Both professionals and hobbyists must have electrical testing knowledge because it guarantees the safety and efficiency of electrical systems. This guide is the ultimate resource for learning how to use a wire tester, which is necessary for detecting and fixing electrical problems. High precision levels at work can be achieved if people know the principles of operation, correct handling procedures, and different available test methods. In this manual, we will discuss the technical features of wire testers and their common applications, as well as provide some tips on good practices that will enable you to become skilled in using them. With this information, no matter whether you are an experienced electrician or just somebody who likes doing things at home, after reading through this piece of writing, all your doubts about what should be done when working with wires shall disappear forever!

What is a Wire Tester and How Does it Work?

Understanding the Basics of a Tester

A wire tester is an instrument for diagnosing electrical faults in wires and connectors. Multimeters are recommended for more detailed diagnostics. Its operation’s principle lies in measuring electric continuity or lack thereof, which may imply disconnections, short circuits, or wrong connections within a circuit. This device sends a small current through the circuit when applied to a wire or terminal. When there is continuity, it shows a closed path for the flow of electricity; if there is no continuity, it means an open circuit somewhere along the tested line. More advanced models can also measure voltage levels, resistance, and signal strength, thus giving all-around insights into electrical systems. These basic concepts must be grasped to diagnose and troubleshoot electrical problems effectively.

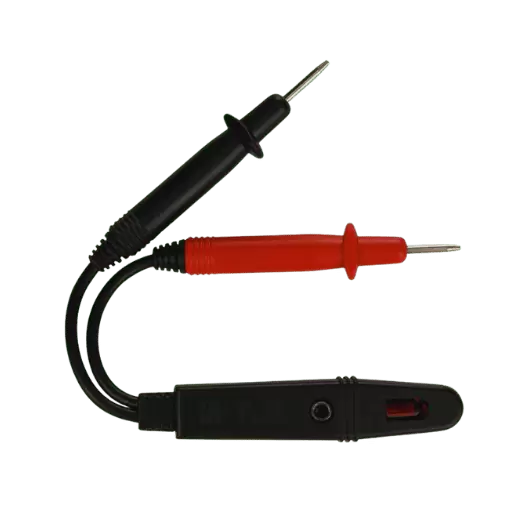

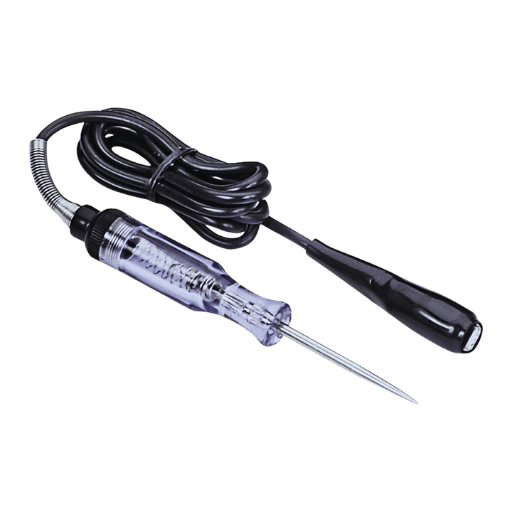

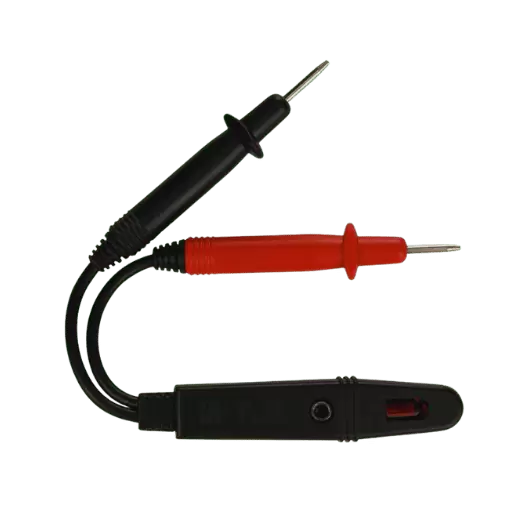

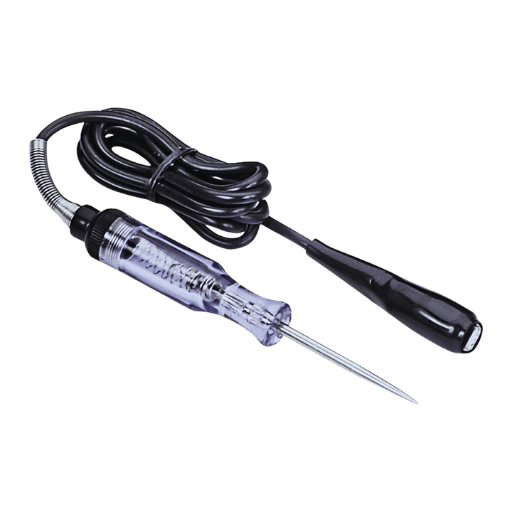

Types of Electrical Testers and Their Uses

Electrical testers are of many kinds, each with its own design for a specific diagnostic function. Here are a few of them:

- Testers for continuity: These simple devices check for electrical continuity, which helps determine whether the circuit is open or closed.

- Multimeters are versatile instruments that measure voltage, current, and resistance. They can be used for basic and advanced electrical diagnostics.

- Clamp Meters are ideal devices for measuring the current flowing through the wire without any direct contact with it. This makes them useful when working with high-current circuits where safety is paramount.

- Voltage Testers: These tools help verify live voltage presence at outlets, switches, and other such components of an electrical system.

- Circuit Breaker Finders: They come handy when searching for right breaker corresponding to a particular circuit thus making troubleshooting easier within complex electrical panels.

- Non-Contact Voltage Testers: Allow users to detect live wires without touching them, making inspections safer.

Each type has a unique role by offering necessary details that enable accurate diagnosis and safe resolution methods during electrical fault-finding exercises.

Voltage Tester vs. Current Tester: What’s the Difference?

Voltage testers and current testers are vital tools when it comes to electrical diagnostics, but they have different uses. A voltage tester is built to check if a circuit has electric voltage and what level it is at. This helps determine if a wire or component is live or de-energized. They are good for initial safety measures and confirming that power is flowing. Conversely, a current tester (such as a clamp meter) measures the actual flow of electric current – amperage – through a conductor. This reading allows people to know how much load there is on that particular circuit, detect overloads waiting to happen, and ensure safe working parameters of electrical systems. You cannot correctly or safely diagnose an electrical problem without knowing how each of these differ so invest in multimeters or non-contact voltage detectors for thorough tests.

How to Use an Electrical Tester Safely?

Precautionary Measures Before Testing

Follow these tips to make sure that you’re safe with an electrical tester:

- De-Energize Circuits: Turn off the power supply at the circuit breaker or fuse box before checking if it works. This is called de-energising. Use a voltage detector to ensure that there is no live electricity.

- Use Personal Protective Equipment (PPE) When Testing Any Circuit—Goggles, gloves, and flame-resistant clothes should always be worn when working near currents to protect against cuts and burns caused by electric shocks. Make sure your PPE can handle the voltages being dealt with.

- Check Tools and Testers: Before use, examine all devices used for signs of damage, such as broken insulation or exposed wires. If something looks wrong, don’t risk using it, as this could pose serious risks.

- Know Your Tester: Learn how your specific testing equipment works according to the manufacturer’s manual. Do not use any tool that isn’t designed for what you are doing.

- Work in a Dry Place: Ensure there are no water spills around where you are operating since wetness can increase the chances of getting electrocuted.

- Test for Proper Grounding: Confirm whether all outlets have been earthed well enough; otherwise, faults may arise, leading to hazardous situations.

By taking these steps, accidents will be minimized, thus creating a safer environment during tests.

Step-by-Step Guide to Using a Non-Contact Voltage Detector

- Check whether the device is working: Before using the non-contact voltage detector (NCVD), establish its functionality by trying it out on a known live circuit. Most detectors have an LED indicator or an audible alert to show they are working.

- Locate the Test Area: Find where wires, outlets, or other electrical components you want to test for voltage. Make sure these parts are close enough for easy and accurate measurement.

- Ensure Proper Positioning: Bring the NCVD near the wire or outlet you are testing. Some types require pressing a button, while others need you to place their sensor tip close to the suspected energized area. In response, this device will display voltage presence through light or sound indications.

- Understand Indicator Signals: Observe signals given by NCVD. A steady blinking light or continuous beeping indicates the existence of an electric field, which confirms that a circuit is live. Absence implies de-energization. However, always cross-check with other methods for safety reasons.

- Observe Safety Precautions: Even after initial tests, such as wearing personal protective equipment (PPE) and double confirming lack of current flow, continue following all safety measures because this can act as another safeguard against accidental harm.

Following these guidelines will enable one to successfully use a non-contact voltage detector for identification of energized circuits, thereby making work on electricity more secure and saving time, too.

