With the rapid development of 400G, 800G, and even 1.6T optical modules, the power consumption of individual modules continues to rise, making traditional air cooling methods insufficient to meet the heat dissipation demands of high-density data centers and AI clusters. Liquid cooling technology, leveraging its higher thermal conductivity efficiency and energy-saving advantages, has been introduced into the optical module field, becoming a key direction for addressing the bottleneck of high-power heat dissipation. It not only effectively reduces energy consumption and PUE but also aligns with the development trends of green data centers.

Iteration of Cooling Solutions Driven by Enhanced Integration in Data Centers: By horizontally comparing the networking trends of current mainstream GPU vendors, we can observe that whether it is NVLink, UALink, SUE, RoCE, or CM384, the core concept of their networking is to reduce nodes and achieve more extensive low-latency connections. The iteration of GPU connection solutions is continuously increasing the integration requirements for data centers.

Traditional air-cooling heat dissipation schemes cannot satisfy the economic and integration demands of computing power centers primarily based on accelerator cards, while liquid cooling solutions—whether cold-plate, spray, or immersion liquid cooling—provide better high-integration solutions.

A liquid-cooled optical transceiver is a high-speed module that incorporates liquid cooling technologies (such as cold plates or microchannels) into traditional optical modules to achieve efficient heat dissipation. As optical interconnect speeds evolve from 400G to 800G and even 1.6T, the power consumption of a single module has exceeded 15W, making conventional air cooling increasingly insufficient for high-density environments.

With its much higher specific heat capacity and thermal conductivity compared to air, liquid cooling can rapidly remove heat, significantly improving heat dissipation efficiency. This prevents performance degradation or failures caused by overheating, while enabling higher power density and port density deployment. The core concept of liquid-cooled optical modules is the integration of liquid cooling technology with optical transceivers to achieve efficient thermal management, thereby enhancing the stability and lifespan of high-performance optical communication equipment.

Liquid Cooling Technology

Liquid cooling technology uses liquids (such as water or other thermally conductive fluids) as the cooling medium, removing the large amount of heat generated during the operation of optical transceivers through continuous circulation. Compared with traditional air cooling, liquid cooling offers much higher thermal conductivity, effectively reducing module temperature and making it ideal for high-power, high-density applications.

