Leverage precise patch panel diligent management strategies because it could result in efficient network performance. Inefficient organized cables can result in connectivity issues, increased downtime, troubleshooting, and many more. In the long run, productivity will suffer for any organization. This blog takes a step further and explains the principles and techniques of Patch Panel cable management that can help optimize networks. The techniques range from the basics of correct labeling to modern innovative organizational style. After you read this post, you will understand the essence of cable management in networking systems. IT professionals and network administrators can benefit from this guide by effortlessly optimizing and upgrading their systems.

A patch panel acts as the main point where several network cables are connected and managed. It also organizes devices that comprise a network by managing the flow of incoming and outgoing data through its ports to various servers and switches. Each of its ports is associated with a distinct cable, allowing for easy identification and modification of network set up, which can enhance the speed at which changes are administered. Consolidated connections through patch panels reduce the complexity of identification for a faulty cable, as well as facilitate the minimization of mess and improve changes within the network.

Patch panels function as the principal point for controlling network interfaces, enabling more efficient organization and access of cables in physical network configurations. Patch panels allow for quick changes to be made to the network without physically interacting with the end devices or the cables, as all the cables are routed to one central location. This minimizes the use and subsequent damage of devices and enhances network reliability which is critical for thorough network monitoring. In addition, patch panels also allow for increased scalability, making it easier to add additional network infrastructure when required. Their prominence increases an organization’s efficiency by alleviating the connection problem which in return enhances the effectiveness of the network.

As a focal point of organization for network cables in rack systems, patch panels make cable management simpler. Their distinct labeling makes it easier to troubleshoot which enhances maintenance efficiency. Patch panels also reduce wear and tear that comes with frequent reconnections, improving network reliability, especially in campus environments. The modular shape makes expansion easier and infrastructure can be scaled up when needed, which greatly helps network administrators.

Just like any other tool in a computer networking environment, patch panels can be categorized in several types that have different configurations and uses. It is vital to know the features and applications of these classifications to be able to use the appropriate tool in a networking setting.

Ethernet Patch Panels

Currently, Ethernet patch panels are the most popular. Sponsored networks use them for wiring the computers to the network using Ethernet cables, such as Cat5e, Cat6, or even the more sophisticated Cat6a standards. They typically come in 24-port, 48-port, or higher configurations depending on the needs of the local area network (LAN). These patch panels are widely employed in business environments where high-speed and reliable data transmission is crucial. For example, Cat6a patch panels, which support speeds of up to 10Gbps, are widely used in large enterprises because of its bandwidth of 500MHz.

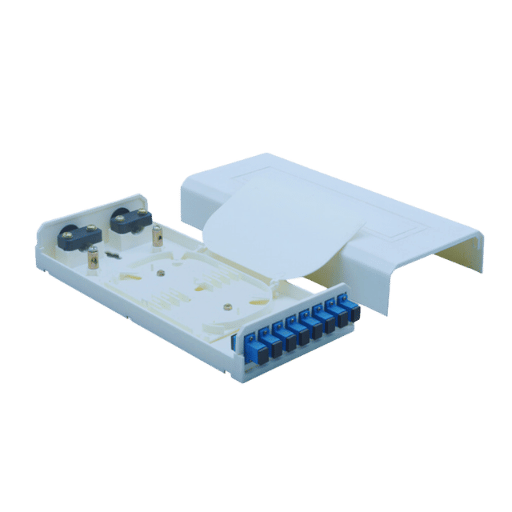

Fiber Optic Patch Panels

Fiber optic patch panels on the other hand are used to manage fiber optic cables. These cables aid in the faster transfer of data over long distances with minimal loss of signal, which makes it ideal for use in data centers, telecommunication hubs, and the backbone infrastructures of high-speed internet. Apart from aiding in the transfer of data, these panels also aid in the organization and protection of fiber cables to reduce the likelihood of breakage. These types of panels are divided into multi-mode and single-mode, the single-mode supporting greater distances while the multi-mode is more cost-efficient for shorter connections.

