Aspects of optical fiber interconnect technology reflect its efficiency and reliability as the key characteristics. SC/APC connectors, as some of the best, determine demand in many areas of telecommunications and data transmission. This in depth SC/APC Connector Guide will provide information such as the design characteristics, dimensions, and other benefits of this connector as compared to other connectors. Readers of this article will also appreciate why SC/APC connectors are relevant in the present-day communication networks as well as their function in such networks.

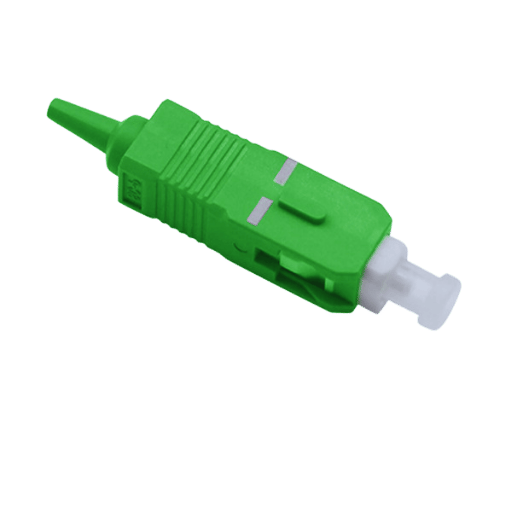

SC / APC fiberglass connectors are equipped with angular polishing of the ferrule end face, which allows the optical fiber to be connected with considerable precision and minimum losses. SC is a Subscriber Connector, which has a liner form but uses push-pull coupling to install and remove easily. APC means Angled Physical Contact, which is basically the polishing of the fiber end with an 8-degree angle to reduce the back reflection noise and improve the quality of the signal. This type of connector is used in High bandwidth applications such as FTTH (Fiber to the home), CATV, and data communications networks.

An SC (Subscriber Connector) is classified as a fiber optic connector with a push-pull mechanism for ease of installation and disengagement. It has a rectangular body with a snapping procedure that locks the connector in position. The connector is characterized by a low insertion loss and a very high rate of repeatability, which makes it especially useful for telecom and data communication applications. The SC connector comes equipped with a 2.5mm ferrule and is very reliable for performing interconnections in networking systems.

The polish of the Angled Physical Contact (APC) is useful in all aspects by limiting back reflections. This is very important when dealing with high-power and high-frequency applications where the quality of the signal is of utmost importance. With an 8-degree angle on the end face of the fiber, the fundamental feature of this type of polish also prevents the core from minute reflections that would have traveled through the core by making the excess light gets refracted into the cladding instead. This proportionately cuts down the optical return loss ORL and improves the overall network.

Some of the important technical aspects of APC polish are:

Also, due to the design, such connectors do not cause fluctuations in connections, which are important in systems such as dense wavelength-division multiplexing (DWDM), and passive optical networks (PON). These qualities rendering a typical intraclconnector apc polisher connector is integral in modern optic communication system fixture.

When it comes to singlemode fiber networks, the use of the APC-polished connectors is particularly beneficial because they help reduce so much back reflection that interferes with the signals. In most cases, this type of network is suited for high bandwidth and long-distance transmission of data, which is steadily enhanced by the use of the APC connectors. Such connectors yield the least amount of insertion loss and more return loss, hence promoting effective data transmission.

APC-polished singlemode connectors are critical in high-precision environments, where there is little tolerance for signal degradation, such as telecommunications, data centers, and long-haul networking. They allow high-speed applications to perform optimally, and improve network performance as well in view of the increasing need for high-capacity communications infrastructure. This makes the use of APC connectors necessary in advanced single-mode optical networks.

The simplex fiber optic connector is a single-channel application. It has one fiber core which is uniplanar in nature. Thus, it only works in one way – it can transmit data, but only in one direction. This type of connector is useful for devices that do not require two-way communication. The overall simple structure of the simplex connector enables easy alignment and placement helping to prevent any significant loss of the signal and securing proper bonding. This allows it to be used very efficiently and economically for certain types of data transfer, specifically carried out in one direction only for a specific paradigm.

While analysis is often useful when studying connectors, it is important to note the distinctions between simplex fiber optic connectors and duplex connectors. The differences include the following key factors:

In conclusion, it is meaningful to find out the factors in the selection process between simplex and duplex fiber optic connectors in relation to application requirements such as data directionality, complexity, and capacity levels.

