Telecommunications are progressing at an unprecedented rate, and efficient fiber optic connections are critical to enhancing the transfer of data at high speeds. Many connectors and adapters exist, but the connection of different fiber optic systems using the LC to SC fiber optic adapter is one of the most effective and efficient adapters. This discussion is aimed at comprehensively introducing the LC to SC adapter, its technical features, working principles, and scope of use in reality. From an understanding of what core structural elements are required for smooth conversion to the type of situations that warrant its application, readers will appreciate how these adapters provide strong and effective solutions to the economies of scale in network infrastructure.

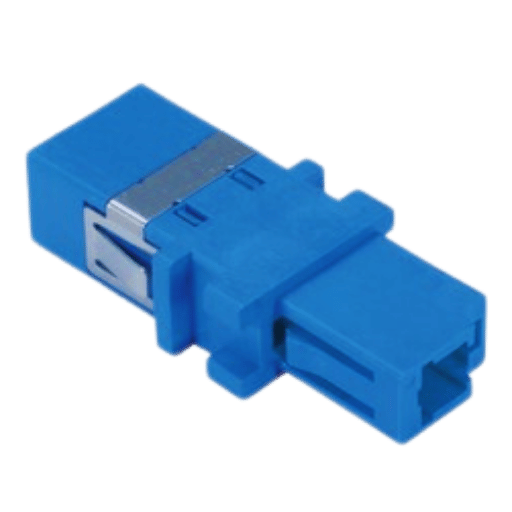

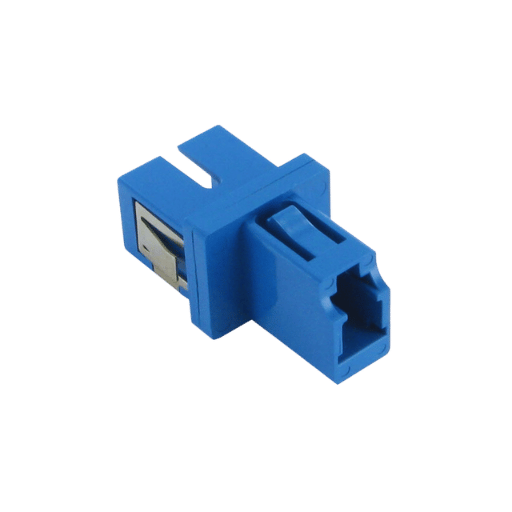

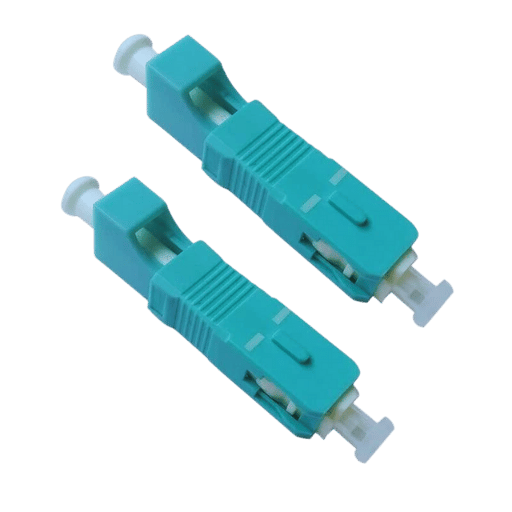

The LC to SC adapter is a type of fiber optic connector that is primarily used to connect an LC (Lucent Connector) terminated fiber with an SC (Subscriber Connector) terminated fiber. It acts as a coupling device that allows two or more distinct fiber systems to communicate while ensuring minimal loss and integrity on the transmission signal. Such types of connectors are mostly required in an interconnection of networks where the various interface components have to be interconnected. They are necessary to achieve an interconnection from LC to SC interfaces, guaranteeing robustness and effectiveness in the performance of optical networking solutions.

In the telecommunication networks, the most widely used fiber optic connectors are the LC (Lucent Connector) and the SC (Subscriber Connector).

In mixing these connectors, the LC to SC adapter serves as the critical point of contact, which reduces the mismatch and loss of signal between a smaller LC ferrule and larger SC ferrule. The utilization of LC to SC adapters therefore aids in optimizing and enhancing versatility across different network configurations.

Fiber optic adapters are crucial components of networking as they enable the cross-connection of various connectors, allowing different optical fiber systems to work together. Fiber optic adapters are classified as passive components as they hold the fiber ends so perfectly aligned to spool them together so that the loss of the signals is kept to a minimum and the transmission characteristics are optimal. In such composite networks, LC to SC etc Adapters provide inter-operability, thereby allowing a large number of disparate components to be integrated into one system. This flexibility not only increases the potential for the future growth of the network but also makes effective daily control easier to carry out because every upgrade and expansion in the fast-moving telecom world is made easier.