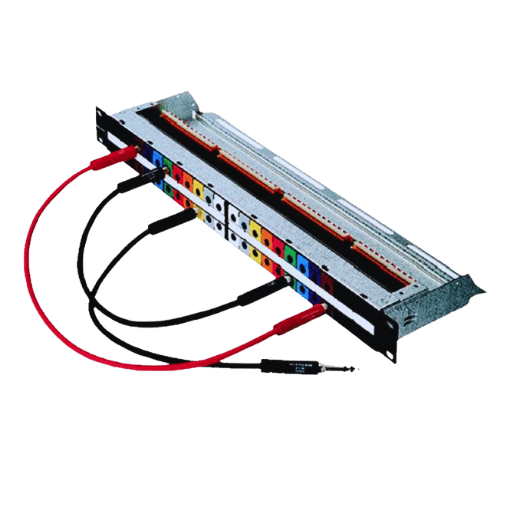

Patch Panels for Audio/Video COnnection

In broadcasting studios or for event management and home theater setups, specialized audio and video patch panels are frequently used. Sophisticated equipment such as mixers, speakers, and video processors can be easily connected and disconnected through these panels. In addition, these panels guarantee proper cleanup of audio/video workflows. With these bridge patch panels in place, signals can be routed with maximum convenience security, simplicity, and speed.

Power Distribution Breakout Patch Panels

These patch panels are often embedded in power distribution PDUs that serve dual functions of network and power connection. Like other server or data centers, true space saving and centralized management of key systems is required for these environments. With a PDU patch panel, organized power allocation can be achieved while eliminating the endless cable management issues. This system offers practicality while efficiency, which both employees and businesses long for.

Modular Vs. Punch Down Patch Panels

For any modification in the system, punch-down panels are rarely needed. These are hardwired systems and therefore provide a secure and permanent connection. In cases where big changes are dictated by the environment, modular patch panels should be employed. Modular patch panels allow for easier maintenance removal and replacement without special tools. In cases, where minimum called-for configuration changes are anticipated, these are more suitable for dynamic networks.

Evidence suggests that the increased use of cloud computing and IoT devices is raising global fiber patch panel implementation by 8% per annum. At the same time, businesses focused on being future-ready have been increasingly using Cat6a and other higher-grade Ethernet patch panels.

Every kind of patch panel has a specific role to perform, and the choice to use one in place of another is largely affected by the magnitude, range, and quality of the particular network system.

Label Cables Above and Below

Identification of cables using color codes or printed labels is done for simple visual recognition. While this is important for network monitoring, it also reduces confusion and simplifies the tracing of connections during maintenance activities.

Use of Cable Management Systems

Zip ties along with Velcro straps that are reusable can be used for securing loose cables to avoid tangling and facilitating organization. Avoid overtightening so as not to damage the cables.

Overhead Cable Management Systems

Using cable trays, raceways, or desk organizers allows the grouping and routing of cables into neat bundles. This ensures they are separated from floor areas allowing minimization of clutter.

Cable Charity

Use appropriately sized cables to drastically reduce slack for improvement of workspace aesthetics and reduction in tangling.

Periodic Maintenance Programs

Development and implementation of an order program to reorganize cables according to condition and arrangement helps maintain adequate assessment as the setup changes over time.

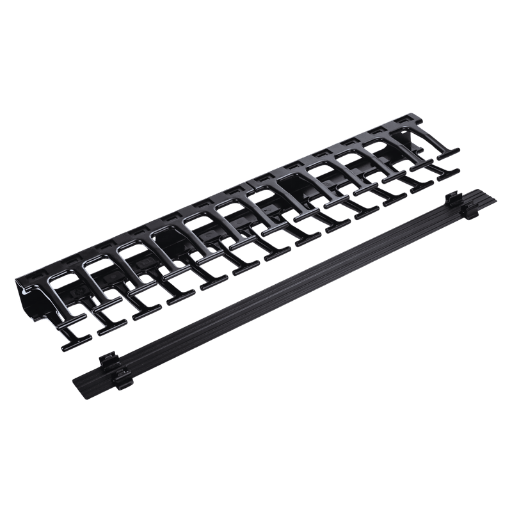

D-Rings serve as practical instruments for effective cable management in both simple and advanced settings. These components are simple, and handy, yet versatile at the same time, and offer a precise pathway that headways the cables to reduce tangling and surface wear. D-rings are usually fabricated using durable materials such as steel or plastic and are mounted on walls, server racks, or cable trays to manage the cables in a routed structured way.

