As data centers continue to scale and demand faster, more reliable connectivity, high-speed copper solutions such as DAC (Direct Attach Cable), ACC (Active Copper Cable), and AEC (Active Electrical Cable) have become critical components in short- to medium-distance interconnects.

High-speed copper cables, with their advantages in high bandwidth and transmission speed, are poised to become the optimal solution for data center connectivity. These copper-based high-speed interconnects are primarily used for short-distance transmission scenarios within data centers, such as between servers and switches or between switches. Copper cable solutions not only help improve data transfer speed and reliability but also offer significant advantages in terms of thermal efficiency, signal transmission, and cost.

Each cable type offers unique advantages in terms of power consumption, signal integrity, transmission distance, and cost. Understanding the differences between DAC, ACC, and AEC is essential for optimizing data center performance and achieving efficient network deployment.

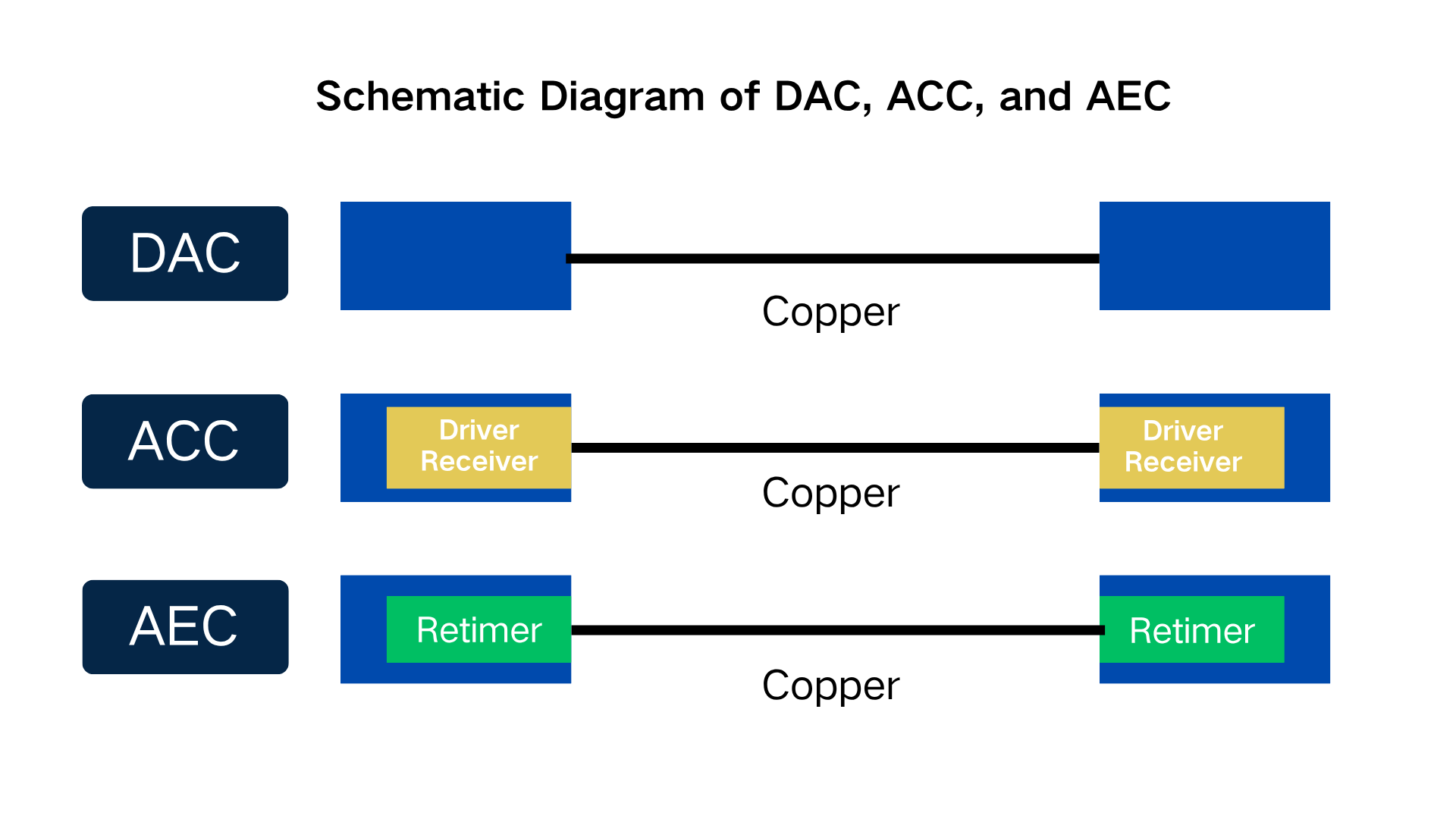

DAC (Direct Attach Cable) is a type of passive high-speed copper cable that does not require external power or signal conditioning chips. It primarily consists of copper conductors and connector modules.

DACs are widely used for short-distance interconnects in data centers, such as server-to-switch and switch-to-switch connections. The core technical principle lies in the carefully engineered physical structure of the copper cable, which enables high-speed signal transmission without the need for any active electronic components.

DAC enables high-speed signal transmission over short distances without any active components. Its key advantages include zero power consumption, zero latency, and ultra-low cost. However, due to the physical limitations of copper cables, DAC is only suitable for in-rack interconnections of ≤5 meters. As data rates increase to 112G-PAM4 and beyond, DAC is gradually being replaced by AEC and ACC solutions. Nevertheless, in ultra-low-cost scenarios within 3 meters, DAC remains an irreplaceable choice.

ACC (Active Copper Cable) is a type of high-speed copper cable used for data transmission. It sits between passive copper cables (DAC) and more advanced active electrical cables (AEC). Its core feature is the integration of a Redriver chip at one end of the cable, typically the receiver (Rx) end. This chip amplifies and equalizes the signal to extend transmission distance and improve signal quality.

