In today’s fast-paced world, internet connection is critical to individuals and enterprises, and it must be stable and fast. In this regard, fiber optic technology has become an essential means of data transmission, considering its capability to carry information over long distances at very high speeds, especially using OS2 fiber. In this article, we will examine fiber optic cassettes in detail, which are important in the interconnection of fibers and arrangement of fiber networks. In doing so, the audience can comprehend the role of fiber optic cassettes in providing contemporary communication network systems and make rational choices concerning their establishment and upkeep.

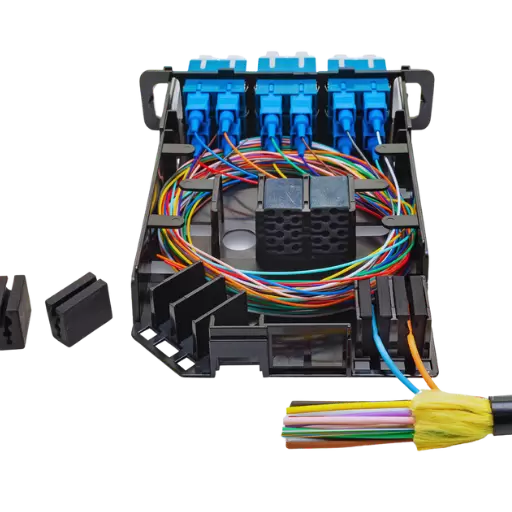

Fibre optic cassettes are considered modular units used in Fiber Systems to accommodate and organize fiber optic cables and fiber optic connections. Their basic role is to ensure the proper organization of optical fibers for better genetic and less damaging attachment whenever optimal conditions are needed. Cassette systems, by offering an ordered arrangement for joining, cutting, and connecting, increase the precision value in any form of fiber network. They have been made to suit different configurations, whether single-mode or multi-mode fiber, which aids in the exercise. Also, fiber optic cassettes play a role in the management of networks by allowing for easy servicing and prompt repairs, optimizing the use of networks in the business and home spheres.

A fiber cassette is an effective solution because it enhances network management in terms of its modularity, the order in which the elements are arranged, and how accessible they are to users. First, their shapes are modular, thus easy to add or remove, allowing fast upgrades or changes to the network design with minimal downtime. This characteristic is useful in active spheres where there is a constant need to make quick changes.

Next, fiber cassettes contain a systematic order of fiber connections’ storage that helps to avoid possible operational mistakes during repair works. If fibers stay organized and labeled properly, it will be easier for a technician to find and fix the problem, which would help lower the time taken to find and fix the problem and reduce working outages.

Finally, modern fiber cassettes are also provided with devices such as transparent covers and internal fiber management systems that are intended to improve the user’s visibility while operating them. These elements enable live observation and the effective replacement of parts before they need post-sale service because the coordinator can beat them to it. In general, cassettes render fiber optic networks status reporting and enhance their performance in how the operations are being conducted.

As is widely known, the average fiber cassette is composed of various components that are essential in making the management and connectivity of the fiber optic networks more practical and efficient. They include:

In general, these components work together to increase the operability and dependability of the fiber optic systems, improving the network speed and making maintenance easier.

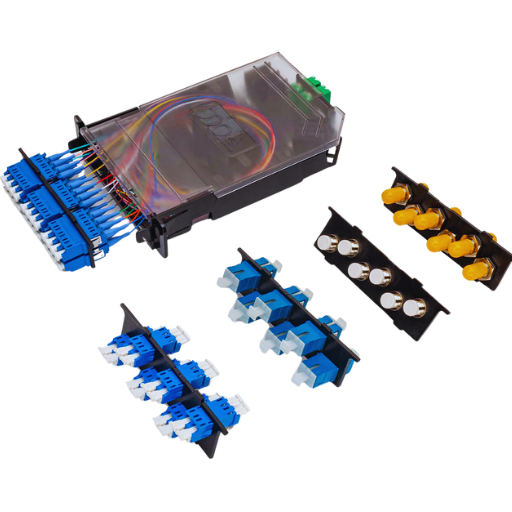

Fiber cassettes have been constructed in so many different forms primarily to cater to the users’ particular needs. The main divisions comprise standard, high density and modular. The standard fiber cassettes are for common use, usually centralizing the management and connection of many fibers. High-density fiber cassettes, on the other hand, are constructed such that a larger number of fibers are concealed in a small space-saving design that is best for data centers with constrained space. Concerning the design of the network, users are provided with a Modular cassette with different types of connectors and different arrangements to cater to a dynamic network. One must grasp the above elaborations in order to choose the relevant fiber cassette that would be appropriate to the design of the network to be able to achieve maximum efficiency and future expandability.