Within industry guidelines employing efficient system and organization strategies alongside the use of D-rings can boost cable lifespan by 50 percent. They eliminate the physical pull, bending, or sudden torque displacement of the cables, which is especially important for fiber optic cables and high-performance data cables in a building or campus environment. In addition, maintaining order within cable infrastructure helps improve the airflow within the data centers, thus lowering the chances of overheating due to airflow blockage.

Think about the cables’ size and volume when installing D-Rings. D-rings come in different sizes, and choosing the right one will make the setup easier and more effective. As instance, larger D-rings are ideal for high-volume cable runs, while low-volume cable runs suit the smaller-sized ones. Also, maintaining regular spacing between the rings, usually 12-18 inches apart helps to mitigate cabling strain and maintain consistency.

Incorporating D-rings into your cable management system improves convenience and look. When used alongside labeling and bundling techniques, these devices simplify the identification and management of individual cables, which in turn reduces time spent on maintenance or troubleshooting tasks.

Implementing proper Ethernet patch cable management solves many network issues and is beneficial in reducing the maintenance cost of a ticket. Using the right techniques makes cable documentation within server racks more organized and manageable. Best practices for proper cable management are discussed below.

Management of Cable Length

Proper lengths of patch cables go a long way in shrinking slack and avoiding loops. Cables that are too long tend to create cable congestion which leads to improper airflow and makes troubleshooting more difficult. Consider using premade or custom-length cables that are appropriate for your specific rack configurations.

Cable Labeling

Every cable needs to have both sides labeled in simplistic and robust label makers or markers; in other words, readers should be able to quickly and easily interpret them. These labels should have at least port number, destination, or device ID information to make them easier to identify. This practice not only aids in cable identification quicker but also reduces the chance of errors being made during upgrades and fixes. Labels that are heated or adhesive-safe tend to last longer in data centers, making them the better choice.

Bundle and Route Cables Strategically

Ethernet patch cables should be bundled with the aid of Velcro straps or cable ties without any slack or overtightening to avoid damage to the insulation or the signal being interfered with. Cables should be guided along set routes, like vertical and horizontal cable organizers or cable management arms used to avoid chaos.

Employ Patch Panels alongside Modular Systems

Modular patch panels can ease the process of adding new devices and cables by grouping them where related cables can interface. Patch panels also facilitate easier access for maintenance. Patch panels are essential components for modular cable systems in racks they facilitate easier patching of cables.

Avoid Overcrowding and Ensure Proper Airflow to maintain the integrity of your optical connections.

Servers tend to overheat when racks are cluttered because the cooling system of the server fails. Servers rely on equipment cooling requirements so do not obstruct or crush cables around the air vent. Use cable management devices that allow for optimal airflow to help keep the equipment cool.

Implement Color-coded Systems

Assign different colored wraps or cables to different network segments such as uplinks cross-connections or other departments in the network. This helps to reduce complexity which increases efficiency when troubleshooting problems.

Metrics and Performance Benefits of Effectively Managing Cables

Data shows that improper management of cables can increase time spent on troubleshooting activities by as much as 60%, which reinforces the need for good cabling practices. In addition, avoiding congestion has been proven to improve the life expectancy of network equipment by over 30%, which aids in lowering the cost and time associated with replacements in the future. Companies that have implemented strict management of patch cables have seen a major reduction in network outages due to spontaneous outages caused by cable mismanagement, which allows for better operational dependability.

These guidelines, together with supporting devices like D-Rings, vertical organizers, and patch panels, provide an effortless way for professionals to manage Ethernet patch cables, regardless of the size and complexity of the network infrastructure.

Port density

Select a patch panel that complements your current and future port needs. Extensive networks will prefer higher density, whereas smaller setups could benefit from lower-density configurations.

Compatibility

Double-check that the patch panel accommodates your particular style of cabling, be it Cat5e, Cat6, or fiber optics as well as the bandwidth capabilities of your network.

Ease of Installation and Maintenance

Choose a form factor that enables fast installation and allows for better cable management, thereby reducing maintenance downtime.

Build quality

Choose a patch panel constructed from high-quality materials that are robust enough to withstand wear and tear in harsh environments.

Budget

Find the most cost-effective solution that does not compromise quality in order to meet the operational needs while avoiding overspending.

Data Transmission

Ethernet patch panels are designed with copper cables in mind, and as such, they mainly focus on electrical signals. However, fiber optic patch panels work with light, offering much faster speeds and a greater bandwidth.