Singlemode fiber, often seen in simplex systems, is able to support transmission over large distances and has a small core size, which reduces modal dispersion. On the contrary, because of the larger core, multimode fiber systems can propagate several modes of light, yet due to the increased level of modal dispersion, it is only suitable for short-distance transmission. The decision to use singlemode or multimode fiber is greatly determined by the characteristics of the network in question, such as distance, bandwidth, and cost, among others.

Optical connectors are the most important elements in a fiber optic network and are intended to connect optical fibers to the equipment with minimum signal losses. As might be expected, there are a number of mechanisms as well as design principles that are inherent to their operation and construction:

As a result of the inclusion of such complex mechanisms, optical fiber connectors increase the durability and effectiveness of optical fiber networks hence supporting the different communication infrastructure requirements around the world.

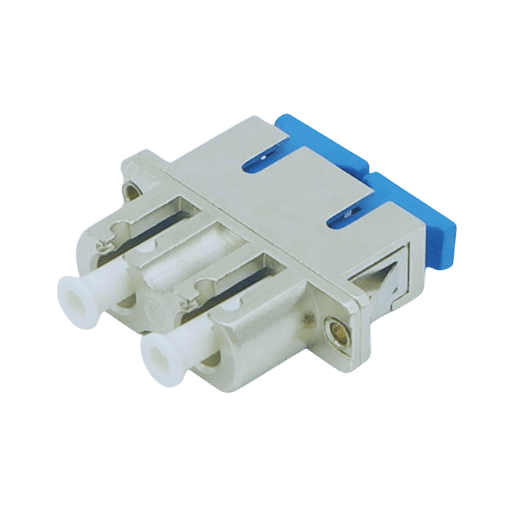

Adapters in fiber optic networks serve as an important connecting device between interconnecting a single or multi-optical connector type. They also help to provide a stable join, whether from mechanical or optical interfaces, by enabling the correct positioning of the fiber cores. Thus, this prevents excessive loss in signals and ensures that data transmission is faithful. Adapters are available in a wide variety of configurations, such as simplex and duplex, to mention a few. They allow networks to be expanded and are particularly suited for applications in areas where there is a need to make frequent reconnections or reconfiguration, such as in data servers and telecommunication networks. Adapters of such high quality have been made to conform to some industry requirements so that their performance remains consistent over a range of environmental conditions.

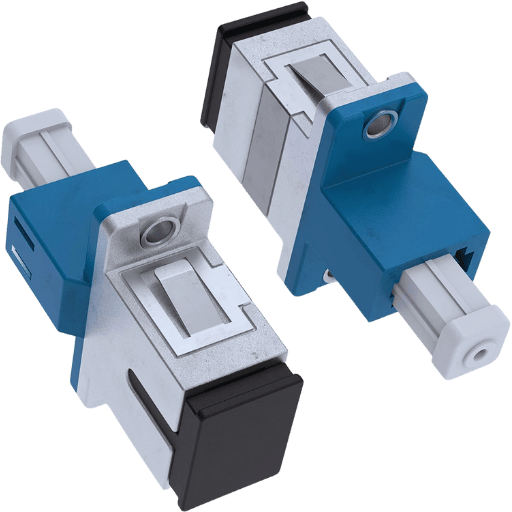

Hybrid connectors have great use in environments that require cross-connection between various kinds of fiber optic cables and connectors. They are best suited for those applications where cross-compatibility among a variety of connector interfaces is necessary, for example, in industrial environments or in fast-triggered changes in the data centers. Hybrid adapters help the existing infrastructure to be incorporated with the new equipment without causing many problems in changing the structure of the system during upgrading or expanding the networks. They also save on costs in telecommunication systems by connecting different types of fibers without having to change the whole system.

Cables made from single-mode simplex fiber optics are extensively used where bandwidth is required to span long distances. Such cables are common in telecommunications and serve the purpose of connecting metropolitan area networks (MANs) and data centers because they have reduced attenuation as well as dispersion, which enhances the quality of the signal transmitted. Also, their deployment has been observed in internet service provision and high-definition video broadcasting, something which requires rapid high speed and low loss of information. These applications utilize the capabilities of singlemode simplex cables to deliver dependable and extensible communication infrastructure essential in today’s modern society with high communication demands.

Alignments of both the sleeve and the flanges are key to ensuring that the interface between fiber optic connectors is tight and accurate. Flange alignment uses a mounting flange that provides an angular location to the connector to avoid being poorly aligned, which would distort the signal. This is crucial in situations where a high level of accuracy is required. Conversely, sleeve alignments have cylindrical sleeves that hold connectors, draw them into the required position, and provide alignment about the angle. These sleeves are mostly made of ceramic or metal, chosen based on their ability to withstand wear and tear while maintaining alignment. End fittings also serve the same purpose as connectors in fiber optics and these are important for maintaining the integrity of fiber optic networks because even slight distortion can create greater problems for data transmission.

