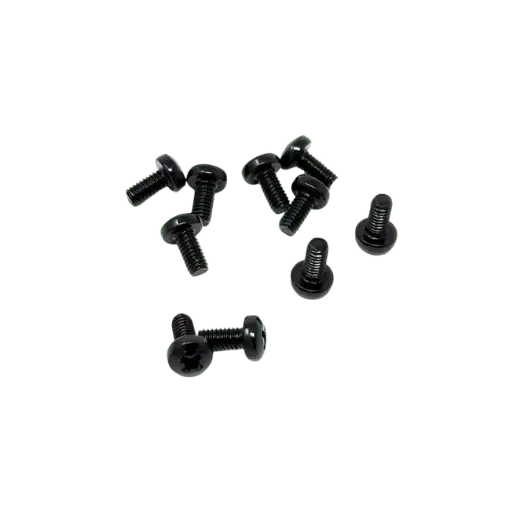

Acquiring the appropriate screws is necessary while organizing a project involving the securing of M.2 solid state drives (SSD) or any other hardware components. This is due to the fact that both stability and functionality depend on having the right screws. M2 screws, in particular, are the best answer because of their compatibility, strength, and ease of use. This article addresses the needs of enthusiasts, hobbyists, and professional IT specialists explaining why M2 screws could be a missing part of the puzzle. Now, M2 screws can also be purchased from Home Depot which offers the screws at reasonable price without compromising quality. Continue reading to understand the advantages of M2 screws, tips on how to choose the right one, and how Home Depot makes your quest for trustworthy hardware easier.

M2 screws are categorized according to their nominal diameter and in this case, the diameter is 2mm. They are widely used for precision tasks like fitting together electronics, small machines, and fine hardware parts. M2 screws are offered in different lengths, materials (such as stainless steel, carbon steel, and alloy steel), thread types like machine or self-tapping, and various environmental and application considerations. For example, securing circuit boards or repairing small devices require meticulous detail which makes M2 screws ideal for these projects. Selecting an M2 screw requires considering the components and materials being fastened along with the goals of the project.

M2 screws are extensively used in the medical industry because of the delicate fastening that is required in lightweight or compact components. Their applications include electronics, where they are used for circuit boards and assembly integration; the medical field includes devices such as surgical instruments; and in the technology industry, they are used in smartphones and laptops among other gadgets. M2 screws are applicable to many industries due to the small size which along with strength serves the purpose which needs precision in high demanding environments.

M2 screws are manufactured worldwide with materials that ensure protection from the environment while maintaining durability and strength. Some examples of frequently used materials include:

The constituents are selected according to the unique properties of the application, including, but not limited to, mechanical strength, resistance to corrosion, and level of environmental exposure.

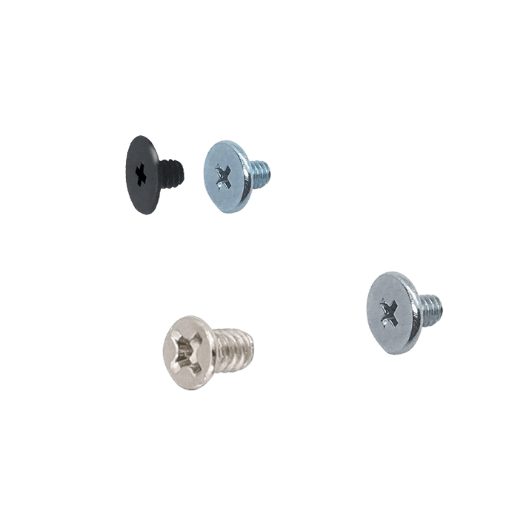

Choosing the right M2 screw entails considering its size and dimensions as these impact the fitting and functionality of the screw. “M2” indicates the nominal diameter of the screw, and in this case, the diameter is 2mm. M2 screws usually come with varying thread lengths and pitches, with pitch usually being the distance between adjacent threads. For your application, ascertain the required thread length, pitch, and head type, e.g., pan, flat, or countersunk. These values guarantee a match with the materials and components in question. Always check precise specs from reputable manufacturers to avoid discrepancies in your project.

