Professionally or in home setups, network connections utilizing RJ45 cables require reliable performance and durability. These cables, however, are susceptible to damage from use, handling, and physical abuse, which may threaten their integrity. Compromised cables may result in connectivity problems as well as hardware damage. This is where RJ45 strain relief boots come into play. These small parts prevent cables from bending, fraying, and other forms of wear in addition to ensuring optimal signal transmission. In this article, we will look at the functionality and relevance of strain relief boots, their selection criteria, and important recommendations for maintaining optimal performance and the life span of the cable.

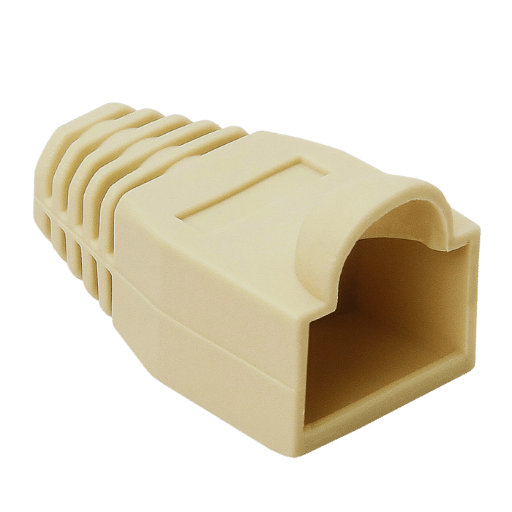

An RJ45 strain relief boot is a protective accessory designed to fit over the connector end of an Ethernet cable. The boot manages the strain at the cable bend and eases stress on the cable. This helps to prevent damage to the internal cabling and enables reliable data flow. The boots protect the cable clip from breaking, improving the lifespan of the clip, which enables better usage of the cable in demanding environments.

The function of a strain relief boot is to guard Ethernet cables against bending or pulling damage at the connector. It mitigates stress on the cable while stabilizing data transmission and protecting the connector clip from breakage. Strain relief boots protect cables, which extends their operational life as well as provide additional wear and tear resistance in high-use applications.

RJ45 strain relief boots consist of some essential parts that offer protection as well as enhance the use of Ethernet cables:

Elastic Collar

Integrated Locking Clip Protector

Tapered Design

PVC or Thermoplastic Material

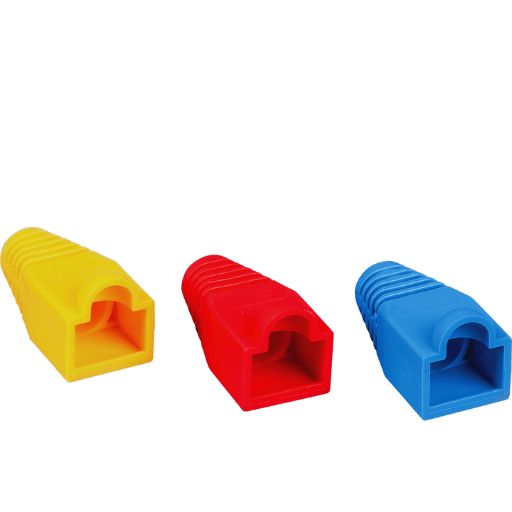

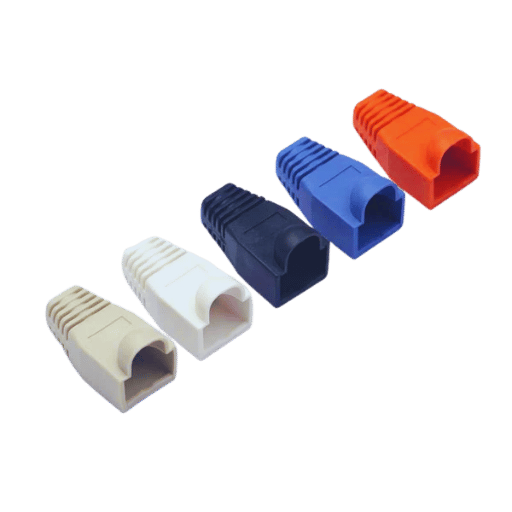

Color Coding Options

Strain Relief Boots Compatibility Standards

It is the combination of these factors that makes the RJ45 strain relief boots both durable and dependable in networking applications, which is Integrable in today’s high data demand infrastructures.

