Fiber optic color codes have revolutionized identifying, installing, and maintaining fiber optic cables. These color codes provide a standardized method of identifying different fiber types, reducing the chances of errors and inconsistencies during installation and maintenance.

The fiber optic color code system is a set of standardized colors used to identify different types of fiber optic cables. These colors determine the core size, cladding diameter, and other physical characteristics of the fiber optic cables. The color code system plays a crucial role in fiber optic communication, ensuring that cables are installed correctly and that maintenance personnel can quickly identify cable types.

Fiber optic cables are delicate and expensive to install. Incorrect installation of fiber optic cables can result in loss of signal strength, data corruption, and reduced network performance. Therefore, it’s essential to follow the proper color codes to ensure the correct installation of cables.

Fiber optic cables can be difficult to distinguish from one another, especially when they have similar physical characteristics. The use of color codes allows technicians to determine lines quickly, even in low-light scenarios.

The International Electrotechnical Commission (IEC) established the fiber optic color code system to ensure uniformity in identifying fiber optic cables. Therefore, the color codes are universal, and technicians worldwide use them to identify fiber optic cables.

The color codes for fiber optics are divided into multimode fiber and single-mode fiber.

Multimode fiber color codes – These codes identify fibers with multiple modes of light propagation within the core. Multimode fiber optic cables are typically used for short-range data transmissions up to 2 km.

Single-mode fiber color codes – These codes identify fibers with only one mode of light propagation within the core. Single-mode fiber optic cables are typically used for more than 2 km long-range data transmissions.

Identifying the fiber optic cable is crucial for adequately installing, maintaining, and repairing the wires. Each fiber optic cable has the unique characteristics that differentiate it from others. The color code system allows technicians to distinguish different fiber optic cable types quickly. This way, they can select the suitable cable for the specific network or applications and ensure that it is installed correctly, preventing damage or data loss.

Recommended Reading: Single Mode vs. Multimode Fiber

The fiber optic cable color code system uses specific colors to identify the physical characteristics of the cable. The core size, fiber type, and cladding diameter are the essential characteristics of these color codes. In the following sections, we’ll outline the different colors and their meanings:

Blue: Primary coating color

White: Unpigmented buffer

Yellow: Single-mode fiber core

Orange: Primary coating color

Black: Unpigmented buffer

White: Multimode fiber core

The fiber optic color code system offers numerous benefits worldwide. One of the significant advantages of this system is that it eliminates guesswork while identifying fiber optic cables. Using color codes reduces human error, resulting in more accurate identification of wires and the selection of the correct line for a specific application. This enhances the functionality and longevity of the network.

Moreover, the color code system allows technicians to select the correct cable for a specific application, saving time and money. Time held on identifying the proper line can be used to undertake other essential tasks that make the network more efficient.

To identify the fiber type using color codes, follow these steps:

Understand the color code of both single-mode and multimode fiber cables.

Identify the primary coating color of the line.

Check the sheath color of the buffer to verify the fiber type.

Verify that the correct fiber type is installed before starting the testing.

Fiber optic cables have revolutionized communication, allowing information to travel faster and farther. Fiber optic cables are used in various applications, from telecommunications to medical equipment. One of the most critical aspects of fiber optic cables is their color coding.

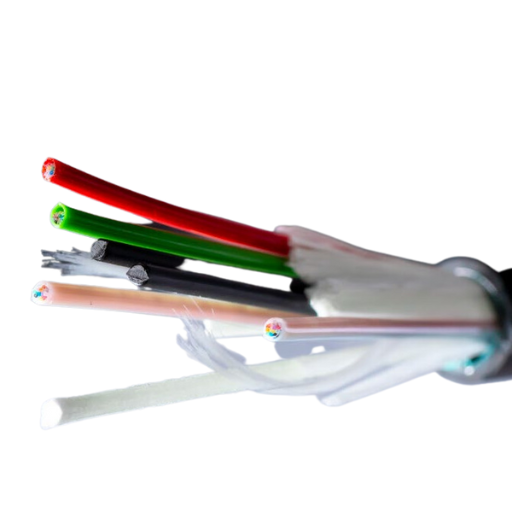

Fiber optic cables are color-coded to indicate the type of fiber and cable. The color of the fiber optic cable can tell whether it is single mode or multimode. Single-mode fiber optic cables are typically yellow, while multimode cables are generally orange or aqua. The cable color can also indicate the cable type, such as patch or trunk cables. For example, a patch cable may be blue, while a trunk cable may be green.

Connectors are also color-coded in fiber optic cables to make it easier to identify them. Connectors may be color-coded based on the type of connector, such as SC or LC, or the connector’s polarity. For example, the LC connector may be color-coded with a blue housing for single mode and an aqua housing for multimode. The SC connector may be color-coded with a blue housing for multimode and a green housing for single mode.

The jacket color code in fiber optic cables is essential for proper installation and organization. The color coding allows installers to quickly and easily identify the type of cable, reducing the risk of errors and allowing for faster installations. The color coding also helps with organization, allowing installers to quickly differentiate between different kinds of lines.

