Today’s world is focused on data processing and its transmission across vast networks. In this regard, it would also be significant to mention that fiber optic cable technology has become essential for all communication systems. Out of the numerous fiber optic solutions available in the market, the MPO breakout cables help enhance interconnectivity within the networks. The purpose of this article is to introduce the readers to the concept of remaining relevant in the global trend towards the deployment of MPO breakout cables by being cognitively equipped on the structure as well as the role of the cable in enhancing network capabilities. There is no shortage of willingness for architects, developers, contractors, and other information technology personnel to have such knowledge, allowing them to make the best decision to take them towards the best decision.

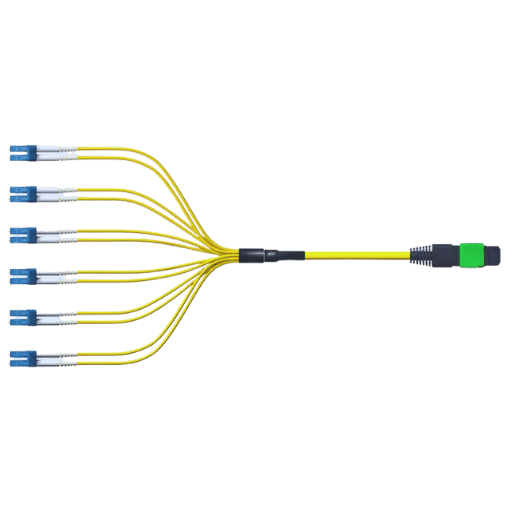

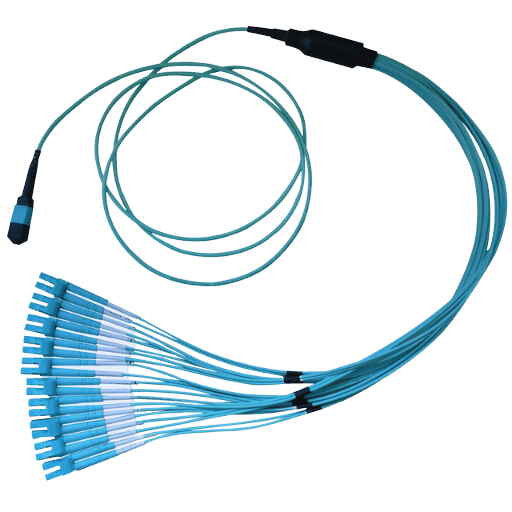

An MPO breakout cable is a fiber optic cable designed to split a single multi-fiber connection into multiple separate connections. It typically consists of an MPO connector on one end, which can accommodate multiple fibers, and multiple connectors (such as LC or SC) on the other end, each terminating a single fiber, including options for breakout fiber. This configuration allows the efficient distribution of data signals from one source to multiple destinations, making it ideal for use in high-density networking environments such as data centers. The use of MPO breakout cables helps streamline connectivity, reduce installation times, and manage cable infrastructure more effectively by minimizing the number of full-length cables required for distribution.

Definition: Fiber optic patch cords are flying leads with connectors at both ends that connect two optical devices.

MPO, or Multi-Fiber Push-On cables, is a type of fiber optic cable with most holes stuffed with fibers within a compact single connector. These cables are primarily employed in areas such as data centers and enterprise networks where a high-density connection is needed.

Features:

Such dense packing of features implies that MPO cables are critical elements of modern, high–network infrastructures.