Strain relief boots enhance cable longevity by mitigating the mechanical strain that is applied to the connection’s point of termination. They hinder overbending, pulling, and twisting that will internally damage wires or cause gradual signal deterioration. These boots enhance protective shielded cable performance while reducing wear, thus increasing the useful life of the infrastructure and its networks.

Selecting an RJ45 strain relief boot requires knowing the specific categories of cables used, Cat5e or Cat6. Cat5e cables are popular for residential and small office settings since they are capable of supporting speeds of 1 Gbps and a frequency of up to 100 MHz. Meanwhile, Cat6 cables are more common in advanced networking setups as they have higher performance parameters, achieving speeds up to 10 Gbps on shorter runs and operating at a frequency of 250 MHz. Their use is also more widespread in demanding networking setups.

Strain relief boots should accommodate the cables’ diameters and physical structures as well. The diameter of Cat5e cables ranges from 5.0 mm to 5.5 mm. However, Cat6 cables, due to their stricter specifications and extra shielding or insulation, have a diameter of 6.0 mm to 6.5 mm. The selected boots also need to provide flexible snugness to not damage the connectors or cable jacket.

Moreover, some strain relief boots offer additional value with materials that are more flexible as well as features that support the tapering geometries of Cat6 cables. Such designs provide adequate support while protecting the cable’s bend radius, which is necessary to protect the signal quality. When used in conjunction with Cat5e cables, ensure that the strain relief can still be effective when boots are scaled to accommodate slight size differences prevalent between the cables while still optimizing durability across different networking conditions.

To ensure compatibility with RJ45 connectors, begin with the appropriate connectors for the cable in hand, be it Cat5e, Cat6, or Cat6a. Confirm that the connector accommodates the cable’s diameter and any shielding that may be present. Prior to insertion, trim and dress the cable’s pairs to the T568A or T568B standards. Use a reliable crimping tool, which guarantees adequate signal retention and operational stability, to complete the connection. In addition, inspect the cable connection with a network tester to verify termination integrity and connection functionality.

Due to its importance in prolonging system performance, optimizing downtime, and future scaling, effective network cable management is essential. Given this, the following is a comprehensive list of considerations.

Organizing and Labeling Cables

Routing and Measuring Cable Lengths

Separation of Data and Power Cables

Proper Use of Cable Management Hardware

Adherence to Industry Standards

Network Scalability

Environmental Considerations

Cable Testing and Maintenance

Aesthetic and Safety Considerations

Taking these actions allows network administrators to adapt and optimize system performance while effortlessly managing cables and technological advancements.

Prepare the Cable

Slide the Strain Relief Boot Onto the Cable

Organize and Arrange the Wires

Insert the Wires Into the RJ45 Connector

Crimp the RJ45 Connector

Position the Strain Relief Boot

Follow these steps to install strain relief boots on RJ45 cables in a way that optimizes durability while ensuring neat and professional cable management.

Improper Sizing of the Strain Relief Boot

Failing to Attach the Boot Prior to the Crimping Step

Over-tightening Or Incorrectly Placing The Boot

Utilizing Inferior Quality Materials

Not Considering Environmental Conditions

Disregarding Appropriate Cable Management

Fixing the stated mistakes will enhance your RJ45 connections’ reliability, performance, and lifespan immensely.

By reducing the risk of abrasion at the points of connection, strain relief boots protect Ethernet cables and their connectors. Boots prevent less than optimal bending, which contributes to strain due to movement or usage. Boots also enhance durability, reinforcing the Ethernet connection and increasing the lifespan of the Ethernet cables.

By preserving the cable structure, strain relief boots enhance patch cable performance and their physical integrity. They also minimize interference or crosstalk by maintaining consistent signal transmission through preventing the bending or breaking of internal wire pairs within the patch cable. Proper strain relief is critical with regard to the modern Ethernet standards like Cat6, Cat6a, and Cat7, which can transfer 10 Gbps, because it reduces stress on the cable’s connectors, slowing down the data transfer rate.

