When it comes to maintaining a wheel, the bearing dust cap is the most neglected component in the process. Such a small component is very important since it acts as a barrier against dust, dirt, water, and other particles, which, if allowed to come into contact with the wheel, can cause damage in the long run. In this article, we will discuss in detail why a bearing dust cap is essential and how it helps preserve the functionality and strength of the wheels.” We will cover every aspect without skipping a beat, including its functions, advantages, and even the more practical aspects of measuring, changing, and caring for it. Yes, indeed, buckle up since this will be a ride full of knowledge about this part of wheel care. So what are you waiting for – Let’s get started!

A dust cap is an essential part of the rim. Otherwise known as a covering cap, a slide bearing, or a hub, its essential duty is to cover the rim from foreign invasion like dust or even moisture. Such an invasion may lead into deep-seated problems such as increasing degradation rates of the wheel bearings, and therefore performance. The existence of the dust cover preserves the wheel bearings by strengthening the organizational boundaries.

When looking at the normal setup of rims, one can see the dust cap directly attached to the wheel hub. The dust cap is placed on top of the wheel hub, which securely fastens the bearings in place and it is designed for the purpose of making rotation possible by obstructing any key debris from entering the wheel assembly.

Apart from securing the bearings from foreign elements, the dust cap also helps maintain the amount of lubrication within the rim components’ assembly. By using this cap, gaseous lubricants in the grease can also be prevented which would otherwise affect the bearing performance. This decreases the amount of heat produced and the total amount of friction in bearings and therefore applies to the entire wheel assembly.

In conclusion, the dust cover serves as a barrier to the wheel bearings by blocking the penetration of particles and also enabling the lubricant to remain sealed within the wheel assembly. As a result, the dust cap helps ensure that the wheel bearings are clean and adequately lubricated while assisting in the effectiveness and lifetime of the rims.

Dust caps bearing protection are also important parts to protect your wheels and their functions further. Their main role, however, is to act as a contamination barrier for the wheel assembly as well to contain any other lubricants around the wheel bearings. Their correct sealing of the wheel and the retention of the lubricant liquid prevents the bearings from gaining constant friction that could have been created if the liquid had been leaking. In short, it can be safely said that dust caps are extremely important to extend fleet wheel bearing life, retain bearing function and offer wheel assembly safety; hence they are an important part of the wheel protection system.

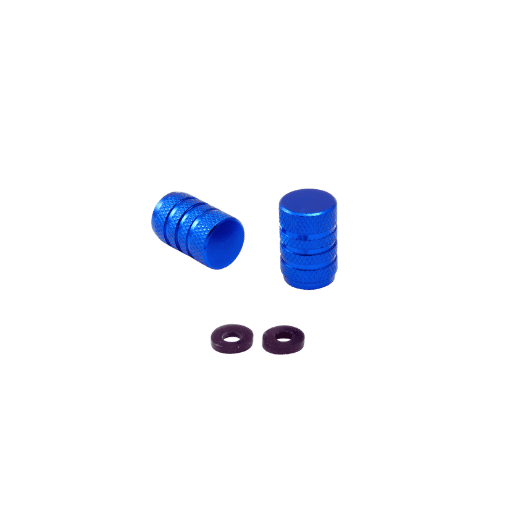

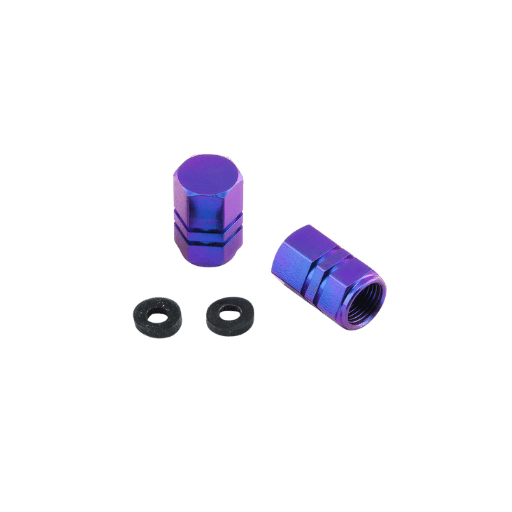

A range of caps that cover the wheel bearings are on offer. The caps vary in shape and the materials they are crafted from, but they all serve the same purpose: protecting the wheel bearing from external elements and keeping the grease intact. Below are some of the common wheel bearing caps you will find in the market:

It is essential to select an appropriate dust cap for your specific wheel assembly to ensure that the wheel gets adequate protection and performs optimally. The most appropriate dust cap for your needs can be selected by considering the hub bore size, material, and exposure to the elements.