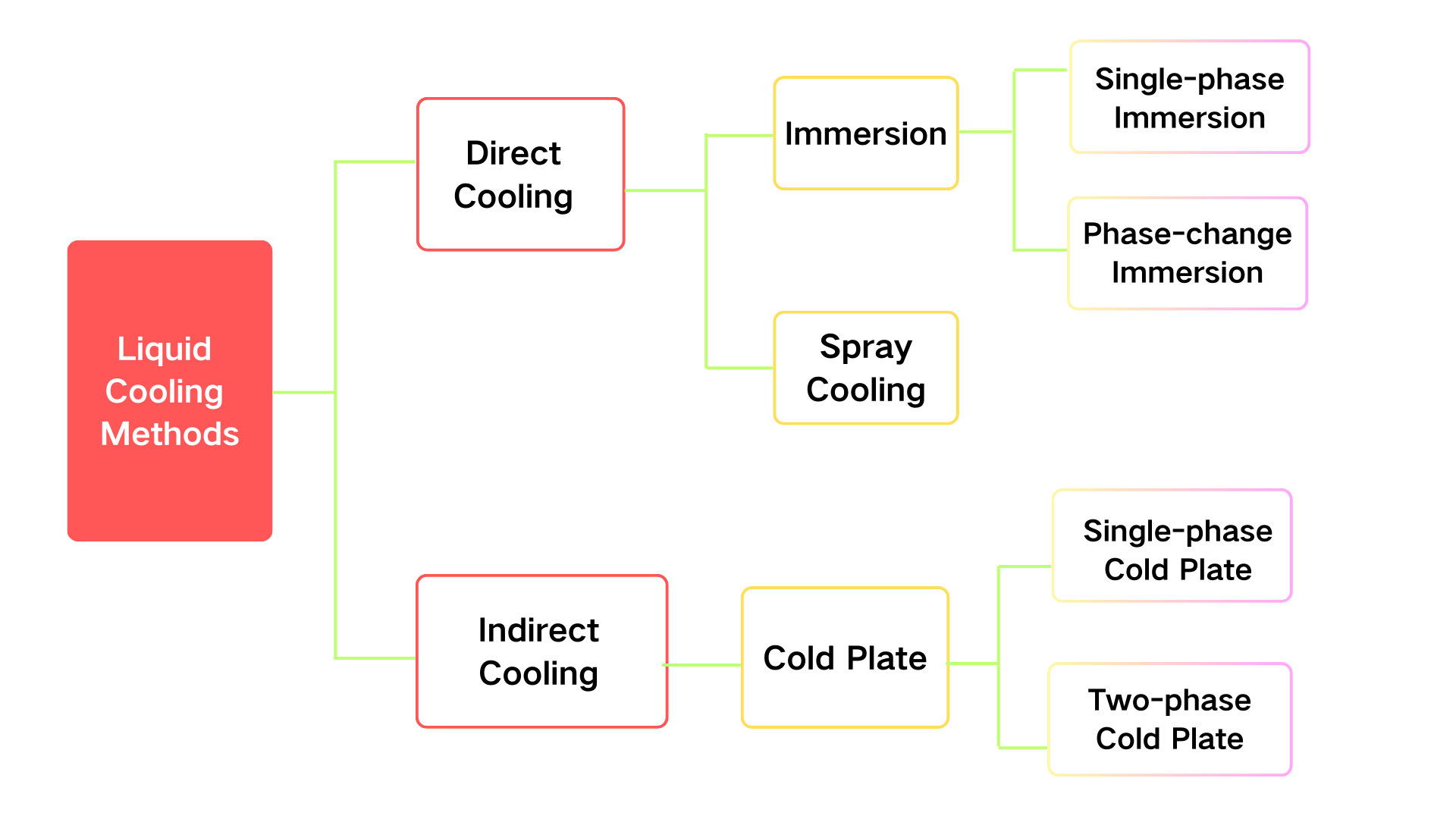

Depending on the contact method between the cooling liquid and the heat-generating device, liquid cooling can be divided into indirect and direct approaches:

Indirect Liquid Cooling: The cooling liquid does not directly contact the heat source. A typical example is the cold plate design, where heat is transferred from the device surface to the coolant via a thermal interface.

Direct Liquid Cooling: The cooling liquid directly contacts the heat source. This includes immersion cooling and spray cooling. Immersion cooling can be further divided into single-phase immersion and two-phase (phase-change) immersion, depending on whether the cooling medium undergoes a phase change during operation.

Compared with traditional air cooling, liquid-cooled optical modules offer significantly higher thermal efficiency, enabling 400G and 800G high-speed modules to operate stably in data centers, 5G networks, and supercomputing environments that demand high density and power. Key advantages include:

However, liquid-cooled optical modules also face challenges such as:

Despite these challenges, liquid-cooled optical modules are emerging as a key technology for next-generation high-speed communications and sustainable data centers, showing great potential in high-performance computing (HPC) and AI clusters.

Liquid-cooled optical modules are particularly well-suited for high-power consumption scenarios such as AI/GPU clusters, supercomputing centers, and green data centers. They can effectively reduce PUE (Power Usage Effectiveness) and align with sustainability goals. With international organizations such as OCP and ODCC driving the standardization of liquid cooling interfaces, liquid-cooled optical modules are gradually moving from experimental validation to commercial deployment, becoming a key development direction for future 800G/1.6T high-speed optical interconnects.

Currently, AscentOptics has launched a series of liquid-cooled optical transceivers, including 10G SFP+, 25G SFP, 100G QSFP28, 200G QSFP56, 400G QSFP112/OSFP, and 800G OSFP Liquid-Cooling Optical Transceivers. This product line overcomes the limitations of traditional optical modules by maintaining reliability even under immersion depths of up to 10 meters. The liquid-cooled series is ideally suited for liquid-cooled servers and high-performance data centers.

