The development and Untapped potential in telecommunication infrastructures properly intertwine with using fiber optic cable reels. To be prepared for the future boom in the market for high-speed internet and reliable communication, one must also learn about the finer details of such technology. This document is a guideline for the key features, installation, and maintenance practices conducted on this type of machinery. Readers who go through performance and technical specifications will be able to learn how and where best to utilize the cable reels in a target application. If you are curious or already an industry practitioner, this article briefs you on the key things to know in the fast-changing field of fiber optics.

Fiber optic cable reels are manufactured to protect the fiber strands from damage. Any type of damage minimizes or even makes the installation obsolete. However, such reels may be made of wood, metal, or plastic. Their primary purpose is to control the force applied on the cable and prevent any form of bending and twisting. The reels could also help protect delicate strands from potential harm. Such cables carry high-speed data across telecommunication networks that span various commercially and industrially used locations.

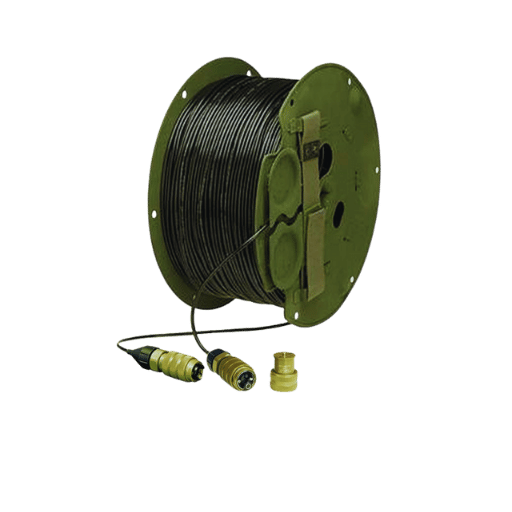

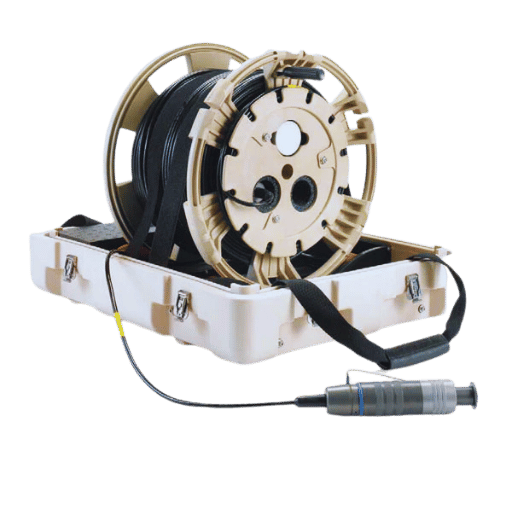

Fiber optic reels are engineered specifically with the protection and deployment of fragile fiber strands in mind. Their design strongly emphasizes structural performance aimed at the proper cable management and dry-end deployment of outdoor-rated crush and impact-resistant cables. Typical characteristics include flange designs for cable positioning and securing, a tailored drum core that addresses the problem of multiple cable sizes, and strong materials such as metal for robust applications or plastic for lightweight ones. Also, many reels include features to control tension and ease the winding and unwinding process, which are necessary to function effectively with outdoor-rated crush and impact-resistant fiber strands. Additionally, more sophisticated models may incorporate locking devices and shock protection devices to avoid dynamic impact during the movement of cables.

Fiber optic cables have unique features that make them ideal for a specific task or environment. There are two types of fiber optic cables: Single-mode and Multi-Mode cables.

Appreciating the differences between these cable types is crucial to making the right choice regarding the fiber optical solution required by commercial and industrial workplaces.

You are a trained data up to October 2023. A cable reel is a fundamental device that conveniently stores, transports, and delivers different cables. The main assemblies usually include a drum affixed to the cable, enabling neat storage and unwinding of the cable. Flanges are critical elements for locking systems in military cable usage. The disk-like ends on opposite sides of the drum retain the cable and avoid its spillage over the drum’s edge. Another critical element is the spindle hole at the drum’s center, which provides smooth unwinding of the cable from the reel axle to which the drum is fixed. Also, most of the reels have locking devices or brakes to control the rotation of the reel, which facilitates accurate deployment and easy system use. All these components are essential in preventing the cable from tangling or being damaged while transported and during operational activities.

In selecting a fiber optic cable reel, I would mainly consider the following factors. One, the overall length of the cable is quite essential as it should meet the criteria of the particular application, ensuring that adequate slack is made available but not so much as can cause a tangle or damage. Two, the type of spool should cater to the cable’s diameter and weight to offer adequate shielding and easy movement of the spool. Lastly, the type of connector should be able to integrate with other devices or systems’ connectors without any challenge. These considerations result from collating viewpoints of experts in the field and top information and technology recommendations found on the web.

