With the strides in telecommunications, fiber optic technology has gone a long way toward providing speed in data transfer. SC/APC (Subscriber Connector/Angled Physical Contact) fiber optic cables are remarkable for their low insertion and excellent return loss. Thus, they have many applications, including data centers and communications systems. This guide seeks to educate its audiences on SC/APC fiber optic cables, their construction and functionality features, advantages, challenges, and best practices for installation and maintenance. Considering these factors of great significance, the guide will enable the readers to acquire the information required to reach a sound judgment regarding the construction of fiber optic systems and their integration within modern connectivity solutions.

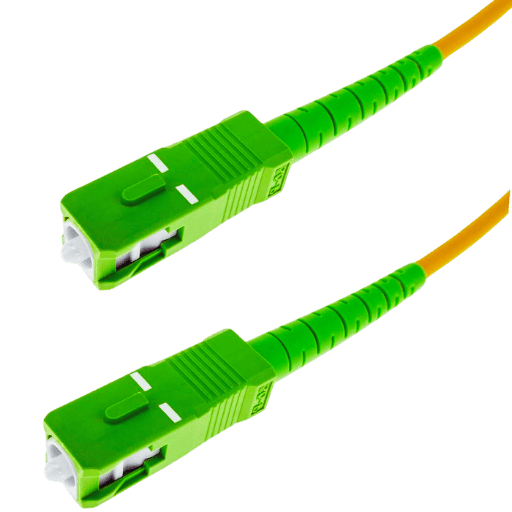

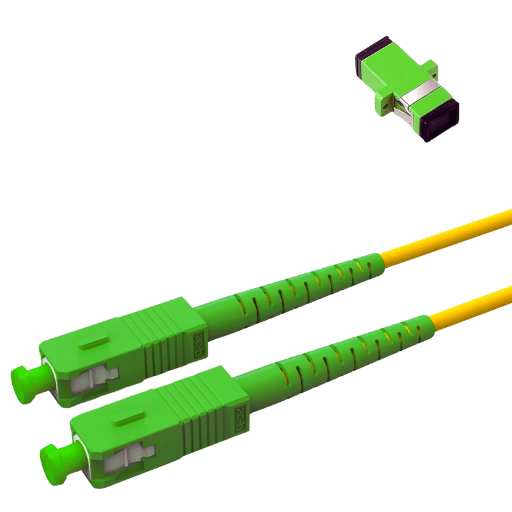

The SC/APC connector is a type of single-mode fiber connector with a square shape and an angled end, making it easy to align the optical fibers inside. The second term, “APC,” refers to ‘Angled Physical Contact’ which specifies that the establishment of optical contact through the collet-tip was done with an approximately 8-degree angle. Such an assembly preserves the movement of light within the fiber better than any standard, and there is very little back reflection compared to other standard connectors. SC/APC connector properties make it perfect for high-performance applications where interference and attenuation are not tolerated, such as in telecommunication and data center installation. Thanks to its strong design, it is also simple to use and does not break while being fitted or when it is being repaired.

SC/APC fiber optic connectors have several features that allow them to be used in various high-performance applications. First, their angled polish leads to very minimal back reflection and, hence, improved return loss parameters, which are vital in reducing signal loss in sensitive telecom systems. SC/APC connectors also have low insertion losses, which help transmit optical signals long distances without too much power loss. Their design also provides further protection against environmental factors, thus improving the reliability and durability of various installations. Last but not least, the square shape of SC connectors standardizes and facilitates the joining process of the connectors, making their performance reliable in its various applications.

The terms simplex and duplex differentiate between the communication modes found in fiber optical systems. Simplex connections are meant to work with one-way data transmission, which can be advantageous in situations where the information is only required to be sent in one direction, such as in broadcasting or monitoring. On the contrary, duplex connections allow data to be sent and received simultaneously. This is particularly important in systems where time is of the essence and information is exchanged continuously, such as during video calls or interactive sessions. The decision to use simplex or duplex mainly depends on the application’s requirements, particularly regarding bandwidth and the type of information that needs to be sent across.

Choosing between singlemode and multimode fiber optic cable also requires an appreciation of the fundamental differences between these fiber types to optimize their performance for a given application. The core of a singlemode fiber is about 9 micrometers in diameter and allows optical waveguide propagation only in a single mode. The design is such that transmission over a long distance is possible and hence suitable for telecommunications and high internet speeds where the distance and bandwidth are essential. On the other hand, multimode fibers come with lightweight fiber cables with larger core diameters. The core diameter is about 50 or 62.5 micrometers, allowing the transmission of several light modes at a go. This structure may be deployed over shorter distances, such as the building or infrastructure networks, due to greater modal dispersion within the signal bandwidth, which makes it unfavored over larger distances. Finally, the preferred option of singlemode or multimode fiber should be determined by the characteristics of the planned network in terms of the range, bandwidth requirements, and the application.

