To make efficient communication possible across different applications, pigtail cable assemblies and connectors are crucial in the ever-changing world of technology. This manual provides a comprehensive study of pigtail cable assemblies that includes how they are made, what they do, and why we need them. By explaining what types of connectors are usually used together with these cables, we can understand better why connections need to be dependable. Knowledge about materials, terminologies, and installation methods will help readers choose pigtails that best suit their requirements, hence improving performance and productivity levels in projects.

Pigtail cable assemblies are a single cable with one or more terminated ends. They connect two or more devices and find their use in telecommunications and data communications, where they serve as a reliable means of transmitting signals. The pigtail’s key role is to offer flexibility in connections so as to minimize environmental signal interference or loss resulting from wearing out. Pigtails usually come together with different connector types like SCs, LCs and STs, among others, thereby making them fit easily into any existing system without much hassle involved during integration stages; they are also made up of materials such as fiber optic or copper wires depending on what they will be used for because different applications require different performances to be met by these components.

Optical fiber pigtail cables are used in many different areas, mainly, telecommunications, data centers, and networking environments. It is ideal for connecting optical devices such as switches, routers and servers because of its flexibility and capacity to transmit high bandwidth signals over long distances. In addition to this, they are often deployed in splice closures, which seamlessly integrate with existing fibre optic networks. More so, pigtails greatly assist in the simplicity of the installation process in LANs as well as WANs, where they can easily terminate to patch panels or connectors within structured cabling systems. Moreover, these wires create reliable communication pathways needed for the industrial automation sector and medical technology field, where reliability is key due to the sensitive equipment being used there.

In fiber optic systems, pigtail connectors are very important components with different designs for various needs. These are some of the most common types:

Every type of pigtail connector is created for different installation environments and performance requirements so they provide flexibility and reliability within many optical networking scenarios.

When choosing pigtail cables for fiber optic systems, there are two main things that must be considered; cable length and American Wire Gauge (AWG).

Conclusively, it is important to take into consideration both the cable length and the AWG while working on any fiber optic system since they affect factors such as signal attenuation, loss or even overall effectiveness within a network.

Understanding the performance variations between male connectors and female connectors is extremely important when choosing pigtail connectors for fiber optic applications. Male connectors have a polished end that can be inserted into another part, and are often used to make outgoing connections from equipment or junctions. In contrast, female connectors have a socket that accepts male plugs. The decision on whether to use a male connector or a female one depends mainly on what kind of application it will be used for and what types of connectors are already being used there. For example, if you want to connect with some device that has got only ports of feminine type – then you need male pigtails; besides this fact must also take into account such considerations as connector compatibility, installation space availability, and network design at large among other things too numerous mention here in detail but not forgetting about them anyway since they might come handy later during decision-making process itself should ensure seamless integration as well as reliable data transmission throughout optical network.

While assessing fiber optic cables and connectors, it is important to look at the following features and specifications:

Following guidelines and best practices is critical for fiber optic pigtail cable installation. Ensure that all elements, such as connectors and pigtail cables, are in line with the compatibility specifications of the network being installed. When routing during installation, ensure that cables do not bend too much or get strained physically because this might affect their performance negatively. Use correct tools for termination and management while ensuring the cleanliness of terminations and connection tightness to prevent reliability problems. Additionally, after installations, it is necessary to carry out appropriate tests like OTDRs, which can be used for testing optical fibers so that connections are verified before the network lights up and also any other potential issues are detected. It is important to always review installations against current standards so that they can remain at optimum level as they evolve with time.

For the long life of a pigtail fiber optic cable, proper maintenance practices must be followed. First and foremost, you should examine them frequently in order to identify any physical damage, such as cuts or abrasions, which could compromise signal integrity. Keep the installation environment clean and dry so that no contaminants can affect connectors; if not stored properly, they may accumulate dirt, which will eventually lead to poor transmission quality. Besides this, it is recommended to keep pigtails away from extreme temperatures, too hot or cold, because over time they get damaged due to exposure, thus losing their effectiveness gradually with time. Equally important is avoiding bending excessively or twisting them too much during the handling and installation process since these actions produce micro bends that result in performance degradation. Finally, it is good practice to regularly test connections by using an OTDR (Optical Time Domain Reflectometer), which helps monitor connection health status while maintaining optimal working conditions throughout the system components’ lifespan. Fiber optic pigtail cables can be made more reliable and have longer life spans by following these tips.

There are multiple brands that produce high-quality fiber optic pigtail cables. These include:

Customers often review these brands to show their durability and superior construction, thereby proving their efficiency in maintaining signal stability over time.

Customer feedback is important for evaluating fiber optic pigtail cable quality. Comments often discuss ease of installation, how well they work over time, and overall trustworthiness. For example, a lot of people who use Corning pigtails say that they are very tough and rarely have signal loss problems; this is often because these cables perform reliably, even in difficult environments. Some MTPs are praised because their design lets them fit seamlessly into any existing system, which can make things go quicker when new connections are set up. People like Amphenol products because they meet industry standards, so signals get transmitted correctly more often than not, which keeps customers happy with what they’re getting from them. What some may see as Tripp Lite’s biggest strength would be its low price tag combined with good performance, making it great for anyone on a tight budget who still needs something reliable but doesn’t want to break the bank over it. The general consensus among users is that all three brands work really well, whereas other things might fail, especially if you need something dependable but don’t have much money to spend.

There are several reputable online retailers that consistently rank on the top search results for high-quality fiber optic pigtail cables.