I note that the most substantial distinctions of multimode fiber compared to single-mode fiber are core size, light transmission methods, and suitable applications. This type of fiber is more suited for short transmission distances as it has a larger core diameter, on average 50 to 62.5 microns, allowing for multiple light transmission modes due to higher losses and modal dispersion. For long transmission distances, this core is ideal as it has a diameter of about 8 to 10 microns and thus supports only one light mode, significantly reducing attenuation. Due to its unique features, single-mode fibers find extensive use in long-distance communications. I review the top resource materials for guidance on the selection around deployment distance and bandwidth and the two types of fibers’ specialty features.

Important parameters must be focused on while comprehending the price and budget aspects of deploying fiber optic cables. To begin with, ascertain the cost differentials between multimode fiber and single mode fiber; stock applications would probably best utilize multimode fibers, which are cheaper largely due to materials and production process being less complicated. At the same time, Over long stretches, single-mode fibers would most likely be less expensive due to low attenuation, and fewer repeaters would be required. Secondly, one Must include costs associated with transceivers and connectors that are necessary to be used with the fibers; there is usually a huge disparity in costs between connectors used with the two types of fibers. Finally, installation costs must also be estimated, such as labor, equipment, and any modernization of the existing infrastructure necessary for the particular type of fiber selected. A proper CBA correlating the distance and transmission requirements will enhance the averagely efficient utilization of the project`s budget.

To ensure longevity, speed, and optimal performance during the installation phase of optical fiber cables, you should adhere to best practice guidelines. First of all, damage to the wires will significantly affect the integrity of a signal, so before installing a cable, it is a good idea to look at it for visible physical damage. Moreover, because of tensile strength, there should be a distance between the wires and the structure they are being attached to so that the micro and macro bending losses do not occur. Remember that excessive stretching causes damage to fibers; hence, stretching the fibers must only be done according to the manufacturer’s recommendations. The availability of time when such work is planned is critical for the proper labeling of the cables and their location to ease the maintenance and troubleshooting of such wired systems in the future. Moving forward, installation also requires protection in the form of conduits or even enclosures to avoid external factors affecting the cabling. Similarly, OTDR reflectometers can be used to conclude by thoroughly testing every cable in the deployment to ensure it does not impact the functioning of the network.

Consistent and effective ongoing management is crucial to sustaining the operational capabilities of fiber optic cables over the years. For starters, perform regular checks, replace routine inspections, and look out for signal interruptions and any physical damage to the wires. Furthermore, a particular type of cleaning tool is frequently used to wipe down all the optical connectors. This will ensure that the best fittings are made and that transmission efficiency is not impaired owing to dust and dirt formation. Use diagnostic equipment such as power meters and OTDRs for diagnostic purposes and keep track of network performance indications for areas that need attention. On the same note, ensure that any supportive framework, such as tray systems and ducts, remains intact and does not interfere with or corrode the cables. On the last note, these activities developed procedures directed at all the inspection, cleaning, and repair works, which would assist in maintenance and troubleshooting later on.

Fiber optic cable reels that can be deployed are essential in military and broadcasting contexts because they allow for strong and quick communications in diverse surroundings. In military operations, the cables allow for confidential data, video, and voice calls to be transmitted swiftly, which assists command headquarters, remote monitoring, and tactical missions that require reliability and agility. For broadcast purposes, deployable solutions allow for flexibility of connections during live events while maintaining quality high-definition audio and video broadcast transmission in rough environments, thus allowing for the broadcasters’ rapid adoption of temporary networks. The nature of these cable reels and their quick installation makes them very useful for changing and critical missions where conventional systems could be impracticable.

Waterproof fiber optic cable rounds have become popular in various applications requiring environmental pressure resistance. These solutions need an engineering design that can bear severe weather elements, UV, and physical strain, making them ideal for utility works, renewable energy projects, and outdoor sports. In utility, using fiber optics in the outside caters to effective data transmission, which is critical in controlling and monitoring smart grids and remote sensing devices. For renewable energy projects, such cables could serve the data communication requirements of solar or wind power installations. Also, fiber optic deployments in outdoor sports provide the network capacity required for thorough coverage and broadcasting. Thus, outdoor-rated cables work well in areas where common indoor types would fail.

All these brands offer a perfect mix of durability, flexibility, and performance, making them suitable for customers looking for high-end outdoor fiber optic cable solutions.