Distance and Signal Integrity

Compared to Ethernet, fiber optic panels enable data transmission over much longer ranges without loss of signal. For long-distance connections, Ethernet panels cannot be used with copper cables due to deprecation and interference.

Installation and Scalability

Ethernet patch panel installation is as straightforward as its cost; they are inexpensive for smaller networks. On the other hand, Fiber optic patch panels are best suited for high-performance enterprise systems that require scalability, but they are expensive needing specialized tools and skills for installation.

Cost

Fiber optic systems have an Ethernet counterpart that is cost-efficient for basic networking. With greater purpose, fiber optics have a higher starting expense due to included cables and equipment.

Every option has its advantages and disadvantages, depending on precise network configurations like performance expectations, distance, and budget limitations.

When selecting between wall mount and rackmount patch panels, the choice mainly comes down to the amount of space available and the required scale of cable management:

Wall Mount Patch Panels

Ideal for more compact installations with smaller available space, these are mounted directly to a wall and are best suited for light cable management in workplaces and smaller network rooms.

Rackmount Patch Panels

For larger installations, these are mounted in standard-sized server racks, making them more useful in data centers or other areas with greater cable density. They offer better scalability and maintenance access, which enhances the overall user experience.

Assess the height of the enclosure needed to store cables, their volume, and anticipated expansion in your networks when making your selection.

Patch panels facilitate improved network performance by helping centralize connections which improves signal and reduces clutter. This centralization also helps facilitate easier troubleshooting when connectivity issues arise because it provides a point of access where issues can be analyzed and dealt with accordingly. Patch panels make future upgrades seamless. Their structured way of design helps to ensure the performance of the network and reduces non-structured cabling that causes improper breaks in service.

With patch panels, all cable connections are centralized in a single location which enhances maintenance and troubleshooting processes. This organized layout enables technicians to quickly identify and resolve issues without disrupting other connections which can prove helpful in saving time. Color-coded wiring catalogs ports and cables, allowing the maintenance process to be simplified. Overall, this approach helps to achieve superior productivity by minimizing downtime and ensuring consistent network reliability.

In both data centers and small businesses, patch panels certainly make an impact in managing network scalability, especially when used with traceable solutions. They provide a centralized point in the infrastructure to ease the complexity of large-scale systems. In data centers, with thousands of cables attaching servers, switches, and storage, patch panels serve as the central hub. The organization is effortless as each labeled cable can be routed, connected, and managed with ease. An organized system like this reduces mistakes, while also making it easier to reconfigure in response to network expansion.

Small businesses benefit from patch panels as a low-cost method or reorganizing their network structure, while future-proofing it at the same time. By creating a centralized point of connection, clients can easily add additional infrastructure without the additional work of having to completely rerun cables. Moreover, data shows that organizations with structured cabling and patch panels can troubleshoot issues 30% faster than those without, which leads to greater operational efficiency and reduced downtime.

In addition, Ethernet, fiber optics, and coaxial cables are additional standard connections that can be made, which makes these flexible for different communication needs of a user. Such flexibility guarantees the compatibility of new technologies, which makes it easier to incorporate new hardware and software. From patch panels in local businesses to high-speed data centers, the promise of reliability, efficiency, and scalable growth in connectivity is always ensured.

Organize the Rack Space

Make a detailed plan for every inch of your network rack space before it is set up. This will help with optimum use of the site and make future maintenance alike easier. Usually, patch panels are placed in the top or middle sections of the rack. These two locations are convenient, and switches are usually placed right below patch panels for easy access.

Set the Right Type of Patch Panel

Cat6 or Cat6a patch panels will be best for network cabling for Gigabit Ethernet, while fiber optic patch panels will help out with fast data transmission. Make sure the panel is compatible with the appropriate number of ports your network needs, as standard configurations usually fall within the range of 12 to 48 ports. Always remember that higher is not always better when it comes to ports. The more there are, the more costly it is, so opt for only what is necessary.

Rest the Panel in Place

Use the supplied mounting brackets and screws to secure the patch panel in the correct position of the rack. Be sure that it is level and securely tightened in order to avoid vibrations and movement over a long period of time which will result in disconnections. Most patch panels are 19-inch standard width which makes them versatile.

