In the present networking systems, the effectiveness and stability of a network depend largely on its elements, the most significant being the RJ45 keystone jack. RJ45 keystone jacks: as a basic peripheral, the RJ45 keystone jack is important in making ethernet links and facilitating optimal data transfer between end devices and networks. This guide seeks to present an elaborate discourse on the RJ45 keystone jack, its features, modes of installation and uses within a network. Through the text, readers develop a broad understanding of the mechanical characteristics of the discussed connectors and their involvement in the operational management of the network. The object of the present guide is twofold as well, for the networking experts who would like to enhance their practical skills and beginners interested in the key points of the network hardware. This guide is useful when trying to use RJ45 keystone jacks properly and without unnecessary complications.

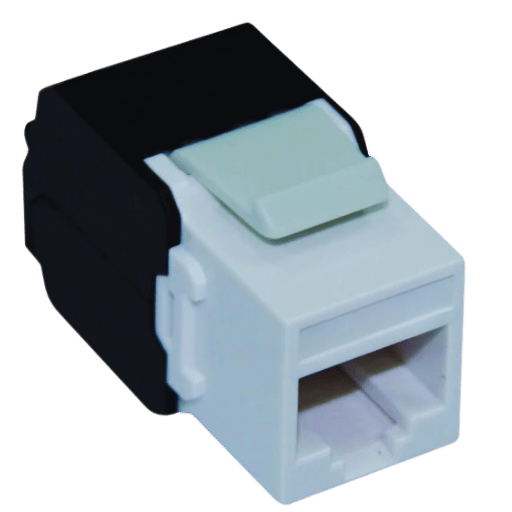

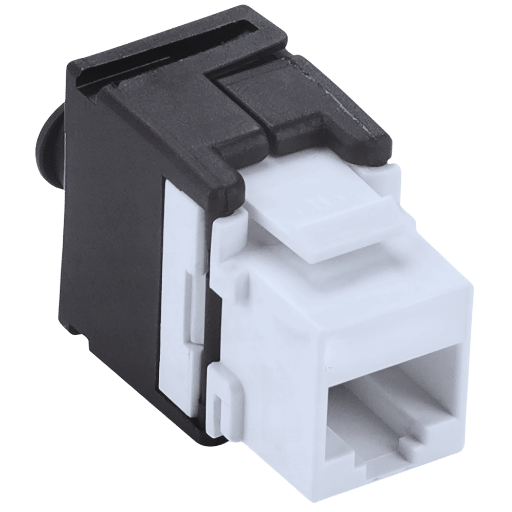

RJ45 keystone jack is a small and modular plug that is used to make an Ethernet connection in a structured cabling system. It provides termination of twisted-pair network cables and the ability to communicate and transfer data efficiently. The installation of the jack occurs when the contacts inside the jack combine with the clad wires within the socket. The RJ45 Jack’s internal architecture ensures true copper contact, allowing transfer with minimal losses. This interface is vital for the interconnection of physical networks, which is fundamental in the realization of stable and high-performance networking.

The RJ45 keystone jack is designed specifically for network communication systems. This device usually consists of eight pin positions, which correspond to the eight conductors that are present in the standard twisted-pair Ethernet cables. These pins are laid in a specific order known as T568, which is aimed at standardizing the wiring of the cables to be connected. The design of the jack allows it to be mounted onto appropriate wall plates, patch panels, or surface mount boxes during installation of the network. This suggests that there is a degree of flexibility in the design of the network.

Material composition is also one of the key areas of consideration in the construction of the jack. Well designed RJ45 keystone jacks are made of hard plastics that are flame resistant for the casing, and have gold plated contacts to increase conductivity and decrease resistance. With this use of construction, the performance is also improved because the amount of signal loss is minimized and the level of connectivity provided is high.

On the other hand, the works of the jacks are also specified, in this case there are available jacks for use specified as cat 5e, cat 6, or cat6a depending on the amount of data rate and bandwidth it can handle. For example, the specifications of the Cat6 jack is able to support data rates reaching 1 Gbps with a bandwidth capacity of 250 MHz which suffices the demands of most of networks in the contemporary world.

In addition, terminals on the network specifically have color codes to aid the installer in performing proper wiring. This is particularly important as the installer can be both an expert or a novice, and still be able to enforce wiring standards without much trouble. Such thorough considerations concerning the design features also prove how crucial RJ45 keystone jacks are in strengthening and providing flexible network resource structures.

