The NEMA L6-20P is a reliable and robust locking plug used primarily in commercial and industrial settings for high-powered electrical connections. This connector operates at 250 volts and handles 20 amps of electric current, making it a standard for equipment which needs a secure and stable power delivery. This article intends to focus on the applications and benefits of the NEMA L6-20P as well as its technical specifications. Knowing how to utilize NEMA L6-20Ps can increase efficiency and safety within power management systems and can be advantageous for facility managers, electricians, and even businesses investing in improving their electrical systems.

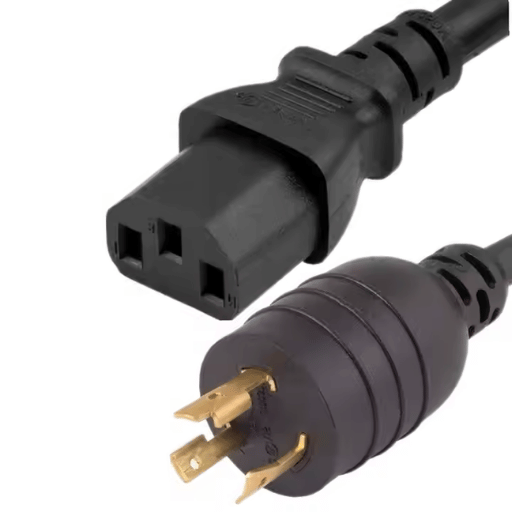

The NEMA L6-20P is a locking plug with a rating of 250 volts and a current of up to 20 amps. It has a unique three-prong configuration that helps prevent disconnection on compatible receptacles. The L6 standard defines its physical and electrical features for industrial and commercial applications. Its design prevents power interruption, making it appropriate for tools that need strong electrical connections.

The Nema L6-20P plug is fitted in requirements where smooth and efficient power connections are critical. Key features and specs of this plug type are listed below.

Current Rating: 20 Amps

Voltage Rating: 250 Volts

Configuration: 3-Prong (Hot, Hot, Ground)

Standard Compliance: Meets Nema L6 specifications for locking devices.

Housing Material: Constrcted and molded باي higher impact and durable materials like thermoplastic.

Connection Method: Use of locking L6-20R Nema connector ensures the plug stays firmly locked into position.

Wire Compatibility: Support wires of AWG #12 to AWG #10

Temperature Rating: -20°C to 75°C (depends on manufacturer).

Applications:

Heavy duty installations for industrial tools and machines

Power management and distribution in data terminals.

Commercial grade welding machines and tools.

Robust locking mechanisms of this plug allows stabilization that prevents unintentional power disconnections. This feature helps a lot in industrial and commercial places. Its advanced design helps with longevity where the conditions are a lot more demanding. The easy reconnection of the plug to the receptacle makes it a very efficient safety mechanism.

The locking feature of the NEMA L6-20P plug is particularly important in maintaining operational safety and reliability. Its functionality helps cement the plug to the receptacle reducing disconnectionssped above armboard that could cancels critical processes, harm delicate machinery and create very unsafe circumstances. This feature increases safety in portable power configurations automation settings where feeling and shaking is frequent. Moreover, the robust materials and construction, along with electrical safety standards of the NEMA L6-20P, support its widespread application in commercial and industrial power distribution systems.

The NEMA L6-20P plug must be detailed to determine its identification accurately. Here are the most important points.

Electrical Rating: Working with this device is safe as it operates with 250 volts and maximum of 20 amps which is perfect for medium duty industrial and commercial works

Pin Configuration: It has a keyhole locking pin and ratchet type snap with three pins – two angled power blades and one ground pin in a circular arrangement. This locking feature provides increased reliability during use preventing disconncetion during operations.

Standards Compliance: This plug follows the ANSI/NEMA WD6 standards which govern the use of locking-type connectors in industrial applications.

Materials: The NEMA L6-20P is a thermoplastic or rubberized material which is stamped or etched to bast NEMA L6-20P for easy recognition. In addition, it is exposed to wear, moisture, and chemicals due to working conditions.

Identification Markings: The Plug contains identification markings which specify voltage and amperage verifying its compatibility to the employed equipment.

These characteristics protect the NEMA L6-20P from enduring harsh working conditions.

Different options have different specifications, so choosing the right cord requires paying attention to various factors. Here is a comprehensive list of considerations that, when properly followed, enable optimal performance and safety.

Make sure that the cord’s voltage and amperage rating matches equipment specifications- overloading or underloading equipment leads to inefficiencies.

Heavy-duty applications may use example markings such as 250V/20A.

