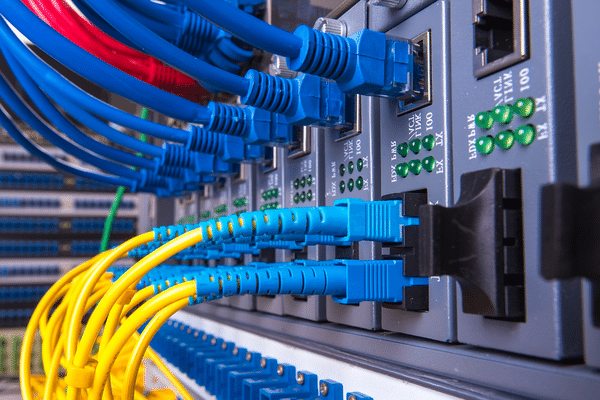

Fiber optic cables, the backbone of modern telecommunications and data networking, are susceptible to damage due to their delicate nature. Even minor cuts or kinks can lead to significant disruption in data transmission. However, professionals with the right tools and knowledge can effectively repair a damaged fiber optic cable and restore its functionality. This involves a set of specialized equipment such as a fusion splicer, fiber cleaver, and fiber stripper, among others. Proper use of these tools and meticulous cleaning procedures and protective measures are essential for a successful repair. This guide will delve into the step-by-step process of repairing a cut or damaged fiber optic cable, prioritizing clarity and precision at each stage.

Fiber optic cables are a revolutionary technology in data transmission, credited with dramatically boosting the speed and efficiency of our communication networks. These cables rely on light, an optimal medium for data transmission, to transfer information from one point to another. The core, the central part of the fiber optic cable, carries light signals and is surrounded by a layer known as the cladding, which reflects these signals and prevents data loss. The protective outer layer, or the jacket, shields the delicate internal components from physical damage and environmental elements. Understanding the composition and working principle of fiber optic cables is critical to repairing them effectively, as it facilitates precise troubleshooting and fosters a comprehensive approach to the repair process.

Fiber optic cables are not immune to damage despite their advanced design and functionality. Damage can originate from various sources, each presenting unique challenges in the repair process.

Awareness of these common causes of damage can guide individuals and companies to take preventive measures, ensuring the longevity and reliability of their fiber optic infrastructure.

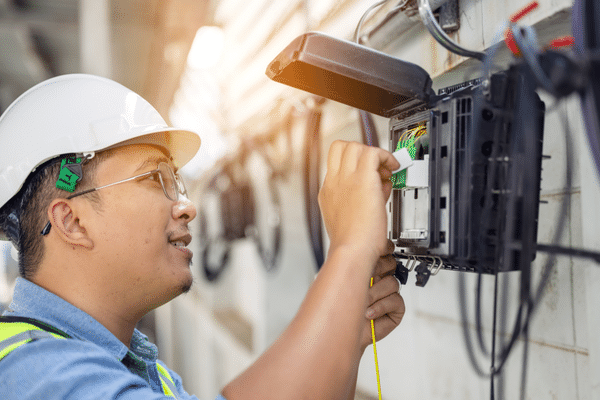

Identifying a cut or damaged fiber optic cable begins with a thorough visual inspection. This involves meticulously examining the entire cable length for signs of physical damage like cuts, kinks, or fraying. Pay special attention to areas where the line is bent or twisted, as these are common sites for damage. Also, look for signs of wear and tear on the protective jacket, as this could indicate potential damage to the internal components. Remember to follow safety procedures during visual inspection, including using protective gear to prevent personal injury.

An Optical Time Domain Reflectometer (OTDR) is utilized for a more comprehensive assessment of cable integrity. An OTDR is a fiber optic technician’s indispensable tool for measuring the time and intensity of light reflected along an optical fiber. By sending a series of light pulses into the thread and measuring the reflected light, an OTDR can provide a detailed profile of the cable’s condition. Any significant change in the line, such as cuts or sharp bends, will cause a substantial amount of light to be reflected and can be detected by the OTDR. The device then interprets these signals and presents the data graphically, enabling the identification of faults with remarkable precision.

By combining visual inspection and OTDR testing, technicians can accurately locate damage, assess its severity, and determine the most appropriate repair strategy.

Before you start the repair process, gathering all necessary tools is essential to ensure a smooth and efficient workflow. The tools needed include a fusion splicer, fiber cleaver, fiber stripper, heat shrink tubing, fiber splice trays, and fiber optic cleaning supplies. You will also need protective gear to ensure your safety throughout the process.

Once you have all the necessary tools, the first step in the repair process is preparing the fiber ends. This involves using a fiber stripper to strip away the protective jacket, exposing the fiber carefully. Next, the exposed fiber should be cleaned using fiber optic cleaning supplies to remove dirt or debris. It’s essential to be gentle during this process to avoid damaging the fiber.

Fusion splicing is a technique that joins two fiber optic cables end-to-end, creating a single long fiber. The process involves aligning the cable ends and using a fusion splicer to melt or fuse the ends. This method ensures a continuous optical path, allowing the light signals to pass through efficiently. It’s crucial to clean and inspect the spliced area for any flaws or inconsistencies.

Using connectors or mechanical splices may be a more suitable option in some situations. A mechanical splice involves aligning the fiber ends and holding them in place with a unique sleeve, while a connector allows the fibers to be disconnected and reconnected as needed. These methods are usually easier and quicker than fusion splicing but may not provide the same level of signal quality. Choose the way that best suits your specific situation and requirements.

