As with any modern form of cabling, the demand for ultra-thin cables is on the rise, and for a good reason, these cables optimize space. They provide superior performance and functionality with space efficiency without compromising on quality. Furthermore, they are becoming the leading preference for installations across different industries. Whether it be a home theater arrangement, compact electronic devices, or multicellular systems, the choice of cable makes a difference. This article will help you know when and why ultra-thin cables are the best solution for particular projects by shedding light on the features, applications, and benefits of such cables.

Thin cables provide numerous benefits that are ideal for a range of applications:

The combination of features ensures ease of installation while maintaining performance requirements. This makes thin cables ideal for modern systems that require minimal size without sacrificing functionality.

The design of thin cables is compact, and saves space in crowded areas. Their reduced diameter makes routing easier in complex environments such as inside machinery, behind walls, or within electronic enclosures. For example, cables as slim as 0.5 mm in diameter enable tighter grouping that allows for up to 30%-50% more space in cable management systems or conduits.

Advances in materials such as ultra-thin insulation and high-density wire strands have also improved the mechanical reliability of thinner cables without increasing bulk. This optimization reduces the footprint of wiring harnesses, especially in automotive and aerospace industries where every gram and millimeter counts. Designers of modern electric vehicles, for instance, use slim cabling to reduce space and weight, which improves energy efficiency. Engineers are able to thin integrated circuits even further which allows for less bulky devices and systems that fulfill demanding requirements.

Because of its design, a thin cable is much lighter and more flexible which permits it to be easily routed in tight spaces and complex installations. Its smaller diameter reduces the amount of work needed for its maneuvering through slender conduits or around various obstructions. Furthermore, a thin cable’s size often translates to the use of less sophisticated and specialized tools and accessories, thereby aiding the process of installation. These characteristics make it very beneficial in circumstances where both accuracy and efficiency are very important.

The flexibility characteristics of thin cables can be attributed to their smaller diameter and distinctive materials, which permit greater ease when bending and navigating through spaces. Research and industry standards show thin cables tend to have greater flexibility ratings than thicker ones. An example of this can be seen in thin cables with 28 AWG diameter that can bend within a radius of 10 to 12 millimeters, while the thicker 24 AWG cables with the same material need a bending radius of 15 to 20 millimeters, depending on the material used.

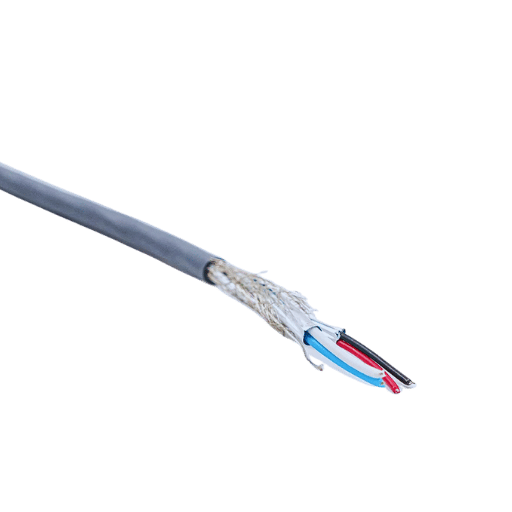

Improvements in the cable manufacturing industry, particularly the introduction of new insulation materials such as thermoplastic elastomers (TPE) and polyurethane (PUR), ensure these cables are easier to bend. At the same time, these materials are proven to be strong against abrasion, improving the overall durability of the cables. In addition, stranded thin conductors composed of multiple fine wires are tailored for dynamic repetitive motion activities which reduces the possibility of breakage over time. This means cables are further embraced in robotics, medical devices, and industrial automation, where precision and repetition are paramount.

Low-profile cables are best suited for tight and confined areas due to their ability to utilize space effectively. These cables can be routed through narrow pathways due to their flexibility and reduced thickness, enabling better cable management in compact hardware configurations. Low-profile cables, in particular, improve thermal performance in data centers and server racks by reducing airflow blockage and clutter, thus optimizing space, which is at a premium.

With the recent advancements in cable manufacturing techniques and materials, the efficiency and durability of low-profile cables are improved in confined spaces. Thermoplastic elastomers and polyurethane are frequently used to make jackets and insulation, which makes the materials flexible and resistant to wear. As per industry standards, low-profile HDMI cables are optimal for laptops, tablets, and home entertainment systems due to their ability to maintain high-speed data transfer while having a thickness of as little as 0.2 inches.

