As data centers evolve towards 112G SerDes technology, OSFP (Octal Small Form Factor Pluggable) has become the mainstream packaging standard for 400G/800G transmission. In this evolution, thermal design has emerged as a key challenge. According to Dell’Oro, by 2026, 800G optical modules will account for 60% of data center spending, with thermal solutions directly impacting 30% of operational costs. This article will delve into the differences between the finned-top and flat-top OSFP designs and their respective application scenarios.

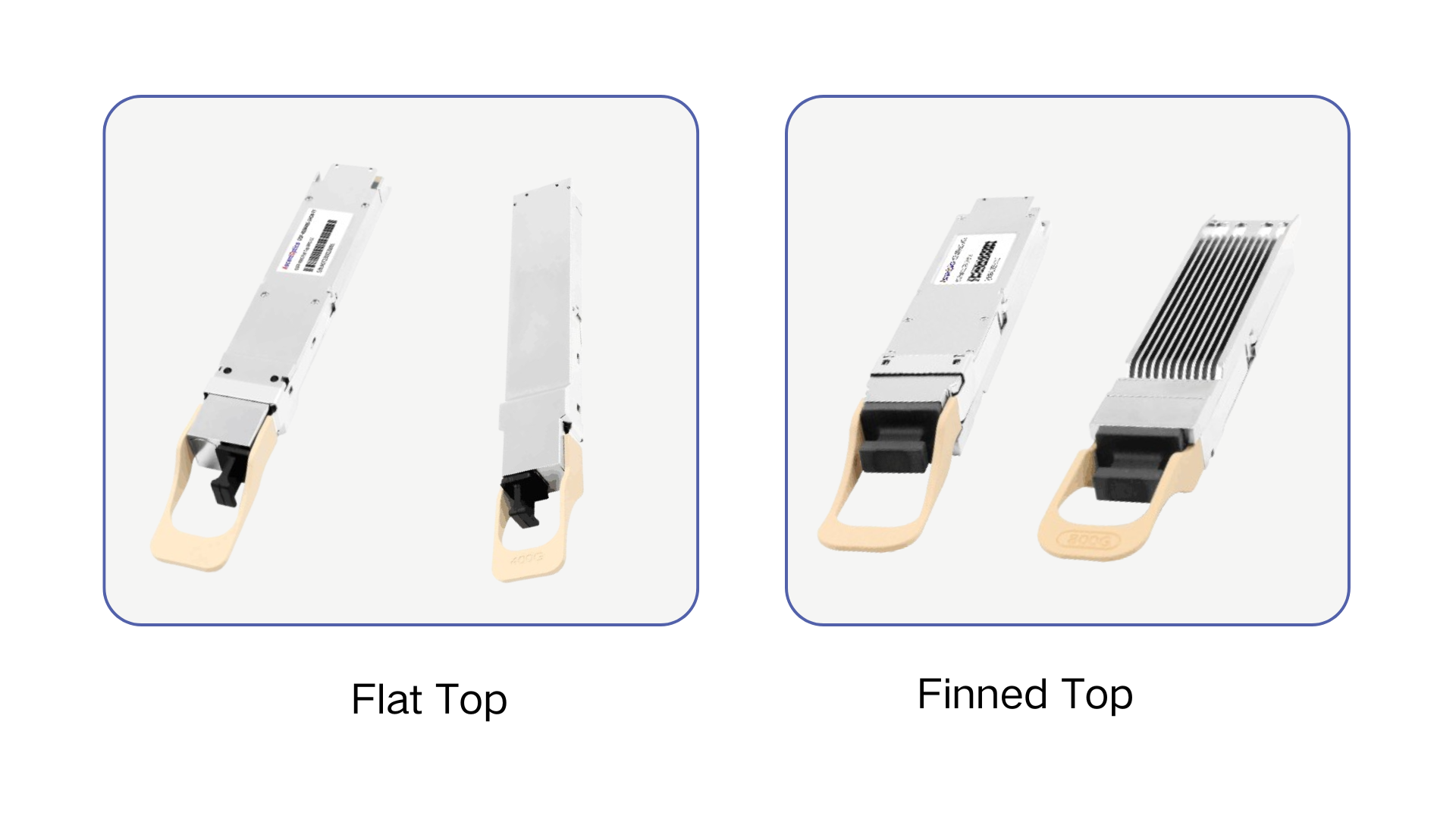

In the field of high-speed optical modules, the finned-top (with heat sinks) and flat-top designs are two key thermal solutions for OSFP packaged transceivers. Their differences directly impact deployment scenarios and performance.