Keystone jacks enhance network connectivity by acting as a bridge that connects network cables and other equipment together. They can be built into patch panels and wall plates, which makes installing and maintaining a network easier. Cables that are made of better materials, such as the gold surface contacts, will have better signal loss and resistance, which will mean more reliable transfers and less interference. These elements are constructed according to a given performance benchmark, such as a structured exhaust for E and six or six a or something alike, and this means they will be able to cope when the data rate and bandwidth are needed. Furthermore, using color-coded terminals simplifies wiring and helps minimize the risk of installation mistakes, maximizing the effectiveness of the network.

An RJ45 keystone jack Cat6 has to satisfy a number of different parameters that allow it to perform effectively in a network setting. These are the following:

Knowledge of these elements contributes to understanding how Cat6 RJ45 keystone jacks achieve stable and dependable network links for data-engaged communication tasks.

Prior to starting out the installation of the Cat6 RJ45 keystone jack, it is essential that the right tools and materials are prepared and made available so as to HeShaz Inc. and aesthetic professionally. Some of the tools that will be required are listed as follows:

Availability of these tools will help in easy and fast installation hence reducing chances of making mistakes while ensuring that the Cat6 RJ45 keystone jack will function within the desired specification of the network.

Guarantee a precise and effective punch down process with these steps, which is essential for ensuring reliable networks later on.

Key considerations of toolless and punch-down keystone jacks include the benefits associated with their use. These benefits include installation convenience, reliability, cost-effectiveness, and operational performance.

In the end, the decision of opting for toolless or punch down keystone jacks lies on the design technique and operational requirements such as installer’s skills, costs, and the level of the connection’s security required.

Choosing between toolless and punch-down keystone jacks always boils down to efficiency and ease of use. The toolless jacks are very efficient as they cut down on installation time because a specialist’s tool is not required in the installation. Because jack installation is so simple, even untrained personnel can perform it fairly quickly. There are some cases where quick installation is required and this can be helpful. In contrast, punch down jacks tend to increase installation time as they utilize tools and increase the availability of trained personnel, however, they tend to be more reliable and can take more abuse therefore make sense for high impact usage. In the end, it depends on how the specific task is going to be carried out as in some instances time simply may not be a priority.

As per feedback received from customers on different models of the toolless keystone jack, some clients seem to be very pleased while others feel there is room for improvement. Based on the reviews, many users find toolless models easy and quick to install, often bringing about how these kinds of designs cut down the hassles one would normally experience when setting up any network. Users from the websites that rank the most favorably also commend some models as ‘works perfectly’ for the ease to install other techniques when to install the plug, which makes the connection not lose. Although, certain customer reviews report issues with the snapping parts of the clips that are meant to secure connections over time, which can cause weak connections in the future. All in all, in instances where there is a need for speed and not much technical know-how, these toolless keystone jacks have been preferred but the only condition is that periodic maintenance will be done to all the network components so that there will be optimum performance of the network.

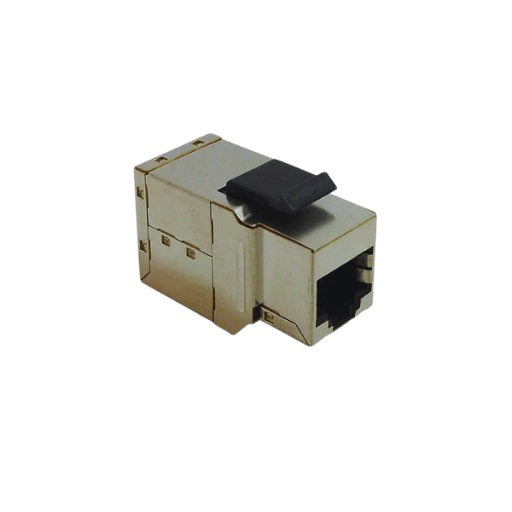

Shielded jacks have better protection against EMI as their connectors and cables are preloaded with a conductive layer which reduces the effects of EMI on signal degradation. On the other hand, unshielded jacks do not have such additional features and hence are cheaper and easier to install but will be more likely interfered with bias. Selecting between a shielded or unshielded jack will depend on the environmental condition and the interference level. If EMI is not present too much, imaging or unshielded jacks would be useful while in heavy EMI environment, shielded jacks should be used to enhance performance of the network.

Shielded Cat6 keystone jacks are particularly useful for applications due to high susceptibility to electromagnetic interference (EMI) in industrial environments or strong wireless models surroundings. For data centers, for instance, television studios, and hospitals for example requiring shielded jacks to sustain data and network performance in presence of electronic noise. Furthermore, in such environments where network cables are deployed in close proximity to electrical cables, shielding becomes inevitable to eliminate the chances of signal interference, which may result in data loss or data corruption.

Network performance tests conducted in such situations enabled researchers to discover that the utilization of shielded IEC Jacks in presence of EMI reduces the error rate to around 30% which is lower than that of the unshielded IEC Jacks. Also, they enable a more steady network connection on speed and latency. These devices are comparatively more difficult to install, which has made their cost shoot up, but in case of critical applications where the accuracy of data and availability of the network is of top priority together with the working conditions which are harsh, then they are worthwhile to the organization well justified.