Checking Continuity with a Continuity Tester

- Make ready the Continuity Tester: Before you begin, check that your continuity tester is in good working condition. You can verify this by touching the probe ends together. A functional tester will elicit a continuous path through a light, an audible signal, or a digital readout.

- Multimeters are necessary appliances for different kinds of electrical tests. Electrical testers products or buy can quickly and accurately detect faults. Disengage Power Supply: To prevent wrong readings or hazards, ensure the power going to the circuit under test is completely switched off.

- Identify Test Points: Determine two points in the circuit across which continuity should be tested; this could be across a switch, fuse, or wire segment.

- Connect the Probes: Attach one probe to each of the component’s or segment’s ends that you are testing; for smaller parts like fuses or resistors, alligator clips may have to be used to hold the probes down firmly.

- Read the Results: Take note of what happens on the continuity tester; if it shows continuity (through light, sound, or digital display), then there is indeed an uninterrupted path, i.e., component/wire is okay but not so where nothing lights up/fails to produce any indication meaning there is open in path somewhere along its length, i.e., component/wire has developed faultiness.

- Report Findings: Incorporate continuity test results into your routine electrical inspection reports to rectify any detected shortcomings for overall system reliability maintenance.

Following such methodical stages guarantees accurate and safe checks for continuity needed when troubleshooting electrical circuits.

Where to Buy a Reliable Electrical Tester?

Top Electrical Tools Shop Recommendations

Several stores provide good electrical testers, and at the same time, they offer quality services to their clients. Below is a list of recommendations:

Home Depot

Home Depot stocks all types of electrical testers for professionals and DIY enthusiasts. The store has many products from different makers, such as Klein Tools and Fluke, among others, which are known for being high-quality and reliable. Their website gives detailed information about each item, including its features and usage instructions; there are also customer ratings/reviews available so that one can know what other people think about them before buying anything online or picking it up at the store.

Lowes

Lowes is another big chain retailer where customers can find various brands like Southwire or Gardner Bender, among many others, depending on budget range or technical requirement levels while looking out for some new electricity-related tools. They have an easy-to-use site that allows users to compare products side by side based on specifications such as price and power source needed, etc.; apart from this, shoppers can read comments left behind by previous buyers who have already used certain items so far. Shoppers can also order shipping or pick up locally from any Lowes store nearby.

Amazon

Amazon offers a wider selection than most other websites because it provides a platform where different sellers can sell their wares side by side, thus increasing the chances of finding exactly what you need at any given time without having too much stress involved. Some popular brands listed here include Extech, Amprobe, Greenlee, etc., which come with features ranging from lower-end basic ones to higher-end models with advanced options like graphical displays showing waveforms, sometimes even Bluetooth connectivity capability built right into those tools themselves! Users interested in fast delivery times should consider signing up for a Prime membership.

In my opinion, these were the top recommendations for purchasing reliable electrical testers; each store offers a wide range of high-quality products at very competitive prices, coupled with great customer service.

Why Shop Electrical Products at Home Depot?

Home Depot is the best place to buy electrical products because it has a wide variety of quality tools and accessories. They stock top brands like Klein Tools and Fluke, so you know they are reliable and will work well for you. Their website is easy to use with detailed descriptions and user reviews that help people make informed decisions about what they need to buy. If you want more choices, come see us at the store in our electrical department. You can order online or do convenient in-store pickup if that works better for you too – we have lots of options! Home Depot also offers competitive prices on all their items and excellent customer service, making shopping here very satisfying!

Review Ratings of Popular Electrical Testers

To review the ratings of popular electrical testers, you need to consider opinions from reputable sources. Current top websites like The Spruce, Wirecutter by The New York Times, and CNET state that many different models are consistently given high ratings for being reliable, durable, and easy to use.

- Klein Tools MM400: This model is highly reliable and accurate in various electrical testing situations and frequently receives recommendations on this ground. Over 2000 reviews from platforms like Amazon and Home Depot have resulted in an average rating of 4.7/5, with users praising its solid construction and intuitive interface.

- Fluke 117 Electricians True RMS Multimeter: Professional-grade dependability sets the Fluke 117 apart; it often gets near-perfect scores, averaging approximately 4.8/5, according to various experts’ reviews and customers. Among other things worth mentioning are the capabilities for true root mean square measurements, which allow accurate readings even in noisy environments.

- Amprobe AM-570: With an average rating of about 4.6/5, people love this unit because it is packed with features yet still affordable. Users especially like how sturdy it feels due to its heavy-duty design and inclusion of advanced functions typically found on more expensive models.

