A network is becoming more critical globally since the latest globalization trends require quick and safe data transfers. Cat6 connectors are one of the components widely used in a networking system and are meant to bring high-speed broadband connections up to 10 Gbps for short-distance connections. In this regard, the guide seeks to demystify the Cat6 connectors by describing their specifications, applications, merits, and the installation process. There may be those in the IT fields who are proficient, as well as those who may be just beginning with the details of enhancing residential networks, and this resource is all set to cater to all different needs.

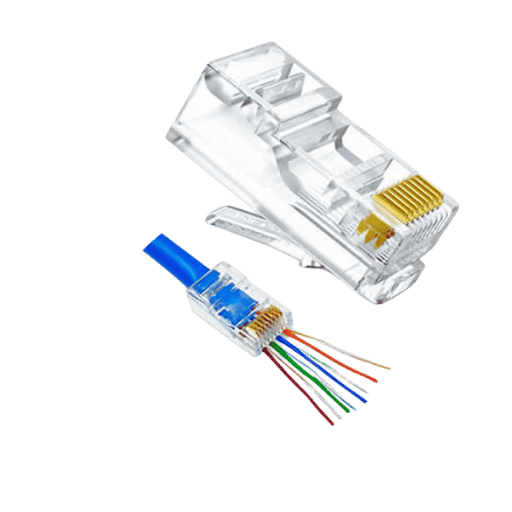

A Cat6 connector is classified as a modular plug or a modular jack, used primarily to terminate twisted pair cables that are Category 6 compliant. The features of this eight-position, eight-contact device 8P8C enable the transmission of information between networking equipment, which may include computers, servers, and Switches. They can handle data bandwidth of up to 10Gbps and operational frequencies of up to 250Mhz. Cat6 connectors, thus, are a vital part of an Ethernet network, ensuring fast and effective communication that can be utilized in homes and businesses.

The Cat6 connectors should be categorized as components of an insulated wiring system and built according to fast data transmission requirements. Some important features are the 8P8C (eight positions, eight contacts) up to the structure, where great contact integrity is achieved by reducing intermodulation interference and crosstalk. Such connectors are usually used with the Cat6 cables, which consist of four pairs of copper wires twisted to provide the needed high-frequency signals. The fact that the G6 standards were preserved explains why the Cat6 connectors can transmit data of a speed reaching 10 Gbps over a range on the order of 55 meters, allowing the users to turn in better results because of lower levels of attenuation and greater tolerance for unwanted signals than previous grades offered. As pointed out above, these fundamental aspects shall help choose a Cat6 connector because of the case at hand.

In terms of structural make and their performance ability, it is noted that there are changes in the connectors of Cat5 and that of Cat6. Cat5 connectors, also known as Category Five connectors, are aimed at networking with a speed of 100MBps and a bandwidth of 100MHz, whereas Cat 6 connectors can enable greater speed. On the other hand, Cat6 connectors have up to 10Gbps of speed and 250 MHz of bandwidth, boosting its performance. The improved parameters of Cat6 connectors result from the better cable design, where a tighter twist in wire pairs is accompanied by thicker sheaths, which avoid interference. Therefore, it can be seen that compared to the Cat5 connectors, Cat6 connectors are much more integrated and efficient for such interactions.

These Cat6 Ethernet connectors are predominantly used in high-speed local area networks (LANs), especially in data-intensive organizations like data centers, businesses, and colleges. They are suitable for routers, computers, switches, and other network devices requiring higher bandwidth and lower noise interference. Also, Cat6 connectors find use in homes primarily for streaming, online gaming, and other activities requiring high-speed interconnects. These interconnects are also used in monitoring systems that require high data rates to support live video feeds. The ability to sustain transfer speeds of up to 10Gbps makes these Cat6 connectors widely preferred by those looking to upgrade their network frameworks.

The requirements of the Cat6 connectors need to be considered, given the networking needs. There are three primary types of Cat6 RJ45 connectors: standard, shielded, and field-terminated.