In addition, optimum alignment of the cable and its shielding improves the electromagnetic interference(EMI), which strain relief boots mitigate. As high-speed networks are increasingly adopted in home and enterprise settings, even the slightest signal degradation becomes unmanageable. More dependable connections for data centers, video streaming, and IoT deployments are made possible by strain relief boots, which make them easier to use in those high-traffic applications.

In order to avoid impacting the physical stress on a plug and cable, to maintain the integrity of a modular plug, it is mandatory to minimize stress. For pulling or bending forces that can damage the connections, make sure that strain relief mechanisms, such as strain relief boots, are in place. Do not execute insertion or removal cycles beyond what is reasonable because doing so may erode the contact points of the plug. Along with this, do not touch modular plugs excessively to avoid dirt, dust, or oils from contaminating the connectors, as this would impact performance. Conducting inspections regularly, along with proper handling, will maintain the reliability of modular plugs and extend their usage life.

RJ45 strain relief boots are created to guard modular plugs and control a cable’s performance by minimizing the strain at the termination point. In terms of usage, both Cat5e and Cat6 cables are able to make full use of job strain relief boots. The Cat5e cables with data speeds of 1 Gbps and operating frequency of 100 MHz do benefit from boots, which reduce wear caused by cable movement, handling, and frequent wear. Cat6 cables also benefit which have higher performance with speeds of 10 Gbps over a short distance of 55 meters and 250 MHz frequency.

Selecting boots that correspond to the diameter of the cable in use is crucial since Cat6 cables have thicker insulation than their Cat5e counterparts. The added thickness is a result of tighter twisting and thicker shielding, which is required to reduce crosstalk and improve signal integrity, thus making the need for appropriately sized relief strain boots critical in ensuring proper-sized connectivity and performance. Well-made boots are usually made of softer plastic and are made from flexible but robust materials like PVC so that they protect adequately while still being easy to install, regardless of the type of cable. Incorporating strain relief boots enables end users to improve the dependability of network connections customized to their usage, whether Cat5e or Cat6 cables.

Changes to accommodate Cat6a and Cat7 cables require that all associated components, including connectors, patch panels, and strain relief boots, be compatible with these higher-order cables. The increased frequency and faster data transmission rates of Cat6a and Cat7 cables make them suitable for high-speed applications. At these speeds, the likelihood of crosstalk and electromagnetic interference (EMI) increases, so shielded components are critical. Maintaining proper installation procedures like bend radius, limiting stress on the cables, and avoiding other forms of excessive physical strain is critical to ensuring performance and signal integrity.

A: RJ45 strain relief boots are covers that protect RJ45 connectors and offer strain relief. They prevent damage to the latch and cable integrity by minimizing stress on the cable strands.

A: Strain relief boots for RJ45 are important to maintain cable integrity because they keep the cable connector latch from breaking and reinforce the cable connection, increasing the lifespan of the cable by mitigating damage.

A: RJ45 strain relief boots are typically very easy to install. Boots tend to be labeled and fit over the connector snugly, with instructions on many, making it effortless for users to protect their cables.

A: Most strain relief boots for RJ45 are intended for use with both Cat5e and Cat6 cables, making them versatile for users with different cabling needs.

A: As an advantage, color-coded strain relief boots assist in the maintenance and oversight of the cables, as well as in complex Networking setups, since they aid in differentiating between various connectors via color.

A: To determine sizing, make certain the cable boots correspond with the outer diameter (OD) of your cable. Many described compatibility, like for 23AWG, so care needs to be exercised to ensure compliance with that standard.

A: Ethernet RJ45 strain relief boots are commonly sold in bulk quantities, at 50 pcs or 100-pack, which caters to larger jobs or installation tasks that need several connectors.

A: Other companies that manufacture and supply strains of RJ45 data cables also cultivate and produce quality strain resolver boots, such as Klein Tools, which are highly renowned for their ease on professional networking assignments.

A: Snagless cable boots are designed so that the attachment for snagging is covered, making them ideal in places where lifting cords are often installed or removed, as they prevent damage to the cords.

A: Cat5e RJ45 connectors can be used with Cat6 cables, but verifying the cable specification alongside the boots is necessary to avoid performance and connectivity issues.