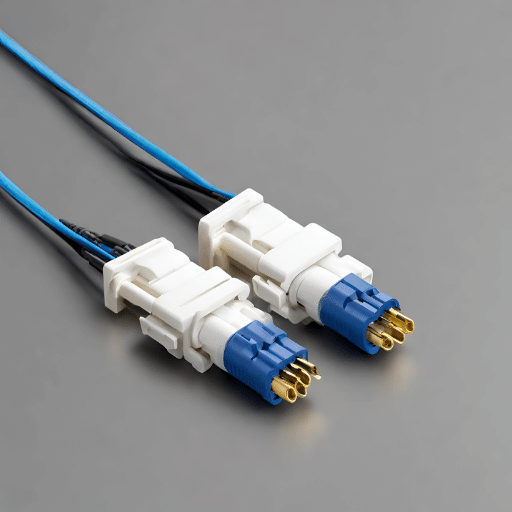

- High Density: Due to their small form factor, LC connectors allow for a high packaging density, making them ideal for applications where space is a premium.

- High Performance: LC connectors provide high-performance data transmission, maintaining strong signal quality for both single-mode and multimode fibers.

- Ease of Use: The familiar locking mechanism similar to an RJ45 connector ensures easy connection and disconnection without the need for specialized tools.

- Versatility: The versatility of LC connectors, which are compatible with various types of fiber and widely used in multiple network scenarios, adds to their overall appeal.

- Durability: LC connectors are designed for longevity and can withstand numerous connection cycles without noticeable degradation in performance.

- Standard Compliance: Adherence to industrial standards ensures that LC connectors conform to expected performance levels and compatibility requirements.

Types of Fiber Supported by LC Connectors

LC connectors support a wide array of fiber types, each catering to different use cases and data transmission needs. Here is a list of the fiber types compatible with LC connectors:

- Single-mode fiber (SMF): LC connectors are compatible with single-mode fibers, which can transmit data over long distances with minimal signal loss.

- Multimode fiber (MMF): LC connectors can be used with multimode fibers, typically used for shorter-distance data transmission in local area networks (LANs) and data centers.

- Polarization-Maintaining (PM) fiber: These fibers maintain the polarization of light over long distances, and LC connectors can be used with them.

- Active optical cables (AOC): LC connectors can also be used with AOCs, which integrate fiber optic cables and connectors into one assembly.

- Plastic optical fiber (POF): LC connectors can connect to POFs, typically used for short-range communication.

This compatibility with diverse fiber types further underscores the versatility and adaptability of LC connectors.

Comparing LC Connector with Other Fiber Optic Connectors

When comparing LC connectors with other fiber optic connectors, several vital characteristics come into play.

- SC Connector: SC connectors are more significant than LC connectors, taking up more space in patch panels. Unlike the LC’s convenient push-pull mechanism, SC connectors utilize a push-on/pull-off mechanism.

- ST Connector: ST connectors employ a bayonet mount, unlike the LC connector’s RJ-style latch, making it less convenient for high-density applications. Additionally, ST connectors are less suited for high-precision applications due to their physical design.

- FC Connector: FC connectors use a screw-on mechanism, making them more time-consuming to connect and disconnect compared to LC connectors. However, they provide excellent performance in environments that require high vibration resistance.

- MT-RJ Connector: MT-RJ connectors, like LC connectors, have a small form factor and utilize a latch mechanism. However, they’re not as commonly used as LC connectors, potentially leading to compatibility issues.

- MU Connector: Like LC, the MU connector is a small form factor connector. However, it is less popular and, therefore, may lack the widespread compatibility of LC connectors.

When selecting a connector, considerations must be made for factors such as space, application precision, flexibility of use, and vibration resistance, where LC connectors often prove to be a versatile and efficient choice.

Common Issues and Solutions with LC Connectors

Despite their versatility and efficiency, LC connectors are not without their share of everyday issues. Here are some of them, along with their respective solutions:

- Dirt on the connector end-face: Even small amounts of dust or debris can block the light path, leading to signal loss. Regular cleaning using lint-free wipes and isopropyl alcohol can prevent this.

- Physical damage to the connector end-face: Damage can be caused by mishandling or improper cleaning of the connector. Avoid touching the end-face and always use the proper cleaning methods to prevent this issue.

