Voltage variable attenuators (VVAs) are essential in engineering radio frequency (RF) and signal transmission control. Such devices control the level of RF signal amplitude with minimum distortion and loss of signal. The working of voltage variable attenuators includes the combination of different electronic principles, such as variable resistive networks or active circuitry, which allows the engineers to adjust the amplitude level from a great variety of devices, from telephones to radio stations. This article aims to offer a detailed understanding of RF and voltage variable attenuators, including their working principles, areas of use, and design specifics relevant to current RF applications regardless of the level of scope of the engineer in this field, whether a novice or an experienced engineer, knowledge about these devices is unsuitable for power management and improvement of communication systems in demand.

A variable attenuator is a device that helps to reduce the strength of a signal systematically. Unlike fixed attenuators, which yield a specific attenuation level irrespective of time, variable attenuators give a user the option of selecting the extent of attenuation debts and, hence, are more flexible in dealing with signals. These elements can be made with resistive, capacitive, or inductive elements and are primarily found in RF systems to adjust the signal strength levels to meet a particular need and avoid interference. However, one must know how to determine the effectiveness of variable attenuators for any specific application installed by looking at the frequency range, its insertion loss, and, most importantly, the range of attenuation levels that can be achieved.

Variable attenuators find multiple applications in both commercial and industrial uses. In particular, telecommunication systems adjust signal levels in transmitting lines to deliver adequate power without overloading the system and causing distortion or interference. In broadcast engineering, such devices are widely and often used to keep the level of audio and video perpetual at the receiving end by varying the strength of the signals transmitted through the RF paths. They are, therefore, also used in laboratories for the measurement and calibration of some equipment whereby the technicians can create different signal conditions. There are also other uses, such as within an electronic warfare system where additional signal control is necessary for radars and communication systems and wireless networking where the quality of service is guaranteed by reduced signal deterioration.

Variable attenuation, as the term implies, also controls the amplitude level of a radio frequency signal but with little or no regard to the geometry of the signal. This can be accomplished using regular or active resistors that change the resistance level automatically. An attenuator reduces the output value of a signal because its construction involves several heat-producing elements. The amount of attenuation is changeable so that the user’s needs are satisfied, such as avoiding overdrive in receptors or balancing the signals coming to different devices. Such capabilities are needed in numerous situations so that the quality of the transmitted signal is as high as possible and all types of distortions are minimized.

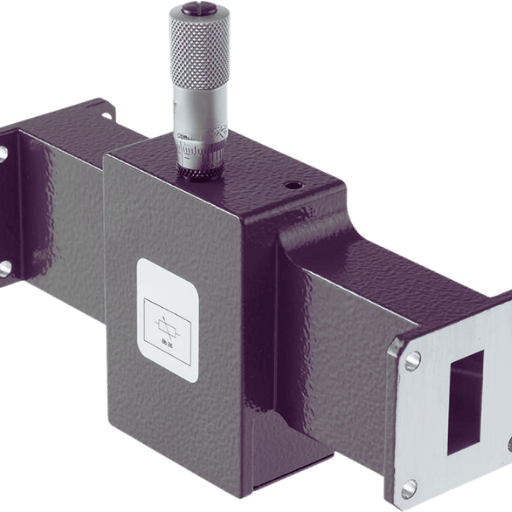

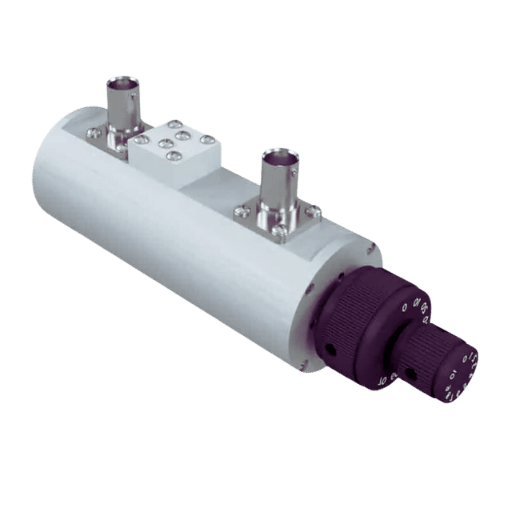

RF variable attenuators are often present in any RF setup to provide maximum or minimum power imposed on the radio frequency signals in different systems. Such devices help in adjusting the power of a transmission, which is of interest in cellular, satellite, or broadcasting networks. Manually operated and automated, the RF variable attenuators can be classified as the primary varieties based on the operational modes displays and electronic variable RF attenuators, with the latter sometimes having auto-adjust servo mechanisms.

