Choosing an appropriate cable is crucial for maintaining the performance and dependability of networking infrastructure. Of the different cable types, Cat6 cables have become the most popular choice for residential and commercial applications because of their increased speed and lowered interference. However, these cables are not the same; their performance can differ drastically with changes in wire gauge, shielding, and even how the cable is constructed. This blog will analyze the differences in wire gauge and other features of Cat6 cables that are necessary for you to make wise decisions about your networking requirements. Whether upgrading your home network or working on a big installation project, knowing how these cable types differ will help maximize efficiency and longevity.

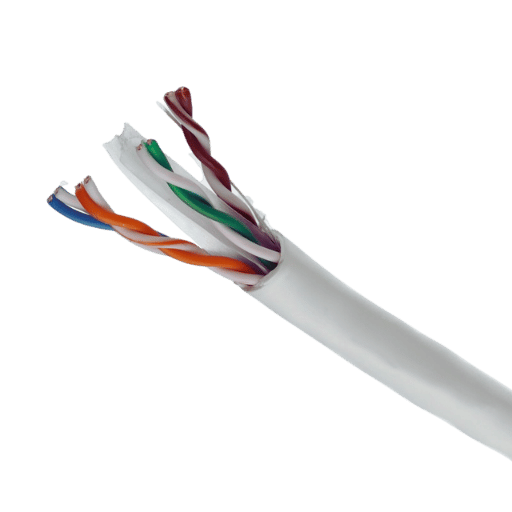

The cable gauge in Cat6 generally refers to how thick or thin the copper wires in the cable are. Most Cat6 cables use 23 AWG (American Wire Gauge) copper conductors that are thicker than the 24 AWG conductors found in Cat5e cables. This enhances the cable’s efficiency by supporting higher data transmission rates over longer distances, improving the cable’s performance.

The American Wire Gauge (AWG) system is a widely accepted standard for measuring the diameter of electrical wires and their components, such as those found in network cables. A lower AWG number denotes a thicker conductor and vice versa. Lower AWG numbers, signifying thicker conductors, considerably reduce signal loss and the current capacity barrier, making them suitable for high-performance applications such as Cat6 cables.

In Cat6 cables, the cable gauge is significant owing to the impact performance and reliability. A lower gauge AWG (a thicker conductor) lessens resistance, which in turn helps to reduce signal loss and makes better data transmission possible over longer distances, especially in cat6 23awg and cat6 24awg. This guarantees that the cables perform to the gigabit standards and higher-grade Ethernet connections. Furthermore, higher durability and lower overheating risk make thicker conductors more acceptable for harsher network deployment environments.

Cat6 is an upgrade to Ethernet, offering greater bandwidth, faster data transfer rates, and better signal quality due to reduced crosstalk compared to Cat5e. Meeting contemporary networking standards and requirements has never been easier with these advancements, providing enhanced scalability for the future.

Cat6 cables are capable of carrying a lot more bandwidth than Cat5 cables. Cat5 cables can support bandwidths of up to 100 MHz, which is usually enough for basic networking needs with speeds up to 1000 Mbps (1 Gbps). Cat6 cables, however, are meant to support bandwidths of up to 250 MHz and can carry a speed of 10 Gbps over shorter distances, making them more suited for high-performance networks. This bandwidth enhancement allows for advanced data transmission levels and greater network efficiency, especially with higher-grade cables like Cat6.

The size of a conductor has a significant effect on how a network cable performs. A larger conductor means lower resistance, which increases signal transmission and reduces the chances of data loss in long-distance transfers. This is critical in supporting signal strength in high-speed or high-frequency applications. Choosing the correct conductor size guarantees network performance and dependability.

When looking to achieve longer lengths, however, Cat6 surpasses Cat5 when it comes to cables because of heightened performance and a lack of signal loss. Cat6 has increased crosstalk and bandwidth support compared to their counterparts, increasing data reliability over longer distances. While Cat5 can effectively carry a distance of 100 meters, it is primarily helpful for lower speeds. Cat6, however, is far more effective at the same distance, especially in strides with gigabit speeds and greater. For better network reliability and future-proofing, Cat6 is the best option.

Indeed, Cat6 cables facilitate Gigabit Ethernet for up to 100 meters. These cables are intended for data transfers at speeds nearing 1 Gbps over this distance with minimal performance drop. Moreover, Cat6 cables have improved shielding to reduce crosstalk and strengthen the signal, guaranteeing dependable and consistent network connections even at the maximum supported length.

The copper wire remains essential for supporting gigabit Ethernet because it provides a reliable medium for data transmission over short to medium distances. Quality copper cables, including Cat 6 or higher, have better shielding and reduced crosstalk, substantially minimizing signal degradation at gigabit speeds. These cables can support transmissions up to 100 meters, fulfilling the communication needs in most standard network setups. Copper wire has proven to be a cost-effective, durable, and widely compatible solution for high-speed connectivity in gigabit networks.