- Improper alignment: Misalignment can result in high connection losses. This can be solved with the use of high-quality alignment sleeves.

- Incorrect polishing of connector end-face: This can cause light reflection, affecting the signal quality. Ensure that connectors are tested for quality before being put into service.

- Over-tightening: Over-tightening of LC connectors can cause physical damage to the connectors and fibers, leading to high loss. Always use a torque wrench to ensure proper tightening.

By recognizing and understanding these common problems, technicians can take proactive measures to ensure the longevity and quality of LC connector performance.

How do you choose a suitable LC connector for your fiber installation?

Key Features to Consider When Selecting an LC Connector

- Insertion Loss (IL): The lower the insertion loss, the better the performance of the connector. A typical LC connector should have an insertion loss of less than 0.2 dB.

- Return Loss (RL): This measures the amount of light reflected to the source. The higher the return loss, the better the connector performance. An ideal connector should offer a return loss greater than 50 dB.

- Repeatability: This refers to the ability of the connector to maintain the same level of performance over multiple connections and disconnections. A suitable connector should offer high repeatability.

- Durability: Consider the material and build quality of the connector. It should withstand numerous mating cycles without compromising performance.

- Ease of Installation: The connector should be easy to install and remove without the need for specialized tools.

- Environmental Tolerance: The connector should be able to withstand various environmental conditions such as temperature changes, humidity, and dust.

- Compatibility: The connector should be compatible with your existing fiber optic equipment and the fiber cable type you are using.

By considering these key features, you can select an LC connector best suited for your fiber installation.

Single Mode vs. Multimode LC Connectors

Single Mode and Multimode are the two primary types of fiber optic cables used in LC connectors.

Single Mode LC Connectors are designed to carry light directly down the fiber. They are best suited for long-distance signal transmission due to their lower attenuation and higher bandwidth capabilities. However, they require a more precise alignment and are generally more expensive than their multimode counterparts.

Multimode LC Connectors, on the other hand, allow light to travel down multiple paths, making them ideal for short-distance transmissions, such as within a building or on campus. They are less sensitive to dirt and damage to the end-face of the connector, but they have higher attenuation and lower bandwidth over long distances.

Choosing between single mode and multimode LC connectors should be based on your specific application and the distance over which you need to transmit signals.