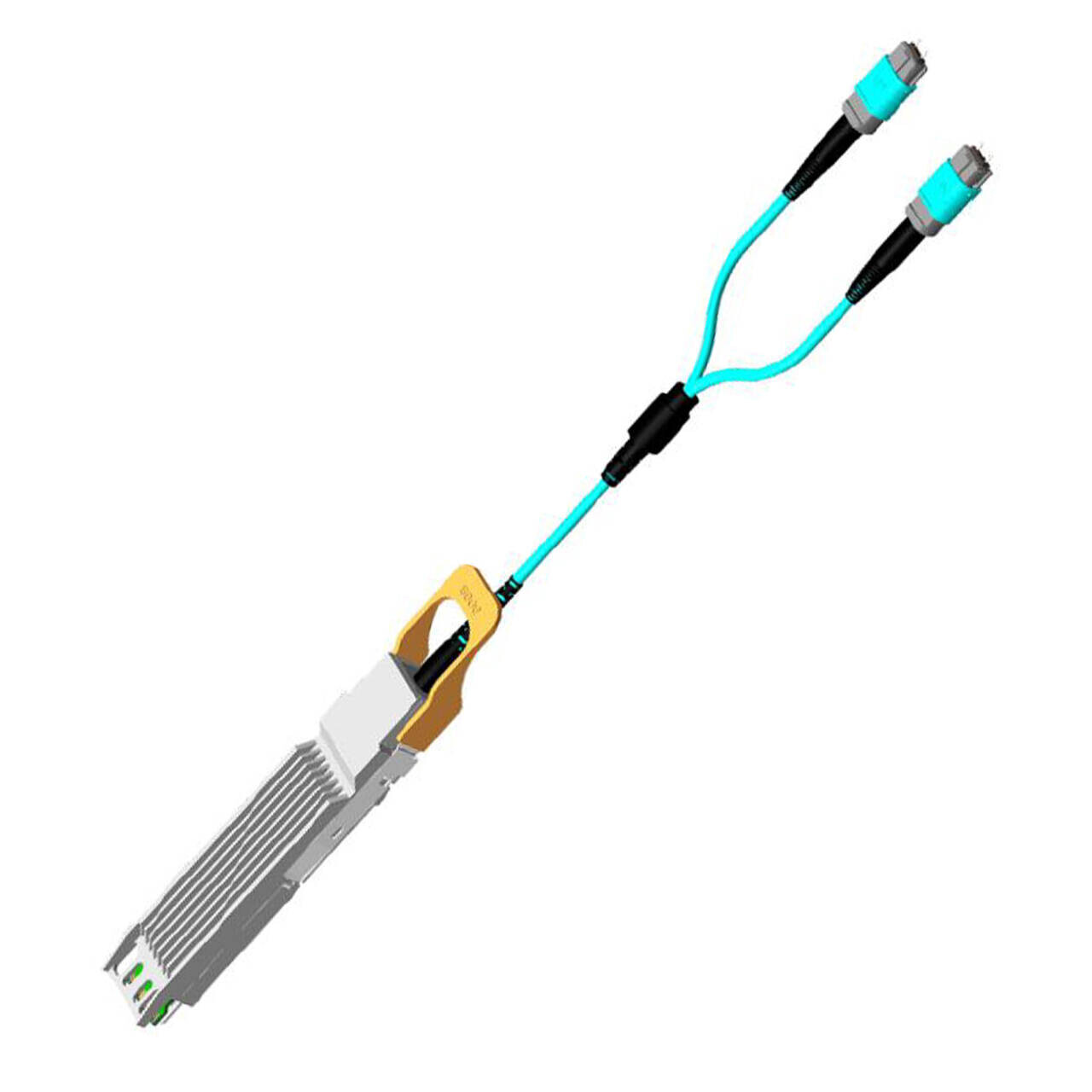

The OSFP 8×100G SR8 liquid-cooled transceiver is a high-speed module supporting 800G optical interconnects. It is designed with eight parallel 100G PAM4 lanes and achieves short-reach high-speed transmission with Dual MPO-12/APC Female Type A Pigtails. Unlike traditional air-cooled modules, this product integrates a liquid-cooling structure (such as cold plates or micro-channels), significantly enhancing thermal performance to meet the requirements of high-power, high-density data center deployments.

As a high-performance 800G module for short-reach multimode interconnects, the OSFP 8×100G SR8 liquid-cooled transceiver combines high data rates, low latency, and efficient cooling. It is particularly well-suited for AI data centers and HPC clusters, making it one of the key solutions for next-generation high-power optical interconnects.

The OSFP 8×100G DR/DR8 liquid-cooled transceiver is a high-speed 800G optical module based on eight parallel 100G PAM4 single-mode optical lanes. Using an MPO-16 fiber interface, it supports medium- to short-reach single-mode transmission (500 m–2 km). Built on the standard OSFP form factor, this module incorporates liquid-cooling technology (such as cold plates or micro-channels) to efficiently handle power consumption above 16 W, making it well-suited for high-density data centers and AI training clusters.

