Within the realm of optic fibers, accuracy is paramount. A process that is uncommonly highlighted yet pivotal in aiding effective fiber optic performance is fiber cleaving. Cleaving the optical fiber affects how light passes through the fiber optic systems, thus determining its reliability. The procedure is not as simple as it might sound. Achieving connections with the least amount of signal loss and the most accuracy possible requires seasoned hands. In this guide, we will look into the science of fiber cleaving alongside the tools and techniques to achieve it step by step. By the end of the guide, you are confident enough to hone your capabilities and skills in working on fiber optic projects.

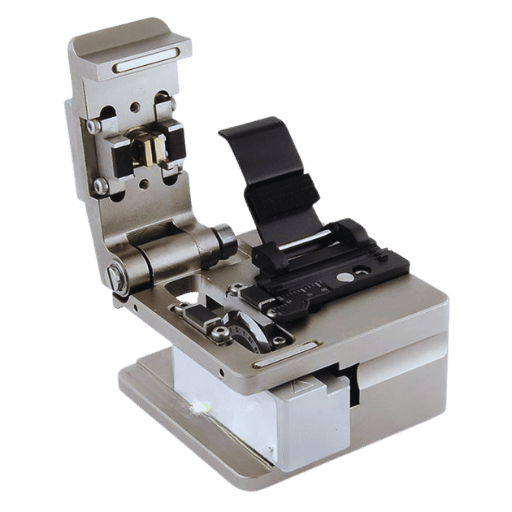

A fiber cleaver is a highly refined device that cuts optical fibers to create a flat end face, which is important for splicing or connectorization. It does this by applying a precise amount of pressure onto the score line and then applying tension, which causes the fiber to break along the score line. All of this is done to reduce edge irregularities and insertion loss, which are significant in retaining optimum signal strength in any fiber optic network.

In fiber optic installation and maintenance, a Fiber cleaver is an essential tool that makes clean cuts of the optical fiber. The cleaved fibers are essential for low-loss connections or splices with intact connections. The cleaving steps require scoring the fiber while pulling it apart to split it cleanly, with an even face perpendicular to the axis of the fiber, and smooth. Supporting reliable light communication systems, precise cleaving bolsters effective light transmission, which is the core foundation of fiber optics.

A fiber optic cleaver works by scoring the fiber and then exposing it to a certain amount of pressure, which causes a clean break. The cleaver uses a blade to score the glass surface lightly, and this score will break off cleanly with tension. High-quality cleavers guarantee that the cut will be straight and perpendicular to the axis of the fiber as best as possible, so the end face will be cut as the end face of the fiber will be best suited for light passage and signal loss.

Optical cleaving Tools are essential in the field of optics. In preparing the ends of the fibers for splicing as part of the Termination processes, cleavers make specific optical cables with minimal signal losses and high quality, ensuring strong connections. In addition, cleaving assists in the placement of the connectors by achieving the correct length needed in the steps performed somewhere to increase the level of measuring device sterility and precision. Concerning testing the performance of the optical fiber, cleaving ensures it is prepared with a smooth edge seamlessly cut perpendicular to the axis, eliminating any common flaws encountered during dependable analysis. These routines underscore the need to maintain control concerning the performance and dependability to be efficiently maintained.

The quality of cleaver blades greatly affects splicing in both single-mode and multi-mode applications. The cleaver blade’s effectiveness hinges on its sharpness, long-term consistency, and durability. A bladed laser application will receive higher-quality signals with lower splice losses due to cleaner cuts provided by high-quality blades. Also, cost-efficient blades with adjustable cutting positions have longer lifespans, making them ideal for frequent use. Infrequent damage and operation will be ensured when a cleaver blade is tailor-made for the fiber type and diameter.

Fujikura and Jonard Tools are well-known in fiber optic technology, albeit for differing reasons. Fujikura garners recognition for its high-performance fusion splicing equipment and cleaving tools, which excel in precision and reliability, making it popular for large-scale telecommunication and data center operations. Jonard Tools specializes in cleavers and stripping tools designed for everyday fiber optic maintenance and installations, and it is popular for its durable yet affordable tools designed specifically for field technicians. While Fujikura leans towards advanced specialized equipment, Jonard Tools focuses on general semi-professional grade tools for practicality.

A fiber stripper is a vital instrument for an optical fiber’s preparation process, meant explicitly for removing coatings while not harming the core and cladding underneath. This step is necessary in the case of cleaving and splicing to guarantee that they can be performed accurately; poorly stripped fibers will cause more excellent attenuation and connection loss, which is undesirable. Primary modern design considerations for fiber strippers include accurate cutting and set blade height of the coatings, whether single-mode, multimode, or specialty fibers, for coarse or fine coating removal.

Studies show that properly designed fiber strippers effectively reduce micro-cracking or scratch damage to the fibers. Most products are designed to accommodate industry-standard coating thicknesses of 250 μm or 900 μm, ensuring wide applicability. For instance, advanced thermal strippers increase process reliability by mechanically softening tacky coatings through heated air applicators, reducing the stripping effort needed.

The fiber stripper must be regularly maintained and properly handled to guarantee optimal performance and the life span of splicers. Technicians are urged to check the blade’s edge for wear and clean it of any prior residue or contaminants. Following the manufacturer’s recommendations and having a dependable fiber stripper within the system prep process greatly improves the consistency and integrity of installations performed on the optical fibers.

The scribe is of utmost importance in the preparation of optical fiber, as it is instrumental in scoring the fiber prior to cleaving. Its role is particularly important in achieving a clean optical break because it minimizes loss and maximizes signal strength across the optical network. A scribe is usually equipped with a blade tip made of either carbide or diamond, which is the choice material given their unparalleled accuracy and longevity.

