Side-cutting pliers are a common household name used in modern woodwork. They are far more useful than they appear. Side-cutting pliers are designed with precision engineering and excellent manufacturing standards owing to their numerous applications in cutting, gripping, and manipulating wires and other materials. However, mastering these tools goes beyond the art of merely pressing the handles together. This article explores the world of side-cutting pliers and their design, applications as well as tips for cutting tools experts use to maximize these side-cutting pliers’ sardonically versatility. Whether you’re an electrician a craftsperson, or a hobbyist, knowing the full potential these essential tools possess will help you refrain from approaching projects as burdens. Prepare to learn side-cutting secrets that mold you into a neck professional and transform your skills forever.

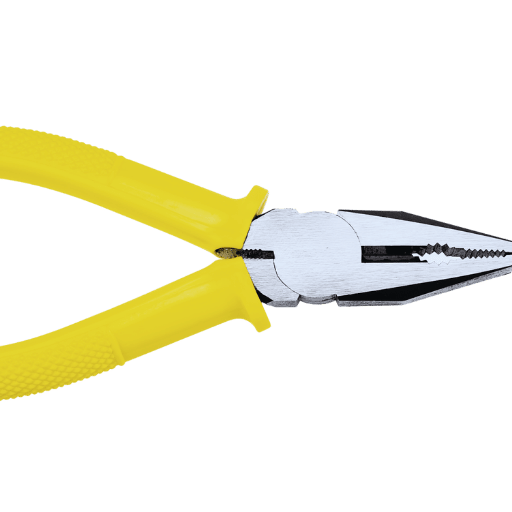

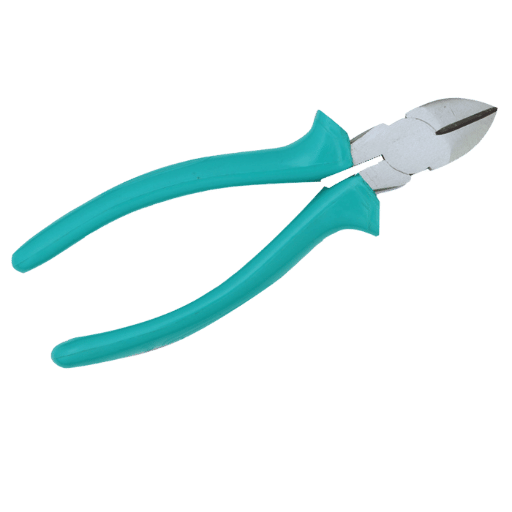

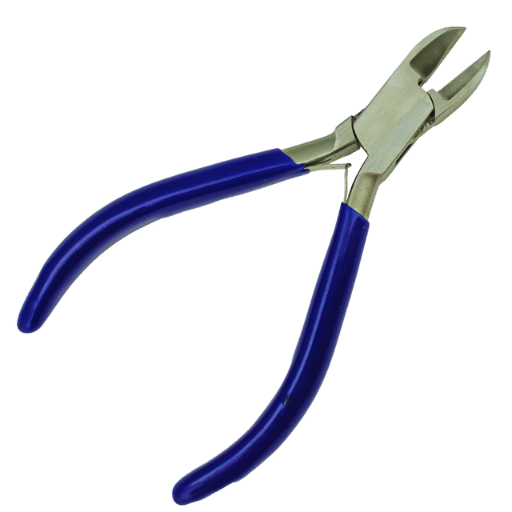

Side cutting or diagonal pliers are hand tools specifically created for the purpose of cutting wires and small metal parts. These forms of scissors have their cutting edges set at an angle, which enables precise cuts without crushing or deforming the material. The tool works by applying or focusing pressure on the material through the sharp jaws, effectively severing it. Side-cutting pliers serve a particular purpose, like trimming wires, cutting thin metal rods or clips, cutting tie wraps and zip ties, etc. Their small size and firm structure make them adaptable and dependable for small tasks and construction projects.

The purpose of this tool is what dictates its design. The jaws of the cutting pliers are precision machined from hardened steel, ensuring sharpness and longevity. Moreover, the handles are ergonomically designed with non-slip surfaces to offer the user’s hand comfort together with a strong grip when in use. The joint construction is designed for optimal force application, allowing the user to make clean and easy cuts with little effort. This uncomplicated design makes cutting pliers useful in a variety of settings, whether professional or domestic.

