In modern telecommunications, fiber optic technology performs a major role by ensuring that data is transmitted at high speeds over long distances with little signal loss. Connectors are some of the key components used in this kind of technology as they help to connect fiber optic cables to different networking devices seamlessly. Among the options professionals have when choosing a suitable fiber optic connector are SC (Subscriber Connector) and LC (Lucent Connector). The main purpose of this article is to give an in-depth comparison between SC and LC fiber connectors, including their design, performance characteristics, and suitability for various applications. It is important for one to know these points so that they can make good decisions about what will work best for them based on their needs in networking.

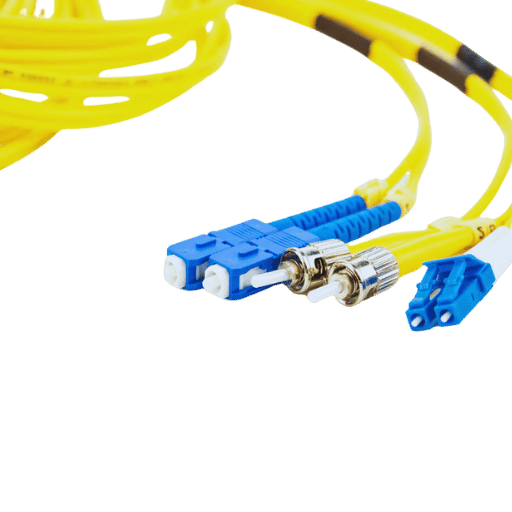

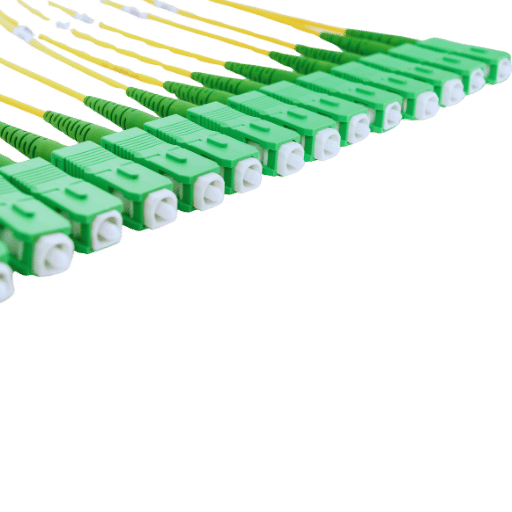

SC (Subscriber Connector) fiber optic connector is a type of optical connector known for its square shape and push-pull locking mechanism. It uses a 2.5mm ferrule, which ensures good performance and durability. Essentially, these connectors are simple to use and this makes them widely used in datacoms as well as telecoms. They are designed for single-mode and multimode applications that could be used for network infrastructure where many high-density connections need to be made; hence, they are best suited when you have to connect SC with LC or SC to SC connectors.

The most common areas where you would use an sc fiber connector include:

Because of their design which allows easy insertion even in crowded patch panels due to the fact that it can be pushed or pulled into place, also being square-shaped so that several can fit closely together; making them perfect for use in environments with multimode sc including other connectors where frequent reconnection might occur since robustness is guaranteed by its 2.5 mm ferrule size, sc fiber connectors work well in situations where space saving is important such as enterprise networks ,data centers among others thus becoming more densely populated areas but still requiring high levels of performance from each connection being made at all times because apart from being affordable they are readily available too which makes sense especially when dealing with large numbers like those typically found within WANs involving multiple floors connected via various switches throughout buildings alongside numerous devices linked together on different racks located within same room whereby all these points need continuous reliable communication having said that there isn’t any reason why anyone should not consider using this type even if they were dealing with fibre optics using multimode sc.

Because they make use of a 1.25mm ferrule instead of the 2.5mm ferrule found in SC connectors (which are often used for SC to-SC connections), LC connectors are smaller and more suitable for high-density applications. The latch mechanism is employed by LC connectors to ensure secure connections, whereas an SC connector uses a push-pull design. In data centers and other high-density networking environments where space is limited, LC connectors can accommodate more connections within the same area, especially when combined with MPO-type connectors; on the other hand, their robustness and ease of use have made them popular in general telecommunications/datacom applications. Both types support single-mode and multi-mode fibers depending on network performance requirements.

Physical design features/construction methods used to secure/optically align fiber strands differentiate between these two connector types, but there are also some similarities, such as size, etc. The primary dissimilarity, though, lies in how they lock or unlock once joined together physically, so this part becomes critical during installations where one needs reliability over another type. A bayonet-style twist-lock with 2.5mm ferrule characterizes the ST connector while its counterpart utilizes a push-pull locking system/scenario, hence more aptly suited for areas having many changes that require easy insertion/removal processes like high-density applications where simplicity outweighs everything else as far connectivity is concerned. However, both single-mode fiber cables can be terminated using any of these connectors.