When determining the appropriate length of fiber optic patch cables for specific installations, the peculiar conditions in such settings must be considered.

To conclude, the correct fiber optic patch cable length depends on the installation circumstances, the extent of available space, and the need for the application. Therefore, the efficiency and effectiveness of data transfer are guaranteed.

Reference OS2 relates a standard related to a single-mode optical fiber cable meant to transmit signals over long distances with deficient attenuation levels. These specifications relate to areas of fiber performance such as modal bandwidth, attenuation rates, and environmental tolerance. In particular, AV cables are characterized by: According to some major contributors to the industry, OS2 cables have:

Finally, as this paper demonstrated, the OS2 parameters are fundamental when choosing these types of fibers to meet a network’s anticipated needs, especially in cases where long-distance communication is becoming increasingly important.

After these steps, SC/APC cables can be reliably installed, and performance certifications can be optimized for applications involving the transmission of large data volumes.

Determining the degree of signal loss experienced during a fiber optic installation is a necessary phase in evaluating the installed system. Broadly, this activity entails making an optical power measurement before the connection point and after that to quantify any losses that may have occurred. The best way of testing the signal loss is through the Optical Time Domain Reflectometer (OTDR), which can provide loss measurements, find faults, and locate them inside the fiber. Apart from that, a power meter together with a light source can be used by technicians to test the total attenuation and make sure it is by the limits set by the norms, which in the case of single-mode fiber OS2 should not exceed a value of about 0.35dB/km. This verification must be carried out regularly during and after installation and during maintenance to maintain the reliability of the fiber optic network and to ease the identification of possible problems.

Fiber optic installation will be reliable and functional by tackling such rigorous issues with the ultimate approach to achieving the best possible solutions and implementing best practices. Frequent education, awareness, and instructions concerning the industry will also reduce most errors.

Simplex optical fiber cables are essential during FTTH rollouts as they provide high-speed internet directly to customers, in this case, residential customers. These are single-fiber cables designed to maintain one fiber for the strain gage signal transmission and another, which is not included in the simplex design, as a receiver, making it possible to increase bandwidth.

To summarize, simplex fiber optic cables can bring efficiency and affordability to FTTH solutions, facilitating the increasing demand for fiber broadband in homes.

Fiber optic simplex cables are ubiquitous in telecommunications because of their capability to provide reliable and quality signal transmission. Their main usage consists of:

To put it simply, hql simplex fiber optic cables in the field of telecommunications allow for increased efficiency, performance, and even cost savings in several communications applications that are keystones to modern centers and systems.

Data centers, also called data center facilities, are essential buildings that mainly hold computer systems and relevant peripheral devices, including telecommunication and storage systems. A data center’s operational effectiveness, capacity, and dependability are dictated by the architecture and construction of the center itself. The construction and operation of data centers present certain factors that should always be considered, including:

Concentrating on these particular elements enables data centers to enhance their physical infrastructure in response to ever-growing data needs while maintaining optimal availability and performance.

It is essential to ensure that the cleanliness of the fiber optic cable connector is observed for practical usage and that the signal is not deteriorated at a minimum. To perform a cleaning on the connector, do the following:

With such regular cleaning, the useful life of the fiber optic infrastructure and transmission quality will significantly increase.

Recommended storage methods for fiber optic cables are necessary to avoid wear and tear and reduce signal loss. Below are some practices adopted from industry standards that are essential for SM and SC-to-SC interconnections.

Following these storage methods preserves the quality of fiber optic installations for a long time, contributing to consistent performance in the razed network.

To ensure that fiber optic systems continue operating optimally, measures to control dust and pollution must be taken beforehand. Some necessary solutions that are in line with the current practices include:

Therefore, it can be concluded that organizations that carry out the above-highlighted practices reduce dust-associated problems considerably, thereby increasing the efficiency of optical fiber systems’ operation.

A: An SC/APC fiber optic cable belongs to the single-mode fiber optic cable class and has SC subscriber connectors and APC polish. It is a fiber optic cable with a green connector and an 8-degree angled end face for frequency signal improvement on data to be transmitted and for enhancing speed on the data transmission over the fiber optic internet connection.

A: Implementing the SC/APC patch cords has several benefits, such as lower insertion losses, superior return losses, and outstanding reliability. They are purposely incidental loss, durability, and performance optimized for SMF-28e fiber designed for Ethernet applications in high-speed networks. These patch cords are versatile accommodations for every fiber optic system, including FTTx connections.

A: The most popular sheath for SC/APC fiber optic cables is PVC (Polyvinyl Chloride). It is preferred because it protects the cable from environmental conditions and allows for bending during installation. Some cables are also yellow, the typical cosplay color used for single-mode fiber optic cables to distinguish them from the other multimode wires in a range of patch cables.