Side cutters are invaluable aids in electrical work since they can precisely cut and remove the insulation of wires. Their custom features make it possible for electricians to reach tight spaces in junction boxes, electrical panels or even conduit systems. Modern side cutters are made out of high quality alloys which increases their resistance to wear enabling the side cutters, even after prolonged use, to retain sharp edges throughout cutting tough materials like copper or aluminum wires.

In a study concerning tools used for manual work on electrical systems, side cutters are reported to be used in roughly 60% of tasks involving wire manipulation, which showcases their relevance to daily operations. Side cutters have features that allow angled cuts to the side which aids in clean cuts that do not squash or mangle the wire and insulation which reduces damaged circuits. Moreover, the advanced design of the handle aids in minimizing operator fatigue while assigning new professionals the ability to accurately and efficiently perform tasks over long durations.

For applications involving high-voltage, a number of side cutters are designed to comply with IEC 60900, which helps protect users from electric shock up to 1000 volts. This enables compliance with the set safety standards and builds assurance during crucial tasks. This and more are the reasons that make side cutters an indispensable aid for electricians bearing the brunt of multiple electrical needs in projects by maintaining functionality, safety, and strength.

Precision Cutting

Versatility

Enhanced Durability

Ergonomic Design

Cost-Effectiveness

Improved Accessibility

Non-Sparking Options

Support for High-Volume Production

These versatile tools accomplish a great deal of tasks including trimming, cutting, and shaping wire, making them useful across many professional fields.

Material Quality

Cutting Capacity

Comfortable Grip

Spring-Loaded Mechanism

Corrosion Resistance

Focusing on the specific features needed from the tools can ensure reliable performance alongside the expected results.

While comparing Knipex to other plier brands, Knipex emerges as a leader in the market due to its emphasis on reliability, accuracy, and strategic design. For instance, Knipex is regarded as a premium brand, as their products are manufactured using advanced standards and high materials that guarantee chrome vanadium electric steel. In addition, Knipex tools are cutting-edge implements because the blade dentures on the cutting pliers are sharpened and extend to greater lengths due to inductive hardening techniques.

Other popular brands, like Klein Tools, IRWIN, and Stanley offer competitive options at a lower price. However, Klein Tools is highly regarded for their ergonomic design that enhances craftsmen’s comfort. Due to advanced mechanisms and retractable adjustment buttons in the Cobra series, Knipex remains the frontrunner when comparing cutting and wear-and-tear efficiency.

It cannot be disputed that Knipex tools are overly priced compared to average manufacturers, which must be paid for their precision and construction grade workmanship. This can be seen in the tools designed for construction or mechanical work where the guaranteed enduring performance justifies the cost.

User reviews, alongside expert evaluations, almost universally place Knipex above competitors in tool longevity and ergonomic considerations. For instance, when evaluating the cutting force applied versus the durability of the tool’s jaw, Knipex tools provide much lower force application and appear less worn compared to other tools. This preference is justified as Knipex stands out for professionals whose primary consideration is precision and durability.

Other brands offer good value for casual use, but Knipex distinguishes itself as the go-to for specialized high-performance tools with exceptional engineering. The right tool is largely an outcome of one’s specific requirements, but Knipex’s unwavering commitment to quality and innovation positions it favorably for those contemplating long-term trust.

Knipex 74 08 200 High Leverage Diagonal Cutters

Channellock E337 Diagonal Cutting Pliers

Klein Tools D248-8-GLW Glow in the Dark Diagonal Cutters

IRWIN VISE-GRIP Diagonal Cutting Pliers

Each of these tools caters to different preferences ranging from professional-grade features to general usability.

Use Proper Instruments for Each Task

Place the Material in the Correct Position

Exert Uniform Force

Clean and Maintain the Unit

Do Not Practice Twisting or Levering

Check for Damage and Wear

Sharpening Blades

Store in a Dry Location

Choose the Right Tool for the Material

Recall assessments Cutting tools

Using such techniques ensures that the effectiveness and durability of the tools is maximized which reduces idle time improving the overall operational efficiency of the workstation.

The leverage system in high leverage side cutters aims to optimize cutting force while reducing the user’s effort level. This is attained through the arrangement of the pivot point which is nearer to the cutting edges, thereby increasing the mechanical advantage. As a result, the tool is capable of thicker and harder material cutting far more efficiently than conventional side cutters. Besides improving performance, the design also lowers user exertion, which is beneficial for demanding professional tasks.

In the electronics field, high-leverage side cutters are other cutting tools used in conjunction with various machines. These tools can be used for a wide variety of multitasking purposes and offer durability for different electronic applications. Enumerated below is a list of their applications.

