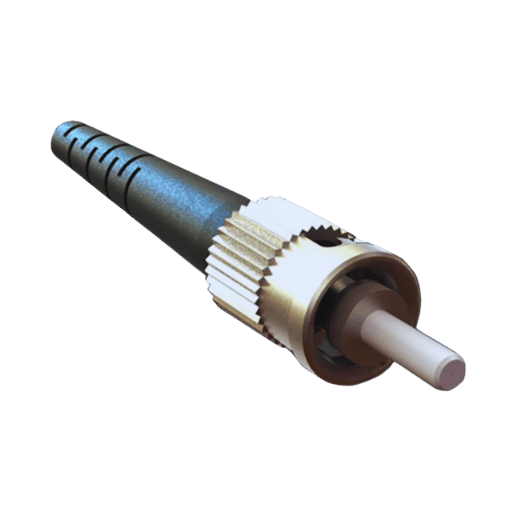

Networking and telecommunications commonly employ ST connectors. AT&T invented these kinds of fiber optic connectors and has gained a reputation for being strong and easy to use. The bayonet-style coupling system they utilize ensures a safe connection can be established that won’t fail easily, making them excellent for situations where reliability is essential or signal loss needs to be kept at a minimum. Most often, an ST connector will include a 2.5mm ferrule made out of ceramic, stainless steel, or plastic, which helps keep the fiber cores aligned correctly so data can be sent accurately.

An ST fiber connector is a type of optical fiber connector. This connector connects optical fibers in such a way that they align accurately for good signal quality during transmission. It is also called Straight Tip because of its shape. For fast and secure connections, it employs a bayonet-style coupling mechanism. Short-range and long-range network systems use ST connectors extensively; examples include LANs, telecommunication networks, and fiber optic instruments, among others. They are designed to be strong so that they can withstand harsh conditions without losing much signal strength.

ST connectors’ strength and dependable performance have seen them widely used in different fiber optic network applications.

These examples show why ST connectors are essential for properly functioning fiber-optic networks. Fiber optic connectors connect and maintain these networks efficiently, preserving reliability while ensuring efficiency is not compromised.

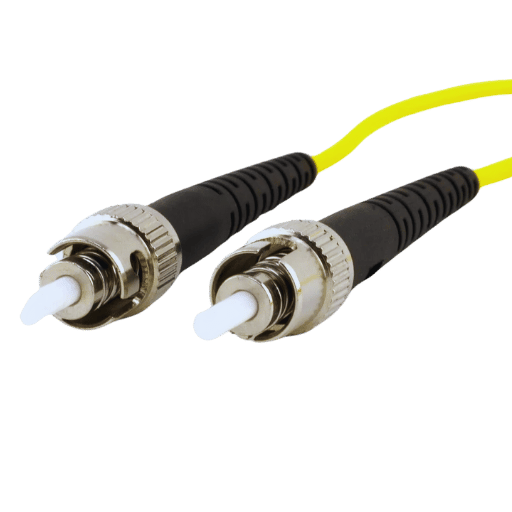

Single Mode ST connectors are particularly intended for far-reaching data transmission with minimum signal loss in high-precision fiber optic applications. They have a small core of approximately 8-10 microns, which means that just a single path of light can pass through them. This greatly decreases modal dispersion and allows data to be sent over more than 10km without corrupting the signal.

Single-mode ST connectors find their greatest use when communication over long distances is crucial, like metropolitan area networks (MANs) or telecommunication backbones that require high bandwidth and long-range connectivity. When making a choice between single mode and multimode ST connectors, always consider your network’s needs. Fiber optic connectors are used to connect different segments based on these needs. For instance, if you want to set up an internet connection between two buildings on opposite sides of town, then I would recommend using single-mode st connectors because they support long hauls at high speeds, while multi-modes work better in short ranges with lower data rates.

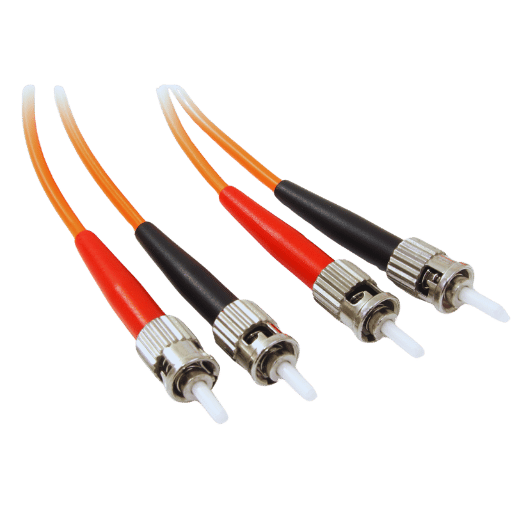

Multimode ST connectors are designed to support different light modes that let light propagate through a larger optical core, typically around 50 to 62.5 microns. This wider core size supports the use of low-cost light sources such as LEDs and Vertical-Cavity Surface Emitting Lasers (VCSELs). Therefore, multimode connectors work very well for short-range data transmission where high bandwidths are required over distances not exceeding 2 km.