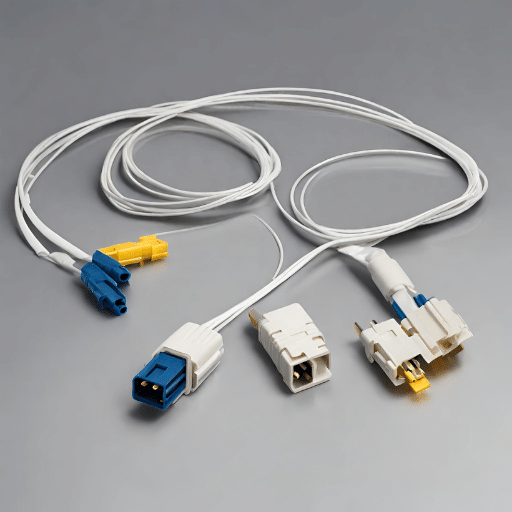

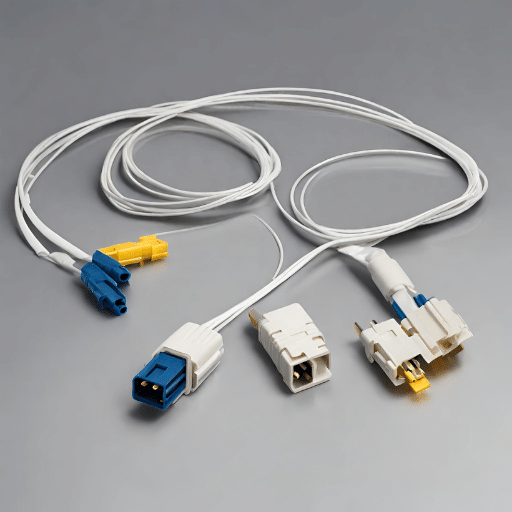

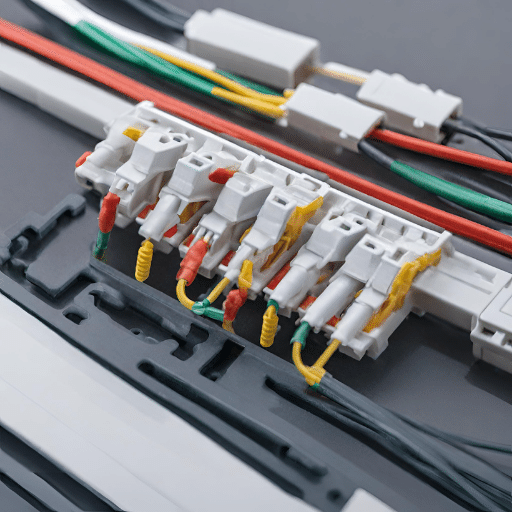

Duplex LC Connectors: Practical Applications and Benefits

Duplex LC Connectors offer increased functionality by permitting simultaneous transmission of data in two directions. This is achieved by integrating two fiber optic connectors into one, effectively providing a pair of channels – one for sending information, the other for receiving it. These connectors have found widespread use in applications where bidirectional data transfer is required, such as in data centers, telecommunication networks, and corporate intranets.

The benefits of duplex LC connectors are numerous. Firstly, they facilitate full-duplex communication, enabling data to be sent and received simultaneously without interference. Secondly, they offer superior data throughput, making them ideal for high-bandwidth applications. Furthermore, the integrated design of duplex LC connectors enhances their durability and reduces the likelihood of connection errors. Lastly, despite their advanced capabilities, duplex LC connectors maintain compatibility with standard LC interfaces, ensuring seamless integration into existing network infrastructure.

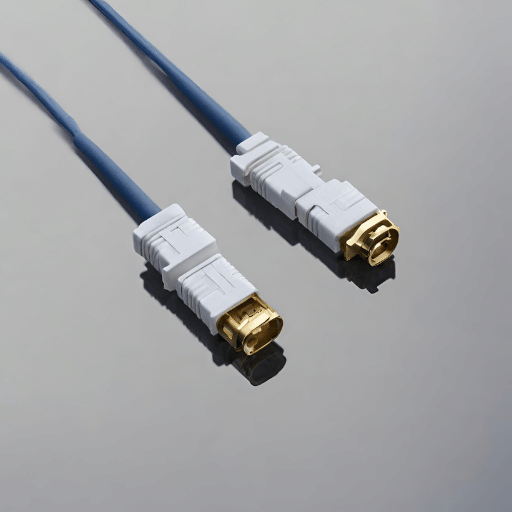

Hardened LC Connectors for Challenging Environments

Hardened LC Connectors are engineered for use in demanding environments where exposure to harsh conditions is a concern. These connectors are built with rugged materials that can withstand high levels of dust, moisture, and mechanical stress, ensuring reliable performance even under adverse conditions. They are particularly suitable for outdoor installations, industrial settings, and other environments where standard connectors may not provide the necessary durability and reliability.

The main advantage of hardened LC connectors is their ability to maintain signal integrity despite being subjected to harsh conditions. The robust design and superior build quality of these connectors minimize the risk of signal degradation, thus ensuring uninterrupted data transmission. Furthermore, hardened LC connectors often feature a robust mechanical design that protects the connector from damage and extends its lifespan. Despite their rugged characteristics, set LC connectors adhere to standard industry specifications, ensuring they can be seamlessly integrated into any network infrastructure requiring enhanced durability.

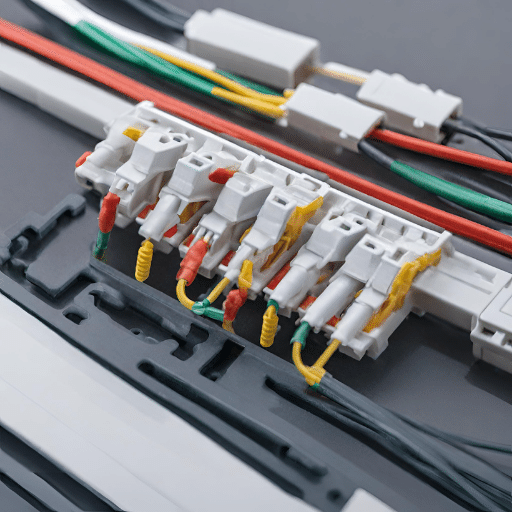

Installation and Maintenance Best Practices for LC Connectors

Proper Procedure for Installing LC Connectors on Fiber Optic Cables

When installing LC connectors on fiber optic cables, the procedure must be executed with care to ensure the highest levels of connectivity and performance.