Cutting Wires and Cables

Trimming Component Leads

Removing Insulation and Sheathing

Cutting Zip Ties and Fasteners

Shearing Small Screws and Bolts

Dealing with Hard Materials

These examples illustrate the productivity benefits that rest up on the high-leverage side cutters used in electronic workflows since the tools need to bring in precision and effectiveness.

The specific requirements of the task assist in determining the choice of either high leverage or standard cutters. High-leverage cutters work best when cutting thicker wires, hard materials, or difficult components. They are perfect for electronic repair or assembly where efficiency and build quality are critical factors.

Standard cutters, in contrast, are more suitable for light maintenance work, for example, cutting thin wires or performing general upkeep. These cutters are more manageable when severe cutting power isn’t required. With the proper tool selection, optimal performance and minimum risk of damaging the materials or components being worked on is achieved.

Amazon

Home Depot

Lowe’s

Grainger

Harbor Freight Tools

To determine authentic Knipex diagonal tools, consider the following steps:

Study The Brand’s Logos

Review The Product’s Cover Box

Assess The Workmanship Standards

Buy Only From Authorised Vendors

Cross Verify With The Brand Site

Using the aforementioned instructions will help you spot authentic Knipex diagonal products while avoiding fake ones with confidence.

The price of side-cutters is frequently indicative of their effectiveness, especially with brands known for their quality, such as Knipex, which offers remarkable materials, meticulous design, and assured functionality. Cutters from less-known brands tend to be on the cheaper side due to using subpar materials, which compromise their effectiveness over time. Cutters from premium brands are not only more durable, ensuring a longer lifespan, but also offer unparalleled performance when compared to their cheaper counterparts, ultimately saving you money down the road. It is still advisable to evaluate the budgetary constraints in combination with the intended purpose of the tool, as excessive or professional use will suffice the premium price tag of high-end tools.

A: Side-cutting pliers or lineman’s pliers are multipurpose tools that have cutting edges on their jaws. Unlike other types of pliers, they have gripping and cutting functions, making them important for electrical jobs and general work. With side-cutting pliers, you can easily cut wires and grip many other materials due to their design.

A: You can do a lot with side cutting pliers when it comes to DIY projects. They can be used to cut wires, nails, and even thin sheets of metal. They can also be used to grip and twist wires, remove staple clips, and bend small metal parts. Having side cutting pliers is ideal for DIY enthusiasts because of the many uses they have.

A: If you want to get the best out of your side cutting pliers, search for top posts that highlight using these tools, maintaining them, and comparing them with other types of pliers. Many online users as well as forum members have shared their experiences so this is a good option for learning tips and tricks of using this crucial tool.

A: The primary consideration when selecting side-cutting pliers should be the tasks being performed. For general use, an 8-inch plier is quite popular, but for working with smaller wires or in cramped places, a 6-inch plier may prove to be more appropriate. If the task is particularly rigorous, then a 9-inch plier, or possibly even larger, may be more suitable. Depending on the country, an inch or a millimeter is used for measurement, so check the specifications you need before making the purchase.

A: Although I cannot show off pictures directly, I can explain various types of side cutting pliers. The standard lineman’s are pliers that come with thick handles as well as protruding jaws while high leverage ones have the cutting edge much nearer to the joint to maximize the cutting power. Some have special ergonomic grips while others are insulated and used for electrical work with colorful handles.

A: To maintain side cutting pliers, clear the surfaces of any debris and clean them after every use. The cutting edges should also be kept sharp and can be honed with a file from time to time. Ensure that light oil is applied on the pliers to prevent rust, particularly on the hinges. Avoid using the pliers on materials they were not intended for, and store them in a dry place. With proper care, these tools can serve you for many years.

A: Side-cutting pliers are simple to use and understand. However, the following precautions ought to be observed: Safety glasses should always be worn to avoid being struck in the eye by loose debris. Always check that you have a firm grip on the tool before pulling, and remember to keep your fingers away from the cutting edges when the pliers are in motion. Never cut into live electrical wires unless they are properly insulated. Do not use them as a hammer or to pry things open, as this poses a threat of injury and can damage the tool.

A: Certainly, there are a number of specific tips on how to use side-cutting pliers more efficiently. While cutting, place the wire as close to the axis as possible. Employ the back section of the jaws for grasping flat items. For more precise cuts, utilize the area closest to the tip on the cutting edge. In case you twist the wire, you must hold it strongly and turn the pliers, not the wrist. Adopting these procedures will enhance your efficiency and the quality of your results.