Research indicates that a fiber scored with a scribe undergoes a more controlled cleaving process with less chance of unsightly fractures. This helps reduce insertion loss while optimizing the fiber’s performance. Sharp blade durability is also vital in providing precision during the profile bounding scribing process efforts. Consistent use ensures smoother fiber ends, which is essential for low attenuation during data transmission.

Users must select their preferred scribe based on the fiber diameter and type being processed, along with some ergonomics designs. Such designs boost accuracy and comfort while reducing the risk of hand strain on repeated actions. Upgrading optical workstations with tested scribes boosts overall operational and guaranteed reliability in fiber installations on top of the need for timely assessments and replacement for sustained accuracy over the years.

The skillful execution of any fusion splicing procedure is determined by the core alignment accuracy of the fiber parts, the cleanliness of the work area, and the capability of the fusion splicer. The splice area must be clean to prevent contamination that may deteriorate the bond. Advanced splicing machines utilize sophisticated alignment methods, which, in conjunction with precise heating, yield reliable, low-loss splices. Consistent maintenance of the fibers and the equipment ensures dependable service.

The maintenance of cleaver blades is critical to ensure precise fiber optic cleaving, which impacts splice quality and network functionality. Damaged or dull cleaver blades provoke irregular cleaving, which increases signal loss. The manufacturer recommends that Optimum performance be achieved through regular inspection and blade replacement. Moreover, the risk of dirt-and-debris interference is minimized by keeping the blade’s surroundings clean, mainly while working with multimode optical fiber cables. Adequate maintenance ensures reliable and efficient operability while extending the blade’s lifespan.

The right tools are critically important to achieve consistent, high-quality splicing results. Pairing the splicer with the proper cleaver ensures the fiber ends are clean and accurate. The stripping tools should also be high quality to prevent damage to the fiber coating, and the cleaner should not be abrasive to the fiber’s diameter. All tools need to be maintained and calibrated regularly per the manufacturer’s recommendations. Otherwise, the performance will be compromised, and the chance of making mistakes increases. Using trusted tools that are well maintained increases the overall durability of the splice in addition to efficiency.

A: Optical fiber cleaver is classified under tools used in the fiber optic industry. With the cleaver, the technician can cut the optical fibers in a way that yields a clean and smooth end face. It is essential to the fiber optic field because a precise cleave is performed to achieve perfection during the fusion splicing and termination of the fiber.

A: The difference between a precision fiber cleaver and a regular type lies in the degree of accuracy a cleaver can achieve. A precision fiber cleaver can have an accuracy of about 0.5°, while a regular fiber cutter has no guarantees of accuracy. This level of accuracy is critical for highly accurate tasks like joining fiber optics using a fusion splicer for termination.

A: Cladding refers to the outer optical jelly-like material enveloping the fiber’s core, which helps maintain the light within the fiber’s core through total internal reflection. As it concerns the cleaving process, ensuring the alignment of fibers with cladding diameter is critical for consistency and precision.

A: In the case of optical fibers, the cleave angle is defined as the angle at which the fiber is cut. The cleave angle is usually 0.5° and is essential because it determines the quality of the fiber end face and affects other processes like optical fiber fusion and splicing.

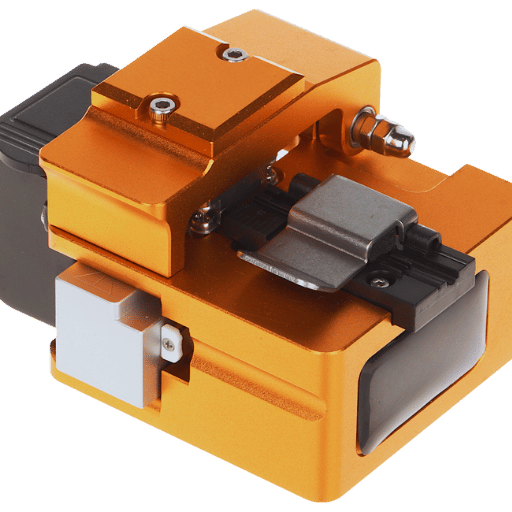

A: Automatic fiber cleavers, such as the CT -30 fiber cleaver, improve efficiency by automating blade and fiber placement. They do not require as much supervision, which saves time and improves the uniformity of cleaves, which is especially important for single-mode fibers.

A: Alignment accuracy is maintained using an adaptor or holder that interfaces with the cleaver at the fiber’s core or cladding. The Jonard Tools fc-500 precision fiber cleaver uses ergonomic features to guide fixed fiber positioning and improve consistency.

A: An optical fiber cleaver finds its practical application in the FTTH domain for preparing spliceable fiber optic cables, making fiber end faces for connectors, and adjusting firing for termination processes.

A: The fiber diameter is critical because the cleaver must be adjusted to accommodate different fiber diameters. Cladding diameters are various, so the cleave must be adjustable.

A: After a cleaving step, a fusion splicer joins a pair of fibers by aligning and fusing them. The cleave’s accuracy determines the effectiveness of the splice; with inaccurate cleaving, high splice loss is virtually guaranteed.

A: Tools like the CT50 fiber cleaver provide automation and extreme accuracy in cleaving. Their automated features often include scrap collectors and rotation mechanisms, guaranteeing a clean environment. They also enhance cleave consistency, improving fiber optic work quality with single-mode and multi-mode fibers.

1. An Examination of the Fiber Cleaving Technique “Breaking Fiber with a Tension Force” for Use in a New Single-Fiber Cleaver Designed for Fiber Splicing

2. Recommended cleavers for fiber-optic information transmission.

3. Development of an Optical Fiber Cleaver with Angled Cleaving Mechanism