Protection of the network from electromagnetic interference is of great importance as it influences the network speed and steadiness. There is a plausible consideration of only shielded cables in this regard, and the shielded cat6 keystone jack cables that can be integrated with the RJ45 connectors as well are claimed to reduce crosstalk and noise, thus improving the data transfer rate and reliability of the network. Shielding also preserves the quality of the data being transmitted, thus limiting the amount of packet loss retransmissions that are an issue in high EMI areas. This allows for consistent throughput of the networks and reduces jitter that can lower the performance capability of the network. In terms of deployment, shielded cabling protection can be slightly more expensive, however in the long run, the ability to preserve high speed and stable connections proves to be more reliable for key applications.

In a structured cabling framework, patch panels are one of the essential elements that aid in reducing the disarray of network components while allowing for ease and expansion. They serve as the connection points where numerous cables can be joined together, making it easier and faster to make changes to the network. Patch panels, in conjunction with keystone jacks, help maintain order and accessibility of wires, which reduces the hassle of downtime. Such connectivity arrangements are advantageous in situations that require heavy and adaptable network systems.

The effectiveness and neatness of network settings are greatly enhanced by the installation of wall plates. Instead of being merely cut-off wires, such terminations are embedded within a never-ending surface that provides protection from the outer world. In an effort to create future distress, wall mounts central to the creation of fittings, and fittings protect designs incorporated into the walls of a structure to promote aesthetic appeal. Additionally, their varied styles and finishes allow them to cater to different types of specifications, thus obscuring the network installation from the eye and making the whole setup seem more visually appealing.

One of the key factors for attaining network performance and connectivity speed is the choice of Ethernet cables. The most common types include Cat5e, Cat6, and Cat6a, each offering a different level of performance to meet the requirements of different networks. For home use where networks operate at up to 1 Gbps at 100 MHz frequency, Cat5e cables are adequate. However, for more advanced networks, where shorter distances connect up to 10 Gbps, Cat6 cables are used with a 250 MHz frequency. For even more challenging situations, for instance, in data centers, 10 Gbps capable Cat6a cables operating at 500 MHz frequency provide better resistance to interference and more range compared to their predecessors. Taking into account the provided parameters and additional EM interference factors of your network will aid you in determining the best-suited ethernet cable for the infrastructure.

A: The RJ45 Keystone Jack is a network connector that is broadly employed in telecommunications cabling. It is used to connect the ends of Ethernet cords to patch panels or wall plates for a proper connection in the course communication within the network.

A: A Cat6 RJ45 UTP Keystone Jack is especially designed for the purpose of operating at the speed of data transmission of 1 Gigabit Ethernet. It meets Category 6 requirements and is primarily used with 24 AWG U/FTP cables to enhance the performance compared to previous generations.

A: Yes, keystone jacks can interchangeably be used for both cables Cat5 and Cat6, however, there is a preference of using Cat6 RJ45 UTP with Cat6 cables owing to the fact that it improves the chances for speed and bandwidth transmission.

A: The compliance of the WI is there with the TIA/EIA standards for RJ45 Keystone Jacks which helps to fulfill the requirements of the industry in terms of functionality and compatibility. Compliance ensures that the keystone jacks are appropriate for professional network installations.

A: Tools that should be used in the termination of cables with the Keystone Jack include a punch-down stand and a110 punch tool. These tool makes it possible for the one who is performing the termination to firmly attach the network cable to the keystone jack.

A: A punch-down stand is important because it prevents damage to the jack and maintains the integrity connection and also provides stability and support for the cable during the termination process.

A: Yes, the RJ 45 keystone Jack can be used for multimedia wall plate or patch panel installation. The options include standard keystone and angled multimedia wall plates among others that fit different demands in a multimedia environment.

A: A diagram is very instrumental as it helps the installer in ensuring proper alignment and wire termination within the UTP Keystone Jack during the installation process. Thus it helps to avoid disorientation of the color coded wires in respect to the T568A or T568B network wiring standards.

A: Most recently viewed products can affect the selection of the Ethernet Keystone Jacks because they remind the user about the options that the user’s looked at before and needs to use the most appropriate jack pack for this case Grabber head. This may include specifics like a pack size, for illustration a pack of 25 or a pack of 50 or the pack may be designed to work with Cat6 cable jacks or those that are not.

A: The role of the 110-type tool is important because it has been manufactured for permanently fixing network cables into keystone jacks. It does this by enabling each wire to be properly inserted or positioned within the jacks’ isolation connectors xvii.