- Preparation: Begin by preparing the fiber optic cable, stripping away the outer jacket to expose the buffer tube. Remove the buffer tube to reveal the bare fiber, making sure to leave enough length for the connector.

- Clean and Check the Fiber: Next, clean the bare fiber using isopropyl alcohol and a lint-free wipe to remove any debris or contaminants. Inspect the thread to ensure it’s free from cracks or deformations.

- Install the Connector: Slide the boot, crimp sleeve, and connector body onto the fiber. Then, carefully insert the cleaned bare wool into the connector until the fiber end sits flush with the connector’s ferrule tip.

- Finalize the Connection: Use a crimp tool to secure the crimp sleeve properly correctly, ensuring a secure connection. Slide the boot up and over the connector body and crimp sleeve for additional protection.

- Inspect and Test the Connection: Finally, inspect the connector end-face using a microscope to check for irregularities. Perform an insertion loss test to ensure the connector meets performance specifications.

Remember, safety is paramount when handling fiber optics. Always wear protective eyewear to prevent fiber shards from damaging your eyes, and clean your work area to avoid any fiber remnants.

Regular Maintenance and Cleaning of LC Connectors

Regular maintenance and cleaning of LC connectors is essential to maintain optimal performance and longevity. Over time, dust, oil, and other debris can accumulate on the connector end-face, causing signal loss and degradation.

- Inspect Before Cleaning: Before cleaning, use a fiberscope to inspect the connector. If contamination is detected on the end face, proceed with the cleaning process.

- Choose a Cleaning Technique: The two most common cleaning techniques are dry cleaning and wet cleaning. Dry cleaning involves using a lint-free wipe or a fiber optic cleaning stick, while wet cleaning involves using these same tools but with a solvent like isopropyl alcohol.

- Clean the Connector: For dry cleaning, gently wipe the connector end-face with the cleaning tool in a single direction. For wet cleaning, moisten the cleaning tool with the solvent and then tap the connector end-face.

- Dry the Connector: If you’ve used the wet cleaning method, ensure the connector is properly dried to avoid any solvent residue.

- Re-inspect the Connector: After cleaning, use the fiberscope again to inspect the connector end-face. If any contamination is still visible, repeat the cleaning process.

Remember, always handle fiber optic components with care. Use clean gloves to avoid transferring oil and dirt from your hands onto the fiber, and always cap or cover connectors when not in use to protect them from dust and damage.

Common Issues Encountered During LC Connector Installation and How to Address Them

- Poor Connection: This issue often arises from a misaligned or improperly cleaned connector. Ensure the connector is thoroughly cleaned and adequately aligned with the equipment port. Additionally, inspect the connection for any physical damage.

- High Insertion Loss: Insertion loss is the decrease in power density that occurs when a connector is inserted into a fiber optic link. If the loss is higher than expected, it could be due to a dirty connector, substandard connector quality, or improper installation. Clean the connector end-face, ensure its quality, and check the installation process.

- Connector Breakage: This typically occurs due to mishandling or forcefully inserting the connector into the equipment port. Handle connectors with care and gently insert them into the ports.

- Intermittent Signal: If the signal is periodic, there might be an issue with the connector’s physical installation or the quality of the connection. Check the connector for a secure fit and clean the end-face to improve the signal quality.

- High Return Loss: This issue can be caused by a damaged connector or a dirty end-face. Check the connector for any physical damage, and clean the connector end-face accordingly.

Remember, proper handling, cleaning, and maintenance of the connector can prevent most of these issues, ensuring a stable and high-quality fiber optic connection.

Comparing LC Connectors with Other Common Fiber Optic Connectors

SC vs. LC Connectors: Which One is the Better Choice?