Through checking out these platforms, one can find reliable choices tailored to his/her individual needs for fiber optic networking.

The length of a fiber optic pigtail cable typically depends on the application and installation requirements. A pigtail cord can be 1 to 5 meters long.

Typically, in most cases, the standard length is around 2 meters (6.56 ft) because it has sufficient reach without so much slack that makes the installation complicated and difficult to manage cables.

When choosing a pigtail cable, you should consider the distance between the splice point and corresponding equipment as well as flexibility for routing within enclosures or cabinets. For more specialized installations longer than 5 meters are available but it should be used with care since this may lead to signal attenuation thereby affecting performance adversely.

The data shows that having an appropriately sized pigtail cable enhances the overall integrity of fiber optic systems which directly affects connection quality and reliability hence need for selecting right lengths basing on network infrastructure requirement.

Although pigtails are comparable with other types of optical fiber cables, they have distinct features that suit certain uses. In contrast to patch cords made for fast connections between devices, pigtail assemblies consist of a single fiber strand terminated by a connector at one end, which is mainly designed for fusion splicing to other fibers. Therefore, pigtails are preferred at termination points in network junctions while patch cords connect devices together over short distances.

Compared to ribbon cables that contain several fibers packaged together as a single unit, using pigtail cables enables more flexibility in managing individual fibers during installation especially when dealing with space-constrained areas. It should be noted though that ribbonizing can allow for higher-density installations but may require more complex termination procedures. Another advantage of using pigtails is their lower susceptibility to damages caused by the fact that each fiber is separate from others within cable construction. Each type has its place in the overall scheme of things within an optic networking environment and selection largely depends on what needs to be achieved concerning installation demands, system adaptability and overall performance expectations.

Pigtails were made for optics and do not work with coaxes. Coaxial cables have a central conductor encased in a dielectric insulator surrounded by an outer conductive shield, but fiber optic cables send data through light signals. These two cable types are necessary for any network to function but their construction methods and operational principles differ entirely from each other. Thus using them interchangeably would be impossible or impractical because pigtail cords cannot be employed for coaxial connections. In regard to good signal strength and performance it is advisable to employ standard types of coaxial cable like RG-6 or RG-59 when dealing with coaxials.

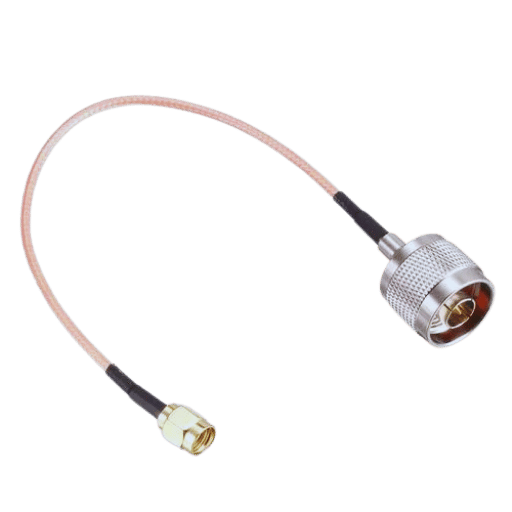

A: On one end of a pigtail cable assembly is a short cable with a connector, and on the other end are bare wires. They are often used for connecting different kinds of devices together and they come in many types like ethernet or coaxial cables.

A: When choosing an adapter, you should take into account what kind of pigtail cables (e.g., coaxial or Ethernet) you’re working with, as well as what type(s) of connectors it requires. Verify whether the part number fits; check if it’s male/female, SMA/RP-SMA/USB compliant, etc.

A: Yes – people frequently use them to link wireless antennas (like those used in Wi-Fi systems) up to routers or other wireless devices. To avoid signal loss, make sure that your WiFi system works with the chosen cables/connectors.

A: The term “pigtail 16 AWG” refers to American Wire Gauge sizing, which denotes how thick wires are – in this case, indicating thicker gauge size than most others at sixteen AWGs per foot length. Sixteen AWG pigtails can carry more current because they have larger diameters compared to thinner ones; therefore, thicker wires would be appropriate when dealing with higher-power applications.

A: There are several kinds of connectors that work together with pigtails, including SMA/RP-SMA/USB/Ethernet sockets, depending on the specific applications involved and the equipment compatibility required.

A: Pigtail jumper cables come in different lengths, such as 12 inches or 10 feet, among others. The length you choose should be dependent on where you are going to use it and how far apart these connection points might be from each other. It is important to use the correct size so as not to affect signal integrity.

A: The terms coaxial cable and coax cable can be used interchangeably. Both of them refer to a kind of wire that has got an inner conductor surrounded by tubular insulating layer, then followed by a metallic shield and outer insulating layer which is commonly employed when transmitting radio or television signals.

A: Absolutely! You can utilize pigtail cable assemblies within 4G as well as cellular systems provided that you have the right type of connectors for your mobile device. Ensure that they match up with each other accordingly in terms of both cable type and frequency band support required by suchlike equipments.

A: If you want to find out which SMA connector suits your needs better, first determine whether it should be male or female based on what is already available on site, then select either normal SMA or reverse polarity (rp-sma) depending on equipment specifications plus types of cables being used.

A: When considering adding foot cable extension; think about what kind of wire would suit this purpose, if connectors are compatible with each other and necessary measurements like number twelve inches or ten feet among others. Make sure also that quality does not suffer due to longer run but rather matches intended application at hand.