Optical fibers, especially the peculiar orange fiber optic cables, are now at the center stage as nations continue to modernize and evolve towards globalization, aided by the internet, which has certainly become a universal basic need. Such globalization practically cannot be achieved without the use of internet technology, and thus, it calls for the exploration of even internet infrastructure inside various countries. The article will delve deeper into various characteristics of orange fiber optic cables and their significance in the telecommunications and IT infrastructure. Readers will also be able to understand how this type of cable helps achieve better global communication. Putting these pieces together, professionals and inquisitive readers will be able to understand the importance and evolution of these cables toward achieving better communication worldwide.

As required throughout this text, data shall include fiber-optic data cables of all sorts. Orange fiber optic cable, as a rule, is a multimode fiber-optic cable used for data transmission over a limited distance. In particular, these fiber optic cables are dense multimode used in data centers and various uses in office networks. The yellow ones are mostly single-mode fibers. These fibers and cables can be used in data centers where fast data exchange is required so that multiple light modes can be transferred along with broadband. They are especially useful for communication within the network, where high data transmission rates are a necessity.

Multimode fiber optics employs a core diameter of around 50 to 62.5 micrometers that is relatively larger than that of single-mode fibers, consequently enabling the propagation of several modes of light at the same time. This property makes it ideal for short-range communication links. As multimode fibers, orange fiber optic cables are able to connect short distances over large bandwidths and at low cost, which makes them suitable for use in campuses, data centers, and LANs. However, it is important to note that the use of larger cores increases ease of use since there’s no need for detailed alignment by reducing the accuracy required in light coupling from equipment, which does come at a cost of increased modal dispersion, thus limiting distance in contrast to single mode fibers.

Core Diameter:

Wavelengths and Light Sources:

Distance and Bandwidth:

Cost:

Applications:

Describe limitations in order to engineer effective and cost-sensitive fiber optic networks that meet operability requirements.

The use of Orange Fiber, which is derived from citrus waste, is an innovative way to use textile materials. This fiber has been used greatly in the fashion industry since it increases the value of the product while decreasing waste and the need for the use of plastics. Orange fiber is also one of its unique features, and it has the capacity to be friendly to the environment through degradation. Furthermore, it has a nice appealing feeling on the body, just like the silk, making it perfect for the luxury market. Recent data suggests the production of orange fiber may create new uses for thousands of tons of citrus byproducts every year, which would fastibrate the practices of a circular economy. Furthermore, firms that use orange fiber have reported increasing customer interest as the focus on sustainability as an element of the purchase increases. Technology and processes governing the production of orange fiber are still being developed, and such improvement surely would expand its use from just textiles to other industries looking for environmentally friendly materials.

The factors that should be taken into account when considering the use of OM1 or OM2 are bandwidth, distance, and cost. OM1 possesses a core diameter of 62.5 micrometers and is suitable for transmissions requiring up to one gigabit per second (1 Gbit/s) over a distance of less than 300 meters. On the other hand, OM2 offers increased bandwidth with a much 50-micrometer core and can support 1 Gbps to about 600 meters, which is good for long distances. One could surmise that OM2 is more expensive than OM1, but the additional performance parameters enhance an organization’s flexibility and potential for growth. Such factors guarantee that the selected medium type fits into the expected transmission goals as well as the financial resources allocated for the network.

The most suitable compression should also be in accordance with the bandwidths and compression ratios determined for other general resources in the network environment. Think about the geographical area of either the end-user or the data center location in conjunction when evaluating these factors. Many applicants might define the requirements for one application, which would include only video streaming or only X services, where X is one of the various data processing services. However, each application has different specifications and bandwidth occupancy capabilities. In addition, reliability and scalability issues should be of prime consideration, accepting that with the advent of newer technologies, the need for further development of the infrastructure will be paramount. A more rational standpoint is achieved where there is just enough provision for the immediate requirements while allowing room for future development without needing any large-scale microwave systems, as the designated fiber optics cable would allow for minor upgrades in traffic and future growth, thus providing better efficiency and cost savings.

The role of polyvinyl chloride (PVC) and riser ratings is critical in ensuring efficient cable installations, particularly in the building’s wiring network. PVC cables are produced with a sheath of polyvinyl chloride, which is much less expensive and provides some degree of protection. However, because it can emit harmful smoke during a fire outbreak, PVC is limited to nonplenum areas only. On the other hand, riser cables, which are indicated by a certain UL rating, can be used in vertical spaces like between stores and buildings. They are, however, better than normal PVC, which is patented, whereas their performance is not as good as plenum-rated cables. In the recent reports, the data presented indicates that riser cables do pass through multiple tests, one of them being the UL 1666, which states that the undetermined basic limit of certain conductors should certainly limit the flame in the riser space. It is advisable to consider project-specific working conditions and fire prevention that have to be built into a building before deciding to take a stance on whether to use PVC cables or riser-rated cables, ensuring that they are compliant with relevant codes.

The orange jacket color alludes to OM1 fibers, forms the base of the shorter allied ranges, and is classified within the multimode fibers with a core size of 62.5 micrometers, which permits gigabit speeds somewhere in the range of 850nm and 275m range. A 1300nm range witnessing impenetrability of 550m remains possible. OM1 cables have a wide numerical aperture of roughly 0.275, enabling them to focus light across a broader range of modes and diameter dispersion. Though these cables are cheaper and well suited for older systems, they are viewed as obsolete, with their growth potential stagnating, especially where newer standards like OM2 and OM3 have been introduced. This brings the need for careful assessment of the speed and requirements of the network to ensure that not only are organizational goals and objectives met, but they remain feasible in the future.