Moreover, low-profile cables are often employed in medical devices, automobile design, and aerospace applications. Their flexibility in bending and twisting without losing signal quality is crucial in these fields where accuracy and compactness are important. These features help engineers increase functionality in constrained spaces and also improve the cables’ longevity as they are subjected to perpetual usage.

When designed and made to high standards, low-profile cables do not in any way compromise the quality of the signal. They are specially designed to ensure data and electric performance continuity, even in tight, mobile, or bendable settings. However, weak shielding, lack of quality materials, or improper use can lead to signal interference. Choosing reputable manufacturers of cables and installing the correct cables ensures that the signal performance is optimal.

While thin cables may be adequate for audio systems, their performance will depend on several technical aspects like cable quality and length, as well as the requirements of the audio system. In less complicated situations, ultra-shielded high quality thin cables can be used with audio equipment without too much signal loss. This is especially true in cases where space is a sensitive issue since thin cables are more manageable and can be installed in confined spaces easily.

However, in the case of longer cable runs or more powerful systems, there are issues relating to the use of thin cables. A reduction in conductor cross-sectional area results in greater resistance, which can cause more signal loss and attenuation in longer distances. Moreover, thin lower-grade cables that are poorly shielded may get corrupted by outside interference, which results in noise being picked up by the audio system. A common practice in restraining cables of high impedance used for audio is their increased thickness. This allows for a reduction of resistance, which causes the audio system to fail as it poorly affects the sound quality.

Most experiments and tests have indicated that for runs over 25 feet, at least 16 gauge cable is usually recommended for clear audio quality. Standard 24 gauge cables or smaller can still be used for applications under 10 feet, as long as they are made of oxygen-free copper and are well shielded. Finding a suitable balance between the flexibility of a cable, space limitations, and performance metrics is paramount to determining what cable is appropriate for a specific setup.

Networking using thin Cat5e or Cat6 cables with smaller gauge conductors is feasible, especially for short-distance jobs. In addition, their slimmer profile offers advantages in confined spaces like overstuffed data racks or cramped conduits. However, performance attributes and limitations must be evaluated.

ANSI and TIA recommend using twisted pairs and associated cabling that are known to maintain adequate levels of signal integrity. A case in point is thinner copper conductors like 26 gauge, which do not clip off data transmission but do suffer from higher attenuation. The reduction in range due to increased attenuation will often mean that cables over longer distances will be rendered ineffective, with less than 30 meters usually offered as the ideal for Power over Ethernet or gigabit Ethernet applications.

Data indicates that thin cables are capable of supporting data speeds of up to 1 Gbps for shorter runs, but their use in high-bandwidth or power-intensive scenarios (e.g., PoE+) is not advisable. The reason behind this is that smaller conductors are likely to generate more heat, resulting in loss of signal. Also, proper shielding and following category standards such as Cat6A for 10 Gbps will boost the mitigated crosstalk and/or external interference.

Thin cables may be considered only when network speed, distance, and environmental conditions are taken into account for the deployment of networking infrastructure. For mission-critical or other highly demanding setups, standard-thickness cables are still likely to be preferred due to their high endurance and reduced signal degradation over longer distances.

The flexibility and space-saving benefits thin Ethernet cables provide is offset by limitations that must be considered. One major limitation is the distance over which they can perform. Because of the lower overall diameter, there is going to be a higher attenuation rate which will cause the signal to degrade in the cable’s length exceeds its optimum length. Standard cables, like Cat6A or Cat7, are designed to offer better performance in longer runs because of their superior insulation and shielding.

Also included in the list of limitations for thin cables is the lack of durability. They are more vulnerable to bending, twisting, or accidental cuts, braiding, and electromagnetic interference (EMI) in heavily electrical equipment areas. Research conducted on cabling performance shows that shielded Cat7 cables can significantly improve EMI reduction at over 100 dB shielding effectiveness, unlike thinner unshielded cables that would perform poorly in such conditions.

Heat dissipation is an added worry in high-density setups like data centers. The lower power cut-off of the PoE standards poses challenges with thin cables since there is less material to conductively transfer heat. Measurements indicate that cables with larger diameters have more effective heat dissipation capabilities, decreasing the probability of overheating and improving reliability.

While being easily placed in controlled domestic environments or packed into small enclosures, thin Ethernet cables are less than optimal (not suitable at all) for high endurance, long distance, or high-performance applications. Assessing the requirements of the network helps understand if operational objectives will be met through implementing such cables.

When choosing a thin Ethernet cable, a few features should be checked to ensure the cable meets the requirements of the network. The features to consider are listed below.