Verify compatibility with the power outlet or power tools.

The NEMA L6-20P plug, for example, goes well with NEMA L6-20R receptacle.

In terms of distance measuring, determine the distance from power source to equipment to calculate the needed cord length.

Long cords can create voltage drop, while cords that are too short hinder flexibility, making this balance critical.

A thicker wire with a lower American Wire Gauge (AWG) number can carry more current.

Choose the wire gauge according to the electrical load and surrounding conditions.

Check what materials make up the cords insulation, temperature could also be a factor, also the ability to resist moisture and chemicals are helpful as well.

PVC (Polyvinyl-chloride) works well for indoor environments while thermoplastic elastomer (TPE) is great for industrial settings.

Keep exposure to chemicals, extreme temperatures or outdoor elements in mind when selecting the cord.

Specialized options that do not leak oil or water are ideal.

Ensure adherence to industry standards like UL (Underwriters Laboratories) or CSA (Canadian Standards Association).

Certified cords undergo comprehensive testing validating their claim of safety and reliability.

Evaluate the jerking force, extreme bending, and exposure to harsh external conditions the cord may undergo.

Reinforced design for harsh environments with all-encompassing strain relief should be prioritized.

As a result of these considerations with specific requirements factors, choosing a power cord becomes a balance of efficacy and safety regarding the task.

Comparison between the NEMA L6-20P with C19 power cord options focus on specifications and applications. Below is a concise overview portraying distinct features of every type operand.

Voltage Rating: 250V

Amperage Rating: 20A

Connector Type: Locking plug with three conductors (hot, neutral, and ground).

Common Use Cases:

Industrial equipment.

High-end servers or other network equipment.

Power tools needing tight engagement.

Advantages:

Prevention of disconnection due to secure attachment of connection during use.

Reliable construction for tough operating conditions.

Voltage Rating: Usual value is up to 250V.

Amperage Rating: 16A or 20A, depending on the cable configuration.

Connector Type: Straight IEC 60320 connector with 3 poles.

Examples:

Equipment in Data Centers, such as rack-mounted PDUs.

High-end servers and network switches.

Benefits:

Well accepted across the industry, easy to interconnect from different vendors.

Shape tailored for server racks.

With these insights, you are able to evaluate and ascertain what product best meets your technical and business needs.

The NEMA L6-20P and NEMA L5-15P connectors have the following specifications and key features as outlined:

Voltage Rating: 250V

Amperage Rating: 20A

Number of Poles/Wires: 2 poles / 3 wires (live, neutral, ground)

Configuration: Locking plug for maintenance of connection and securing adherence

Applications: Industrial machinery, high power data center appliances and commercial equipment.

Advantages: Enhanced power capacity, increased reliability due to locking system in high vibration areas.

Voltage Rating: 125V

Amperage Rating: 15A

Number of Poles/Wires: 2 poles / 3 wires (live, neutral, ground)

Configuration: Locking plug for stable connection between devices.

Applications: Office equipment, light duty servers, small office networking equipment.

Advantages: Economical solution for low power applications, common connections.

The connectors are easy to assess for a particular operations need by focusing on numerous factors such as voltage, amperage, and functionality. These features structured for further understanding ease practical considerations.

Using advanced technological tools to improve efficiency and reliability of the given operation has always been a top priority. Modern systems feature intelligent real-time monitoring, predictive maintenance, and strong fail-safe mechanisms which minimize downtime while maximizing performance. To illustrate, cloud-based systems offer unlimited scalability and up-to-the-minute cloud updates which keeps the systems functioning optimally without requiring workflow halts. Adopting standardized equipment and widely accepted connectors also enhance safety and compatibility while simplifying maintenance, thus creating a conducive operational environment.

The following list identifies key application areas and environments involving these technologies and methodologies:

Use of industrial robots to automate various manufacturing processes.

Integration of real-time monitoring using sensors and IoT devices.

AI and machine learning technologies supporting predictive maintenance.

Remote monitoring of power grids and energy distribution network.

Smart metering for analytic and optimization of resource usage.

Automation of fault detection and the subsequent response.

Managing patient records through cloud-based systems.

Developing telehealth platforms to provide remote medical services.

Wearable technologies for real-time health monitoring.

Advanced Traffic Management Systems Optimized for Intelligent Mobility Management.

Automated Management of Utilities with smart water and lighting systems.

Creation of Integrated Systems for Safety and Security.

Advanced Supply Chain Optimization with Route Optimization Algorithms.

Automated Inventory Control Systems for Warehouses.