Finned-top OSFP transceivers feature a heat sink with protruding fins on top, designed to maximize surface area for heat dissipation. This makes them bulkier but highly effective in environments with high thermal loads.

Flat-top OSFP transceivers, in contrast, have a smooth, flat surface, resulting in a more compact design suited for space-constrained applications. The physical dimensions of finned-top transceivers often make them incompatible with certain low-profile slots, while flat-top models fit more easily into compact devices like network adapters.

Thermal performance is a critical differentiator. Finned-top transceivers excel at dissipating heat, thanks to their finned heat sinks, which allow for better airflow and cooling in high-density environments like data center switches.

Flat-top transceivers rely on passive cooling or external airflow, which may limit their performance in high-heat scenarios but makes them suitable for less thermally demanding setups. Effective thermal management directly impacts transceiver reliability and longevity, particularly in 800G applications where heat generation is significant.

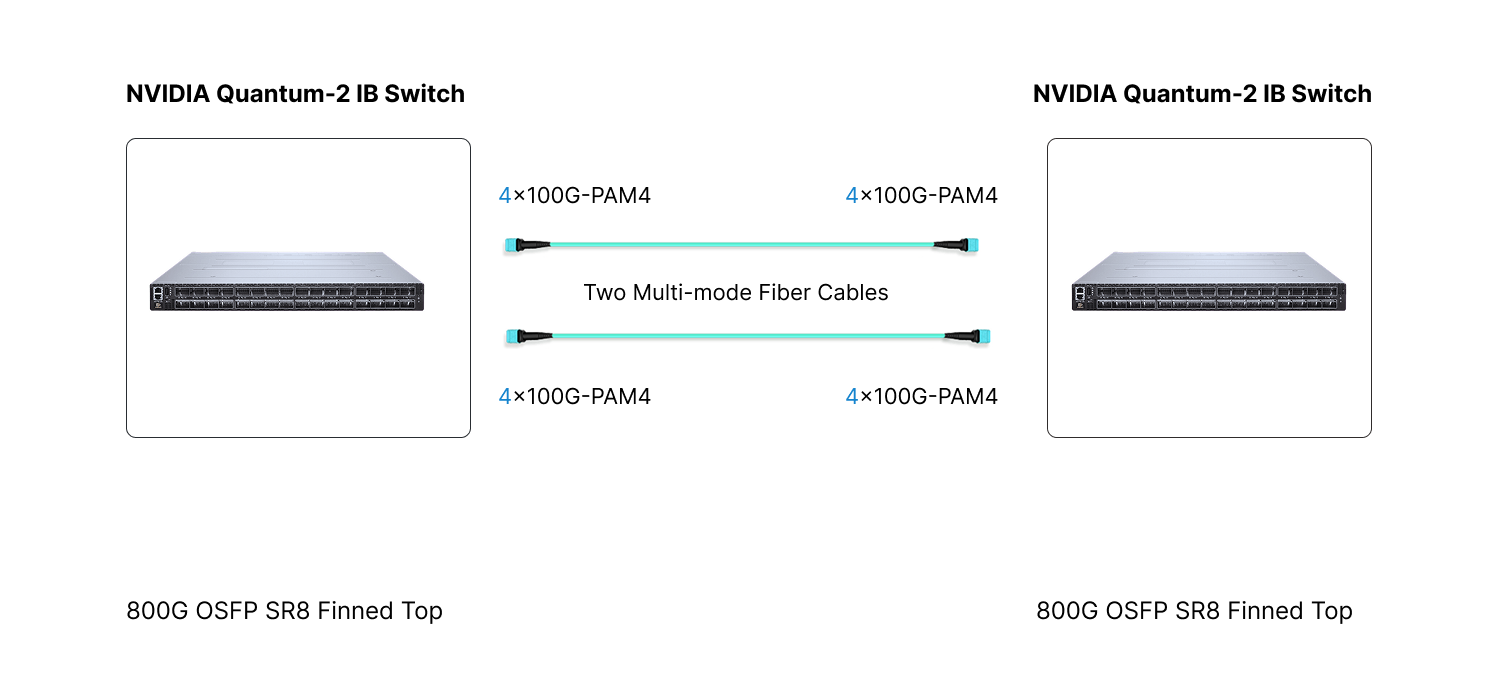

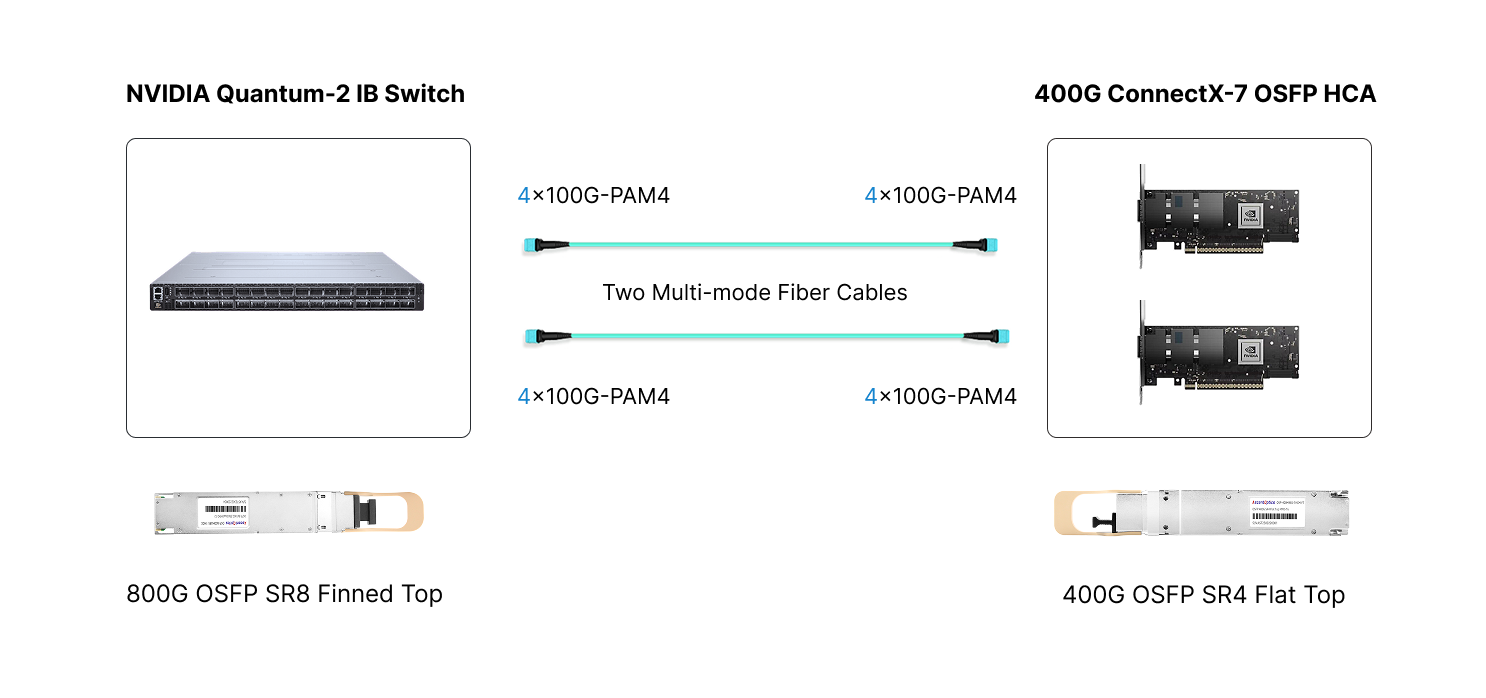

Finned-top transceivers are commonly used in high-performance switches, such as NVIDIA’s Quantum-2 InfiniBand or Spectrum-4 Ethernet platforms, where robust cooling is necessary to support high data rates.

Flat-top transceivers are typically found in network adapters (e.g., NVIDIA ConnectX-7) or Data Processing Units (DPUs) like BlueField-3, where space constraints are a priority. Compatibility with specific slots and equipment must be verified, as finned-top designs may not fit in low-profile slots, while flat-top models may struggle in high-heat switch environments.

Finned-top transceivers are ideal for high-density data centers where thermal management is critical. They are commonly used in 800G OSFP models like SR8 (short-range, multi-mode), DR8 (single-mode, 500m), and 2FR4 (single-mode, 2km), which support high-throughput applications such as AI training clusters and cloud computing. Their ability to handle intense thermal loads makes them a go-to choice for large-scale, high-performance networks.