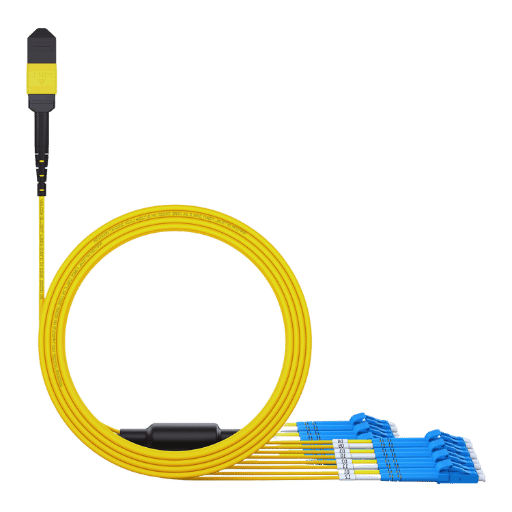

The ten-fiber MPO to MPO Breakout Cables bring forth important benefits that are key for modern networking systems. Firstly, they allow high-density connections in a compact form, making complex networks easier by using fewer connectors and cables. This allows for better cable management and space utilization within data centers. Secondly, they enhance data transmission rates and performance reliability, making them suitable for today and future broadband networks as they handle single-mode and multimode fibers. Lastly, since the cables use modular designs, they are easy to install and maintain, providing plug-and-play capabilities and reducing the time required for non-operational network systems. This increases efficiency in operational processes.

MPO breakout cables are mainly deployed in environments with high bandwidth and density, such as data centers and enterprise networks. These cables are essential in connecting optical devices like switches, routers, and servers, enabling data to be transferred at high speed with minimal signal degradation. The data centers allow rapid deployment, easy scaling, and effective patching, critical in addressing the increasing needs in cloud computing and virtualization. They are also widely applied in telecommunication networks because they can handle large-capacity, long-distance links without compromising the data. Such flexibility and compatibility make MPO breakout cables an essential element in multimedia broadcasting, as they facilitate the transport of audio and video signals without hitches.

Which breakout option to select between 12 and 8 fiber will be well guided by your network’s design. The use of the 12 fiber option is recommended for areas with high bandwidth and spatial diversity since it allows more fiber strands to be fitted within a single cable, thereby enhancing data capacity and setting room for future network expansion. It is well suited for high-density data centers that are highly sought after and require the best connection and transmission. Selectively, the eight fiber option is much cheaper and is suited for implementation scenarios for low to mid-sizes concerning data needs while offering a good middle ground in price and performance. Such a layout configuration is optimal for applications where just the right size of the conduit is required and not too large to accommodate excess loads, making it suitable for some enterprise configurations. Ultimately, it depends on a tradeoff between the present requirements, which are backed up by the finances available to satisfy the requirement, and the anticipated needs, which are expansion plans.

The choice of plenum cables demands an evaluation of the installation environment, especially concerning the building code and fire safety measures. These specific cables feature a fire-resistant cover and are thus appropriate for use in the air plenum regions of ceilings. This feature aids in reducing the amount of smoke and poisonous gases that can be produced in the event of a burning, thus aiding in safety compliance measures. Besides, the cable parameters such as size, flexural characteristics, and signal strength should also be suitable for existing installations. Since plenum cables are more expensive than non-plenum variants, budgetary issues and compliance requirements also need to be considered. It is these factors that guarantee that the chosen plenum cables satisfy both the safety requirements and the functional requirements for network installations.

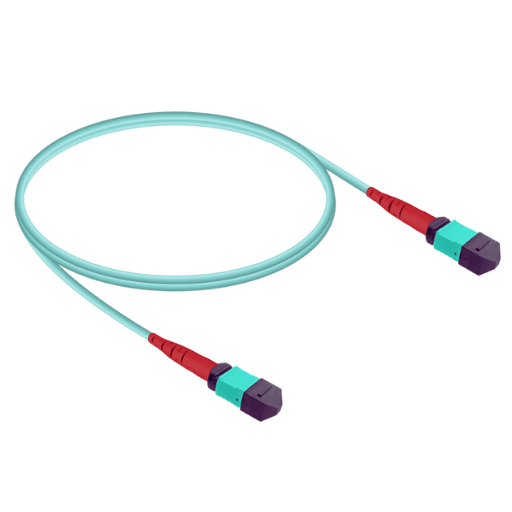

Understanding the differences in the performance and the application of OM3 and OM4 cables is crucial in evaluating OM3 or OM4 fiber cables. For example, consider the OM3 fiber cables designated for use with 10 Gigabit Ethernet, effective for distances of not more than 300m. They utilize a laser-optimized application and are recognizable by their aqua-colored sheath. They most commonly provide a satisfactory option for most standard data center environments. Networks requiring higher bandwidths and/or long distances are better served by OM4 cables, which support up to 550 meters in distance and approximately 40 and 100 gigabit Ethernet transmission rates. They are usually connected with breakout fiber cables. This newly found addition made the OM4 cables a better option for long-term use and bulk infrastructure performance. Lastly, both make use of a core size of 50 micrometers but for the best performance outcome of the network application OM3 or OM4 should match the distance and speed needs, the OM4 however would be pricier in comparison to the OM3.