Present-day manually operated RF variable attenuators usually consist of several dial-controlled potentiometers, which allow users to choose a given attenuation level as per their choice. As opposed to physical potentiometers, most electronic RF variable attenuators use friendly microprocessor controls, which can adjust the RF signal more efficiently using the feedback of respective measurement systems. Both are available for application over a wide frequency and power range parameters, providing efficient signal management while minimizing distortion. Such versatility justifies using RF variable attenuators where RF communications are in dire need of continuity in several adverse conditions.

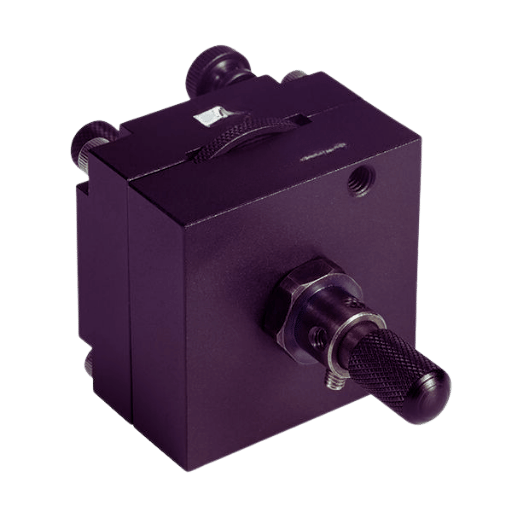

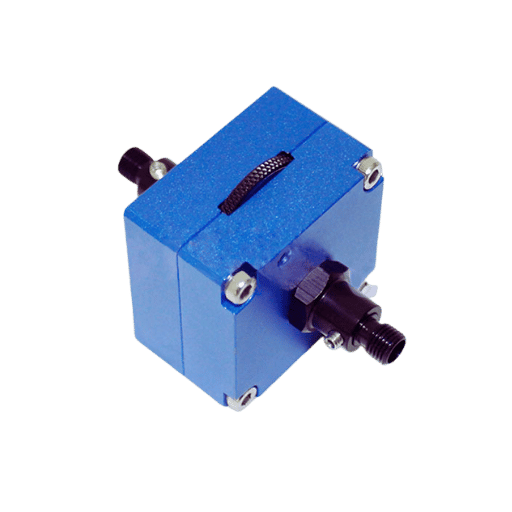

Voltage variable attenuators (VVAs) are devices in analog and digital signal processing circuits that reduce the signal’s power by an input control voltage. Fixed attenuators, which apply the same amount of attenuation at all times, are rigid and cannot be changed. These devices are known as voltage variable attenuators since they allow all adjustment requirements.

Most features come as either resistive voltage variable attenuators or capacitive voltage variable attenuators, where each solution has a unique frequency range operation, even where a narrow band is necessary. A basis of resistive VVAs is to change the input resistance according to the bias to attenuate the output signal. Capacitive VVAS, in the same manner, integrates capacitors for minor attenuation, which is highly applicable in applications that require high speeds and efficiency in performance.

The factors that influence the design and selection of voltage variable attenuators include the ill factors, which are always necessary in engineering, the need to control the signal amplitude, and the risk of introducing undesirable noise or distortion. VVAs have proved to be versatile, so designers can design them based on the application they are needed for, extending from the use in Obado electronics to high-end communication, making them relevant in modern electronics design practice.

Active optical attenuation devices are components of an optical communication system that reduce the optical power without having to turn off the system. In the systems, reducing brightness helps prevent optical detectors from becoming saturated and maintain acceptable signal levels. Generally, there are three types of optical attenuators: fixed, variable, and programmable. Fixed optical attenuators provide a constant amount of attenuation, making them ideal for most applications requiring constant performance. Attenuation using variable optical attenuators (VOAs) can be performed almost continuously to respond to signal changes. There are reprogrammable optical attenuators, which are more sophisticated as they allow the customer to select the attenuation function within the system through a program.

The selection of an optical attenuator depends on several parameters, such as the light wavelength, possible respect for the minimum reach of the signal, and actual use in telecom, fiber optic networks, or equipment under test. Apart from satisfying the required signal levels, these devices also help reduce the amount of reflection that occurs, thereby contributing to the system’s robustness.

While picking a variable optical attenuator (VOA), some critical design aspects must be addressed so that the desired performance is achieved in a given application.

These considerations allow engineers to thoroughly justify their choice of the optical variable attenuator and its applications elsewhere, increasing the efficiency and effectiveness of the systems designed.

The range of attenuation of a Variable Optical Attenuator (VOA) signifies the range in which the component effectively reduces optical signal outpower without introducing distortion errors. The measurement of the attenuation range is usually in dBs and is among the significant parameters that now control the efficacy of the VOAs in any given optical network. Most quality VOAs can give degradation ranges from as small as 0.1 dB to values exceeding thirty dB, but this will depend on the design and application of the attenuators.