Fiber optic cables are typically color-coded to make it easier for installers to identify the type of cable and fiber. In addition, color coding allows for faster installations and reduces the risk of errors. Proper color coding also makes troubleshooting and maintaining fiber optic systems easier.

Identifying the type of fiber optic cable based on its jacket color is relatively straightforward. As mentioned earlier, yellow jackets typically indicate single-mode fiber optic cables, while orange or aqua jackets typically indicate multimode cables. Different lines may be color-coded differently, such as patch cables blue and trunk cables green. However, it is essential to note that not all manufacturers follow the same color coding standards, so it is always best to double-check the cable specifications to ensure proper identification.

Fiber optic cables have revolutionized the way data and voice communications are transmitted. Splicing fiber optic cables allows for seamless connections between multiple lines and enables uninterrupted data transmission. To understand the intricate workings of fiber optic splicing, it is vital to comprehend the principles of color coding and the available types.

Color coding assigns a color to each fiber optic cable to denote its specific usage. This facilitates easy identification and tracing, making troubleshooting and maintenance simple.

Several types of splicing techniques are available, the most common being fusion and mechanical splicing. Fusion splicing involves fusing two fibers by applying heat, while mechanical splicing relies on clamping to join two threads.

Regarding 12 fiber cables, ribbon splicing is the technique most often used. Ribbon splicing is a fusion splicing variant that allows multiple fibers to be spliced simultaneously, resulting in a more efficient and consistent splice connection.

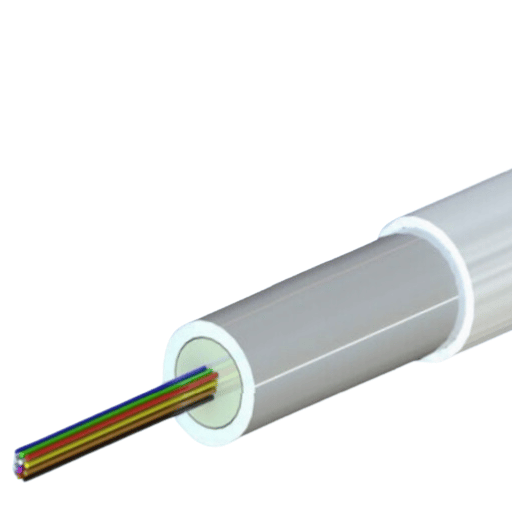

A fiber optic cable comprises multiple layers that work in cohesion to ensure smooth data transmission. The innermost layer is the optical core, where data is transmitted through the optical fibers. This is surrounded by the cladding, which protects the fibers from physical damage.

The next layer consists of the buffer coating, designed to absorb any shock or dent that may affect the cladding or core. The outermost layer is the jacket, which protects the entire assembly from external influences.

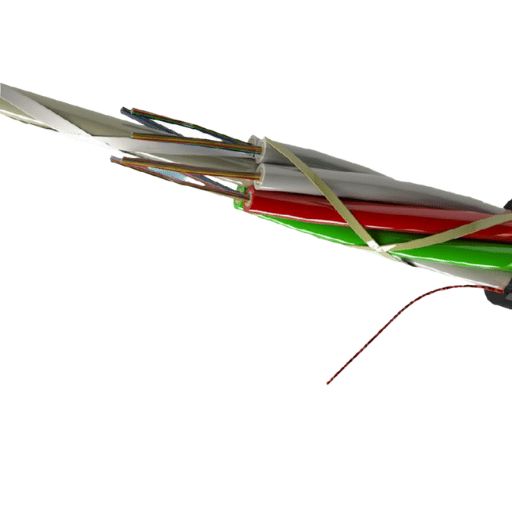

A group of 12 fibers is typically called a ribbon. Ribbons are identified and arranged in a line by their color codes. The color codes used on individual threads within the ribbon are consistent, allowing for simplicity in tracing and easy identification.

Identifying fiber color codes is critical for splicing fiber optic cables. Without proper identification, it is impossible to determine which fibers need to be spliced together. Moreover, matching the color codes between spliced fibers ensures that data transmission remains uninterrupted.

Fiber optic cables have become increasingly common in modern communication systems and networks. They provide an efficient and reliable means of transmitting data over long distances, making them ideal for applications ranging from Internet connectivity to industrial automation. However, to ensure optimal performance and prevent errors or malfunctions, it is essential to use fiber optic cables that are correctly identified and connected. This is where connector color coding comes into play.

Recommended Reading: What is the difference between single-mode fiber and multi-mode fiber?

Connector color coding is used to identify different types of fiber optic cables and connectors. It allows technicians and users to easily distinguish between wires, connectors, and other devices, reducing the risk of errors and providing a quick means of finding the correct cable for the task. For instance, in a complex fiber installation with multiple lines and connectors, color coding can make locating particular cables and patches easy, minimizing downtime and reducing the risk of damage.

The most common connector color codes for fiber optic cables include blue, orange, green, brown, gray, and black. These colors correspond to different cable types, distinguish between single-mode and multimode fibers, and identify various connector types such as ST, SC, LC, MTRJ, and FC.