SC (Subscriber Connector):

LC (Lucent Connector):

Singlemode Fiber:

Multimode Fiber:

In conclusion, the decision on the singlemode and multimode fiber optic cables depends on the network requirements, especially with regard to the length, bandwidth, and cost.

A low value of insertion loss is an important criterion for fiber optic systems as it has a bearing on the operation and efficiency of the optical network. Insertion loss is defined as the light that is extinguished when adding a new optical element like connectors, splices or adaptors. Lower insertion loss implies that more optical power is directed towards the intended target enhancing the signal levels and data quality. Both signal degradation and increased bit error rates due to high insertion loss undermine the reliability of the entire communication system. Low insertion loss is however critical for the preservation of the high level of performance especially in the case of long and high rate networks where the quality of the signals is crucial. Replacing components with better quality and using better placement techniques may lower insertion losses to yield stronger and more efficient networks.

Prepare the Fiber Optic Cable

Cleave the Fiber

Cure the Epoxy

Polish the glass of the SC/APC Connector

Examine the Connector

Test the Connector

Install Fiber Cable Assembly

By adhering to these steps, SC/APC plug connectors will be fitted with high standards on quality of installation and reliability when used in connection with a fiber optic installation.

Insertion Loss Too High

High Return Loss

Epoxy Not Curing

Fiber Breakage During Polishing

Connector Not Fitting Properly

Contamination on the End of the Face

Most, if not all, issues outlined above with empowering solutions should allow one to fit within en optimal range if not continually seeking to push the limits with their fiber optic installations.

As in any technical installation, maintenance is very important in order to maintain proper functioning and prolong its operational life.

Putting all these maintenance practices in place, will go a long way in increasing the reliability as well as the efficiency of your fiber optic network.

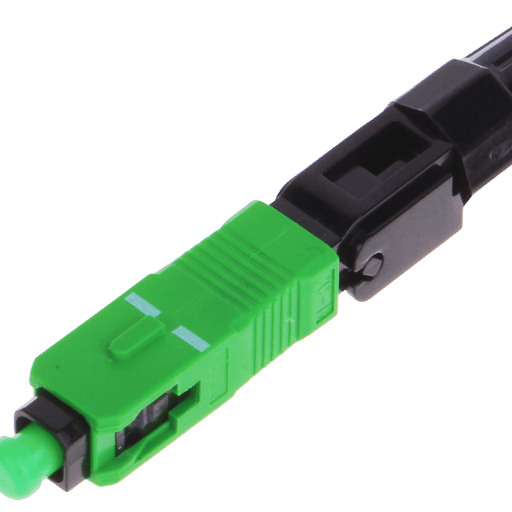

Field Installable SC/APC Connectors possess several characteristics that are very important for the purposes of network installations. To begin with, they enable quick and easy deployment on-site, thus eliminating the need for factory pre-terminated cables. Furthermore, they ensure a high performance from the connections which include low insertion losses and high return losses. In addition, these connectors help to cut the total expenditure and construction period by reducing the use of specialized tools and complicated termination procedures. Finally, of course, they can be used in many projects, such as fiber to the home FTTH, data centers, or enterprises with effective network performance.

Connectors and field installable SC – APC connectors, which are known for minimizing time with fast and simple installation, stand out in efficiency. The installation of these connectors at the site does not need factory pre-termination because termination may be done as soon as the connectors are required, which cuts downtime. Their nominal configuration facilitates the construction of a reliable and high-quality connection by a technician with little or no skills. Further, there is a reduction in operational costs because there are no, or very few, expensive tools or complex processes. So, you can use them for FTTH deployment as well as in the data center where they still offer use for small and large networks.

Switching to Field Installable SC/APC Connectors can enhance the economy of the fiber optic networks. These connectors do away with the need for pricey pre-terminated cables, thus providing the advantage of on-site termination and cutting down the capital costs that would have otherwise incurred. Most of these devices are easily fitted, reducing the efficiency of the wage bill as less skilled people are used. also there is less operational costs due to the reduced tools and equipment required coupling with other aspects of the fiber expansion. The applicability and functionality of these connectors over time tend to reduce the cost that could have been incurred through maintenance and repairs in the fibers. Therefore, they are an economical solution with regard to Fiber-optic connections since they allow deployment of the networks in a cost-effective manner while upholding higher levels of performance and reliability.