All other connectors, except one, will be used differently depending on their location, the network’s use, and even the manner and means of installation.

When using Cat6 decking in solid or stranded form, it is essential to understand the scope of work and the conditions in which it will be carried out. A solid Cat6 cable comprises one continuous thick-stranded copper wire for each conductor. These cables are highly flexible and are generally used for temporary connections, such as patch cords to connect computers to monitors and hubs. All their design features justify their use for backbone cabling since they do not lose signal due to attenuation and crosstalk over long stretches of connection.

Stranded Cat6 cables, however, comprise many bundles of small wires twisted together to form each conductor. This construction grants them greater tensile strength, which is serviceable to short, movement-permitting connectivity such as patch cords. When it comes to passing signals across long distances, stranded wires will tend to transmit weaker signals than robust cables. All in all, the decisive factors for solid vs. stranded Cat6 are the place of installation and the requirements of the given network.

When choosing between shielded and unshielded connectors, it is important to consider the electromagnetic environment’s effects and the requirements of a particular network. Shielded connectors have an additional conductive layer over the internal wires, which protects the cables from stray electromagnetic and radio frequency interferences. This makes them suitable for noisier environments such as networks, where data loss or performance drop chances are highly limited. Areas where machinery is used or a radio transmission is an example of those sorts of places.

On the other hand, unshielded connectors do not have extra shielding, which may be an advantage in cost and installation as there is a reduced bulk mass. They are most useful in average home or office premises that are not exposed to much interference. The choice regarding the utilization of connectors in a shielded or unshielded manner draws on the environment in question as well as the expected performance against cost and portability during installation.

Installing a Cat6 cable connector by crimping requires specific tools to be implemented in the right and professional manner. First and foremost, a good wire stripper is essential to strip only the outer PVC layer from the cables without harming the internal copper wires. Then, a couple of cable cutters accompany this one to shorten and prepare the wires to the right size for connecting to the connectors. It is essential to use that kind of specific crimping tool to connect the Cat6 cables to the connectors, which confers tight gripping longitudinally onto the wires and the connectors. Furthermore, one can use a network cable tester for test launches after a certain phase to check the functionality of the established network. Every one of those tools is necessary for installing the Cat6 cable, which is functional and durable.

Observing these procedures guarantees a secure and efficient assembly of a Cat6 RJ4 connector, thereby enhancing network efficiency.

While assessing the best Cat6 RJ45 Ethernet connectors, one should also look at customer reviews, as they are critical to understanding a product’s efficiency or reliability. Quite a number of these reviews are given by top brands found on some of the top shopping sites.

In general, the factors discussed above and the constructive criticism of the customers provided on these sites can assist buyers in choosing the best Cat6 RJ45 connectors that fit their requirements.

When you are purchasing a 100-pack of Cat6 RJ45 connectors, there are a few essential guidelines that will help you to get the best pay for your money by evaluating the critical factors:

Studying these factors on the leading sites, Amazon, Newegg, and Monoprice, one can get all the necessary information on Cat 6 cables.

To help you avoid any damage to your Ethernet connectors, it is necessary to abide by their best practices as offered by them. One, regularly examine connectors and cables for any signs of wear or damage and replace damaged parts to avoid losing proper connectivity once more. Insert connectors into their ports, reducing the chance of disconnection and contact wear. Fastening cables with clips or using ties is recommended to lessen the effects of mechanical force and tangles that could cause the cables to fracture or overstress and stretch. Do not allow any moisture or extreme heat around the connectors and cables, as this will lead to the faster wearing out of the gold-plated contacts due to corrosion. As a last step, accumulated dust or other particles that settle on them from the air are forced out of the socket by a soft brush or compressed air in the normal manner. By these methods, users would be able to keep the network in optimum conditions, and the life span of the Ethernet connectors would also be increased.