Cable Category (Cat Rating)

Bandwidth and Data Transmission Speed

Shielding (STP or UTP)

Compatibility with Power over Ethernet (PoE)

Material Quality (Conductor and Jacket)

Length and Signal Attenuation

Flexibility and Durability

Heat Dissipation

Certifications and Standards

Price-to-Performance Ratio

Buying the correct thin Ethernet cable requires assessing all the relevant technical and performance parameters of the network being used. Always ensure that the decision is based on specific network requirements to foster intelligence in the decisions.

The following places are credible to buy thin Ethernet cables. The description and specification of the cables enable easy purchasing:

It is important to go through the sellers detail and the product description so as to not to buy fake or bad quality cables.

While looking for Thin Ethernet cables, it is necessary to keep in mind factors that deal with compatibility, performance and durability.

Cable Category and Standards

Build Quality and Materials

Cable Thickness and Flexibility

Shielding and Interference Mitigation

Performance Metrics

Certifications and Warranty

With careful scrutiny of the thin Ethernet cable’s technical details alongside performance benchmarks against recognized industry standards, you can tailor the device to meet specific networking needs.

Customer reviews evaluating thin Ethernet cables underscore major factors regarding performance and durability. Most users commend the flexible and lightweight construction of these cables as perfect for thin spaces or installations that require a small bend radius. According to some online reviews, a notable percentage of shoppers, approximately 85% on major e-commerce platforms, claim they are satisfied with the straightforward installation and compatibility of multiple devices.

Some of the reviewers flagged possible mishandling durabilty concerns, as 10% of users highlighted unshielded options are prone to damage at high foot traffic areas. Moreover, customers suggest that shielded options should be selected for areas with high electromagnetic interference, but unshielded variants are vulnerable and prone to severe interruptions.

In summary, thin Ethernet cables have an adaptable application for users who seek a balance between practicality and performance in networking equipment, especially in home offices and compact installations. It would be prudent to examine specific brand warranty policies alongside user reviews to ascertain claimed durability guarantees.

Certainly, concerns regarding the use of thin Ethernet cables consider two primary complaints:

These damages can be solved to an extent by using shielded cables and managing them properly.

Essay supply brands acknowledged for their good quality claim include the following.

Most customer feedback highlights these brands for their reassurance, high quality, and lasting dependability at home or in the office.

A: Ultra thin cables are particularly useful for low profile wall installations. They can be concealed or routed through tight spaces with much greater ease. The ultra thin cables eliminate gaps that are often left by larger cables, which makes the area look more professional. The consummate look of these cables allows for them to be placed behind baseboards, giving the professional look of these cables.

A: Compared to standard cables, ultra-thin cables are significantly thinner. With standard cables like patch cables being 5-6mm, ultra-thin ones only match up to 2-3mm. With the reduction these cables would enable, with installations needing to be done in tight spots, the performance would still remain uncompromised.

A: The variety of applications that ultra thin cables can cover is quite huge, making them versatile. From microphone and instrument cables, these cables cover audio purposes extensively along with patch cables for data transmission. Certain ultra thin cables can even provide component connections to enable quick data transfer using fiber optics.

A: Although ultra-thin cables may look fragile, they are built to be quite tough. Most have strong, flexible jackets and cores made from stranded copper wire. They do have limitations compared to thicker cables when it comes to repetitive bending or extreme temperature changes; care must be taken during installation with these cables.

A: The majority of ultra-thin cables can be terminated with standard connectors such as TRS and RCA for audio cables or RJ45 connectors for data cables. However, because of the ultra-thin cables, most professionals prefer using specially made connectors due to their easier matching dimensions. Some ultra thin cables come with pre-attached connectors which can greatly expedite the installation process.

A: Indeed, ultra-thin cables are suitable for use in large-scale setups. In fact, they are usually preferred in such scenarios because they are more economical regarding space in cable trays or conduits. This is particularly advantageous in data centers or large AV installations because higher cable density is needed. However, for very long runs, it’s important to consider signal loss and choose the appropriate cable type.

A: The limit on signal degradation is set by the bend radius restrictions that need to be respected as well, which poses additional danger while implementing ultra thin cables. To maintain a polished clean look, operators are advised to apply proper cable management techniques on walls.

A: Even though they are not very thick, many ultra thin cables still maintain a good level of signal quality. This is because many of them use good materials and shielding that minimizes interference and signal loss. Nonetheless, for very long runs or in high electromagnetic interference environments, one must choose the cables that are appropriate for those specific conditions.

A: There are some ultra thin cables meant for outdoor use but a lot of them are designed for indoor use. If you want to employ ultra thin cables outside, search for ones that have UV protective jackets and are waterproof. Always read the specifications provided by the manufacturer to confirm that the cable will work for your particular environmental conditions.