To determine the type of fiber based on the connector color, it is vital to understand the different types of fibers, their applications, and the corresponding connector colors. Single-mode fibers are typically used for long-distance, high-speed applications, such as telecommunications and cable systems, and are usually identified using yellow cables. Multimode fibers, on the other hand, are used for shorter distances and lower-speed applications, such as local area networks (LANs) and data centers. They are color-coded using orange or aqua cables.

Fiber optic connectors come in different shapes, sizes, and colors. Each connector type serves a unique purpose and is designed to fit a specific cable type. The color of the connector body and boot, which is the protective covering of the connector, can also tell a lot about the connector type. For example, SC connectors and cables use blue as their color code, while LC connectors and cables are typically coded with green.

Fiber cables are color-coded for identification purposes to simplify installation and maintenance. Technicians need to identify lines at a glance in large cable infrastructures. This simplifies the lead time for those who can do their job quickly while minimizing the risk of errors. For instance, a fiber optic technician working in a data center or telecommunications environment may need to examine hundreds of cables simultaneously. Being able to easily differentiate between cable types, connector types, and cable functions can be critical to the success of an installation.

Using color-coded connectors in fiber optic installations is of utmost importance as it minimizes errors, reduces downtime, and improves productivity. Incorrectly connected cables can lead to data loss, signal degradation, and even system failure. Furthermore, incompatible connectors can cause damage to expensive equipment, which could lead to costly repairs and downtime. A simple solution to these issues is to color-code the cables and connectors correctly to minimize the risk of errors and avoid the risk of damaging equipment.

Industry standards for connector color codes provide guidelines for color-coding connectors in fiber optic installations. Standards vary depending on the type of fiber optic installation, but commonly used measures provide consistent guidelines for connector color code. For instance, TIA-568, a widely used standard in North America, specifies the color-coding of cables and connectors for structured cabling applications.

Fiber optic cables are a crucial component in modern network infrastructure. They allow for faster data transmission and longer distance transmissions and are immune to electromagnetic interference. Different types of fiber optic cables are designed for specific applications.

Recommended Reading : Single and multi-mode universal fiber

There are two main types of fiber optic cables: single-mode and multimode fibers. Single-mode fibers are designed for long-distance transmissions and are used in applications such as telecommunication networks. Multimode fibers are used for shorter-distance transmissions and are commonly used in data centers and LAN networks.

Color coding of fiber optic cables is essential to fiber optic network installation and maintenance. It helps identify and distinguish different fibers necessary for proper installation and maintenance.

How are 12 Fiber Cables Color-coded for Identification?

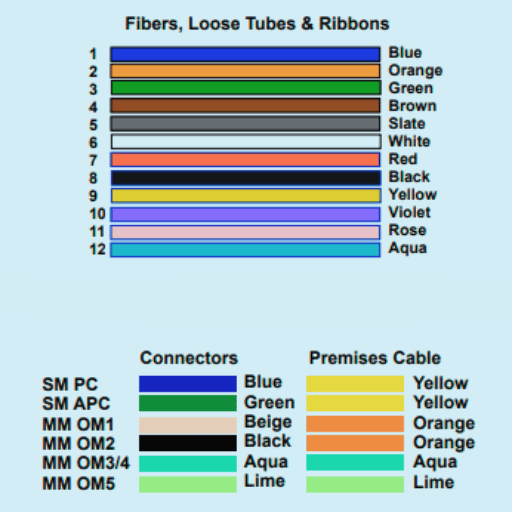

12-fiber cables are color-coded using a standard color code system that identifies each color with a particular fiber. The fibers are numbered from 1 to 12 and are color-coded as follows:

Blue

Orange

Green

Brown

Slate

White

Red

Black

Yellow

Violet

Rose

Aqua

Single-mode and multimode fibers have different color code systems. Single-mode fibers are typically color-coded with blue, whereas multimode fibers are usually color-coded with aqua. Understanding the color codes for single-mode and multimode fibers is critical in identifying the type of fiber being used in a network.

Loose tube cables are used in harsh environments and are designed to withstand extreme temperatures, moisture, and mechanical stress. The color code for flexible tube cables is essential because it helps identify individual fibers within the line. This is important when splicing or terminating threads, making tracing and placing threads easy. Correctly understanding color codes for loose tube cables is critical to the success of any fiber optic network installation and maintenance.

A: The fiber color code aims to help distinguish fiber types visually and facilitate identifying and installing fiber optic cables.

A: Fiber optic cables are typically color-coded using different colors for the outer jackets or strands. Each color represents a specific type of fiber or function.

A: A group of 12 fibers consists of 12 individual strands or fibers.

A: The parts of a fiber optic cable include the fiber optic strands, buffer tubes, fiber connector, and the outer jacket.

A: Fibers are color-coded for identification to distinguish different fiber types and make it easier to match them during installation or troubleshooting.

A: Color coding helps us distinguish fiber types visually from the colored fiber jackets or strands. Each color corresponds to a specific fiber type.

A: The outer jacket color in fiber optic cables helps identify the overall cable type or category.

A: Fiber optic cables are color-coded to facilitate easy identification and installation.

A: The jacket colors for other fiber types may vary. Depending on the specific fiber type, they can include blue, green, yellow, or white colors.