Considering the most accessed sources, it has been noted that there are common issues with Cat6 connectors, and these mostly relate to improper termination, sub-standard crimping, and overwound cable pairs. Mismatches in wiring or failure to fully embed the connector pins frequently leads to termination failure, which in turn causes problems with prospective connections because pins fail to connect. This is usually corrected by following the usual wiring patterns, such as T568A or T568B, during installation and checking the cable for discontinuity after using the last wire. An oversized crimp may cause intermittent connections or loss of signal, so it is important to use the best crimping tools. Then it goes beyond the normal of 0.5 inches, which is considered maximum retainable untwisting for the goodness of the signal quality of the patch cable, too. This can really be changed by observing the twisting limit about withstanding crosstalk. With this common concern of many people, users will significantly improve the capabilities and reliability of Cat6 cable connections, especially in the case of solid wire.

Cat6 cable connectors are used in many circumstances and can be replaced easily in frequent connection problems, physical damage, or network upgrades. Damaged connectors, such as cracked or corroded or those having missing locking tabs causing signal loss, should be renewed quickly. So, when any connection issues cannot be solved by troubleshooting, replacing connectors may improve connection quality and stability. In the modernization of the network, new connectors need to be used to satisfy modern requirements for their operation and compatibility. The specific focus should be on how often connectors are checked and changes made to them, which would assist in running effective networks.

A: Categorized as a DHCP, the Cat6 connector is an RJ45 modular plug designed to connect with Category 6 (Cat6) network cables. This connector differs from other connectors in that it can handle high bandwidth and data transmission speeds of up to 10 Gbps. While Cat6 connectors can accept Cat5 and Cat5e cables, they outperform the connection of the two types of network cables in most respects.

A: Yes, Cat6 connectors apply to solid and stranded Ethernet cables. However, caution must be taken when selecting the wrong connector for the wrong type of cable. Solid conductor cable connectors are constructed with sharper prongs since the mass is solid copper that has to be penetrated. In contrast, stranded cable connectors have more forgiving prongs as they do not penetrate any wires.

A: Generally, the standard Cat6 connector should be inserted reasonably after trimming the wires exactly, while a pass-thru connector can have wires that pass through the open end of the plug. Pass-thru connectors are great because, in most cases, the installer will correctly position the wires, and therefore, good termination will follow. They’re also great when dealing with Cat6 cables, whose insulation is slightly thicker, making it more difficult to terminate.

A: Cat6 connectors and other RJ45 modular plugs contain eight positions and eight conductors (8P8C). A T568B wiring configuration is the standard for a straight-through Cat6 cable. The pin numbering follows the color code: 1- orange-white, 2- orange, 3- green–white, 4- blue, 5- blue-white, 6- yellow-green, 7- brown-white, 8!- brawn. This arrangement prevents the occurrence of daisy chaining in network cables in which data is intended for transmission.

A: Cat6 connectors are generally sold in bulk packs manufactured to fulfill the needs of IT/network installers. Common package sizes include 50-pack and 100-pack options. Common package sizes among network professionals First and foremost, these bulk packs are economical for large network installation maintenance or for users who are constantly using Cat6 cable termination.

A: A crimp tool designed for RJ45 modular plugs will be necessary for the proper termination of the Cat6 connector, and wire strippers and/or cable cutters will also be handy. Some professionals pack all these in a complete toolkit together with a cable tester for checking termination. Some kits also contain a punch-down tool in case you need to terminate cabling onto patch panels and keystone jacks.

A: Yes, there are unmanaged Cat6 and shielded Cat6 connectors in the market. Shielded connectors for Cat6 shielded cables are mostly used in areas with heavy EMI radiation. Such connectors provide superior protection against crosstalk and noise interference. However, unshielded Cat6 connectors are used without such environmental conditions and are also the most suitable types for most homes and office facilities.

A: Looking specifically at the design of the connectors for Cat6, it would be wise to select one with gold-plated contacts, a load bar, and a straining relief boot. Some also feature color-coded caps, especially when deployed over other connectors in a 100-pack, thus making them easier to use in complex network setups. Ensure that the connectors are rated “up to or exceeding” the performance standards of Category 6.