By receiving such high ratings, these models prove their commitment to delivering quality products that perform well, thereby becoming trustworthy tools for anyone needing electrical testing.

How to Interpret Tester Readings?

Understanding Voltage Levels Displayed

Understanding voltage readings on electrical testers is essential for safety and accurate diagnosis. Generally, voltage levels can be divided into three categories: extra-low voltage (ELV), low voltage (LV), and high voltage (HV).

- Extra-low voltage (ELV): This refers to a range between 0-50 volts AC and 0-120 volts DC. It is used in areas such as small electronics, LED lighting, and telecommunications. When you need to check if there’s any voltage quickly, use the non-contact AC voltage detector. Besides, this range is known to be safe even when in direct contact with humans.

- Low Voltage (LV): Low voltage ranges from 50 -1000 volts AC and 120 – 1500 volts DC, commonly found in residential homes and commercial buildings for appliances like lights, among others that are powered by electricity from outlets. However, during testing, care should be taken against shocks caused by electricity or damaging equipment because of its sensitivity towards them.

- High Voltage (HV): High Voltage can be defined as any amount exceeding one thousand volts AC or fifteen hundred Volts DC. Multimeters are usually employed to measure such high voltages safely. Due to their dangerous nature, high voltages are limited to industrial setups and power transmission, where only trained personnel should handle them. Without proper knowledge about what they are doing, accidents could occur, which might result in loss of lives.

Once these classifications have been understood, then it becomes easier for people reading testers to correctly interpret their readings while at work as well as apply necessary precautions according to safety standards within their environment.

Interpreting Continuity Tester Results

Being able to read continuity tester results accurately is vital for the proper diagnosis of circuit continuity. This is an essential part of testing a circuit. It checks if an electrical path can be between two points, thereby establishing whether the circuit is complete or open.

- Indication of Continuity: Continuity testers commonly give out either visual or audible signs that show that there’s a continuous path. A steady light signal or continuous beep means that current can flow through uninterrupted when the circuit is closed.

- No Indication of Continuity: If this instrument doesn’t produce any signal, it indicates an open or broken circuit, i.e., somewhere along its route, there is a disconnection or fault. This knowledge is very helpful in finding and fixing wiring problems.

- Signals that Come and Go: Sometimes, we may get an on-off beep sound with intermittent light flashes; such signs represent loose connections or partial continuity. This implies that there are joints where wires have not been properly soldered, hence failing to maintain consistent contact at all times.

Depending on how one interprets these findings will significantly affect one’s ability to diagnose electrical faults correctly, thus assuring dependable systems while maintaining safety measures within them.

What Are the Common Problems When Using a Wire Tester?

False Readings: Causes and Solutions

Wrongful readings while employing a cable tester can be problematic and are caused by many factors:

- Battery Problems: A prevalent cause of wrong readings is a low or bad battery in the tester. Make sure that the tester’s battery is fully charged, or replace it if you see any signs of depletion.

- Dirty Contacts: Dirt, grease, or corrosion on the contacts for testing may prevent proper connection, leading to incorrect results. Clean all the contacts using an appropriate contact cleaner to achieve correct readings.

- Human Error: Using a tester wrongly, like placing probes at the wrong points or failing to follow the manufacturer’s instructions, can give false results. Always refer to electrical tester products’ use instructions from manufacturers or purchases. Always follow specified operational procedures and ensure correct probe positioning.

- Interference from Environment: False readings can also be caused by high electromagnetic interference (EMI) or static electricity in the surrounding area where testing is being done. Hence, accuracy may be improved by carrying out tests with this instrument under controlled conditions free from such interferences.

By tackling these common problems, one may minimize inaccurate readings and improve the reliability of their wire test findings.

Troubleshooting Common Electrical Tester Issues

When you encounter troubles with your electric tester, go through these troubleshooting steps for precise and dependable outcomes:

- Battery Check: Make sure the battery is good and charged. Weak or dead cells may cause fluctuating readings; therefore, replace them where necessary.

- Probe Inspection: Check for signs of weariness, dirtiness, or corrosiveness on the probes. Clean them using a contact cleaner and ensure they firmly connect with the wires under test.

- User Manual Review: Refer to a user manual for specific operational instructions. It should be appropriately used according to the manufacturer’s guidelines because this can prevent many problems.

- Test in Known Good Circuitry: Test on a circuit with a known stable voltage to prove whether it works. This will help you determine if there is something wrong with your device or what you are inspecting.