Tracking and Monitoring of Shipments with Tracking Devices IoT-enabled.

The various approaches tailored for each case epitomize adaptability as well as the efficiency demanded with the advancement of different industries.

Smart Lighting and Water Systems: Implementation of smart lighting has the potential to reduce energy consumption by nearly one third, while smart water systems can reduce water loss by around one fifth. Smart water systems are equipped with sophisticated sensors to monitor water usage and control distribution.

Public Safety and Security Platforms: With the aid of integrated platforms, response to incidents is increased by 40% due to real-time data analysis and efficient communication exchange among emergency response units. AI-powered systems are capable of forecasting threats and addressing them before they escalate using advanced analytics.

Supply Chain Optimization: Advanced algorithms for route planning have shown a 25% to 30% improvement in delivery times while reducing logistics expenditures by as much as 15%. These algorithms improve operational efficiency by traffic forecasting, map checking, and using historical data.

Automated warehouses have reported an increase in order fulfillment by 50% and a decrease in order-related errors by 70%. These systems are equipped with robotics and artificial intelligence (AI) that help manage the product stock.

Shipment delays across different businesses have been reduced by 18% with the use of tracking devices integrated with IoT technology for shipment visibility. These devices track movement, temperature, and handling of shipments during travel to mitigate risks.

With NEMA L6-20P, one of the most common mistakes is using the wrong wire gauge. Because the NEMA L620P plug is for 20-amp circuits, there must be at least 12 AWG of wire. Using smaller than required wire can lead to overheating and fires.

A common problem is misconnecting the terminals. Make sure the black (hot) wire goes to the brass terminal, the white (neutral) wire, which may not be used, goes to the silver terminal, and green (ground) goes to green terminal. Proper labeling and checking them is extremely important.

Blatant disregard of national and local electrical code policies are bound to get one into trouble in the form of fines or other legal action. Always check for compliance with the NEC (National Electrical Code) and local statutes before proceeding on the installation.

These two extremes in tightening cause different hazards. Over-tightening them can cause terminal damage or strip screws. Under-tightening creates loose connections which produce arc or intermittant connection.

Ignoring confirming properly wired with a voltmeter or continuity tester presents unexplained problems one day which may have to do with aging equipment once it starts carrying the load under which faults can develop.

Not securing the strain relief clamp on the cable could result in an excessive force on the internal cross connections, causing irreparable damage in the form of wear or failure of the wiring.

The NEMA L6-20P plug is not intended for use outdoors or in wet environments unless used with suitability weatherproof equipment. Exposing the plug under those situations would be dangerous and could violate its integrity.

Safety and functionality considerations when using the NEMA L6-20P plug can be achieved with avoiding the common mistakes and following through the rest of the step-by-step guide for correct sequence during installation.

To check whether anything is wrong with a NEMA L6-20P’s connection, you must execute the following actions:

Visual Inspection: Look for significant damages like bruises, scratches and chip out debris on the plug and receptacle as they might hinder effective contact.

Continuity Testing: Continuity check the plug with its corresponding parts using a multimeter for every joint of the terminal. Depending on how a terminal is configured, you must check it for interlock with the receptacle.

Voltage Verification: Using a voltmeter, check the voltage at the terminal and make sure that the electrical supply is relative to the specifications required by the L6-20P connector which is typically 250 volts.

Load Testing: After confirming the connection, perform the controlled load test to check if the plug can handle 20A without overheating or any irregularities.

Troubleshooting: For problems with the intermittent connection or lack of power, check the loose wiring, corrosion, and damaged terminals first. Defective parts should be replaced or repaired as appropriate.

The NEMA L6-20P requires regular check-ups and maintenance. Moreover, the connections defeat electrical issues which makes the apparatus completely safe. When performing troubleshooting, obey local electrical regulations and the manufacturer’s instructions.

The NEMA L6-20P connectors hold a certification from the National Electrical Manufacturers Association (NEMA). This distinguishes its brand from competitors and assures absolute trust in relation to commercial and industrial utilization. This document also strengthens the device reputation because these connectors have a voltage of 250 and a current rating of up to 20 amps. This helps ensures effective power supply in cases of heavy electrical equipment being used.

Another important aspect of these connectors is because of the UL (Underwriters Laboratories) certification which scopes beyond these. Having a UL certified means that there was testing done that guaranteed the product meets the set requirements in terms of marks of safety set by the ANSI standards. Also having the device guarantee that it complies to the standards set under ANSI devices makes sure that there is a broad range of systems and devices that they will work with and use interchangeably.