Stainless steel and carbon steel offer different advantages. Consider streght, corrosion resistance, maintenance, and price of the material. Stainless steel is made from iron, chromium, nickel, and other alloying elements, which makes it well known for corrosion resistance because of passivation. This makes stainless steel perfect for harsh and corrosive materials like the marine, chemical processing, and medical industries. 304 and 316 grade stainless steels are a popular choice because of the harsh durability and rust resistance.

Carbon steel contains a high amount of iron and carbon with very few alloying elements. With this makeup, it has great strength and is economically cheap. On the downside, it does not have the natural corrosion resistance of stainless steel and needs protective coatings of paint or galvanization in rust prone areas for long term use. High carbon steel grades are used in extremely harsh and abrasive areas such as cutting tools and automotive parts.

Depending on the grade, stainless steel has a tensile strength of approximately 500-750 MPa while carbon steel varies from 400 MPa for mild steel to ultra-high-strength variants over 2000 MPa. Additionally, stainless steel is more expensive than carbon steel, costing roughly 3-5 times more, which accentuates the urgency of cost-benefit analysis while choosing the material.

As with any dilemma, the choice of stainless steel or carbon steel lies in the unique needs and requirements of the project, such as ecological factors, mechanical loads, desired lifespan, and the financial budget. This selection becomes pertinent from both a functional and economic standpoint provided these parameters are considered.

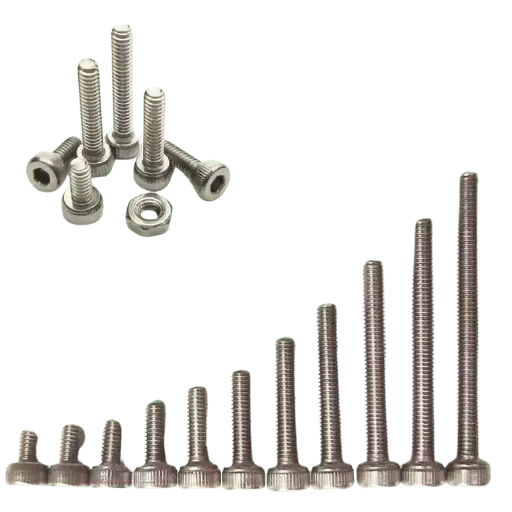

As with any selection decision, consider the intended use first when selecting socket head and Phillips head screws. Socket head (or Allen) screws are best for applications that require high torque and a neat appearance, as they sit flush with the surface. They are frequently employed in machinery and other confined areas because of their size. Phillips head screws, on the other hand, are generally more useful and ideal for everyday tasks since their shape helps reduce the chances of slippage. Nevertheless, their resistance to high torque is usually lower than that of socket head screws. Phillips and socket screws differ in their mechanical limitation and accessibility promise particular functions for each application.

Tweezers or needle nose pliers are fundamental for holding and placing the small screws.

If the components fastened are without rotational movement, the desired result has been achieved.

M2 socket cap screws are precision fasteners that are widely used in the fields of electronics, robotics, and machinery due to their compact size and their ability to provide strong connections in small spaces. By incorporating durable materials such as stainless steel or alloy steel , these screws are capable of withstanding corrosion and boasting remarkable mechanical strength. Alongside featuring a cylindrical head and recessed hexagonal drive, M2 socket cap screws are also crafted to accommodate secure tightening using hex keys or Allen wrenches. Moreover, these screws are effortlessly installed and securely fastened due to their accurate threading.

Flat and pan head screws have different uses, and their shapes are also different. Pan head screws have a dome shaped head that is above the surface when installed which makes them suitable for use where there is moderate load distribution and requires a good appearance. Flat head screws have a head that is conical in shape allowing it to sit flush with the surface or below the surface of the material which makes it ideal for use where smoothness is needed. The selection of any of these two is based on the design and functional needs of the assembly structure.