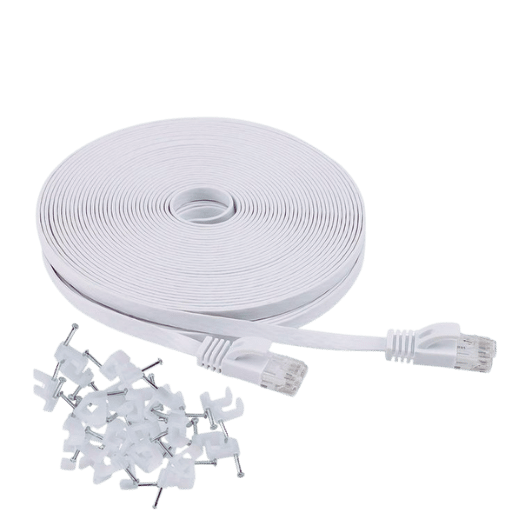

It is well known that solid wire is preferred over stranded wire when it comes to the installation of Cat6 cables due to its enhanced performance in fixed installations. Unlike stranded wire, solid wire employs a single conductor per wire for the cable, thereby minimizing the attenuation of signals and ensuring stable and consistent data transmission over long distances. This capability is particularly critical in category cables. Because of minimal data interference, solid wire makes it possible to install the cable in walls, ceilings, and other permanently wired infrastructure, which is critical for high-speed Ethernet performance. In addition, solid wire enables better termination in punch-down blocks and connectors, ensuring secure and stable termination.

To ensure there is no issue with the cable’s performance over high speeds, the use of quality Cat6 cables paid with proper installation procedures is vital. This is even more true when comparing cat5e and cat6. Such practices include observing the prescribed cable bend radius, not over-untwisting the wire pairs during termination, and employing certified connectors and punch-down blocks. On top of that, avoiding placing cables near sources of electrical interference, such as power lines and fluorescent lights, reduces signal degradation. If these instructions are correctly followed, the performance and reliability of the network will be optimized in highly demanding, high-speed scenarios.

The differences between the performance specifications and applications of Cat 6 and 6a cables are what sets them apart. For instance, Cat 6 pendant cables can achieve up to 1 Gbps with a frequency of 250 MHz, but only for a distance of 100 meters. On the other hand, Cat 6a cables are more advanced and better equipped for demanding environments, enabling the support of 10 Gbps speeds over 100 meters with an impressive frequency of 500 MHz.

Further, the enhanced performance of Cat 6a cables is attributed to the shielding and reduced crosstalk, which makes Cat 6a an ideal candidate for data centers and networks that face significant EMI interference. Conversely, Cat 5e and Cat 6 networks are more suited for lower-scale standard ethernet networks.

A: The primary difference between Cat6 cable 23 awg and Cat6 cable 24 awg is the diameter of the wires. Compared to 24, 23 awg has thicker wires and can handle more electric power while maintaining signal quality over distance. Because of these qualities, 23 awg wires are more appropriate for Power over Ethernet (PoE) applications, making them ideal for advanced data transmission needs.

A: Indeed, Cat 6 cabling is appropriate for PoE use cases. Cat 6 cables can deliver the proper power due to the thicker wire diameter, particularly with 23 awg. This is helpful for powering devices with data transmission capabilities, such as access points and cameras.

A: Cat 6 cables outperform Cat 5 and Cat 5e cables. Their enhanced construction features thicker conductors, enabling faster data transmission and better signal integrity. Consequently, Cat 6 cables can be utilized in higher-bandwidth 10-gigabit networks, which is impossible with the lower-level cables.

A: For certified performance, the maximum distance that Cat 6 cables can support for 10 gigabit Ethernet is 55 meters (approx. 180 feet). With Cat 6a cables, the distance can reach 100 meters (328 feet), which does not apply to certification standards.

A: Cat 6 cables can be utilized with Cat 5e and Cat 5 systems, making them backward compatible. As a result, existing network infrastructures can be enhanced without requiring a complete replacement of cables.

A: The AWG number for Cat 6 cables refers to the American Wire Gauge, which measures the thickness of the wire. Thinner wires with a higher AWG number are more resistant and have a weaker power capability. In contrast, cables with a lower AWG number are thicker, easier to handle, and more capable.

A: Wire gauge is crucial because it impacts signal transmission quality and the cable’s current-carrying ability. In Cat6 cables, when the wires are thicker, maintaining performance and integrity over distance is more leisurely. Thus, the cable 23 AWG is more suitable for Ethernet applications.

A: Cat 6 cables can support data and power transmission, making them suitable for PoE applications. These cables use their thicker conductors to transmit power while simultaneously transmitting high-speed data.

A: Category 6a has the advantage of facilitating 10-gigabit Ethernet over a longer distance of up to 100 meters. Cat 6a cables are constructed with more shielding and better materials to reduce crosstalk and retain the signal’s integrity at high frequencies.

1. Industrial Cable 8wire Cat. 6 Outdoor_PVC_en

3. Wire