Pre-terminated fiber optic cables are advantageous in the contemporary world, especially in networking, as they are efficient and eliminate the need to deal with excessive cabling. These cables are manufactured and packaged with attached connectors inside a factory or manufacturing facility, ensuring the cable’s ease of installation and durability in service. In this detailed guide, the various facets of pre-terminated fiber optic cables will be discussed in depth, including their design characteristics, areas where they’ve advanced over other cabling systems, and the design features for specific applications where those cables are used. This has been detailed because it will enable the readers to understand all the crucial elements, which would allow them to appreciate why these cables effectively boost network performance and offer better network infrastructure in diverse professional contexts.

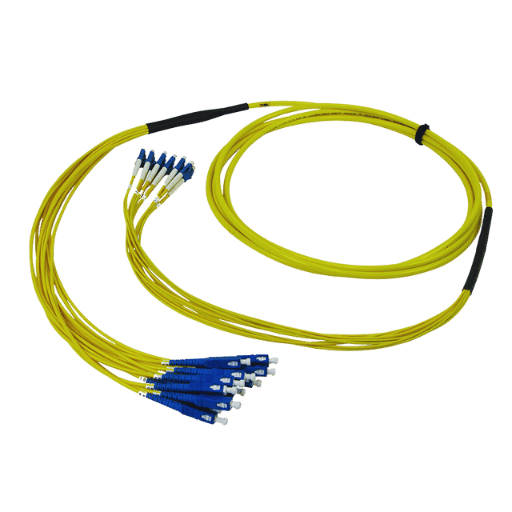

A pre-terminated fiber optic cable is an assembly of fiber optic cable in which a connector termination is already done in the factory on both ends. Because there is no requirement for field termination, this method reduces time and the possibility of making mistakes during installation. Cord units of different lengths and types are manufactured and used per the network’s design. Because these terminations occur in a controlled environment, pre-terminated cables also guarantee the same credentials, making them suitable for use in both data center environments and enterprise-network installations.

The prefabricated cables are changing the networking fabric, and the benefits in terms of time and accuracy of fiber optics cannot be overemphasized. The pre-terminated cables are said to have connectors already attached by the manufacturer, thus eliminating the need for additional installation at the site. Premanufacture termination, as CNET notes, means that there will be adequate quality control, and there are fewer chances that the connecting devices will malfunction due to the termination process that is carried out manually. In addition, according to TechRadar, pre-terminated cables save time and enhance performance consistency, which is essential, especially regarding high-speed data requirements. Also, as PCMag indicates, these cables are not only scalable in data centers. Still, they can also be used to extend enterprise networks with some more speed, thus increasing the durability of the network. In short, all these aspects highlight the fact that the modern network tends to use prefabricated fiber optic cables.

Pre-terminated fiber cables have many merits that appeal to contemporary telecommunication requirements. First and foremost, time is significantly saved during and after the installation process of these cables since the connectors have already been assembled, which, according to Network World, eliminates the need for termination in the field. Secondly, these cables alleviate the chances of mistakes, which, in a way, leads to enhanced performance of the network concerning reduced downtimes, as per the explanation provided by TechRepublic. Also, they enhance network reliability and durability needed for high transmission mediums that do not interrupt services, thus strengthening the networks, as reported by Enterprise Networking Planet. Such characteristics lead to increased opportunities for organizations with a desire to create sophisticated and influential networks to use pre-terminated fiber cables.

Pre-terminated fiber optic cable assemblies are adopted in many networking scenarios as they are high-performing and efficient. The most reputable networking authorities make it known that these cable assemblies are critical in data centers where the idea of putting up the cable bundling and the downtime is limited is essential. They simplify upgrading and enhancing the existing network system, making scaling up very easy. In addition, terminated pre-fiber cables are utilized for these features in the company’s networks since this allows robust and stable data transmission, which is essential for non-stop and high-speed interconnectivity. Moreover, in telecommunications, the 5G networks that these fiber cables support because of their ability for data transfer have great strengths and good speed, which is needed for the high connectivity requirements of modern wireless communication systems.