Remember, repairing a fiber optic cable requires high precision and care. Following these steps, you can effectively improve a cut or damaged fiber optic cable and restore optimal data transmission.

A comprehensive repair kit is instrumental when dealing with a damaged fiber optic cable. This ensures you have all the necessary tools to swiftly and effectively rectify any issues.

Remember, each situation may demand different tools and components; the above list is a fundamental guide. Always ensure your kit is well-stocked and fits the specific requirements of your fiber optic infrastructure.

Regardless of the complexity of the repair, the success of a fiber optic cable repair hinges on meticulous attention to detail and adherence to best practices. The following are a few pro tips to consider:

Keeping fiber optic cables clean is a prerequisite for successful repair. Always carefully clean the exposed fiber ends with specialized fiber optic cleaning supplies before proceeding with repairs. Make sure to inspect the fiber closely for any residual debris. A dirty or damaged thread can cause an unsuccessful splice and increase the cable’s signal loss.

The quality of your fiber cleaves directly impacts the success of your repair. A high-precision fiber cleaver ensures a clean, perpendicular cut with minimal fiber end face defect, which is crucial for a successful fusion splice. Be sure to handle the chopper carefully and replace the blade as the manufacturer recommends to maintain optimal performance.

After performing the repair, don’t forget to test and verify the quality of the connection. Use an Optical Time Domain Reflectometer (OTDR) to validate the integrity of the splice and ensure the light signals are passing through efficiently. This step is critical in confirming the successful repair of the fiber optic cable and ensuring optimal data transmission.

Maintaining the health of your fiber optic cable is fundamental to ensuring long-term, optimal performance. Routinely inspect your lines for visible damage and perform quality tests using tools like the Optical Time Domain Reflectometer to detect any issues early. Regular cleaning using specific fiber optic cleaning supplies also reduces signal loss and prolongs the cable’s lifespan. When repairs are necessary, adhere to detailed procedures and use the appropriate high-precision tools to ensure successful restoration of data transmission. Remember, the goal is not only to repair but to maintain the integrity of your fiber optic infrastructure, which requires a consistent and proactive approach. Following these best practices, you can safeguard your fiber optic cables and ensure their sustained performance.

A: To repair a broken fiber optic cable, you must first locate the cut or damaged area. Then, you can use a fiber optic cutter to cut out the damaged section. Next, strip the protective sheath and yarn from the cable to expose the fiber ends. Finally, use a fusion splicer to splice the fiber ends together and restore the continuity of the line.

A: If a fiber optic cable is cut, you can repair it by following these steps: 1) Locate the cut end. 2) Cut any sheath and yarn to expose the fiber. 3) Use a fiber optic stripper to remove the protective coating from the fiber. 4) Clean and inspect the fiber ends. 5) Use a fusion splicer to splice the fibers back together carefully. 6) Test the repaired cable to ensure it is working correctly.

A: To repair a broken fiber optic cable, you will need several tools, including a fiber optic stripper, fiber optic cutter, fusion splicer, fiber cleaver, and a high-precision fiber cleaver. These tools will help strip and prep the fiber ends, cut and splice the fibers, and ensure a precise and secure connection.

A: A fiber optic cutter is specifically designed to cut fiber optic cables. It is a precision tool that allows you to make clean and precise cuts without damaging the fiber. However, it is essential to use the cutter properly and follow safety guidelines to avoid accidents or damage to the cable.

A: A fusion splicer is a device that combines two fiber optic cables by fusing the fiber ends together. It works by aligning the stripped and prepared thread ends with an automated or manual alignment, then applying heat to melt the fibers and fuse them. This creates a strong and permanent connection between the two threads, restoring the continuity of the cable.

A: You will need a fusion splicer to splice fiber optic cables. First, strip and clean the fiber ends. Then, align the fiber ends using the fusion splicer’s alignment mechanism. Once the fibers are aligned, initiate the fusion process to melt and fuse the fibers. Finally, protect the splice point using a protective sleeve or heat shrink tubing. Follow the manufacturer’s instructions for your specific fusion splicer.

A: While it is possible to repair a broken fiber optic cable without a fusion splicer, it is not recommended. Fusion splicers provide the most reliable and secure connection for fiber optic cables. Alternative methods like mechanical splicing or connectors may introduce more signal loss and can be less reliable than fusion splicing.

A: A fiber optic stripper is a tool used to remove the protective coating from a fiber optic cable without damaging the fiber itself. It typically has adjustable cutting blades to ensure precise and consistent cuts. In cable repair, a fiber optic stripper strips the protective coating from the cut end of the cable before splicing the fibers together.

A: If the end of the fiber is damaged, it may not be possible to repair the cable. In this case, you will need to replace the damaged section of the line with a new one. Contact your fiber optic supplier or a professional technician for assistance obtaining and installing a replacement fiber optic cable.

A: To prevent fiber optic cable damage, it is essential to handle the cables carefully and follow proper installation and maintenance procedures. Avoid bending the lines beyond their minimum bending radius, protect them from excessive tension or pulling forces, and ensure they are adequately protected from environmental factors such as moisture or extreme temperatures. Regular inspections and cleaning of connectors and cables can also help prevent damage.

Recommend Reading:xd dd