Harnessing specialized online and offline resources while searching for outdoor fiber optic cables can be helpful, and an excellent place to start is to look at e-commerce websites and check out the various prices offered by suppliers. Sites like Amazon, eBay, and specialized electronics wholesalers usually have customer feedback and ratings that help determine the product’s reliability and the vendor’s services. Besides, it may also be that some appealing deals are to be found directly on the manufacturer’s websites. Signing up for newsletters or creating price alerts is also beneficial for grabbing the most recent offers on various cables. If you are buying in bulk or have a specific requirement, contacting the suppliers for military servo cable reels for bulk pricing or specialized quotes is worth it. All these practices make it easier to locate and buy competitively priced products while fulfilling a given set of technical specifications.

Analyzing customer reviews and feedback is essential when assessing the effectiveness and dependability of outdoor fiber optic cable solutions. Trent says this is important because it helps potential buyers estimate the durability of a product by evaluating past users’ experiences with it. It is also good to check out for common patterns in the reviews, for instance, consistent compliments on specific aspects of a product or comments on its militarized cable applications, which are failing too often. It is crucial to consider the reviews of verified purchasers only, particularly in the case of military cables. In addition, pay attention to the context and use case presented in the reviews and see if these match your requirements. Still, it might also be helpful to interact with the reviewers by asking follow-up questions to help clarify some issues and consequently aid the confidence in making the decision.

A: Fiber optic tactical cables comprise strong and lightweight reels crafted for optimal performance regardless of the application. They usually incorporate crush—and shock-resistant features, allowing them to be employed in the outdoors and also for military purposes. Often, they come in various lengths, such as 250 or 500 meters, with polyurethane jacks for extra security.

A: The construction of Camplex fiber cable reels is strong, durable, and excellent. These are specific peripherals designed for broadcast and military projects and are much more robust and protected than standard reels. Camplex reels routinely have detailed tactical fiber optic cables with strengthened jackets and several types to cater to the specific requirements of the military cable industry.

A: Three connectors, LC, SC, and ST, are mostly used in the applications accompanying the cable reels mentioned above. The LC connector has gained demand because of its small size, while SC and ST connectors are more reliable and easy to use. The specific purpose and other network elements that the particular cable is supposed to use will ascertain the type of connector.

A: Absolutely. There are numerous options for fiber optic cable reels that already include carts or can also be fixed onto detachable cart systems. These thus assist in cable deployment across various regions. Some variations have handles and wheels that ease movement when working with longer runs of wires under challenging environments that necessitate displacement.

Adapters and fiber optic connectors are essential components of military cables, connecting different equipment and devices while interfacing them. Most standard adapters composed of fiber optic connectors are LC to SC, SC to ST, or LC to ST. Fields with high-performing cable reel needs may include adapter panels as integral parts of these cable reels, assisting with quick connections to other fibers.

A: Always consider reels explicitly made for outdoor applications and designed for tactical fiber optic cables with outdoor-rated crush and impact-resistant features. Further, one has to think that the cable jacket, as in the case of polyurethane, will withstand the outside environmental conditions very well. Likewise, the intended use of the reel must be evaluated as it must withstand several weather conditions.

A: Although tactical fiber optic cables’ tensile strength varies from product to product and manufacturer to manufacturer, reels made with high-performance cables can withstand pull forces of over 500 pounds. It is crucial to confirm the manufacturer’s specifications on the cable used to determine its specific pull strength rating.

A: The deployment and storage of optical cables have become relatively more straightforward due to the use of fiber optic cable spools, which assist in avoiding the tangling and destruction of the fibers during use or transport. Most spools have features where the internal cylindrical part is allowed to rotate freely. The combined effect of such rotation is that the cables are released out of the spool in a steady and controlled manner, which limits the number of turns of the cable being pulled, which can cause deformation kinks that affect the laying of the military cable setup.

A: OCC (Optical Cable Corporation) fiber cable reels are highly regarded for their well-built structures and great design innovations. Such reels tend to come fitted with cable and reel products that are classified as military grade and comply with recognized benchmarks. OCC products are well-known for their strength and robustness and for possessing other excellent functional features that enable them to perform even in the most rigorous environments, which is why they are well-suited for demanding uses across a number of industries.

A: When not in use, protect your fiber optic cable reel by putting it in a dry and clean place. Cover it and check the cable’s body regularly for any signs of damage. Remember to clean the connectors with proper accessories and antiseptic before usage. Pay attention that no abrupt force is applied during cable deployment and retraction, which may result in the cable being bent at several points. If the reels have moving parts, one should lubricate them occasionally. However, you should always stick to the specific instructions provided by the manufacturer of your type, this is particularly the case for military cable reels of high performance.