Commonly used in local area networks (LANs) and data centers, multimode ST connectors provide strong yet affordable connectivity solutions for applications that do not require the long reach of single-mode fibers. Although they may have higher modal dispersion than single-mode fibers, thus causing potential signal degradation over longer lengths, their simplicity and lower costs make them suitable for many commercial and industrial environments. As such, whether to use single mode or multimode depends greatly on the specific distance and data rate needs of the network under consideration.

If we compare the ST connectors of single-mode and multimode, we will find that they are different in several aspects which suggest what they should be used for. It is only one light mode that can be allowed to propagate through Single-mode ST connectors since they have a small core diameter, usually around 8-10 micrometers. This kind of fiber allows data transmission over long distances exceeding 10 kilometers with low signal loss and high data rate, thus being best suited for long-haul telecoms systems or cable TV networks. On the other hand, multimode ST connectors have large core diameters (50-62.5 μm) so as to accommodate cheaper light sources. These are meant for short-range applications within buildings like campuses or data centers where the maximum distance required is less than two kilometers. Although multimode ST connectors suffer from modal dispersion, they still provide affordable means of transferring large amounts of data quickly over short distances. Fiber optic connectors are used effectively in such cases. Therefore, whether one opts for a single-mode or multi-mode ST connection would depend on such factors as the specific network needs in terms of distance, speed, and cost constraints among others.

Ensure you have the tools and materials below to put in or remove ST fiber connectors:

Light Source & Power Meter: After installation, testing connections made during the setup phase to identify whether they’re functioning as expected is important. Thus, a light source plus power meter will help you do this task easily.

An ST connector has many benefits in different environments. Fiber optic connectors are used extensively due to these benefits. The first is that they are known for their reliability and durability, which is why they can be used indoors or outdoors. I like the fact that you only need to twist and lock the connector because it makes a solid connection that wont break when shaken or dropped. Also, this type of connector is great because it can work with single-mode or multimode fibers, so it’s very versatile. Lastly, another reason why these connectors are so good is because they have been around forever, and everyone knows how to use them. Plus, if something does go wrong, there are plenty of spare parts available, which means less downtime for businesses that rely on their systems running 24/7.

These connectors are unique among others of their kind because they are made strong and always work. In order to resist environmental damage and mechanical stress, these connectors adopt a rough stainless steel structure. To ensure the connection is firm, this mechanism involves twisting and locking it in place, which also helps enhance signal integrity, hence reducing interruptions. Moreover, different sectors have used them widely under various conditions, proving dependable over time, thereby becoming an industry standard. Therefore, professionals from all walks of life can rely on them since physical toughness goes hand in hand with demonstrated dependability; no wonder I always recommend ST for use in unstable areas as well.

ST connectors are cost-effective, which is why many companies prefer them. They are available at competitive prices because they have been used widely and in the market for a long time. Bulk purchasing options also reduce costs when implementing them on a large scale. Another reason is that they have simple designs and can be easily installed without requiring special tools or much training, thus reducing labor expenses. Given the fact that there are many spare parts, maintenance, and replacement of these connectors become cheap, too. The general inexpensiveness, durability, and versatility of ST connectors make them an affordable choice for fiber optic networks, which need to be reliable but not expensive.

Visual Examination: Start by visually checking the connectors. Check for any signs of damage, dirt, or dust on the mating sleeve and ferrule. Even minor pollution can cause signal loss or connection failure.

Cleanliness: Make sure connectors are clean. Use a fiber optics cleaning kit to remove debris or oil. Before retesting the connection, clean both connector end faces and ports.

Optical Power Meter Test: Measure signal strength using an optical power meter. Compare this with expected values for your system. If there are noticeable discrepancies, this could indicate a problem with the cable itself or at one of its ends.

Alignment of Connectors: Ensure connectors are properly aligned and fully seated. Fiber optic connectors are used to connect components securely when properly aligned. Mismatches may result in weak signal transmission and additional insertion losses.

