In the field of computer networking, there is little room for errors. As one word of inaccuracy, while installing RJ45 network cables may render the connection useless, the installation process has to be sufficiently accurate. One of the simplest but most efficient devices for this is the punch-down tool. This guide has a major aim of bringing out the basics of the punch down tool within the context of installing network cables. We will consider how it works, so many factors and considerations in its operation, tools used, and more considering its effectiveness. This article emphasizes the punch down tool, which is not well understood by users. At the end of the article, the readers will be well versed on how to quite effectively run a punch-down tool, such as improving their installation and maintenance procedures of dependable networks.

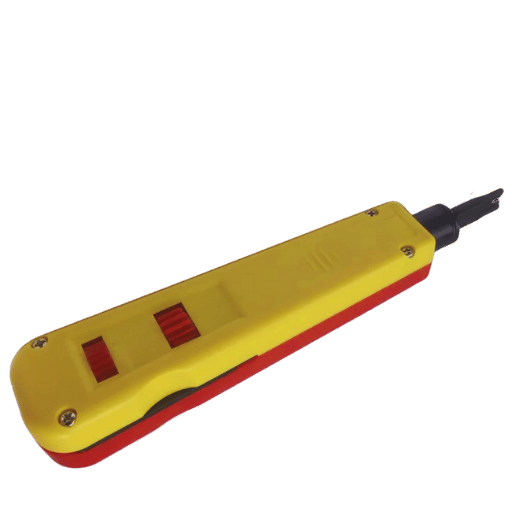

A punch down tool is a specialized hand-operated instrument that is meant for the termination of the wires of the telecommunications and network outlets like patch panels and keystone jacks. A neat closure defines and secures the position of the wire by first running the wire through a plastic terminal block and then cutting the excess wire off. The punch-down tool has a handle with a spring mechanism, which is designed in such a manner that interchangeable heads are fitted to different types of block clear, e.g., 66 and 110 block types.

Grasping the utility of a punch-down tool presupposes an understanding of its importance with regard to being able to maintain proper network functions. This is the tool which helps in terminating the copper network cables fit to the connection blocks and houses them firmly. The good use of the punch-down tool will also ensure that there is little or no signal loss and interference when placing the conductors in their respective positions in patch panels or jacks. This is a good practice as per the industry standard guidelines that up to 1 Gbps pulse is transferable at wire deployment with the use of a punch down tool and appropriate wire category, avoiding cross talk and electromagnetic interference. This performance is critical for networks that demand high speed, hence placing the punch-down tool as an asset for the IT Engineer responsible for configuring and managing networks.

Although the punch down tool has only limited applicability; its efficiency of performance relies heavily on its some of its crucial parts, rationally the blade which and specially made versions catering to different block designs:

Having relation to these parts and their particular use is important especially to network experts for the purpose of carrying out construction and maintenance of different telecommunication and computer networks without elevating data transmission concern.

These are some tips and guidelines that seem necessary and will make sure that your punch down tool is used comfortably and correctly. The first and foremost guideline is to wear personal protective equipment such as eye goggles to avoid injuries from clip wires or flying materials. Always check that the blade of the tool is in line with the terminal block or the pressure is not going to be applied since it will damage the wires and the block too. Still firmly holding the tool, push down until a click is heard that indicates that the wire has been pushed into the connector and cut off. It is also advisable to look for loose wires for the reasons that they may undermine the stability of the entire network for instance by causing balun MCB failures. Proper usage of the punch down tools, for example, replacing or sharpening blades once the performance of the tool is affected, any extensions provided will add onto secondary lifetimes. Following these steps facilitate delivery of dependable networks with the least negative outcomes to IT practitioners, and coincidently little effort is required of them.

Terminating the network does, however, call for careful and proper use of impact tools. Precise impact tools help place wires accurately, reducing signal loss and connection failures. The impact tools also prevent wire and blocks damage hence increasing the durability of the network. Accurate termination also enhances troubleshooting and the overall reliability of a network, which makes impact tools very valuable to any professionals who intend to carry out effective and non-troublesome installations.

A standard practice in installing an Ethernet cable is to ensure that it is appropriately connected to the Ethernet keystone jack. It starts off with determining which cable category suits the keystone jack such as Cat5e, Cat6 or Cat6a. Since each category is intended for a different data rate and bandwidth, having the wrong pairing will only serve to bottleneck the network performance. Further, the jack sizes and the pin configuration should fit the cable structures so as to make a more reliable and tighter fit. Confirming both the technical attributes and physical properties gives the IT professionals an upper hand at making sure that all components are functional for optimal performance of the networks.

It is important to prepare oneself with the relevant tools and components, even before the terminator is punched down. Begin by measuring the length of each Ethernet cable and proceeding to cut it off. Other than that, examining the cables also means that they should not show any break or cuts. A cable stripper can be used to take off around two inches of the cable jacket but be very careful not to cut it over the twisted pairs. Inside these outer coverings and the interstices, many wires called twisted pairs are present within the safe length distance. Arrange these pairs either in T568A or T568B order depending on the type of wiring of the network. Locate the properly color coded connectors on the keystone socket and insert it till there is no more forward movement and there is no confusion with any other wiring. These few measures, though they appear different, are the basis of how tight termination, thus reducing connection problems and improving the performance of the network.

