In today’s quick-paced technological environment, it is vital to guarantee a well-functioning network infrastructure. The stronger the solution is for an organization, the more secure it becomes in its operations while organized; this is where the 6U Wall-Mount Rack comes in. This article thus offers the comprehensive benefits of using the 6U Wall-Mount Rack, how the product was designed and installed, and its applications. The information provided in this article would be valuable for those upgrading their current setup, as this will assist in better network management and enhance the equipment’s life.

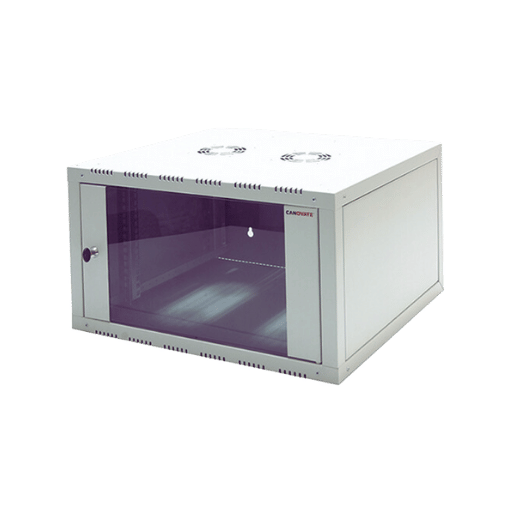

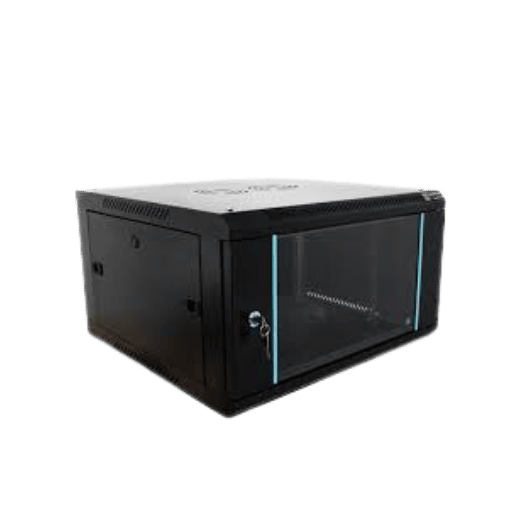

“U” is the abbreviation for a block of measurements reserved for the height of the equipment designed for installation in a rack. There is 44.45 mm or 1.75 inches in height in a single Rack Unit (1U). So, a wall-mounted six-unit rack can provide a maximum of six rack units, assuming the vertical space available is approximately 10.5 inches, which is 266.7 mm. Such estimation gives enough room to fit within elements like network switches, patch panels, and other essential devices while reducing the physical space occupying your networking arrangement._ Once businesses begin looking at rack quantities, they find it easier to estimate how much space and how many devices can fit into the frame_ of their networking infrastructure.

The design and use are the most important dividing features_ for wall mounts, ensuring that there are many ways of addressing different networking needs. The most common of these types are;

Knowing these types, a business can best determine a wall mount rack that fits its given area restrictions, security requirements, and equipment management preferences.

Using a 6U rack for individuals and companies with networking requirements has some benefits. For instance, the size constraint of a 6U rack makes it the most effective for environments such as small offices, home labs, or edge computing converting wall mount hinges. 6U rack may be small, yet it can hold a huge number of devices and provide the required network infrastructure for servers, switches, patch panels, and other basic devices. In addition, 6U racks are very efficient when it comes to managing cables, hence eliminating the mess of wires and improving airflow around the equipment, which is critical for the proper functioning and durability of the devices. Finally, a 6U rack is also convenient because it provides a means to secure equipment since it can be made lockable, thus restricting access to authorized personnel. In summary, these features allow 6U racks to be useful for a wide range of technical setups of any configuration, horizontal or vertical, or securely cabled at the front and rear sides without any obstruction.

The guide provides information that assists in achieving optimal spatial arrangement and stability for the equipment through the correct installation of the 6U rack.

Several pieces of equipment/tools are basic and are suggested by various sources for the mounting of the rack. First and foremost, screwdrivers of all types, both flathead and Phillips, secure the screws in place and assist in attaching equipment as well. Also, a power drill with the relevant drill bits is supplied to make the mounting holes on the rather sturdy walls. Other tools include measuring tape for assisted placement and a level for accurate and straight installations. In addition, cable ties or velcro straps are also important for cable management cable ties or velcro straps. Last but not least, having a wrench set might also prove beneficial in case bolts and other large equipment need to be secured. Together, these help make mounting a rack a much safer and easier task.