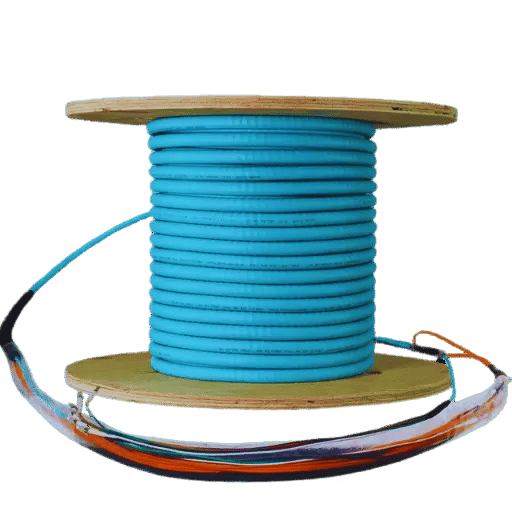

When selecting the appropriate fiber type for a project, it is critical to distinguish between singlemode and multimode fiber. Singlemode fiber has a relatively low core diameter of about 9 microns and is used in long-distance data transmission applications that range up to several kilometers without significant attenuation. Therefore, this type of fiber is best suited for usage in telecommunications systems where high-speed data throughput is required for long-haul networks. In contrast, multimode fiber has a core diameter of 50 or 62.5 microns, which allows the transmission of several light modes and is maximally efficient for data transmission shorter than 600 meters, depending on the type of fiber and data rate. Its adoption is normal within data centers or where cost and ease of equipment deployment suffice instead of increasing the distance. Regarding fiber selection, as showcased from leading online sources, factors such as distance, bandwidth requirement, and cost need to be evaluated and balanced together.

Szczegółowe wymagania dotyczące włókien OM3 i OM4 dotyczą kategorii włókien multimodalnych, które różnią się głównie swoimi walorami użytkowymi ich aplikacji. Obie te klasy masowych nośników danych będą wspierały dalszy rozwój. Włókna OM3 umożliwiają efektny przesył 10GBit/s z odległości do 300m. OM4 włókna mają teoretyczne maksimum efektywnego przesyłania 40Gbit/s do 100Gbit/s linków na odległość do 550m: aż efektywne modalne pasmo sięga 4700 MHzkm. Czyni to włókna OM4 pożądanym włóknem w otoczeniach centrów danych, gdzie priorytetem są wymagania przysovej wydajności i czasy rozwojowe. Odległości i wymagania projektów zawężą przeskoki pomiędzy przepustulosciami všeho w zakresie om3 a om4.

In cases where I am faced with choosing the type of fiber to use between armored fiber and non-armored fiber, the deciding factor becomes the environmental conditions and the installation requirements. Such construction of armored fiber cables allows them to be used in industrial environments or areas expected to be afflicted by heavy physical stress. In this case, the heightened durability can be fundamental to protecting the medium where the data is being sent. On the other hand, non-armored cables are more easily mounted. They are relatively lightweight, making them ideal for less harsh environments and saving money where reinforcement is unnecessary. Ultimately, I look to decide on an option that meets my requirements by providing enough physical protection yet not being too complicated to install.

Three basic precautionary steps must be carried out to prepare for the cable pull of prefabricated cable assemblies: Avoid bends and any interference that will tear the cable. Make sure proper equipment and tools are available. The sequence, such as the pull path, has to be checked out correctly to ensure it is clear of any blockage, dirt, or hindrance. Mark the path clearly and cut to length to avoid additional strain while pulling. This is followed by erecting support structures so that the strands of the cables can be held in position, and necessary cable trays or conduits may be installed. In the end, the pull of the fiber optic patch cable would be designated to an able-bodied team with proper measures, where everyone is in scope to communicate, and even more, everyone is in sync with one another, which will also reduce teething problems that could occur within the system allowing for installation to be faster.