Correct alignment of connectors in fiber optics systems can only be achieved with an application of best practices. First, before installing connectors, confirm that end-faces do not have debris or scratches, as these will greatly affect the quality of the signal. Use precision devices appropriate to particular kinds of connectors, such as ferrule holders or diluents, for proper alignment while making connections. There is a need to follow the manufacturers’ instructions during the installation of the connectors in order to avoid excessive insertion loss and reflectance due to inaccurate alignment. Frequent evaluation and tests with optical loss meters and reflectance meters can be used to detect shears in alignment that can be rectified when noticed in time. These methods not only improve but also guarantee the retention of the functionality of the fiber optic system in general.

Connector end faces are regularly faced with adverse issues like misalignment, contamination, and damage that cause the connection in fiber optic adapters to be problematic. During the installation process, it is possible for connectors to become misaligned, but this can be fixed by making sure all the connectors are realigned in their appropriate position. Connectors and adapters require careful cleaning because contamination is often caused by dust or oil. To avoid decreases in signal quality, damaged connector end surfaces ought to be checked and replaced when necessary. A comprehensive optical loss test is necessary to check the reliability of the connections and also locate any problems in the system.

In order to keep fiber optic adapters functioning as intended, they must be checked and maintained frequently. Properly scheduled cleaning using appropriate implements, such as cleaning pads dampened with isopropyl alcohol, minimizes the risk of contamination. As a rule, the use of excessive pressure should be avoided in order to prevent scratching the surfaces of the connectors. Furthermore, the application of Optical Time Domain Reflectometers (OTDRs) and other calibrated optical test equipment can help check changes in the performance of the adapters within the set time frames. Also, the performance data retrieved from such tests can be evaluated to indicate whether conditions exist to warrant some form of remedial action. For example, it seems normal that there is an increase in loss during experiments with power meters, which is a sign of pollution or wear. By keeping records of such information, it would be useful in arranging for maintenance so that interruption of work is minimized. This, in effect, would guarantee the reliability and efficiency of the fiber optic systems.

In terms of material, performance, and cost, ceramic and plastic connectors are very much different from each other. Because of their material characteristics, ceramic connectors offer high return loss and very low insertion loss, rendering them favorable for applications where high performance, sorting, and reliability are essential. Thus, fittings in high-density networks become more protected since there is less possibility of tearing through repeated connections, and they also retain excellent thermal stability. However, for applications that are not as stringent, plastic connectors do suffice as they are cost-friendly, lightweight, and biased towards the economy. However, plastic connectors are at a higher hold of factors that affect the environment, like insertion loss or humidity change. So, in cases where one has to make a decision between using a ceramic or a plastic connector, satisfying the communication budget, standards, and specific operational conditions should frame the controlled parameters.

A: An LC to SC Fiber Optic Adapter allows users to speak to devices with different interface standards, LC and SC, respectively. It enables numerous devices to connect to networks that employ different types of devices.

A: The core diameter of a single mode LC to SC Adapter supports signalling over long distances (within the range of few kilometers), while a multimode OM3 adapter type is used over shorter distances (up to 300 meters) and has wider core diameter.

A: “UPC” is an abbreviation for Ultra Physical Contact. It addresses a fibre optic connector polish type that helps improve the return loss by enabling more effective contact between fiber connections.

A: Yes, LC female to SC female adapters may be used for duplex connections and hence data transmission in two directions at once can be achieved.

A: A ceramic alignment sleeve in a connector serves to align the fiber assembly’s or the fiber’s cores to reduce the amount of loss that occurs at the joint of the two fibers and thus enables optimal performance to be achieved.

A: Yes, LC to SC simplex adapters are available. They are mostly applied where single fiber connections are needed, for instance in some cases of telecommunication and installation in a data center.

A: The case of an LC to SC Fiber Optic Adapter should be strong enough and able to meet global requirements. Regularly, it is quad in cross-section and made of materials that are strong enough and low loss in order to reduce the effects of interference.

A: Several numbers of LC to SC adapters are RoHS compliant thus indicating that they adhere to the requirements of the directive regarding the restriction of the use of certain hazardous substances in electrical and electronic appliances.

A: An adapter busks different types of connectors like LC and SC which are mostly connected through a coupler of the same type and this coupler is frequently used to unite or branch the signal.

A: LC to SC Fiber Optic Adapters are sold by numerous online and brick-and-mortar stores that are involved with networking products and components and such stores normally offer same day delivery services.