To terminate the wires safely, orient the separated pairs of cables and fit them on the terminals of the keystone jack. Using the impact tool, get the sharp part of the tool in line with the terminal slot, ensuring the wiring is seated properly. Hold the injection molding nozzle on the wire over the terminal and push gradually and evenly to seat the wire down in the terminal and cut off its excess simultaneously. People need to pay attention that the tool impact level is set correctly, so as not to damage the jack or the wires. Proceed in an orderly manner, wire by wire, so that every wire is tightened and there is no slippage of any sort in the connections. This assures that the network connectivity is efficient and reliable while substantially reducing the number of failure points.

After completing the termination wires, check the keystone jack to see that all connections have been made tightly and correctly as per the wiring configuration. In the same manner, insert the keystone jack into the faceplate or the patch panel ensuring that it snaps into position securely. With the help of a cable tester, perform a continuity test to check if the connections are properly done; that there are no short circuits and there are no wires crossed. Such flaws should be rectified, if any, by inspecting the affected terminations again and correcting as necessary. Adherence to this process with appropriate detail will lead to the establishment of a solid and high performance network.

There are certain features and kit contents that should be borne in mind when seeking to purchase a punch-down tool for network cabling. The following is a comprehensive description of normal features and types of kits that purport to be found in the market:

Considering such features and understanding the entire range of tools present in different kits, professionals can choose a punch-down tool that will enable quick and precise cable termination without making mistakes.

Other variants of punch-down tools can be compared according to factors such as accuracy, strength, and multi-functionality, such as Krone, Vcelink, etc. In industrial applications, Krone tools are zealous for their built quality and cutting accuracy; thus, these tools overall are quite popular. In the case of Vcelink, pricing is reasonable but still covers important aspects such as well-balanced ergonomic design and movable blades, thus being a great choice for professionals and amateurs. Apart from that, some tools like Fluke Networks and Klein Tools may be intended for diametrically opposite uses, featuring more advanced aspects such as built-in testing devices and more durable materials. Every brand focuses on certain case applications, so it is recommended that professionals should consider the purpose in order to choose the best-aided tool for their network-building bounded activities.

To keep your punch-down tool in good working order, perform the following functions: First, clean the tool on a regular basis by wiping down the surfaces with a soft cloth to get rid of dust and other residue. For even more effective cleaning, use isopropyl alcohol to carefully wipe off any accumulated dirt on some of the more important dusted components. Making sure that all the moving parts are properly lubricated in accordance with the manufacturer’s instructions is critical in preventing excess friction, which could damage the moving parts of the tool. Consider the condition of multifunction hand tools like cutting blades, teeth, etc. Replace these blades when working with them risks injury, neither of which allows the fine work to be done. Keep the tool away from any moisture as this contributes to rusting and corrosion. Performing all activities described above will lead to an efficient maintenance of the tool and it will not be damaged easily and will be efficient in performing all the tasks.

By resolving some of the recurring problems associated with punch-down tools, users can improve its overall performance and durability. Here’s a study of some of the most common problems and how you can solve them:

Blunt or Damaged Blades:

Misalignment:

Jamming:

Spring Mechanism Fatigue:

Corrosion:

Addressing such problems in time with appropriate remedies increases the efficiency and dependability of your punch down tool and use it to full effect in all network activities. Planned maintenance as well as unplanned repairs are very important especially how they affect the productivity of the tool and the usage period of the tool.

A: Punch down tool sometimes called as RJ45 punch down tool is a type of hand tool that network installers use for wire termination into insulation displacement connectors usually positioned on wall plates or patch panels. Pouring the wire in to the connector safeguards the proper and stable attachment of the network cable as well.

A: Of course, there is an RJ45 punch tool which is used to disappear wires into patch panels or wall plates, and a crimping tool is used to apply plugs to the wire ends, for example, when making patch cables.

A: As a rule, such a the networking tool kit contains a crimping tool, an RJ45 punch down tool, cutters or strippers and occasionally there might be other items including a tester kit and plugs and caps to perform a range of different networking activities.

A: In spite of the fact that 110 and 66 blocs have been created differently, they serve the same purposes. Such tools are constructed in such a way that they can work on both methods of action, but it is advisable to be sure that your particular tool will take both types of use.

A: One of the reasons why it is advisable to use a punch-down tool is that it makes a firm mechanical and electrical coupling and so minimizes any chances of failing. There is always a chance that bare wire connections through insertion will not be strong or firm enough and will, therefore, stand the risk of things like vibrations and causing loose connections.

A: Sure many such demonstrations can be seen on the net, especially YouTube tutorials which show how to use RJ45 punch down tool rather proficiently while making the RJ45 ethernet cable connections.

A: Although the methods of working with both tools are similar, a telephone punch down tool would most likely be suited to a different style of connectors used with telephones whereas a RJ45 punch down tool is intended for network connectors.

A: Adheres to this method but do take care in extending the length that the ‘untwist’ is from the connector when working with large diameter Cat 6 cables. Apply the appropriate dedicated punch down tool as instructed for maximum benefits.

A: It is advisable to perform maintenance activities by replacing the tools periodically as well as cleaning the blades and inspecting the tool parts for any signs of wear. Certain tools will include blades or tips that are replaceable and may be used when the original ones are worn out or damaged.