To optimize MPO to LC breakout cables and guarantee that they are seamlessly integrated with the system, I have developed a set procedure that I follow strictly. First, I check the requirement specifications for the existing network and the cable details to ensure interoperability. I then uncoil the cables carefully to avoid tension or twisting that could obstruct signal transmission. In this step, I ensure that the MPO connectors to be connected are appropriately oriented to their corresponding signal pathways. Then, I plug the LC connectors into the relevant ports, ensuring that the connection is tight enough not to lose the signal. I then run a continuity test to guarantee that all the connections are complete and that there are no errors in the fiber path connections. This ensures that the commissioned breakout cables can perform their intended roles reliably and effectively within the operational network.

Fibre optic networks with escalated density need to be maintained to guarantee the highest post-installation performance and lifespan. It is advisable to perform duty clearly, which entails optimally regular cleaning and inspection, as dust and other particles significantly affect the signal quality. All the networks in the central office setting above should also be performed by skilled personnel, as it is recommended that specialized fiber optic cleaning kits and solutions be used. Creating a good and effective documentation system is also needed to provide information on all installed parts, junctions, and parameters throughout the network. Moreover, routine measurements taken with properly calibrated apparatus may also allow for the investigation of the network for any faults, improving its efficiency. Much more importantly, using standard cabling methods, including but not limited to appropriate minimum bend radius and excessive tension, should be avoided to maintain the cable integrity of the infrastructure. Adherence to the above points guarantees that the network remains efficient and reliable.

In the case of fiber optic networks, there are tools and accessories, such as cleaving tools and tools for cleaving fiber patch cables, which are deemed essential in the network. Firstly, however, fiber optic patch cords pose an important determining factor for the network’s performance since they are never in walls or buildings and, thus, susceptible to damage. 홄 secondly, a microscope is an essential tool for maintenance as recording the fiber patch cords must be checked for any physical imperfections. Furthermore, specialized tape and fluids are critical components that the cleaving device must carry out. Thirdly, cleaning wipes and aids such as alcohol can prevent stretched NP C from becoming amorphous and redundant and lingering on the cable housing, ultimately leading to poor transfer rates. Such tools as fiber optic visual fault locators and optically powered meters are crucial for improving maintenance and installation efficiency within the network. Having fully equipped tools ensures the quality and precision management of fibers, which ensures better network performance.

The singlemode fiber was developed for Wavelength-Division Multiplexing systems with long distances and high bandwidth. Its small core, which ranges from 8 to 10 micrometers, allows only light to travel in a single mode. Because of this, signal loss and dispersion can be minimized over greater distances, which is useful for large metropolitan areas with dense populations and broader networks. Due to its slight core diameter, it has little modal dispersion, but owing to the multi-mode configuration structure, up to 12 strands of high data rates and long distances can be achieved. It is mainly utilized by the internet backbone, cable TV, and enterprise networks where reliability and quality are paramount. The initial costs of singlemode fiber network installation and equipment are greater; however, due to the features of the fiber with wider transmission distances and greater bandwidth capabilities, it proves to be a much more suitable option for future communication needs.

The use of multimode fiber is suitable for short- to medium-distance communication where the LAN, data centers, and feeds exist within the building. The core is what is the differentiating factor, which explains the diameter being around 50 to 62.5 micrometers, which means that several light waves pass through it at the same time, which allows for an easy alignment. This subsequently leads to the system expenditure being lowered as cheaper light sources such as LED are used. Multimode fiber makes the installation and maintenance of the service easier as none of the complex processes associated with single-mode systems are required. Distance for the transmission is not an issue with this type of wire, although it can only support low bandwidth applications as it possesses high modal dispersion compared to single-mode wires.