In practice, a more extensive attenuation range achieves more salability to control the signal level in different conditions of the network, and this is more useful in variable scenarios where the conditions of the network and or weather are liable to change. Acquisition of any suitable VOA entails determining how much attenuation range is acceptable for the application to ensure that signal quality and effectiveness are not compromised in the communication system, particularly within microwave and millimeter wave systems. Thus, it becomes essential to accommodate the attenuation capacity of the VOA to the technical requirements of the network topology to be implemented.

It is essential to remember the connector types and their compatibility when choosing a V O A since they affect the existing optical systems’ composition. SC, LC, ST, and MTP/MPO are some of the standard connectors found in optical networks, and there must be no signal loss due to incompatibility with these connectors. Not all the connectors for the V O A should be fitted on the V O A unit in use as connectors that do not have a corresponding connector on the connecting fibers, which increases the loss of the entire system as well as its performance.

Also, due to its usage, a VOA may come with either non-removable or removable connectors that may ease the deployment of the devices. Moreover, connector misalignment, insertion loss, and return loss are other parameters that need to be taken into consideration as they affect the overall signal management effectiveness in the optical network. Even more, since the installation of the preferred VOA is made easier by having suitable connectors, the performance of the optical communication system is bound to improve.

Attention to the mechanically robust and well-placed Variable Optical Attenuator (VOA) is essential for effectively functioning the components in an optical communication system. First, one must decide on a location that will cause the most minor interference on the already established optical paths and yet afford reasonable access for movement.

If you follow these steps, it will be guaranteed that the Variable Optical Attenuator is also fitted correctly, enhancing the efficiency and reliability of the optical communication systems.

When considering control options for Variable Optical Attenuators (VOAs), both manual and automatic control have respective benefits.

Given that optical networks have manual and automatic control options, the specific operational requirements for rendering the service, such as precision and responsiveness, and the figure increments of optical integration in the network determine the choice made.

There are many methods and procedures to test or calibrate the Variable Optical Attenuators (VOAs), and all of these procedures aim to enhance the use of VOAs in an optical communication network. However, some few pointers gathered from the best articles in this field are as follows:

If operators follow these testing and calibration guidelines, they can greatly improve the dependability and efficiency of VOAs within their optical networks.

Insertion loss is the loss of signal power normalized, usually in dB, through a device on a transmission line. In optical communication systems, there is a need to locate insertion loss since it causes several problems, and for this purpose, a stepwise approach must be adopted:

These recommendations are intended to enable the operators to quickly locate and correct the causes of insertion loss problems, thus increasing the efficiency of the optical system in general.

Problems related to connector compatibility are some of the significant factors that help preserve the reliability of optical fiber systems. To overcome these issues, follow these guidelines.

These practices will assist technicians in addressing connector compatibility issues, thus preventing the degradation of optical network performance and reliability.

Through these methods, the attenuation level can be commendable; therefore, maintenance of the dependability and durability of the performance of the optical communication systems will be enhanced.

A: A Voltage Variable Attenuator (VVA) is a type of device that enables the control of signal power reduction in a microwave or RF signal path by varying a Direct Current (DC) voltage. One important use is in instances where the signal level needs to be varied over time.

A: 50 ohm impedance is the most used impedance, especially for RF purposes, as it is required for maximum power dispatch and power dispersion. This impediment is very important in protecting signal quality, hence enhancing performance in the RF attune.

A: Yes, functional, also known as manually adjustable rotary attenuators, have an additional knob or dial for adjusting only the level of attenuation. This helps in controlling the desired level of output signal.

A: Ordinary RF attenuators can function within a wide bandwidth, from the baseband up to 18 GHz or more. Hence, they are not restricted to microwave and millimeter wave technology applications only. The specific frequency range depends on the attenuator’s model and design.

A: A dual-mode RF attenuator means there are two different modes of attenuation—two alternative methods of controlling the signal attenuation. This allows the user of the device a little flexibility for switching purposes as per their requirements.

A: It is possible to have a wide dynamic range that is continuously variable up to 30 dB or even more. This extends the range of tuned fine signals to meet the output level wanted.

A: Yes, various RF attenuators can be custom-manufactured for particular needs, such as non-standard impedance values, certain frequency bands, or specific connectors. You are encouraged to talk to the manufacturer, specify your needs, and ask for a quote.

A: Common connectors used in RF Splitters include SMP, N connectors, and BNC, among others. These connectors are most commonly used due to their smaller size and good performance at high frequencies.

A: Return loss quantifies how much of the feedback signal is actually received at the unit’s input. A high return loss means decreased return of the signal at the source, which signifies better performance in which no reflection of the signal takes place.

A: When an order with required RF attenuators in stock is usually made, it gets dispatched in two to three working days. However, in some cases, lead times may differ, depending upon the order undertaken and the configuration of the model as well. To obtain more details, don’t hesitate to get in touch with the supplier directly.