Flat-top transceivers shine in scenarios with lower thermal demands or space limitations. They are often used in 400G OSFP models like SR4 (short-range, multi-mode) or DR4 (single-mode, 500m), which are deployed in network adapters or DPUs for enterprise networks or edge computing. Their compact design ensures compatibility with devices where physical space is at a premium, such as in rack-mounted servers.

Both 400G and 800G OSFP transceivers leverage PAM4 (Pulse Amplitude Modulation with 4 levels) to achieve high data rates. 400G transceivers operate at 425 Gbps, while 800G models push up to 850 Gbps, using electrical interfaces like 800GAUI-8 for efficient signal transmission. The choice of finned-top or flat-top does not directly affect data rates but influences the environments where these rates can be reliably sustained.

Transmission distance varies by transceiver type and fiber used. Finned-top and flat-top transceivers support similar standards, such as SR8 (100m over multi-mode fiber), DR4/DR8 (500m over single-mode fiber), and FR4/2FR4 (2km over single-mode fiber). The choice of design depends on the thermal and spatial requirements of the deployment rather than distance capabilities.

Finned-top transceivers typically consume more power due to their advanced cooling requirements, often ranging from 12-16W for 800G models. Flat-top transceivers are more power-efficient, consuming around 8-12W for 400G models, making them attractive for energy-conscious deployments. Data center operators must balance power efficiency with performance needs, as higher power consumption can increase operational costs.

Finned-top transceivers offer superior cooling, making them ideal for high-density, high-heat environments like large-scale data centers. Their integration with advanced switch architectures ensures optimal performance in demanding applications, such as AI and machine learning workloads. The robust design also enhances reliability under continuous high-throughput operation.

Flat-top transceivers are compact and versatile, fitting into space-constrained devices like network adapters and DPUs. Their lower power consumption and simpler thermal management make them cost-effective for enterprise networks or edge deployments where heat dissipation is less of a concern.

Finned-top transceivers may be incompatible with low-profile slots, limiting their use in compact systems. Flat-top transceivers, while space-efficient, may underperform in high-heat environments, risking thermal throttling or reduced lifespan. Network architects must weigh performance, cost, and compatibility when selecting a design.

When choosing between finned-top and flat-top OSFP transceivers, consider the network environment (e.g., data center vs. enterprise), thermal requirements, and hardware compatibility. Budget constraints and scalability plans also play a role, as finned-top models may require additional cooling infrastructure, while flat-top models offer cost savings in less demanding setups.

Choose finned-top transceivers for high-performance switches in data centers with significant thermal loads. Opt for flat-top transceivers in space-constrained or lower-heat environments, such as network adapters or edge devices. For future-proofing, consider hybrid setups where both designs can coexist to meet evolving network demands.

Evolution of OSFP Transceivers

The transition from 400G to 800G OSFP transceivers reflects the growing demand for bandwidth in AI, cloud, and 6G applications. Emerging standards, such as 1.6T transceivers, are on the horizon, promising even higher data rates. Photonics and coherent technologies are also shaping the future, enabling longer transmission distances and improved efficiency.

Market Predictions

The adoption of 800G transceivers is expected to accelerate in data centers, driven by AI workloads and high-speed computing. Advances in thermal management, such as liquid cooling integration, may reduce the reliance on finned-top designs, while compact flat-top transceivers will remain popular in edge computing. The market is likely to see increased standardization and cost reductions as 800G becomes mainstream.

A: The main difference lies in their thermal management and physical design: finned-top transceivers have heat sinks with fins for superior cooling in high-heat environments, while flat-top transceivers are compact with simpler thermal management for space-constrained setups.

A: Check the equipment’s documentation for slot compatibility and thermal requirements. Finned-top transceivers fit high-performance switches with robust cooling, while flat-top models suit adapters or DPUs with low-profile slots.

A: Finned-top transceivers may have higher upfront costs due to their advanced cooling design, but pricing varies by vendor and model. Check with suppliers for specific cost comparisons.

A: Flat-top transceivers may be used in switches with adequate external cooling, but they are less effective in high-heat environments compared to finned-top models.

A: Future trends include the rise of 1.6T transceivers, advancements in photonics, and improved thermal management solutions like liquid cooling, driven by AI and 6G demands.