Splice cassettes provide essential connectivity between filament strands of fiber as it enables fiber-to-fiber splicing, which is necessary for extending or connecting fiber links”. It most commonly applies to cassettes where optics or fiber splices are stranded and managed proportionally to damage and preservation of signal loss. These explicit features highlight the necessity of splice cassettes, including splice trays to where the fiber’s bend radius is sustained, enclosing venues that prevent internetworking elements, and labeling for identification and management. Some industrial areas of use of splice cassettes include central offices, data centers & increasable network distribution points where integrity of connectivity is critical. They gain the necessary performance, simplify maintenance operations, and provide system capabilities when expanding in the future after the appropriate splice cassette is chosen.

In high-density fiber optic installations, especially in data centers and telecommunication networks, MPO (Multi-Fiber Push On) and MTP (Mechanical Transfer Push On) cassettes are critically important. Both types provide efficient interconnections between several fibers in a single connector but have several important distinctions.

The most important difference is the construction and functional features of designs. Most of the polishing dominant in the MPO connector is addressed in MTP cassettes, with new technologies resulting in greater precision in mechanical alignment and, thus, lower loss. MTP connectors may also include the polarity feature and other advanced capabilities and do not require waiting for migration to MPO systems.

MTP cassettes, on the other hand, have clip-on carriages that aid cleaning, thus enhancing uptime in high-volume operating conditions. A lack of knowledge of these issues may mean that network architects and operators do not optimize their selection of appropriate cassette type to achieve the desired level of performance and reliability in fiber optic applications.

Realizing these common difficulties, teams are in a position to take preventive steps toward increasing the success rate of fiber cassette installations.

To ensure that fiber optic installations perform adequately and last long, some of the methods are given below.

Through integration of these practices, organizations are able to prolong the life and efficiency of fiber optic systems, thereby decreasing costs of downtime and more.

Fusion splicing cassettes are key elements in high-density fiber optic networks and have the following significant advantages:

To sum up, in relation to the benefits the growth given by splice cassettes is what not only hinges modern fiber optic networks but also will enhance them in the future.

Breakout cassettes are important when organizing and managing the cabling connectivity in a fiber optic system since they help structure the fiber connections’ neatness. To begin with, they provide separation of focus fibers from greater multifiber cables which may then be evenly distributed even within the network enclosures. This lowers the chances of tangling and makes it easy for maintenance as well as upgrades since the fibers would be easily sighted or accessed.

Besides, the removal of breakout cassettes also helps to lower the bend radius of fiber optic cables as these management devices carry routing guides. This arrangement also serves the cooling and airstream requirement of the network and in turn lowers the overheating level of the optic device.

Moreover, the Modular design of a breakout cassette provides ease as it permits rapid change of connections without the risk of tearing down extensive cables. This is important especially in environments characterized by high density gerichal\Traits:biginner Cressezut Stressonodendromae they dont baddod many it.ioe, Signup now resulting exposes e in excessive rearrangement loss of normality. To summarize, breakout cassettes are considerably effective with regards to cable management because of organization, protection and flexibility that could be of great value in furthering the usage and durability of the fiber optic networks.

A reasonable and flexible approach to network upgrades is now more relevant than ever. Aging networks create a growing need for agility. Breakout cassettes help personnel quickly alter reconnections with little to no service interruptions during the upgrade phase. The modular system breakdown further enhances this self-restoration capability; parts and the whole infrastructure are overhauled without discarding the existing components.

Also, there are break-out cassettes that help to order and tape up extra resources, cataloging potential future upgrades or changes. They enable the washout of new fiber strands or technologies, which are increasingly becoming requisite with the Subsequent bandwidth growth. Therefore, while some immediate benefits may be derived from the introduction of break-out cassettes, the main reason for their use will be the evolution of the network owing to technology shifts and changing user requirements. To sum up, breaking out cassettes as a part of total cable management pushes for a timely and flexible network system.

The fiber cassettes are available in various fiber counts, including 12 fiber cassettes and 24 fiber cassette configurations to meet different types of networks. Standard configurations typically consist of 12, 24, 48, and 72 fibers, but higher configurations are available up to 96 or even 144 fibers for more demanding applications. As such, designers will be able to select for now and possibly for the future, the above infrastructure will expand proportionately to the flow of traffic over the network. In addition, these cassettes enable easy reach of every fiber for effective management or easy maintenance.