Label the Ports on the Patch Panel

To maintain effectiveness in cable management and troubleshooting, each port on the patch panel has to be labeled. Make sure that your labeling system makes sense in regards to the devices or endpoints that are connected to each respective port, and that includes patch cords connected to the network. Modern panels often have writable surfaces or slots that can be labeled which helps make this process much easier.

Terminate the Cables

For proper termination, use a trimming method for the end of each wire that minimizes slack as well as excess length, and make sure you prepare the cables properly. Follow that step using a punch-down tool to terminate the cables. For connecting the wires to the patch panel, it has color-coded connectors on the back which makes that step much more straightforward. Follow either the T568A or T568B wiring standard depending on what your network needs are.

Bundle and Secure Cables

Make sure you use cable management bars, Velcro straps, as well as cable ties to organize the cables or bundles to avoid tangling and significantly improve troubleshooting. Be mindful in terms of affixing the band, as damage to the cables, as well as degrading their performance, is very possible. Proper bundling allows even greater performance, as well as permitting the dissipation of heat.

Examine the Connectivity and Performance

Upon finalizing the installation of all cables, apply a cable tester to confirm the connection of the cables and signals. Before connecting the patch panel to live equipment, it is necessary to check for miswiring, crosstalk, or weak signals. This ensures that there are no unspotted errors that can trick a user into a non-functional setup and cause downtime.

Link to Network Devices

Use shorter patch cords to connect the front-facing ports of the patch panel to the switches or routers in the rack. When connecting the cords, ensure that they follow proper bend-radius rules as it will minimize stress on the connector, therefore, ensuring the best performance and life span of the cables.

Maintain the Configuration

Keep records of the patch panel configuration, which includes port numbers, cable paths, and device connections. Such documentation can be done digitally or using network management software for easier follow-up to implement changes and schedule maintenance for better long-term efficiency.

Conduct Maintenance Follow-Up

From time to time, the patch panel setup should be checked after maintenance to confirm that cables are tightly fitted and the connections still hold. If these simple regular checks are applied, wear and tear can be identified early, reducing the chance of system failure and enabling easy updates when technology changes.

Following these methods provides the backbone for well-structured, reliable, and efficient network rack organization, which is essential for improving performance in both large and small network setups.

Regarding the strategic installation of patch cords and cables, my primary goal is to ensure that these cables are orderly and well arranged in the vertical cable management structure of the rack. I employ color coding and labeling to make identification easier and to minimize mistakes during troubleshooting. Additionally, I ensure cable lengths are reasonable so that they do not create tangles, while still allowing the necessary flexibility for reconfigurations in the future. This approach maximally aids me in reducing the interference, increasing the airflow, and ensuring that the network rack is easily accessible for maintenance and upgrades.

Optimal Equipment Allocation

Maximize rack space by integrating high-density network equipment, including servers, switches, and storage devices. For example, 1U rack servers have compact form factors that accommodate a multitude of devices while maintaining optimal performance levels. Also, modular solutions like blade servers can be integrated for better spatial efficiency and scalability.

Apply Vertical Cable Management

Route cables vertically by applying cable managers to the side of the rack. This maintains organization and also salvages important horizontal rack space. Effective cable management can improve accessibility while still maintaining proper airflow throughout the rack.

Utilization Of High-Density Patch Panels

The primary purpose of using high-density patch panels is to consolidate connections so as to make better use of rack units. As an example, panels that accommodate 48 or more ports in a single 1U height can provide better connectivity without the need for additional rack space.

Using Controlled Cabling Techniques

Controlled cabling elimination techniques can be employed to minimize disorder and signal interference. For example, bundling of cables using cable ties or Velcro straps as well as labeling each for easy identification. A well-organized subset of cables allows for efficient troubleshooting and precision adaptation for scalability in the future.

Employ Rack-Mountable Power Distribution Units (PDUs)

Power distribution becomes easier with rack PDUs since they are mounted vertically into the rack and minimizes the amount of wiring PDUs need. This saves energy because it improves power management and saves space. Advanced monitoring PDUs are also able to keep track of energy usage for better load balancing.

Embrace cooling airflow management strategies to enhance the performance of your cable assemblies.

Blocking unused space and cooling pathways in a rack enclosure with blanking panels can enhance cooling by ensuring there‘s no hot air recirculation. Improving airflow in a data center by ensuring every piece of equipment has a front-to-back airflow path as well as clearing the appropriate aisle space can greatly enhance cooling efficiency, protecting the equipment while minimizing energy costs.