The decision process surrounding the choice between OM1, OM3, and OM4 depends on the particular needs of the network infrastructure. OM1 fiber uses a core diameter of 62.5 micrometers, making it ideal for systems utilizing a bandwidth of 1Gbps for shorter distances. In contrast, OM3 and OM4 fiber typologies employ the 50-micrometer core diameter, allowing them to perform better as they are more suitable for laser applications. OM3 will enable data transfer of 10 Gbps over a distance of up to 300 meters. In contrast, with OM4, this distance is expanded to 550m, which is more effective for high-speed LANs and modern data centers, especially with breakout cables. Such a decision would depend on the pace desired, the range requirements, and the future potential of the fiber optical cable network infrastructure.

Insertion Loss is also referred to as attenuation, defined as loss of signal power resulting from transmission through a fiber optic component or connection. The measurement unit is decibels (dB), and it carries great importance when evaluating the operation of a fiber optic link because too high a value of insertion loss may cause a noticeable deterioration of the signal and, therefore, the efficiency of the network. Insertion loss may result from fiber ends being misaligned, connector defects, and splicing weaknesses. It is essential to keep insertion loss to a minimum in order to maintain high signal fidelity and true data transmission, especially in instances where speed and distance are factors. Considerable measures can be taken for the maintenance of acceptable levels of insertion loss which include the use of quality parts, proper installation procedures, and regular maintenance, thus increasing the effectiveness and durability of a fiber optic system.

Several strategies can be employed to enhance the efficacy of fiber optics networks and, at the same time, reduce the overall insertion loss. The first one is to ensure the ends of the fibers or cables are appropriately joined during the splicing process and when using connectors. In most cases, this is accomplished by applying high-precision cleaving tools and alignment fixtures, which are necessary to ensure the optimal performance of the patch cable during installation. Secondly, using good-quality connectors and splicing techniques is essential as they are critical in improving end-face imperfections that cause signal loss. Moreover, an appropriate selection of the core optical fibers, especially low attenuation ones, can help reduce insertion loss. It is also essential to clean and check the optical parts and components regularly since dirt may lower the signal quality. The strict adherence to these installation and maintenance measures guarantees the efficient performance of the fiber optic network throughout its service life.

Testing and measuring insertion loss in fiber has been stressed for its importance in network performance. The normal approach is to utilize an optical power meter and light source or an Optical Loss Test Set (OLTS). The procedure begins with one end of the fiber being attached to the light source and the other using a power meter. The light source provides the fiber with a continuous signal of a desired wavelength captured by the power meter. The difference in the two signals, which are transmitted and detected, quantifies the insertion loss. In practice, however, two or even more wavelengths, such as 1310 nm and 1550 nm, are used more commonly to circumvent functional attenuation at a particular frequency band. Precise measurement should be seen as a necessity because it assists in identifying probable faults and inspecting any given system.

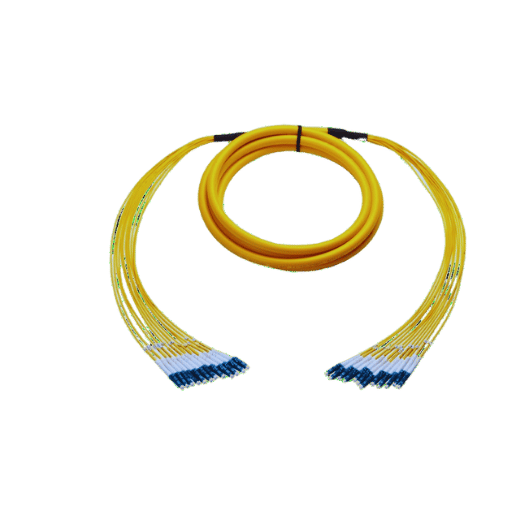

The manufactured-to-order cable assemblies have improved data centers by the bespoke goods they provide and the technical and space constraints they satisfy. They enable better airflow and better organization since cables are cut out at the precise length that is needed to reduce mess and the chances of tangling. This enhancement could improve thermal management, which is vital in controlling the working temperatures of high-density apparatuses. Furthermore, wire cable assemblies improve the robustness of cables because they are custom-made and tested for precise application. This custom fabrication and engineering process could improve installation effectiveness, minimize maintenance, and maximize the system’s dependability, especially when quality patch cables are used. The last point is that custom cables facilitate relying on expansion and upgrades in the future without major changes in the infrastructure.