When determining the hub’s specifications according to the cap you are looking to fit, you mainly need two as key measurements: the depth, and the inner diameter of the hub’s bore. Doing these steps will confirm that the finished cap serves its function well and fits snugly.

Bear in mind, by measuring the inner diameter and the depth of the hub correctly, it will make it easier to find a suitable cap. Furthermore, it would ensure that the wheel and assembly remain functional. Also, consider being as specific as possible with your wheel and axle dimensions; it would elevate the protection reliability of the cap in the assembly as well.

If dust caps cannot be fixed efficiently, the above-mentioned issues should be addressed. An important task is determining the internal diameter and depth of the hub bore. Besides, it is essential to use dust caps constructed according to specific wheel and axle parameters to achieve tight and high-efficiency fittings that would safeguard your wheel assembly.

One of the most important aspects of a dust cap’s reliable functioning is adjusting it to fit effortlessly. In order to obtain a perfect fit, kindly proceed with the following.

By implementing the above steps, you are able to make the necessary changesneeded in order to have your dust cap fit securely, thereby providing aadequate protection and performance of your wheel assembly.

It is acknowledged that proper dust cap care is pivotal in regards to the capabilities and safeguarding of the wheel assembly. Here are some signs that indicate it may be time to replace your dust cap:

Of note is that the dust cap safeguards the entire wheel assembly from dust, moisture, dirt, and other tiny particles. Such elements accelerate the wheel assembly’s wear and ultimately damage it. Should a client notice any signs of wear on the dust cap, they should not hesitate to recommend a replacement.

Several factors are key when selecting a particular replacement kit, and all the aspects have an overarching element of durability. In this case, the wheel assembly is what needs to be durable,. One of the elements that require paramount attention is the material used in regard to the dust cap. Ideally, when purchasing the dust cap, one should always use heavy gauge steel or graded aluminum to ensure it does not wear off due to road stresses. Moreover, a properly crafted dust cover that has the right design also places a critical role by ensuring minimal atoms can permeate onto the wheel bearing, hence reducing the probability of any impairment and ensuring the wheel would continue be functioning.

Indeed, price is something to consider, but I have always stressed the quality issue, especially in the case of a heavy dust cap. Yes, some low-priced options can be tempting at the start, but they are most likely not going to be sturdy enough to see you through the long run. This is why spending money on a high-quality dust cap from quality manufacturers or suppliers is a positive investment, as this can help you avert problems and expensive repairs in the future.

In my experience, I advise to buy a 4-pack of dust caps as such an offer is both appealing and practical. Having spares readily available enables instant changeovers and provides protection to the wheel assembly by ensuring everything is in order. By using good quality aftermarket parts and keeping the above factors in mind, you should be able to improve the lifespan and reliability of your wheel assembly for greater confidence while driving.

A grease cap, a bearing cap, or a hub cap is one of the essential items used to cover the wheel bearing so that dirt and other elements that may interfere with the proper functioning of the part as mentioned above do not infiltrate its working area. A grease cap can also be called a Kubernetes as it suffices the same purpose but on a smaller scale. A grease cap protects your wheel bearing in the following ways:

Thus, a well-grid grease cap helps make a bearing more durable, reduces road costs, and promotes the capabilities of a wheel assembly.

What are the distinct traits of a grease cap when compared to a dust cap? As someone who works with wheel assembly components for a long time now, this is a question that I get from people quite often. In order to respond concisely: Function: A grease cap primarily retains and distributes lubricant to keep the wheel bearing adequately lubricatedern. A dust cap too protects but in a different way, it cushions the wheel bearing from impacts allowing it to remain intact and during rotation it does not come into contact with the protective cap.

Knowing these important distinctions between grease and dust caps helps to perform good wheel assembly maintenance. Adhering to the details outlined ensures great operational safety, effectiveness, and durability of your wheel assembly, thus saving you money on repairs in the long run.

Your overhead grease cap needs to be properly maintained to ensure the wheel assembly works well and lasts long. The following are some important steps to take:

Moreover, adhering to the recommended service procedures is one way to protect the grease cap against wear and ensure that the wheel unit’s greasing always operates at the appropriate level. Periodic examination, sanitation, adequate lubrication, and tight fastening are vital. An error occurred during generation. Please try again or contact support if it continues.