- Environmental Factors: Avoid environments with too much static electricity and electromagnetic interference (EMI), which can give false results. Do tests in controlled environments whenever possible.

- Test Setting Verification: Ensure that the measurement mode selected suits the task being done by your tester. Correct settings in multimeters guarantee accuracy, while wrong ones can also produce incorrect results.

By going through each one of these possible causes systematically, the majority of common issues related to electrical testers can be diagnosed and fixed, thereby ensuring reliable outcomes.

Can an Electrical Tester Help in Household Repairs?

Using a Voltage Tester for Home Electrical Work

Regarding home electrical work, a voltage tester is necessary for safety and accuracy. With it, you can identify live wires, gauge voltage levels, and check if circuits function well. Voltage testers are considered invaluable tools by The Spruce, Family Handyman, or Home Depot that should be used when installing new outlets, switches, or light fixtures, among other things. Homeowners must establish whether the electrical supply is active not to get electrocuted accidentally and ensure their repairs are successful. In short, this means that apart from helping diagnose electrical problems within a house setting, a voltage tester is an essential precaution during such repairs.

Checking Appliances with a Multimeter

Using a multimeter to test appliances effectively identifies electrical problems and ensures that they work. It can measure voltage, current, and resistance, which makes it very useful in various diagnostic tasks. Home Depot, WikiHow, and Bob Vila are among the best sources where I found this process on how to use a multimeter for checking appliances:

- Safety First: Unplug the device and discharge any capacitors before testing to avoid electric shock.

- Set the Multimeter: Turn the dial of your multimeter into an appropriate place. Set it to “AC Voltage” or “DC Voltage” for voltage checks, depending on what you want to check. For continuity or resistance checks, set it to Ohms.

- Test Voltage: Plug back in and then put one probe on each terminal while measuring volts. This helps determine if there’s power coming through this particular item being examined.

- Check Continuity: Unplug once more. To verify continuity, probes placed across different components (such as switches and fuses) should ensure a complete path for current flow; a low or no reading means good continuity, while a high or infinite reading points out a broken circuit.

- Inspect Specific Components: Measure resistance over specific parts like heating elements, motors, etc. Comparing readings with the manufacturer’s specs will tell whether they are working fine or not.

When used correctly, a multimeter follows these steps and can help diagnose and fix household appliances faster without compromising safety measures.

Reference Sources

Test light

Voltage

Electricity

Frequently Asked Questions (FAQs)

Q: What is a circuit tester and how does it work?

A: A circuit tester is an apparatus for determining whether there is electrical voltage in a given circuit. This device can locate live wires and help detect faults like broken circuits or bad wiring.

Q: How do I use a volt tester to check for live wires?

A: A non-contact voltage detector, also called a volt tester, can be used quickly to check whether wires are live. Such a tester works best for testing on the go. You just need to place the tester close to the wire; it will produce either sound or light (or both) when detecting electricity flowing through the wire.

Q: What should I look for in the product description when buying an outlet tester?

A: When purchasing an outlet checker, one must note certain important characteristics indicated on its packaging, such as simplicity in use, display type (e.g., LCD), range of voltage shown, and compatibility with GFCIs.

Q: Can I find low-voltage testers in Home Depot events?

A: Yes, during Home Depot events, different types of electric meters that measure low levels of electrical energy may be available. You may want to consult their listings or contact local stores for more information.

Q: What is a multimeter, and how is it different from other electrical testers?

A: A multimeter is any device capable of measuring current flow, resistance level, and potential difference across components connected within electric circuits. Unlike specialized testers, which merely detect the presence/absence of voltage, this tool provides more detailed information about various properties associated with electricity passing through conductors.

Q: What is the purpose of outlet testers about electrical safety?

A: Outlet testers verify that electrical outlets are correctly wired and functional. They can detect problems such as improper grounding, reversed polarity, and defective GFCI protection devices, thereby ensuring safe electrical connections compliant with codes.

Q: How important is CAT IV rating for circuit testers?

A: A circuit tester with a CAT IV rating is designed for use in high-voltage environments, such as industrial or service settings, where there may be transient voltage spikes. This rating ensures safety during electrical circuit testing.

Q: How should I choose the right cable for my electrical project?

A: When selecting an appropriate cable for your electrical project, consider factors such as voltage rating and application. Look at cable specifications and product descriptions, or seek advice from experts at local Home Depot events near you.

Q: Can automotive voltage testers be bought online?

A: Automotive voltage testers can be purchased online from different retailers. Look for terms like “12v-1000v” and “automotive” in product descriptions to identify what best suits your needs.