In the design of data center cables, earned attention companies must consider performance, scalability, and environmental conditions. Cables have to be chosen based on their bandwidth and data transmission rate characteristics to ensure current and future requirements are met, allowing plenum-rated options, for example. Scalability is necessary because it is not uncommon for data centers to require expansion and subsequent upgrading of technology; thus, implementing a modular and flexible cable plant architecture is recommended. On the other hand, environmental parameters such as temperature and humidity have a significant influence, and therefore, materials and designs able to deliver good thermal efficiency and reliability have to be utilized. Appropriate materials and designs can reduce downtime and improve the efficiency of slaves on operational tasks. Attention to these aspects guarantees the presence of a strong and modernized cable infrastructure, especially when looking for operational and management purposes.

When choosing a supplier for custom cables, careful analysis of their capability, reliability, and commitment to quality is necessary. Top suppliers traditionally highlight their engineering capabilities, enabling innovative solutions for each project while ensuring the systems are durable and efficient. Furthermore, most reputable suppliers will guarantee their cables through rigorous testing and quality assurance procedures suitable for various applications. It is also advisable to consider suppliers with a verifiable record of completed projects and several satisfied customers, which indicates their ability to meet deadlines, especially with fiber optic patch solutions. Dealing with suppliers that are clear in their communication about the workload and customer support is vital in preventing potential problems and aiding in quickly resolving existing challenges. If these factors are considered, successful relationships will likely be established, and custom cable requirements will be fulfilled.

A: An mpo breakout cable, or a mpo fanout as commonly known, is a multi-fiber optic cable assembly that is configured to terminate multiple individual connectors, such as duplex lc or sc on one end and a multi-fiber mpo/mpot connector on the other end. This cable makes it possible to interconnect high-density MPs with single fibers for patching purposes with different network devices with differing connectors and types.

A: The standard mpo breakout cable type is eight fiber qsfp to 4x duplex lc, 12 fiber mpo to 6x duplex lc, and 24 fiber mpo to 12x duplex lc. Such wires can be configured in many types of fibers, including om3/om4/om5 for multimode applications and os2 for single mode. Setting up standard and custom cables will require strict compatibility and configuration.

A: Type A and Type B are two different locking designs utilized in MPO breakout waveguides. Type B, which is more popular, retains the straight-through mapping of fibers in the assembly that goes from the MPO end to the individual connectors. A type A cable, on the other hand, has a reversed polarity, which is needed for some network configurations. It is important to get the right type for your network topology design.

A: MPO breakout cables offer several benefits, such as space-efficient connectivity, better cable management, and convenient transition across varying network capacities (that is, 10G, 40G, and 100G). They further allow the use of high-capacity device interfaces, such as the QSFP transceiver, to be connected to several lower-capacity devices through SFP+ connectors.

A: When choosing an MPO breakout cable, consider the fiber type (multimode or single mode), connector type (MTP to LC and SC or other), fiber count (e.g., 8, 12, or 24 strands), cable length, and polarity (Type A or Type B). Also, make sure the cable is compatible with your networking devices and the required bandwidth.

A: When the jacket of a cable is aqua, it is easily recognized as a multimode fiber optic cable, usually rated OM3 or OM4. This system assists in the rapid location of the cable type in complicated network field installations. Single-mode cables are often yellow, e.g., OS2, while OM5 multi-mode takes on lime green; switchboard patch cable is commonly used for connecting multifunctional devices in the network instead.

A: MPO breakout cables facilitate high-density installations by terminating multiple individual fibers with a single MPO connector. This lessens the amount of connector and cabling required and, therefore, takes up less room in patch panels or cable trays. This is especially useful in data centers and other places where high density is an issue.

A: The MPO breakout cables offer a wide range of connector types. These include the more familiar duplex LC connectors, as well as options with ST, SC, or FC connectors. The MPO end typically has MTP connectors, which are an upgraded version of MPO designed by US Conec.

A: When working with MPO breakout cables, it is necessary to avoid applying excessive force that would result in bending them below their minimum bend radius to prevent signal loss. Avoid working with or using connectors if dirty, or do not forget to wear dust caps when not in use. When a certain installation requires certain fire ratings to be met, use the right cables with jackets with the right ratings, such as LSZH or OFNP. Check and clean the connectors from time to time to guarantee peak efficiency.