SC/APC connectors are distinguished by the advanced physical contact orientation (APC) making sure that back Reflection is minimal. This makes them suitable for high bandwidth applications as well for long distance signals. Also, their field- installable feature enables fast and effective termination and therefore increases the level of efficiency and cost-effectiveness in different sets of network deployment.

No, SC/APC connectors are usually used in the application of single-mode fiber optic designs. Multimode applications normally make use of SC/UPC (ultra physical contact) setup as it does not require angled polish, which is a must for reducing back reflection in single-mode fibers. Different optical properties and core sizes exhibited by single-mode and multimode fibers require that suitable connector types be used if optimal performance under normal operating conditions is to be achieved.

There are many critical steps involved in connecting and terminating SC/APC connectors. First and foremost, all fiber optic connectors, as well as splices, must be cleaned properly to remove dirt, which can cause signal loss or reflection. The fiber ends are to be stripped, cleaved, and polished using appropriate tools as precisely as possible. Connectors should be attached to the fiber using the casing according to the instructions provided by the manufacturer while making sure that it is well-positioned and stable. A VFL is used to perform final checks on the fiber alignment and the connections. Connectors should occasionally be checked and serviced where necessary to maintain their performance and usability within the network.

A: The term SC/APC stands for Subscriber Connector/Angled Physical Contact. It is a fully exploited type of fiber optic connector that is most commonly seen in the connections of fiber optics networks. The SC connector is grab-and-pull type of a fastened connector that supports easy relocation, while the APC simply means the 8-degree polish cut ferrule which helps to reduce back reflection and loss of the light signal.

A: The SC/APC-Connectors are widely employed in simplex single mode fiber applications. They are made in green housing for ease of recognizing and the endface is angled distinguishing it from SC/UPC and other spacetone flat endface connectors. Since they are straightforward to use in high dense optical interconnecting networks, SC/APC connectors have low loss and high performance with many optical fibers such as OS2 optical fibers.

A: A fiber optic cable is basically made of one or more fiber strands, protective buffering and an outer jacket and is mainly used to interconnect differenct networking elements. A pigtail also known as pigtail fiber optic is a small section of fiber optic with one end terminated with a connector the other being a connector. Pigtails are mostly resorted to in the case of fusion splicing or connecting devices to a patch panel.

A: SC/APC connectors have several benefits, within: 1. Very low insertion loss and high return loss 2. Wide usage under high density bandwidth requirements 3. Easy coupling provision either through pull push mode 4. Easily identifiable by green colour 5. Usable on fibre optics systems 6. Not susceptible to very moist conditions These facts make SC/APC connectors suitable for various applications, such as Fiber To The Home networks.

A: There are two generally accepted techniques to connect an SC/APC connector to a fiber optic cable. 1. Fusion splicing: This technique incorporates inter-fiber melting with inter-fiber attachment fusion, where heat is supplied to soften various portions of the end portions of the fibers in question. It demands extra equipment but results in low loss and high reliability. 2. Mechanical splicing: In this method, a mechanical device quickly holds the two ends of the fiber in place and aligns them. It is faster and cheaper but there could be slightly more loss in comparison to fusion splicing. In both cases, however, requisite preparation of the fiber prior to splicing then involves removing 900µm buffer and cleaving the fiber end.

A: Simplex SC/APC connectors have one fiber connection. Hence, the data transmission is uni-directional over a simplex configuration. It is commonly deployed in instruments wherein information passes in only one direction. A Duplex SC/APC connector comprises two simplex connectors back to back, thus allowing communication both ways. Network equipment or switches requiring data to be transmitted in both directions frequently use duplex connectors to link other pieces of equipment.

A: To clean the SC/APC connectors and maintain them: 1. Other fiber optic cleaning tools such as Megan wipes or cleaning cassettes should be used 2. The end of the connector should not be as bold as a touch with bare hands 3. A fiber microscope should be used to check the connector both before and after cleaning 4. The connectors should be kept with dust caps on when not in use 5. The connectors are to be treated with care to prevent the request for repairs of the ceramic ferrules. Appropriate cleaning and treatment of specific SC/APC connectors will go a long way to enhance their performance as well as durability.

A: SC/APC connectors are made for SC/APC connector pairings. There is no sure way to achieve connector-to-connector pairing with the ordinary connectors, including SC/UPC connectors, because these connectors just have an angled recess face. Nevertheless, SC/APC connectors may be adapted for use with other types of connectors by means of hybrid patch cables or adapters when absolutely necessary. Using the right connectors is very crucial since the connectors are designed to keep signals intact without any strive from the fiber optic networks.