Using a pulling eye during pre-terminated fiber cable assemblies installation enhances the process by providing a reliable interface for attaching pulling equipment. Pulling the eye means a pulling force is created at the fore portion of the fiber cable assemblage and securely fixed to the assembly. Therefore, the anchor means should be vital to withstand pulling force during use. A strong knot or lock may serve this attachment better. The rope or cable is connected to the pulling eye, after which the eye is pulled, altering the tension on the fiber cable by distributing the force to many fibers. Thus, such an arrangement not only simplifies the installation but also lowers the chances of destruction of individual fiber strands, ensuring the protection and delivery of maximally effective signals through the cable.

Best Practices for Installing Fiber Optics in Electrical Conduit Systems The fiber optic conduit cable system can be damaged or compromised if specific installation practices are not observed; this is particularly true for installing such armoring of the cables during conduit fitting. First, ascertain that the conduit size requirement accommodates the optic cable and will allow additional wires in the coming period. Use conduits with smooth walls to help reduce the potential for friction. In addition, it is essential to consider the minimum bending radius and not use tight bends because excessive bending may cause signal interference or damage to the cable. A variety of lubricants should be used due to the protective sheath to reduce the pulling tension placed upon the wires. At the beginning of the 60s, about 30 cable loops electrically delegated the joint to the cable sheath, allowing for easy later repairs. Lastly, the conduits’ outer surfaces must be coated to keep moisture and dust from the respective atmosphere for better operational integrity of the system and prolonging its life span.

LC connectors are recognized for their effective and robust design. They are characterized as small form factor fiber optic connectors due to their optimized size, allowing them to handle a reasonable amount of data traffic. This is made possible by the 1.25mm ferrule, which is indeed half the diameter of the ST and SC connectors. With such attributes, an LC connector is suitable for high-density networking systems. Due to such characteristics, LC connectors are highly effective when conserving storage space is needed, such as in a data center or telecommunication room. Also, the disconnection of LC connectors is very rare due to the inclusion of latch or clip mechanisms in the connectors. Many users have identified the LC connectors as highly reliable since the insertion loss of their ties is below standard and quite consistent across multiple connector units. Because of their specific features and low density, these connectors are recommended for data networks with high-performance requirements. The trendiest modern networking technologies comprise the features of high reliability and high efficiency in the use of space as well as the maximum throughput capabilities of such connectors.

SC connectors, also known as Subscribers and Standard Connectors, are widely known for their strength and simplicity. These ensure good interconnection with a robust connection that is very appropriate for connection and disconnection practices found in the telecommunication environment and fiber optics networks with a 2.5mm ferrule. The main disadvantage of the SC connector over the LC connector, which is more compact, is that the SC connector is bulkier than the LC with a push-pull design that makes it easy to insert and extract from multiple ports in a panel. Compared to ST connectors, the SC enables greater benefit because it fits somewhat into a square hole, gives a non-twist connection, and allows for easy insert and dismount of the segment, an advantage in mass-installed sectors. Again, SC connectors are compatible with multimode and single-mode fibers, making them more accommodating. Their large-scale utilization is proof of an okay thought-through plan that obtained a compromise between ease of handling the connectors and performance requirement expectations, hence making them suitable for diverse networking systems.

When selecting a fiber optic connector for assembly, it is critical to look at the performance and application parameters of the connector. It is also important to mention that insertion loss and return loss specifications are essential in connector discrimination since they determine the overall obtainable network performance. LC connectors are suitable for applications where space availability is limited, as they are designed for high-density networks requiring high data rates but with low signal degradation. SC connectors are more appropriate in situations that require frequent transgendering or in environments that need easy manipulation of the connectors as they are mounted in a simple push-pull mechanism. On the other hand, ST connectors may be exploited for older systems with a bayonet attachment or where there are minimal reconnections to a bundle of networks. Considering the rate of network expansion, environmental factors, and requirements for specific transmission systems will help choose the right type of connector that will yield desirable performance and reliability for the fiber optic assemblies. This particular strategy adds future diversity and compatibility with what exists, contributing to the effective management of the network.