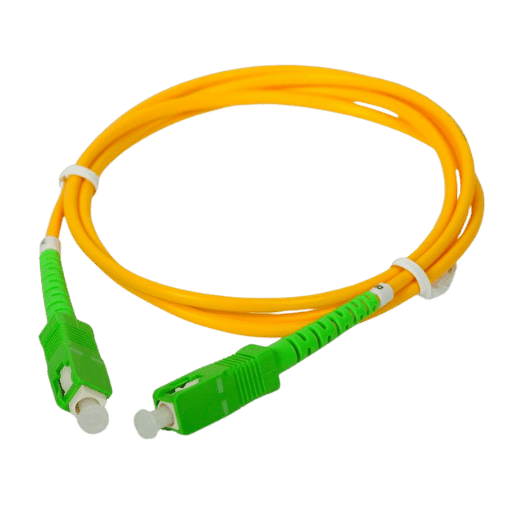

A: SC/APC to SC/APC fiber patch cables come in different lengths per installation requirements. Available lengths include 1m, 2 meters, 3 feet, 10m, and more. It is also possible to place orders for lengths that are not standard. It is best to exercise caution when selecting the ideal size in this case, particularly with singlemode simplex fiber optic patch cables, as this also directly impacts the adequate performance of the cabling system for the reasons stated above.

A: Simplex SC/APC fiber optic cords, such as the simplex 2.0mm fiber cord, contain a single fiber radius and are, as a result, used in one-way communications. On the other hand, duplex cords consist of two fiber strands that perform two communication sessions in one go. Simplex cords are typically a common feature in applications whereby one of the two ways of communication is carried out in separate cables, while duplex cords are what most of the employed network configuration designs require full-duplex communication use.

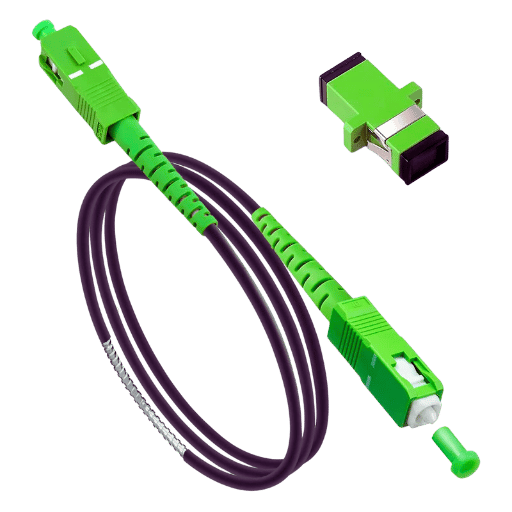

A: SC/APC adapters electrically connect the two free ends of SC/APC connectors, commonly called connectors, and are also used when connecting an additional fiber to an existing fiber optic cable. These fibers orient the support connectors at an angled machining point in the adapter. The adapters maintain the 8-degree angle of the APC polish, and low back reflection and signal quality are supported. For instance, they are fundamental in the fiber optics network, which permits the extension of interconnected fiber optics cables or different fiber optics devices such as SC and SC fiber optics.

A: Although classified as single-mode fibers, SC/APC fiber optic cables have high data transmitting capabilities. Under optimal conditions, 100Gbps and above can be achieved, depending on the cable specifications and the electronics used. Residential subscribers using fiber optic broadband access, high-performance data centers, and telecommunication infrastructures are some of the wide ranges of applications they can use.

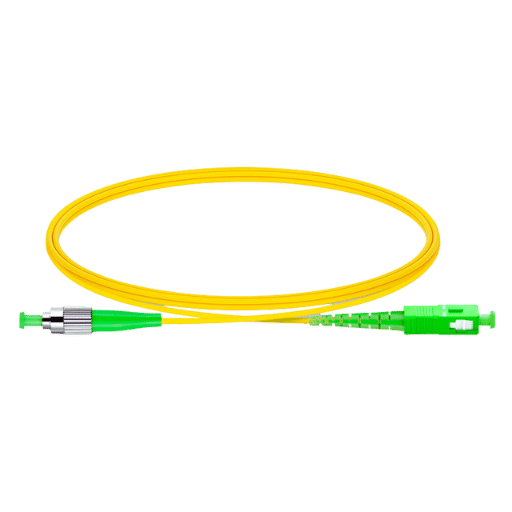

A: SC/APC connectors are designed for SC/APC coupling, although they can be used with other connector types using hybrid patch cords or connectors. The correct cable assemblies or adapters, including fiber optics jumpers, SC/APC to LC, SC/APC to FC, or even SC/APC to SC/APC connections, are also possible. However, observing the correct polishing type is important to prevent breakage or damage to the fiber ends.