Network Tester: A network tester can be used to diagnose fiber optic network issues more precisely. This will help you determine whether the connectors or other network components are the problem.

By following these steps, you will be able to identify systematically some typical ST connector installation problems that may affect the reliability and performance of your fiber optic network.

Proper Techniques for Cleaning: Be sure that both the connector ferrule and mating sleeve are clean. In order to eliminate contamination which can interfere with proper alignment, use alcohol-free cleaning solutions along with specialized fiber optic cleaning tools.

Inspection and Adjustment: Scratches, chips, or defects on the ferrule end face should be examined with an inspection scope. Replace any damaged connectors as necessary. Make certain that the connector is polished correctly for best contact maintenance.

Tools for Alignment: When installing ST connectors, use alignment tools and fixtures to achieve accurate alignment. Ensuring correct alignment is critical as fiber optic connectors are used to connect network segments precisely. To minimize issues with alignment, consider purchasing higher-precision connectors with tighter manufacturing tolerances. Fiber patch panels can help in organizing these connections effectively.

Managing Tension: Test fiber cable tension levels; excessive tension may lead to misalignment and signal degradation. Take strain relief measures to maintain correct alignment and connection integrity.

Following these techniques, technicians will be able to effectively address problems related to alignment and ferrules, thereby ensuring that fiber optic networks maintain high-performance levels. Fiber optic connectors are used to connect components accurately, maintaining high performance.

Physical Damage: It is necessary to replace the connector if there are any visible signs of physical damage, such as cracked sleeves, bent pins, or discolored housings. These types of damages can greatly affect a connection’s performance and reliability.

Performance Degradation: Monitor your fiber optic network’s performance regularly to check its performance. If signal loss or bandwidth decreases noticeably, inspect connectors. Continuous and unexplained problems with system performance could mean that they need replacing.

End Face Contamination: Change the connector when you realize that after cleaning, the ferrule end-face remains contaminated or damaged beyond repair. This will ensure good signal transmission and prevent other network troubles from occurring.

Following these conditions promptly guarantees strength and effectiveness throughout your whole fiber optic system.

A: Straight Tip connectors, also known as ST connectors, are a type of fiber optic cable connector with a bayonet-style mount. They are widely used in multimode and singlemode fiber networks because they are strong and easy to use, incorporating components like the LC connector.

A: The difference between ST, LC, and SC connectors is in the method of attachment, where the first one has a bayonet mount system; LC has a snap-in lucent design, while SC employs a push-on square mechanism. Each type is specific to certain applications based on installation needs and space restrictions.

A: Ceramic ferrules align fibers with the high precision required for the efficient transfer of light between them, hence their use in optical connections. They are also very tough and can withstand abrasion, which makes them last longer than other materials used for this purpose.

A: A fiber patch cable connects two runs of fiber optic cables so that different network devices within an optical network can be linked. These cables come with different types of connectors, including ST, LC, or SC fiber optic connectors.

A: Singlemode refers to the mode of light propagation through an optical fiber having only one path, whereas multi-mode fibers have many paths which cause modal dispersion, thus limiting bandwidth over long distances; therefore, it uses an adapter mechanism to connect two single-mode st fiber optic cables end-to-end ensuring consistent, stable connection necessary for long-distance data transmission through – this is what is called “ST to ST bulkhead fiber coupler Singlemode.”

A: Fiber optic patch panels are assemblies with many connections for fiber optic cables. They serve as a central point for the management and organization of cables and connectors, including LC connectors and snap-in lucent connectors, thereby streamlining network maintenance and enhancement.

A: An st-to-st coupler is employed when linking two ST-terminated fiber optic cables together. It is perfect for extending the length of current fiber runs without extra splicing or complex connections, often utilizing FC connectors for seamless integration.

A: Yes, adapters can join various types of fiber optic connectors, such as LC to SC or SC to ST. Fiber optic connectors are used to connect different types of adapters. They make it possible to switch seamlessly between different connector types, thus enabling diverse network configurations.

A: Due to their ruggedness, ease of connection, and ability to withstand harsh conditions, ST connectors find wide applications in industrial settings, including military installations and healthcare facilities. Additionally, they feature prominently on secure and stable multimode/single-mode fiber networks where reliable fiber-optic links are required, often utilizing snap-in lucent connectors. Fiber optic connectors are used extensively in these systems.

A: Regularly clean your fiber-optic cable connectors by removing dust particles and contaminants that may have accumulated over time using appropriate cleaning tools designed specifically for this purpose. Proper storage should also be observed to prevent them from getting damaged physically, while signal integrity must always be handled with care.