Pre-terminated fiber optic assemblies decrease the overall cost and time of the installation process. In this approach, the cables are reduced dramatically by eliminating long processes of installations and tests that call for on-site terminations. The labor cost decreases with less time spent on the installation process, and the project’s onset is faster. Moreover, pre-termination solutions tend to have lower rates of errors because they are quality assured in the factory, this in turn makes the chances of expensive reworks or repairs to be minimal. Therefore, the introduction of pre-terminated fibers could help in reducing the timeframes and budgets of the projects while upholding the standards of performance and reliability.

To ensure the highest performance and reliability, the factory’s manufactured pre-terminated fiber optic cables have passed many quality control checks and procedures. The fabrication of these cables occurs under controlled conditions with the help of high-end tools for polishing and alignment of the cable ends. This accuracy helps increase return loss and decrease insertion loss, guaranteeing better data transmission performance. Furthermore, before despatch, each assembly is thoroughly checked for compliance with industry standards such as TIA/EIA and ISO/IEC. Such a level of assurance reduces the chances of faults, confirms interoperability with other parts of the network, and minimizes the amount of readjustments required after installation, ensuring easy integration and maintenance of the network.

Pre-terminated fiber optic systems can give the network structure remarkable flexibility and scalability advantages. Because such solutions are inherently modular, an expansion of the network or modifications of its topology can be done quickly and without long downtimes. When a company’s business activities increase, more pre-terminated cables can easily be added to the existing system for growing data transmission. Also, their nature allows for easy and fast installation and reinstallation, making them ideal for fast-changing or expanding situations. Pre-terminated optic solutions enhance and foster greater flexibility in a constantly changing network without being intrusive. Hence, such solutions are beneficial in high-paced environments and technologies that are constantly changing.

A: A pre-terminated fiber optic distribution cable is a type of optical fiber cabling with connectors on both ends. It requires no termination at the site, which can save a lot of time and expenses when installing it.

A: The primary benefit of using pre-terminated fiber optic jumpers is that they ensure quicker installation, as the quality is uniform and less workforce is required on site. Moreover, the chances of contamination are also minimal, and it is easier to conduct tests. These types of cables are quite famous in data centers, enterprise networks, and other such use cases where rapid installation is required.

A: Yes, pre-terminated fiber optic cables are available in different modes, including single-mode and multi-mode fibers, which vary in terms of construction for both indoor and outdoor use, armored fiber optic cables, and the plenum type of cables. They can also be fabricated with various custom options, such as 6-strand or even 12-strand, plus variant connectors such as LC, SC, or ST.

A: When selecting a pre-terminated fiber optic cable, consider the length of the network run required, the bandwidth needed, whether it is to be used indoors or outdoors, necessary fire ratings (for example, plenum), and the specific connectors that can fit your equipment. Custom-made pre-terminated fiber optic cable assemblies are also available for clients with particular needs.

A: Yes, there seems to be a classification for pre-terminated fiber optic cables for indoor applications and those for outdoor applications. Outdoor cables are constructed for robustness and thus can withstand tough weather and other conditions. Features such as water-blocking materials and UV-blocking jackets are quite common extra features. Cables rated for indoor use, such as those rated for plenums, are used per building code requirements.

A: Most of the time, pre-terminated fiber optic cables are equipped with a pull hook or pulling eye through the strength member and installed with the strength member attached to the cable. This allows the technicians to make the installation easier by pulling the required cable length through the conduits or cable trays. The connectors are already on the cables and are covered against damage during the installation. After placing it at the right spot, the cable can be quickly connected to the patch panel or equipment.

A: A comparison of both types of cables in core diameter will show that single-mode fibers have smaller cores, and the larger ones are found in multimode fiber optic cables. Also, single-mode fiber optic cables have been designed for long runs for a single data stream. In contrast, MM and multimode cables have a larger core diameter and are extensively used in short distances in the range of multi-building networks. Both types can be pre-terminated, with single mode having wider bandwidth and long-distance coverage.

A: Custom pre-terminated fiber optic cable assemblies are permissible. These may vary in length, connector types, number of fibers, and even cable construction. Custom assemblies are especially ideal for non-standard networks and designs or when a particular off-the-shelf option does not provide standard coverage for the specific project requirements.