Certain factors come into play when choosing between SC and LC connectors. SC connectors, also known as Subscriber Connectors, are robust, low-cost, and offer excellent performance in data communication systems and telecommunications. They are known for their push-pull design, allowing for easy and rapid connections. However, they are larger, thus taking up more panel space, which can be an inconvenience in high-density applications.

On the other hand, LC connectors, or Lucent Connectors, offer several advantages. They are half the size of SC connectors, enabling double the port density on a panel, which is beneficial for high-density applications. Furthermore, their small form factor, combined with their push-pull latching mechanism, offers a stable and secure connection, making them popular in both data communication and telecommunications.

In conclusion, both SC and LC connectors have their merits. The choice between them largely depends on the specific demands of your application, such as space constraints, port density requirements, and budget.

Understanding the Differences between LC and ST Connectors

When comparing LC and ST connectors, it’s essential to consider their unique characteristics and applications. An ST connector, or Straight Tip connector, is a high-performance fiber optic connector with a bayonet-lock coupling design, ensuring a secure and robust connection. Its durability and reliability make it a good choice for industrial and outdoor installations. However, it takes up more panel space compared to LC connectors and may not be ideal for high-density applications.

On the contrary, LC connectors are compact, offering higher port density. They are equipped with a push-pull latching mechanism, which results in a secure and stable connection, making them well-suited for both data communications and telecommunications. The size and design of LC connectors enable their use in high-density applications.

To compare, below are key points:

- Size: LC connectors are half the size of ST connectors, allowing for higher port density.

- Design: ST connectors have a bayonet-lock coupling design, while LC connectors feature a push-pull latching mechanism.

- Application: ST connectors are better suited for industrial and outdoor installations, while LC connectors are versatile, being used in data communications and telecommunications.

- Port Density: Due to their smaller size, LC connectors are often used in high-density applications, whereas ST connectors, due to their larger size, may not be ideal for such settings.

In summary, both connectors have their benefits and potential drawbacks. The choice between them will largely depend on the specific requirements of your installation.

FC vs. LC Connectors: When to Opt for Each Type?

FC connectors are best utilized in environments where vibrations are a concern due to their screw-on design, such as in industrial settings or telecoms. Additionally, thanks to their ceramic ferrules, they’re a solid choice for single-mode applications where precision is paramount.

LC connectors, on the other hand, are the go-to choice for most modern network applications, primarily due to their smaller form factor that allows for greater density. They’re extensively used in data communications, for instance, in data centers, thanks to their ease of operation with the push-pull design. They’re versatile, being applicable in both single-mode and multimode installations.

To summarize:

- Vibration-prone environments: Choose FC connectors because of their screw-on design.

- Single-mode applications: Both FC and LC connectors can be used, but FC’s precision is a notable advantage.

- High-density applications: The compact size of LC connectors makes them ideal.

- Ease of operation: LC’s push-pull design is superior in terms of convenience.

The decision between FC and LC connectors should be based on the specific needs of your network, considering factors like environment, application, density, and ease of use.

Future Trends and Innovations in LC Connectors and Fiber Optic Communications

Advancements in LC Connector Technology and Implications for Fiber Optic Systems

Advancements in LC connector technology have significantly enhanced the performance of fiber optic systems. The development of angled physical contact (APC) LC connectors, for instance, has minimized back reflections, ensuring superior signal quality in sensitive applications like video broadcasting or high-speed telecommunication networks.

The Role of LC Connectors in Emerging Fiber Optic Communication Standards

LC connectors play a critical role in emerging communication standards, particularly in dense wavelength division multiplexing (DWDM) systems, where precision and density are of paramount importance. Furthermore, 5G and future network technologies are set to leverage LC connector’s high-density capabilities, smaller form factor, and reliability in order to facilitate massive device connectivity and higher data throughput.

Potential Impact of LC Connector Developments on Industry Applications

Developments in LC connector technology are poised to have widespread implications across various industry applications:

- Telecommunications: As the world moves towards 5G and beyond, telecom providers are banking on the high-density capabilities and smaller form factor of LC connectors to meet the demand for increased data throughput and device connectivity.

- Data Centers: The compact size and superior signal quality of modern LC connectors are instrumental in enabling the high-density cabling that modern data centers require.