There are several reasons why people prefer sc-type plugs over others; the first is user-friendliness, which stems from their push-pull mechanism, making it easy to plug/unplug without much effort, hence minimizing the chances of getting damaged due to constant pulling or yanking. Secondly, its tough nature – sc connectors come designed with a strong mind and are therefore suitable for both indoor and outdoor installations since they can withstand harsh conditions such as extreme temperatures and humidity levels, among others, that may be encountered during cable laying activities. Another point worth noting is stability; these particular types employ 2.5mm ferrule, which provides a stable, reliable connection needed to support high-performance single-mode/multi-mode networks using sc-to-sc connections frequently. Finally, standardization – this kind of factor ensures compatibility among different devices/equipment so upgrading or maintaining infrastructure becomes simpler because all one has do is swap out old components new without any fuss, thus saving time and money

To accomplish the successful installation of SC fiber patch cables, the following tools and equipment must be possessed:

Single-mode fibers have a tiny core – about 8 to 10 micrometers. They are designed to allow light to move directly down the fiber without bouncing off its walls. This reduces loss of signal, enabling it to support long-distance communication links that span considerable bandwidths. Conversely, multimode fibers possess much larger cores – usually around 50-62.5µm – which make it possible for different light modes to propagate simultaneously. It is these kinds of optic fibers that are found to be useful within shorter-range applications such as local area networks (LANs) and data centers alike. Both varieties can work well with an SC connector type, though you need to ensure whether your installation requires single-mode or multi-mode connectors because they should match corresponding fiber optic cables for best performance.

The typical core diameter for OM1 fiber is 62.5 micrometers and is used mostly in multimode applications. You can definitely employ SC connectors in conjunction with OM1 fibers only if those sc connectors were meant specifically for multi-mode operation purposes; otherwise, there may be some issues during transmission over short distances, i.e., up to 275 meters at 850 nm wavelength & 550 m at 1300nm wavelength commonly found on old network installations and certain legacy systems still being used today so take care always check whether your sc connector matches om1 correctly otherwise it will not perform as expected leading into the degradation of performance eventually resulting into failure of the complete system itself.

When selecting the right fiber for use with your application, there are several things that you should take into consideration.

Always consider these factors when making your decision on which fibre optic cable will work best with your requirements and budget constraints.

Cleaning them is very important. Below is a step-by-step guide to cleaning SC fiber optic connectors properly:

SC Fibre Optic Connectors require accurate adherence to these steps in order for them not only to function optimally but also last longer whether they are used in SC – SC, SC-ST among others connections.

The above steps will ensure that no damage emanating from SC Fiber Optic Connectors exists, thus lowering their performance, especially when dealing with SC-SC or SC-ST connections.

A: An LC connector, or Lucent Connector, is a type of small form factor fibre optic connector used for high-density patch applications. The push-pull mechanism of this device enables easy connection and disconnection, which makes it useful for both duplex and simplex connections.

A: The difference between LC and SC connectors lies in their sizes as well as coupling mechanisms. While being compact connectors suitable for high-density networks; SC connectors are larger in size with a push-pull coupling mechanism. For many applications where cost is an issue, SC connectors can be manufactured cheaply.

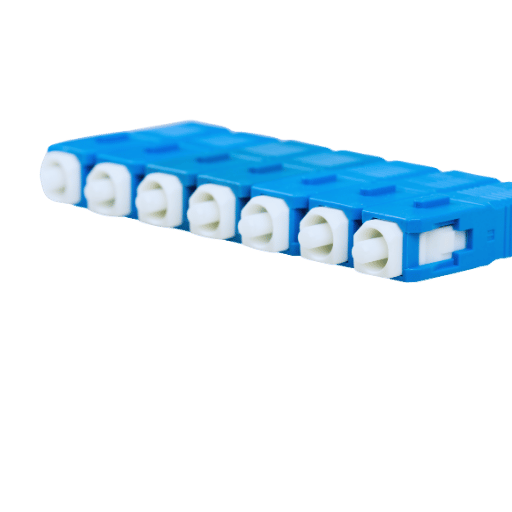

A: Yes, LC connectors are preferred when it comes to high-density patch panels and switches. They have a small form factor that allows more connections within limited space, making them ideal for modern networking equipment and fiber optic patch cables.

A: Yes, indeed, LC connectors can support duplex connections, which use two fiber strands for bidirectional data transfer. Therefore, they are applicable in gigabit ethernet, among other fiber channel network applications.

A: Fiber optic patch cables usually use LC and SC connectors. These connectors are made for single-mode and multimode fibers, and they are needed for SC-to-SC connections in networking. They find wide applications in data centers, telecommunications, and high-speed ethernet networks.

A: A duplex fiber optic patch cable means that there are two optical fibers packaged in one jacket. This allows them to be used for simultaneous two-way data transfer. It is common for this type of cable to have LC or SC connectors which make it suitable for gigabit ethernet among other high-speed networking applications including those with LC to SC connections.

A: The term “small form factor” refers to LC connectors, among others, which were designed specifically for saving space on network equipment and patch panels while providing more connection points per square inch, which is especially useful when working with high-density types such as MPO connectors. This becomes critical in environments like data centers where many devices must be accommodated within a limited area, and telecommunication rooms have similar requirements.

A: Due to its small form factor, LC fiber optic connector provides the highest possible number of connections per unit area, hence considered as the best choice for compact networking equipment in modern times. SC connectors, on the other hand, offer reliable performance through a strong push-pull mechanism that suits various fiber optic applications.

A: FC connectors have threads that enable them to be screwed into place, making them more durable than other types of single-mode fiber optic connectors. Commonly found in telecommunication networks and fiber optic test equipment, they provide higher precision required for long-distance communication systems.