Combining advanced PAM4 technology with liquid-cooling advantages, the OSFP 8×100G DR/DR8 liquid-cooled transceiver delivers reliable 800G connectivity across 500 m–2 km single-mode links. It is an ideal solution for backbone interconnects in data centers and high-speed optical interconnects in AI clusters.

| Model | Data Rate | Lanes | Connector | Fiber Type | Reach | Cooling | Application |

|---|---|---|---|---|---|---|---|

| OSFP 8×100G SR8 | 800Gbps (8×100G PAM4) | 8 parallel lanes | Dual MPO-12 Pigtail | MMF | 100m | Liquid Cooling | Intra-rack, Short-reach DCI, 8x100G Ethernet |

| OSFP 8×100G DR8 | 800Gbps (8×100G PAM4) | 8 parallel lanes | Dual MPO-16 | SMF | 500m with FEC | Liquid Cooling | Mid-range DCI, AI Clusters |

| OSFP 8×100G FR / DR8+ | 800Gbps (8×100G PAM4) | 8 parallel lanes | Two MPO-16 | SMF | 2km | Liquid Cooling | Campus DCI, AI/HPC Networks |

The OSFP 8×100G FR/DR8+ liquid-cooled transceiver is a high-speed 800G optical module based on eight parallel 100G PAM4 single-mode optical lanes. Featuring an MPO-16 interface, it supports medium- to short-reach optical transmission of 2 km and beyond. Unlike conventional air-cooled designs, this module integrates liquid-cooling structures (such as cold plates or micro-channels) within the standard OSFP form factor, ensuring efficient and stable operation under 16–20 W power consumption. It is particularly well-suited for high-density data centers and AI training clusters.

Designed for 2 km-class single-mode transmission, the OSFP 8×100G FR/DR8+ liquid-cooled transceiver combines ultra-high data rates with efficient thermal management. It is an ideal 800G optical interconnect solution for data center interconnects, AI/GPU clusters, and HPC networks in medium-reach scenarios.

Looking ahead, liquid cooling will continue to evolve to meet the thermal challenges of next-generation optical modules. By 2026–2027, 1.6T OSFP liquid-cooled transceivers are expected to emerge, supporting ultra-high bandwidth demands. In addition, two-phase immersion cooling, which leverages boiling fluids for higher heat transfer efficiency, and direct-to-chip cooling with integrated microfluidic channels inside transceivers, are likely to become mainstream solutions for extreme-density deployments.

Liquid-cooled 800G OSFP transceivers are not for every scenario, but they are highly recommended if you operate AI/ML clusters (e.g., NVIDIA DGX, AMD MI300), run data centers with rack power density above 20 kW, or require future-proofing for 1.6T optics. On the other hand, if your switches consume less than 15 W per port, or if your facility lacks a liquid cooling infrastructure, air-cooled modules may still be sufficient for your needs.

Q1: What are the advantages of liquid-cooled optical transceivers compared with traditional air-cooled modules?

A:Compared with traditional air-cooled modules, liquid-cooled optical transceivers offer higher thermal efficiency, enabling stable operation of 400G/800G and future 1.6T modules, reducing energy consumption and PUE while extending device lifespan.

Q2: In which scenarios are liquid-cooled optical transceivers typically used?

A:Liquid-cooled optical transceivers are ideal for high-power, high-density environments such as AI/GPU clusters, supercomputing centers, high-density data centers, and edge computing.

Q3: Are liquid-cooled optical transceivers compatible with existing network equipment?

A:Most liquid-cooled optical transceivers are compatible with existing networking equipment in terms of optical interfaces and protocols, but they require supporting liquid cooling infrastructure (e.g., cold plates, pipelines, or immersion systems).

Q4: What are the main challenges of deploying liquid-cooled optical transceivers?

A:The main challenges include higher design complexity, increased maintenance costs, potential leakage risks, and compatibility issues with existing data center standards.

Q5: What are the future trends of liquid-cooled optical transceivers?

A: The future trend is the evolution toward 1.6T OSFP liquid-cooled modules, along with two-phase immersion cooling and direct-to-chip cooling as key solutions for high-power interconnects.