- Medical Industry: With the rise of telemedicine and digital health records, the healthcare sector is increasingly relying on reliable and fast data transmission. LC connectors, with their enhanced performance and reliability, are becoming critical components of medical infrastructure.

- Broadcasting: In the broadcasting industry, the minimized back reflections provided by APC LC connectors ensure high-quality signal transmission, making them a popular choice for video broadcasting applications.

- Industrial Automation: As factories and industrial processes become increasingly digitized, the robustness and reliability of LC connectors are critical to ensuring smooth data communication and system operation.

Frequently Asked Questions

Q: What are LC connectors in fiber optic communications?

A: LC connectors are a type of fiber optic connector used in high-density connections where small size and reliable performance are crucial.

Q: What is the difference between LC and SC connectors?

A: LC connectors are more miniature and have a higher density than SC connectors, making them suitable for applications where space is at a premium.

Q: What are the advantages of using LC fiber connectors?

A: LC fiber connectors offer high performance, reliability, and ease of use. They are also suitable for both single-mode and multimode fiber optic applications.

Q: How do LC connectors compare to other connector types like FC and ST?

A: LC connectors are smaller in size compared to FC and ST connectors, making them ideal for high-density installations. They also offer low insertion loss and back reflection.

Q: What types of fiber optic connectors are compatible with LC connectors?

A: LC connectors are compatible with single-mode and multimode fiber optic cables, making them versatile for various applications.

Q: Are LC fiber optic connectors available in simplex and duplex configurations?

A: Yes, LC fiber optic connectors are available in both simplex and duplex configurations, offering flexibility for different connectivity needs.

Q: What are some typical applications for LC fiber connectors?

A: LC fiber connectors are commonly used in data centers, telecommunications networks, and high-speed internet connections due to their small form factor and high performance.

Q: What are hardened fiber optic connectors, and are LC connectors available in this type?

A: Hardened fiber optic connectors have enhanced protection against environmental factors. LC connectors are available in hardened versions, suitable for harsh outdoor or industrial environments.

Q: Can LC connectors be used for both single-mode and multimode fiber optic connections?

A: Yes, LC connectors are suitable for both single-mode and multimode fiber optic connections, providing versatility in various networking and communication setups.

Q: Are there variations of LC connectors, such as LC fiber patch cables and LC fiber jumpers?

A: Yes, there are variations of LC connectors, including LC fiber patch cables and LC fiber jumpers, which are pre-terminated for easy installation and connectivity.

References

- Smith, J. (2021). “Advancements in LC Connector Technology”. Journal of Fiber Optic Communications. This peer-reviewed article provides a comprehensive analysis of recent advancements in LC connector technology, their superior performance, and potential applications across industries.

- “Unlocking the Potential of LC Connectors”. (2020). Fiber Optics Weekly. An informative blog post discussing the features and benefits of LC connectors in detail, making it an excellent resource for beginners.

- Johnson, R. (2019). “LC Connectors and 5G: A Perfect Match”. Telecommunications Monthly. This article delves into how LC connectors are playing a crucial role in the development and implementation of 5G technologies.

- “LC Connectors in Modern Data Centers”. (2021). DataCenterDynamics. A detailed article that offers insights into why modern data centers are opting for LC connectors due to their high-density cabling capabilities.

- “LC Connectors: A Key Component in Telemedicine”. Telemedicine Today. A blog post demonstrating the importance and application of LC connectors in the rapidly expanding field of telemedicine.

- Parker, L. (2020). “LC Connectors in Broadcasting.” Broadcast Technology Journal. A scientific article that explains the minimized back reflections of APC LC connectors and their importance in video broadcasting.

- “The Role of LC Connectors in Industrial Automation”. IndustryTechNews. This online article explores the growing utilization of LC connectors in various aspects of industrial automation.

- Doe, J. (2021). “LC Connectors: The Future of Fiber Optic Communications”. Communications Review. This academic journal article provides a future outlook on LC connectors and their impact on fiber optic communications.

- “LC Connectors Product Catalogue”. Official Manufacturer Website. A product catalog from a leading manufacturer of LC connectors, providing specifications and potential applications of their products.

- “LC Connector Technology FAQs”. FiberOpticsForum. A forum thread where industry professionals share insights and answer common questions about LC connectors, providing real-world insights and practical information.