ACC and AEC are both solutions designed to enhance high-speed copper cable signal transmission, but they differ in implementation and effectiveness. In simple terms, ACC is built upon DAC by adding a Redriver chip at the receiver (Rx) end to amplify and equalize the signal.

ACC places a Redriver chip at the receiver (Rx) end, using CTLE (Continuous-Time Linear Equalizer) and a driver to compensate for signal loss and reduce overall attenuation across the PCIe channel. Its primary function is to mitigate high-frequency signal degradation during transmission, thereby improving signal integrity and extending transmission distance.

ACC effectively expands the reach of traditional DAC (Direct Attach Cable), making it suitable for intra-data center connections, such as between servers and switches.

AEC (Active Electrical Cable) is an active cable technology used in data centers and high-speed network applications. By integrating signal processing chips (such as retimers) at both ends of the cable, it enhances signal integrity and extends transmission distance, making it suitable for high-performance computing and data center environments.

AEC enhances high-speed signal transmission by using a Retimer chip, which not only amplifies and equalizes signals at the receiver (Rx) end, but also reshapes and re-drives signals at the transmitter (Tx) end. This full-path signal regeneration significantly improves signal integrity and allows for longer transmission distances compared to ACC.

The Retimer chip in AEC is more advanced than the Redriver used in ACC. It integrates CTLE (Continuous-Time Linear Equalizer), DFE (Decision Feedback Equalization), CDR (Clock Data Recovery), and FIR drivers. These components work together to compensate for high-frequency loss, recover timing, and eliminate noise, ensuring cleaner and more reliable data transmission.

AEC cables are ideal for scenarios that require longer reach and higher signal fidelity, such as cross-rack connections or server-to-switch links in large data centers. They often integrate DSP (Digital Signal Processing), Retimer, and FEC (Forward Error Correction) technologies to maintain performance at longer distances and higher data rates.

In summary,ACC is suitable for scenarios where signal integrity requirements are moderate but transmission distance needs to be extended, such as intra-rack or short-distance server interconnections. In contrast, AEC is ideal for applications that demand higher signal quality and longer transmission distances, such as cross-rack connections or server-to-switch links in large-scale data centers.