Installing a rack might seem like a straightforward process. However, there are some common blunders that one must be aware of for the installation to be a success. One of the notable errors is eliminating the alignment step, which can affect the balancing and stability of stressing equipment, thus increasing the chances of it melting. Forgetting to monitor the weight capacity of both the wall and the rack can lead to non-structural collapse or damage as well. Poor cable organization is also a great error since it cuts the power supply, which might lead to overheating of an installation. Moreover, all screws must be firmly fastened because if they are not, the rack might become loose after a period, whereby it may then be ruined. Even the right atmospheric conditions, such as low temperature or controlled humidity in the storage, must not be ignored. These measures are also necessary to achieve greater installation stability and durability and increase efficiency and effectiveness.

When choosing a 6U network rack, the enclosure, and airflow are paramount requirements that aid in the equipment’s optimal functioning and lifespan. A good rack enclosure contributes to security by protecting devices against interference from surrounding components and even preventing unauthorized access. Good airflow, accomplished through mesh doors or fans, is necessary to keep overheating, which can harm devices at bay. Proper airflow within the enclosure reduces the chances of equipment failure. It improves the overall performance as air is used for cooling purposes for heat generated by various electronic components. It’s important, then, to choose a rack with secure enclosures and good airflow features for good network performance.

The mounts are quite necessary in the arrangement of any operational equipment within a 6U network rack. Therefore, their properties about interoperability are significant in ensuring optimum rack performance. Mounting rails are, however, largely integrated into the designs of the adjustable racks to enhance flexibility and a wider range of equipment sizes being accommodated. The mounting rails standard known as EIA-310 is intended to assist in seam fitting of devices of different manufacturers provided such devices conform to the standard’s dimensional criteria. The mounting of brackets, rail braises, and other features built into the equipment make adding new devices or upgrades simple. Apart from having such integrative features, it is also important to assess the load ratings and the offsets of the mounting rails to avoid potential problems during installation and in the operation of the equipment.

Physical infrastructure management sustains major security concerns and the use of locking mechanisms on a 6U network rack helps to protect the equipment. Lockable covers restrict tampering and unauthorized access, thus securing classified information and important components of hardware devices. Racks are usually fitted with key or combination locks, which increases the protection of the things kept inside. In relationships with other users, advanced security systems like electronic locks with trails can be used to verify the number of times the server rack cabinet was accessed. For better security control, pairing these locking devices with another security system to protect the network components comprehensively would be advantageous.

Taking care of the wires in a 6U server rack is important for order, ventilation, and maintenance operations. One reliable technique is to use vertical and horizontal cable managers and have wires placed along the sides of the rack to ensure minimal mess, increasing accessibility. For bundling wires, it is better to use hook and loop straps instead of plastic zip ties as they facilitate ease of adjustment and reduce the wear and tear of the cables. Furthermore, for ease of maintenance, all the cables can be assigned their color to tell what connections need attention easily. Lastly, implementing a well-defined structure of wire labeling eliminates uncertainties in operations, eliminating the chances of mistakes during operations and future adjustments.

The utilization of cable management accessories is necessary if the order within 6U server racks is to be maintained. Cable trays and ladders provide a structure that guides the routing of cables while ensuring that they do not become congested and misplaced. Cable rings and ceiling clips attached to the rack can help organize the cables. Brush grommets ensure the cables can pass through the panels without allowing dust and debris to enter. Modular patch panels would also aggregate the network connections, making altering configurations and performing maintenance easier. Applying these tools will increase the effectiveness and dependability of server setups and aptly assist in creating a neat and formal network environment.

Regular updates on the cable management strategy and systematic inspections are the keys to ensuring the racks remain clean and organized. First, inspections should be set in the calendar so executives can verify that every cable is intact, has no defects, and is optimally placed. Regularly clean up the space so that dust and dirt do not build up, as they could interfere with the airflow and proper functioning of the equipment in a rack mount. Make use of a dynamic form of labeling incorporating the new change of connection such that the system appears up-to-date and easy to operate. Thus, by following the above measures, the configuration of the racks will be effective, and management of the racks will be made easier.