Data shows that installers and manufacturers of electrical devices and standard connecting plugs can avoid the electric faults non certified plugs and connectors suffer by over thirty percent. Standard compliant electrical equipment can reduce electrical faults by up to thirty percent and highlight the importance of maintaining reliance of non certified equipment.

Current And Voltage Rating:

Sized to suit requirements for high power equipment in demanding environments to be rated at 250V and 20A.

Designed For Use With Nema L6-20R Receptacles:

Compatible with presumed restraining locking.

Durability:

Achieved through the use of impact-resistant thermoplastic housing as well as metal parts resistant to corrosion

Safety Standards:

Meets electrical safety requirements as certified by UL (Underwriters Laboratories) and CSA (Canadian Standards Association).

Locking Mechanism:

Increases safety on workplace as unintentional operation disconnection is prevented through unintentional twist lock.

Operating Temperature Range:

Reliable functioning from -40 °F to 140 °F providing suited use in extreme environments.

Wire Accommodation:

Permits use of 10 AWG to 14 AWG wires, thus enabling flexible wiring configurations.

Applications:

For use in compressors and welders and HVAC systems as an industrial-grade power source.

Metropolitan regions have increased explosive population which results in additional construction on power plants, electric power system builders, and telecommunication lines have to apply the NEMA L6-20P It is built to withstand extreme conditions giving it versatility and the ability to satisfy the varied requirements of industry and commercial grade users along with unparalleled dependability.

Designed specially for industrial and commercial use, the NEMA L6-20P connector’s capabilities are outlined below:

Voltage Rating: 250V AC for high voltage compatibility.

20 Amps for current rating, suitable for medium-duty equipment.

Contact Material: Optimally conductive high bronze or copper alloy.

Durability: 10,000 average mating cycles ensuring repeated use.

The operating limits of the device is from -40°F to 140°F (-40°C to 60°C), which covers a wide environmental range.

Certifications and Compliance:

UL Listed

CSA Certified

RoHS Compliant

These listed features confirm the NEMA L6-20P connector’s strong construction and reliability, which is essential in harsh electrical environments.

A: It is a locking power plug configuration made for 20 amp 250 volt uses. It has a twist-lock feature for secure connection which allows use in industrial and commercial settings.

A: The locking feature of a NEMA L6-20P power cord keeps a secure connection using a twist-lock design which requires a slight twist which keeps the plug securely inserted.

A: The primary advantages of utilizing NEMA L6-20P locking connectors are the twist-lock security which enhances safety and maintaining positive latch hookup for override disconnects, as well as meeting rigorous power level specifications typical in industrial applications set at 20 amp 250 volt.

A: A NEMA L6-20P to C19 power cord is appropriate for equipment that must be connected via C19 and makes use of NEMA L6-20P’s 20 amp 250 volt capacity. Confirm that the fuse power requirements fit the specifications of the cord.

A: The main distinguishing factor between a NEMA L6-20P and a NEMA L6-15P plug is the amperage rating. The L6-20P is rated for 20 amps while the L6-15P is rated for 15 amps. Both are for 250 volt applications and have twist-lock mechanism.

A: Grounding is properly done on a NEMA L6-20P plug with the third prong which connects to the ground wire. To achieve utmost safety, make sure the receptacle and all wiring is done properly in accordance to the local electrical codes.

A: While using a NEMA L6-20P, pay attention to the features of the power cord such as heavy-duty power construction, hassle-free fully molded design, and a wire such as 12AWG which meets the 20 amp 250 volt requirements needed. Environmental safety standards are also met by cords that are RoHS and REACH compliant, making them even safer.

A: No, because of the mismatching amperage ratings and different plug configurations, a locking plug L6-20P cannot fit a receptacle L6-30R. Furthermore, the L6-30R is meant for 30 amp applications so the plug configurations also clash.

A: The extension cord must also have a 20 amp 250 volt rating as that of the NEMA L6-20P, which is 20 amp 250 volt. Additionally, the construction of the extension cord as well as the wire gauge must be heavy duty like 12AWG, a gauge that can safely carry the required electrical current.

A: There are converters that directly do this. Through these converters, equipment that uses a NEMA L6-20P outlet can be connected to power sources that supply IEC C19 inputs.

1. “High-energy quasi-monoenergetic proton beam from micro-tube targets driven by Laguerre–Gaussian lasers”

2. “Photoacoustic LED imaging apparatus using a low-cost system”

3. “Single-Laser Krypton Tagging Velocimetry Investigation of Supersonic Air and N2 Boundary-Layer Flows over a Hollow Cylinder in a Shock Tube”