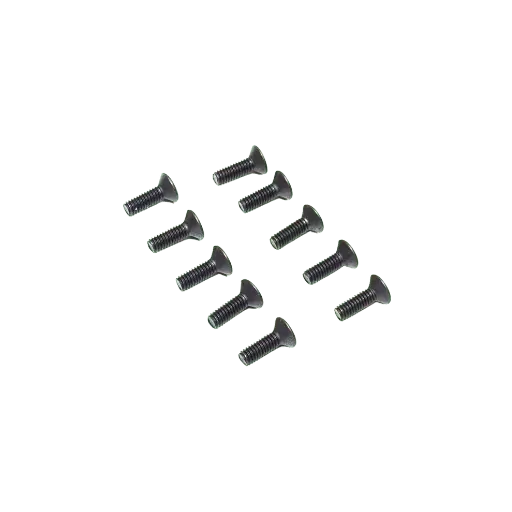

Countersunk M2 screws are very versatile because of its unique features. For one, countersunk M2 screws are flush with the surface of the material which increases the smoothness of the surface and also minimizes snagging. They are made from strong materials like alloy and stainless steel which makes it corrosion and wear resistant. Furthermore, they provide solid fastening due to the precise threading which makes them suitable for use in delicate and aesthetic machinery parts and electronics.

In the case of M2 screw kits, online retailers frequently have lower prices because of their reduced operating costs. These sites have low price offerings and great discounts, particularly when buying in bulk. They also have increased demand for bulk orders. However, local hardware stores have the advantage of immediate access to the products since there is no waiting period for shipping. Even though prices at local stores might be somewhat higher because of operational costs, these stores offer the benefit of personnel assistance where an attendant checks the customer’s requirements. Lenders ought to evaluate the convenience associated with shopping through the internet vis-à-vis immediate attention and personal, face-to-face service associated with going to local stores.

A: M.2 screws are designed to match and securely affix M.2 components such as SSDs (solid-state drives) to the motherboard or appropriate interface. They maintain a solid connection and make sure that the drive does not shift or come loose with movement

A: No, not all M.2 screws are of the same dimension. The majority of M.2 screws are categorized under the M2 classification which means that their thread diameter is 2mm. However, its length and thread pitch may differ slightly depending on the manufacturer of the device or motherboard. Always verify the specifications of your M2 drive alongside your motherboard to ensure they are compatible.

A: Yes, a selection of M2 screws intended for M2 drives is available at competitive prices, including Home Depot. You can purchase them for individual or bulk use, making it easier to obtain the necessary components and tools for your work.

A: To ensure compatibility, review the user’s guide or technical specs of your motherboard, paying special attention to the type of mounting that includes a screw for an M.2 socket. Most screw diagrams are available for motherboards as well and indicate the appropriate size and type of screw for mounting.

A: Home Depot offers M.2 screws. For minor repairs, you may find them individually and for larger projects, you can find them in kits that include other screws, fasteners, and hardware essentials. He provides flexibility in purchasing options.

A: If the original is lost, the screw can be replaced with an appropriate M.2 screw that meets the specifications provided in the manual for motherboard and devices. Such screws are commonplace and can be purchased at Home Depot.

A: M.2 screw prices at Home Depot differ according to dimensions, material type, and packaging quantity. Generally speaking, the price of single screws is accessible; they are strikingly inexpensive, often just a few dollars. However, pricier packs or kits may be offered, but individually packaged screws typically have higher prices depending on their contents.

1. Mechanical and Biological Behaviour of Additive Manufactured Biomimetic Biodegradable Orthopaedic Cortical Screws

2. Additively Manufactured Medical Bone Screws: An Initial Study to Investigate the Impact of Lattice-Based Voronoi Structure on Implant Primary Stability

3. Functional Outcomes of Anterior Cruciate Ligament Reconstruction Using Titanium Adjustable Loop Button and Poly-L-co-DL-Lactic Acid-Beta Tricalcium Phosphate (PLDLA-bTCP) Interference Screws: A Single-Center, Retrospective, Observational Study

4. Predisposing Factors for Migration of Epiphyseal Screws into Physis in Tension Band Plating

5. Mechanical and Biological Behaviour of Additive Manufactured Biomimetic Biodegradable Orthopaedic Cortical Screws

6. Screw

7. Hex key