Fiber cassettes have certain benefits when compared to conventional patch panels in terms of density, structure, and administration. For starters, fiber cassettes are more efficient because their overall design incorporates more connections within a smaller area’s footprint, which utilizes the limited rack space more effectively. This is particularly helpful in data centers and spaces where area maximization is crucial. Further, fiber cassettes have a modular design and structure that allows for better organization by lessening the weave of cables and ensuring that every individual fiber can be accessed in an orderly fashion. This order and organization increase the efficiency of maintenance and repair activities in addition to the repairing processes. Moreover, due to the installation design of fiber cassettes, most of the time direct embedded snap-in don’t require tools, which makes them quicker for installation than patch panels. To conclude, even if traditional patch panels are still being used, fiber cassettes provide a better alternative as they meet the requirements of modern advanced network systems.

Indeed, fiber cassettes may be used in both single-mode and multimode networks. They are designed to fit the different types of fiber optics and hence have wider coverage. A single-mode fiber cassette handles long distances with low loss and high bandwidth capabilities and is, therefore, more suited for telecommunication and data center applications. On the other hand, a multimode fiber cassette handles shorter distances but has higher light throughput integration and is used in many intra-building or intra-campus short communications systems. Fiber cassettes’ compatibility with both fiber types encourages network designers as they allow for performance optimization and seek to address future requirements. This flexibility guarantees that when there are changes in demand, the organization will still survive because efficient communication networks will still be in place.

A: A fiber optic cassette is a small modular structure incorporating a few or all the fiber terminations into a single unit. It plays a significant role as an element within the structure, allowing fiber optic interconnections to be arranged in a compact, structured, and high-density manner. Cassettes are usually filled with pre-installed fibers, and most operations and repairs can be done with limited effort in data centers.

A: One particular fiber optic cassette designed in this manner, the available fiber optic cassettes would include the LC and SC connector types, also known as the E note connectors. They can be configured as duplex ports for bidirectional communication. Many cassettes have fiber connectors that apply to various networks, including high-density MTP® connectors.

A: Fiber optic cassettes with pigtails feature thin-walled materials that are terminated by extending short pieces of fiber the length that members the connector would dwell in the rear end of the said cassette. These pigtails provide versatile connection possibilities and can be used with splicing or in plug-ins to the devices. This arrangement does away with inbuilt splice trays, and I felt that it might ease the mounting process in some instances.

A: 12-fiber and 24-fiber cassettes are more dense and efficient in fiber optic networks. This means more connections can be implemented in a smaller dimension, which is quite useful where space is at a premium. Such cassettes can handle many high-bandwidth applications and are usually applied together with MTP®/MPO trunk cables for effective and versatile network uses, including those with duplex LC.

A: Fiber optic cassettes offer efficient connectivity in a data center, considering that they are high-density components that enhance an active rack space. They allow for the fast installation of pre-term connectors, reducing the time wiring is required and making it easier to make moves, additions, and changes. Cassettes also support various types of fibers, such as the single-mode and multi-mode OM3/OM4, so they can fit almost any data center demand.

A: The terms UPC (Ultra physical contact) and APC (Angled physical contact) describe the fiber optical connector polishing process. UPC connectors are flat-ended and widely used in various data communication applications. In contrast, APC connectors have an 8-degree angled end face that optimizes reflection characteristics and is primarily common in telecommunication and FTTx applications. A fiber optic cassette may be ordered as UPC or APC per the customer’s network specifications.

A: LGX-style fiber optic cassettes are to be used with LGX frames or panels, also called Lightguide Cross-Connect (LCC) cassettes. These cassettes facilitate a modular management method for the end users and are recognized for ease of installation and handling. As with other fiber/cassette combination styles, the LGX cassettes do not showcase wide variation in dimensions despite using different connector types and varying fiber counts, which, therefore, promote flexible and scalable network designs.

A: During the selection of fiber optic cassettes for a network upgrade, considerations such as the required fiber type single mode or multi-mode, the connector type LC, SC, MTP®, the fiber count 12F, 24F, and so on, and the compatibility with existing systems must be made. Also, look at the density of the cassettes, how easy they are to install, and options for growth, especially with regard to the design of the front panel. Make sure that the cassettes purchased fit and support the bandwidth requirements of the network and conform to the industry’s norms aimed at enhancing performance and durability.