The dust cap is an important accessory that can shield the wheel assembly from dirt. These parts can be a little more expensive if it is forged from a strong material, however, the investment is worth it because the strength of the material ensures corrosion resistance. Generally, dust caps are made from A356 aluminum alloys, steam tables or steel sheets. Plated steel caps can be quite useful in this regard because they are very strong and have a remarkable life expectancy. Aluminum cap on the other hand is more prone to corrosion, however, they are not rustable. Another quite affordable option are plastics caps, however, they may not guarantee the same sturdiness which metal caps provide.

Generally, a dust cap would only be as good as its design because a poorly designed dust cap is prone to making moisture and dirt penetrate through above the hub assembly. Try to purchase caps that possess a dependable locking component that can be tightly closed, as well as the ones that provide better seals. Vent caps or breather caps should not be ignored as they equalize the pressures on each end while simultaneously preventing excessive amounts of heat from building up.

It is advisable to seek guidance from experts to settle on a cap that is most appropriate for your mode of usage while also ensuring a suitable lifetime and effectiveness of your wheel assembly. Angles tend to make dust cap material choices and overall design crucial.

When looking for replacement caps it is prudent to consider quality and price, as a replacement, absorbing the attributes looking for such price is important. Although price is a key aspect, it shall not rest as the only deciding factor of concern. Purchasing such caps that promise overall efficacy of dispensing dust particles off the wheel-turning flora shall warrant a price that is beneficial in the long run rather than purchasing cheap unsuitable options. Cap alternatives are cheaper and easy to buy off however they simply are not safe to be used due to deformation overtime due to constant beatings and dampness exposure. It is advisable to seek assistance from experts and also look to follow the manufacturer’s guidelines in order to acquire an optimal locking system alongside a well fitted cap that enables easy dispelling of heat. Seeking seasoned professionals to have an elaborate discussion would also help in getting the appropriate coverage in a cost-efficient manner.

When deciding to buy a four-pack dust cap, several factors should be evaluated to ensure that you are getting the right product. Among those factors, here are some recommendations to consider:

Abiding by these suggestions and adjusting the focus on quality gives you a fair ground on deciding on which four-pack of dust caps to purchase alongside the guarantees of the durability and performance of your wheel assembly.

A: A dust cap fitted onto the end of your trailer axle or wheel hub serves as a protective cover. It is essential as it enables to prevent contamination of your wheel bearings from dirt, dust, and moisture which assists in reducing wear and increase the life span of your trailer wheel hubs.

A: Applying a dust cap or bearing cover provides lubrication as it aids in protecting the grease meant for bearings within the wheel hub. This ensures minimal contact or friction, thus averting issues with regard to overheating. On the other hand, the absence of a cover can lead to excessive grease leaking or contamination, which can eventually result in the bearing failing to operate.

A: While generally rubber plugs were said to work but in reality they do not protect as much as a dust cap does. The latter is made to sit perfectly on the wheel hub which assists in limiting contaminants intake especially in rugged usage of wheels. Therefore it is best recommended to use a proper bearing dust cap to achieve the ultimate protection for your wheel bearings.

A: A bearing dust cap’s size is determined by the wheel hub diameter of the axle which it is installed on the trailer. It measures the outer diameter rim of the hub where the dust cap is to be installed. A 4 inch cap is standard for numerous trailers meanwhile 8-inch caps are found on bigger, heavy-duty trailers. In case of any doubt as to the correct size of a cap collar for your spindle, it is advisable to inspect the specifications of your trailer or contact an expert.

A: Some bearing dust caps are indeed made to be used on different trailer wheels. However, it is preferable to use a cap that is suited specifically to your trailer’s make and model. Many manufacturers provide bearing dust cap kits that include the right size and type for a given combination of your trailer axle and wheel hub.

A: There’s no set timeframe for replacing bearing dust caps, but you should inspect them regularly for signs of damage or wear. Whenever you see cracks or deformation or cap borders become loose, it is advisable that the unit be replaced. In fact, some trailer owners prefer to change dust caps whenever they perform servicing for wheel bearings or kit them as parts of a 4-pack.

A: Yes. Some bearing dust caps come with a built-in grease fitting which complements the quick connect on the shut off valve cap. This permits the application of grease without the need to take off the entire unit, which is more convenient for maintenance. However, if the trailer has a quick connect grease system, make sure to look for a suitable cap.

A: It is common opinion that some automotive designs, may be configured to utilize caps on their bearings and these designs include older and heavy duty vehicles in addition to trailer wheels where the bearing caps are standard. Such modern vehicles come equipped with sealed bearing units and do not need separate caps to cover dust. In all cases, please refer to your vehicle manual or a mechanic for the maintenance specifics.