Compared to traditional passive copper cables (DAC), AEC offers several advantages such as lower power consumption, lighter weight, higher reliability, and a smaller bending radius. These features make it ideal for the high-density and flexible cabling requirements of modern data centers.

Functionally, AEC provides stronger signal recovery capabilities and supports longer reach than ACC, though it also comes with higher cost. Therefore, the choice between ACC and AEC should be based on specific performance requirements and budget considerations.

| DAC | ACC | AEC | |

| Signal Integrity | Low, Susceptible to Attenuation | Moderate to Good, with Equalization/Amplification | Best, with Retiming Capability |

| Transmission Distance | ≤3 meters | 3–7 meters | 5–15+ meters |

| Cost | Lowest | Medium | High |

| Power Consumption | 0W (Passive) | Low Power Consumption | Higher than ACC (typically <1W per end) |

| Flexibility and Cabling Complexity | Stiff, Limited Bendability | Slightly Flexible | Highly Flexible, Ideal for Complex Routing |

| Application Scenarios | Short-distance, Cost-effective Deployments | Medium-distance Deployments | Medium-to-Long Distance & High-Performance Scenarios |

When selecting among DAC, ACC, and AEC cables, it is important to consider factors such as the actual application scenario, performance requirements, cost budget, and cabling environment. Below is a comparison of the three cable types along with selection recommendations.

DAC is suitable for short distances (≤3 meters), such as connections between servers and Top-of-Rack (ToR) switches within a rack. Its advantages include zero power consumption, low cost (approximately one-fifth of AOC), and low latency (<0.1 μs). However, due to physical limitations of copper cables, the maximum distance reduces to about 2 meters at 800G speeds. DAC is widely deployed in high port-density environments, significantly reducing overall costs.

ACC (Active Copper Cable) extends transmission distance to 3–7 meters by using a Redriver chip—for example, up to 5 meters at 56G-PAM4. It features relatively low power consumption (1.2–1.8W) and a cost that falls between DAC and AEC. ACC is well-suited for medium-distance connections such as cross-rack links, offering a good balance between cost and performance.

AEC integrates a Retimer chip to significantly improve signal quality and system stability. It supports distances up to 10 meters (typically 5–7 meters at 112G-PAM4) and has higher power consumption (2.5–3.5W). However, it offers superior signal integrity, with up to an 8dB improvement in SNR. AEC is ideal for high-performance computing and longer-distance transmission. It is also preferred in complex cabling environments or when high flexibility is required.

DAC is suitable for short-distance connections such as server-to-ToR (Top-of-Rack) switch links. It is ideal for cost-sensitive applications and in-rack interconnects where flexibility requirements are low.

ACC is suitable for medium-distance interconnects, such as from a 2U chassis to a rack switch. It fits deployments that require moderate signal integrity—offering better performance than DAC but without the higher cost and capabilities of AEC.

AEC is ideal for high-density, high-throughput data centers. It is well-suited for multi-hop links or scenarios requiring signal retiming, as well as cabling environments with space constraints or tighter bending radius requirements.

Over the next five years, the high-speed cable market is expected to triple, with AEC accounting for a larger share due to its advantage in transmission distance. As major companies increasingly adopt custom ASIC-based networking, demand for AEC in AI data centers is driving rapid growth in its market potential.

Since DAC is passive and consumes no power, it will remain one of the preferred solutions for most data centers, especially non-AI data centers. According to LightCounting’s forecast, the global high-speed cable market (including DAC, ACC, AEC, and AOC) is expected to reach USD 6.7 billion by 2029.

In summary, DAC, ACC, and AEC cables each have their own advantages and play distinct roles in high-speed, low-latency data center interconnects. ACC is suitable for medium-to-short distances and cost- and power-sensitive applications, offering a good balance of performance and price. In contrast, AEC—with its superior signal integrity and flexibility—is better suited for medium-to-long distances and complex cabling environments with high-performance demands.

Choosing the right solution requires a comprehensive consideration of transmission distance, system performance, cost budget, and deployment environment to achieve optimal network architecture and long-term sustainable development.