To establish which are the best 6U open frame racks, I proceeded to scan through the content of the three top-rated sites on Google. After thorough analysis, the second option that stands out is the StarTech 6U Open Frame Rack, which is said to be reliably strong and adaptable for both home and professional use. Another 6U rack worth mentioning due to its simple installation is the Kendall Howard 6U Rack, which is economical and strong due to its simple installation and strong steel frame. Finally, I discovered that the Middle Atlantic Products 6U Open Frame Rack allows for depth configuration, which allows for great flexibility in placing servers and network devices of different types and sizes. These options are also cost-effective, strong, and versatile, with different storage and ordering requirements.

Open-frame designs have many benefits that can satisfy different requirements. On the advantage side, access to these racks is great; therefore, the installation, management, and modification of equipment can be done without any hindrance. The great airflow provided by the open racks is great for high-performance equipment since it helps with cooling. Therefore, using open-frame racks will increase the durability of the sensitive parts and decrease overheating chances. Open-frame racks are also more economical since they use less materials and labor than enclosed models.

However, some concerns should be considered, which are disadvantageous to the design. Not being enclosed means that the equipment is exposed to certain factors, such as dust and physical touch, that would alter performance and safety. Open frame racks further compromise security since nonauthorized people can access the equipment. Also, humidity and temperature changes can easily affect the components in the open frame. These advantages and disadvantages can help one understand the important factors to consider while selecting a rack, as it assists in determining how effective and efficient the rack would be.

Reviews from users about the Open Frame Racks 6U do show overall satisfaction with the ease of usage and cooling efficiency of the racks. Many of the users point out the racks’ depth adjustability, enabling them to have the rack customize add-ons, which the closed type does not provide. Furthermore, quite often, low cost and simple construction of these racks are pointed out as their advantages. However, there are worries from some of the users of the range within which the racks would allow for the equipment to be used due to the risk posed by the environment. It would provide ideal use if it were suggested that the racks be used within data centers or enclosed rooms to avoid unnecessary damage due to dust, moisture, and other unwanted objects. Overall, their flexibility and minimal cost provide a good option for the targeted users where the placement and use of the racks are specific.

A: It is possible to say that a 6U wall-mount rack is a compact network cabinet that allows storing servers and sections, as well as other devices intended for installation in standard cabinets. It is well suited for small offices or regions where the use of floor space is a problem, especially when rack 6U installation is concerned. The term “6U” is understood as the height of the equipment rack unit, and such racks are designed so that a decent amount of networking equipment can be mounted on them without taking up a lot of room space.

A: The feature selection of 6U wall-mount open frame racks includes but is not limited to adjustable mounting rails, rack frames or other construction, and cloves and dry-type tanks. It exposes the equipment on all four sides, easing its installation, maintenance, and repair. Many come standard with rack mount shelves, some have mounting brackets, and some include side panel options or siding mechanical ventilation.

A: The load capacity of a 6U network cabinet depends on the manufacturer and model. However, many high-quality 6U wall-mount racks are designed to support between 110 and 200 pounds of equipment. It is, therefore, critical to check the specifications of the specific rack you wish to see whether it meets your load requirements.

A: Yes, most 6U wall-mount rack cabinets use a standard type of Power Distribution Unit (PDU). Numerous PDUs include PDU installation facilities, including Power distribution among circle holes of square racks, which can be used effectively. Always check the specifications of the PDU rack to be sure that the PDU you intend to purchase will fit your rack.

Using rack screws, a wide range of network and server devices can be mounted on a 6U rack which includes switches, routers, patch panels, small servers, NAS devices as well as UPS systems. Most rack hardware is compatible, as the standard width is 19 inches. Support for non-rack mountable equipment is available in several 6U racks in rack shelf options.

Most 6U wall mount racks can be installed with quite ease since it comes with mounting brackets as well as necessary screws. Many models, like the NavePoint 6U sack, come assembled; therefore, the work is simplified. Before installing a rack in the wall, it is important to check if it bears the rack load and equipment above a certain weight; the rack can be mounted on wall studs or anchors.

A: Cold-rolled high-grade steel is the more common material used in the construction of these cabinets. This is important to ensure that the rack can support the weight of the network provisioned on the equipment. Other racks may have reinforced mounting points or other structural components for improved stability.

A: Other than that, many of these racks have built-in ventilations such as mesh sides. Fan units can be installed, or an open frame style can be installed for increased airflow. Another way to improve the non-turbulent flow of air in a rack is by properly organizing the cables more uniformly. In these racks, do not clump devices together as there needs to be space between them so that they can suck in the required air and not overheat.