Install Fiber Optic Cabling

Now it’s easier to connect to the network due to the reduced space fiber optic cabling required because of their thinner diameter and high-bandwidth capabilities. Allowing for increased future data demands coupled with longer transmission distances results in minimal signal loss, making this technology a great addition to any modern organization.

Ongoing Reviews and Updates

Racks should be periodically audited of their configuration and decommissioned unused devices or ports should be removed to optimize the rack’s performance and scalability alongside upgraded maintenance. This will ensure the avoidance of potential bottlenecked connectivity.

When implemented correctly, these procedures maximize rack space efficiency, enhance interconnectivity, and aid in network performance over time. To keep network infrastructure organized, efficient, and scalable, it is essential to consistently plan and review activities.

Guidelines and Documentations of the Manufacturer

Obtain the installation and maintenance documentation for the patch panel as a starting point for local area network (LAN) compliance. These documents contain patch panel brand-specific information such as guide, configuration, and troubleshooting methods. For instance, following TIA/EIA standards will guarantee system reliability.

Best Practices in Managing Cables

Installation of patch panels is highly reliant on proper cable management. Studies show that structured cabling helps minimize interference and leads to quicker problem resolution. Always label both ends of the cables, opt for Velcro straps in place of zip ties, and make use of cable trays and panels.

Certifications and Standards of the Industry

Having a basic knowledge of ANSI/TIA-568 is essential. These standards establish a set of rules regarding color coding, connector pin configurations, and performance ratings and requirements for telecommunications cabling. Compatibility and scalability are greatly enhanced for systems adhering to these protocols.

Courses for Training and Certification

Consider attending courses organized by BICSI or CompTIA. This body provides courses on structured cabling, installation, and maintenance of patch panels in network systems as they are advanced-level certifications.

Routine Maintenance Schedules

Examination highlights the necessity of set maintenance schedules towards the reduction of downtime. Suggested frequencies differ, although inspections for wear, cable tension, and dust build-up are recommended every three months. Damaged components need to be replaced quickly to minimize disruptions.

Online Tutorials and Professional Assistance

Digital resources such as professional social network forums or video tutorials can assist with the installation and maintenance of cable assemblies by providing step-by-step instructions. Pair this with guidance from certified network engineers for more sophisticated installations.

Integrating these different types of resources will help you in patch panel installation and maintenance, and in turn, guarantee that your network infrastructure is efficient, scalable, and high-performing. Using industry standards lowers risks and increases the uptime and reliability of the systems.

Whenever complex challenges go beyond simple maintenance, like deploying megasystem infrastructure, solving chronic disconnection issues, or implementing sophisticated technologies such as virtualization or cloud systems, consult a Network Engineer. Also, extend professional help for critical assignment undertakings like network security audits or system upgrades for scalability because they need adherence to industry standards and best practices. This guarantees optimal efficiency, reduces risks, and ensures dependable systems over time.

1. In What Ways Do Professionals Use Patch Panel Cable Management and Mistakenly Mess It Up?

They do not label the cables properly which can make problems more complex when they need to be solved.

They allow cables to hang loosely leading to a bundle of cables being useless in a rack due to their inefficient placement.

They place cables on the patch panel applying great amounts of tension and bending them which will lead to failure in the long run.

They end up putting too many cables on cable management trays making them difficult to use in the future and can also lead to overheating.

2. How Am I Supposed to Manage Cables Labeling When It Comes to Patch Panel Management?

Coming up with a labeling method for the whole infrastructure, numbering or color-coding for example, makes it easier to identify the specific cable in question. In conjunction to being easy to identify, every cable label should be of good quality, be located next to the terminations, and fall under The ANSI/TIA-606-C labeling standard for networks to be monitored easily and more systematically.

3. At what Lengths Should Patch Cables Be Accessible For the Best Cable Management Possible?

Patch cables need to be of appropriate length with 1 to 2 inches of slack in them while also not being too tight to avoid pulling the connectors off.

4. Which Tools Will Make Me Put Patch Panel Cables In Order In The Best Way Possible?

The most useful tools are:

Velcro straps and cable ties will also work and maintain the integrity of the cables.

Horizontal organizers or cable management bars should be put in place to organize the cables to suit your local area network (LAN) performance.

To produce precise and uniform labels, machines are required.

Cable testers are used to check connectivity and locate wiring faults.

5. What is the best bend radius for patch cables?

To avoid any signal loss or bodily harm to the cable, a bend radius of a minimum of four times the diameter of the cable should be maintained based on TIA/EIA-568 recommendations.

6. How can I avoid overheating cables on a congested patch panel?

Cable management that is vertical or horizontal should be employed to facilitate airflow and avoid overcrowding.

Use patch panels that have separators or ventilation ports to improve heat dissipation.

Periodically check and redistribute the cables to allow appropriate airflow in the enclosed racks.

7. How frequently should a patch panel be checked and reconfigured?

Routine checks and maintenance should be done every 6 months to a year which includes verifying and relabeling cables and reorganizing the existing connections due to any changes in network infrastructure or capacity.

By following these recommendations, the most common problems associated with cable management can be solved effectively helping sustain patch panel operation.

A: A patch panel refers to the hardware used in the interlinking and controlling of network wires and serves a vital role in organizing wires coming from switches, servers, and other devices in a network. Patch panels are crucial because they serve as the focal point for the management of network wires, which helps in the troubleshooting, maintenance, and modification of the network easier. They additionally aid in safeguarding the delicate pieces of network equipment while ensuring better signal strength and quality.

A: In selecting a patch panel, always pay attention to the port quantity required: 24-port or 48 port, the type of wires used: Cat5e, Cat6, or Cat6a, and if there is a requirement for shielded or unshielded (UTP) panels. The available space, is the rack or cabinet, should also be considered because patch panels are available in different dimensions like 1U and 2U sized. The current network infrastructure and future expansions also need to be considered.

A: With modular patch panels, there is the option to add or remove individual modules or cassettes as needed. This is particularly useful in mixed media environments where both copper and fiber optic cables are in use. Pre-loaded panels, on the other hand, come with a set number of ports which are fixed. They may not be as flexible, but pre-loaded panels are often more affordable for pre-established standard installations that utilize one cable type.

A: Labeling and organizing cables is essential for efficient patch panel cable management. Employ a labeling system that is predictable and covers both ends of each cable such as port number and device that is connected. Color-coding different segments or purposes of cables can also aid in identification. Neatly route the cables using horizontal cable managers and finger ducts. To follow changes over time, maintain an up-to-date network document or transcript to trace the connections made and changes done.

A: Yes. However, when working with a local area network (LAN) configuration, patch panels for copper and fiber optic cables are often not used in conjunction unless in modular-style panels. For copper cable types (Cat5e, Cat6, or Cat6a), RJ45 patch panels are the best fit. For fiber optic cables, fiber patch panels with LC or SC connectors will be more suitable. Certain modular patch panels allow the user to mix cassette types so both copper and fiber connections can be used.

A: For setting up a patch panel on a server rack or a cabinet, make sure you have the correct mounting hardware first. The panel should be placed around eye level, preferably on the upper side of the rack to make cable management easier. Fasten the panel with the provided screws or cage nuts. After that, use horizontal cables to connect to the back of the patch panel and then use patch cords to connect the switches or servers to the front ports.

A: There are numerous benefits to the use of patch panels as opposed to direct connections. For one, they provide a convenient cable management approach that keeps tangles, messes, and clutter to a minimum and makes it easier to build traces and solve problems. Patch panels keep expensive network equipment safe from damage because there is less direct access to the ports on the switches and servers. It also makes network maintenance, changes, and additions easier without having to deal with permanent wiring.

A: To guarantee optimal network performance with patch panels, ensure that you use good quality cables and connectors that are appropriate for the specific network requirements (e.g., use Cat6a cables for 10Gbps networks). Ensure there is appropriate cabling management to reduce interference and stress on the cables. Routinely check and clean the terminals to avoid poor signal quality over time. Use short patch cords when connecting devices to the panel to avoid signal loss. Apply a structured cabling systemand comply with the TIA/EIA standards for installation and maintenance.

1. Title: P7 (P4 Programmable Patch Panel): an instant 100G emulated network testbed in a pizza box

2. Title: The Experimental Study of Several Techniques for Measuring the Server Rack Airflow in Respect to the Optimization of Data Center Cooling Management

3. Title: Improvement of Electrical Safety System at Ngaliyan Health Clinic Semarang City

5. Twisted pair