When contrasting OM1 and OM2 cables, it is important to examine their core size, technical characteristics, and operating conditions. What follows are the principal distinctions and characteristics:

Core Size:

Jacket Color:

Maximum Speed Transmission:

Maximum Transmission Distance:

Mean numerical aperture:

Working Conditions:

In terms of improved reach and marginally greater effectiveness, OM2 cables have a distinct edge which fits into contemporary networking requirements without a noticeable increase in cost. According to network planners, the only consideration about whether to choose OM1 or OM2, would be factoring in the current requirements of the infrastructure as well as plans for expansion in the future.

As a first generation of multimode fiber, OM1 compromises high performance of data rate and distance and so is on more outdated Networks. In practice, OM1 is often used in data centers to provide an intra-building link of short distance within an installation that seeks to lower infrastructure costs or in situations in which older OM1 cables do not warrant an upgrade. Although it has lower bandwidth than the technology that succeeded it, OM1 is still able to operate at up to 1 Gbps, which suffices for basic networking works, which include everyday video communications and voice. Additionally, OM1 remains suitable for networking in small and medium enterprises where the low cost of opting leaves little opportunity cost of not choosing the faster available fibers. The advances in networking techniques are prompting most companies to switch to better types of fibers like the OM3 or OM4, but OM1 is still useful for some applications, for example, those where cost and the hardware setup are the most important aspects.

In particular, by inviting the description of the steps in sequence, the installation of a multimode fiber optic cable is completed correctly for proper performance in the network infrastructure.

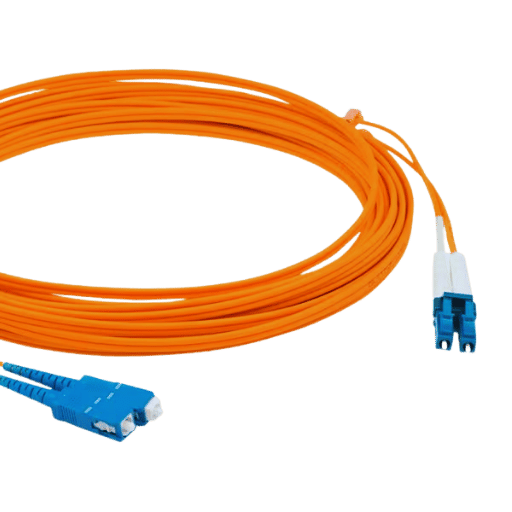

LC to LC fiber optic connectors are essential components of fiber optics communication technology because they are better compacted, and performance-wise, they are several leaps ahead. LC connectors are among the most commonly used mechanical splices for optical fiber wires and networks, given that they have low return loss and low insertion loss, thereby ensuring constant and efficient data flow. Their small form factor makes it possible to cluster them, thus increasing the number of ports available on switches and patch panels. Furthermore, LC connectors are easily applied in singlemode and multimode applications, which strengthens the base of such patch cords within structures. LC-to-LC connectors enables the organization to provide a better communication network by providing lower levels of noise, better distance effects, and increased overall effectiveness of the system.

In order to secure the accountability and the workability of the fiber optic installations, it is necessary to pay attention to the proper securing and management of the cable jackets. In order to achieve satisfactory outcomes, the following procedures are recommended:

Incorporating these best practices into new technologies will improve cable management strategies, minimize the chances of signal degradation, and enhance the efficiency of the network as a whole.

Feedback received from customers regarding the patch cords’ performance infers that factors such as durability, signal integrity, and ease of installation and application are critical. Customers always express satisfaction with patch cords produced by leading manufacturers such as Belden and Leviton because of their strong construction and dependable functions, even in extreme data networking use. As gleaned from the last information provided by Google, it has also been emphasized that the focus of patch cords aids in the effective usage of dielectric insulation materials and gold connectors, which address signal loss problems. Apart from this, users prefer products from various manufacturers that come in different lengths and colors so that the cable management system is efficient and neat in terms of appearance.

Analyzing the comments of brand customers , it has been noted that there are a number of advantages concerning the quality of patch cords. To begin with, users appreciate the quality of the cord materials themselves, emphasizing that the reinforced materials and the exact manufacturing make the product last longer without getting damaged. Next comes signal performance, which is quite often mentioned also, here the clients express their satisfaction with the fact that the data transfer metric is stable and is, as a rule, because of high-quality materials used for use conductors and appropriate shields from electromagnetic interferences. Thirdly, and in most cases, there are many satisfactory remarks regarding the installation factor, whereby users seem to appreciate simple designs that allow quick application and easy merging with different network formations. Together, these factors improve the client experience by providing networks that are effective, simple, and robust.

Users have highlighted several issues regarding patch deployment cords, which have been frequently discussed, as evident from the data. Signal attenuation, for instance, is known to be a common problem that contributes to both data and transmission loss. To circumvent this issue, patch cords that are manufactured using top-grade copper or gold connectors tend to do the trick as they decrease resistance and help transmit signal over longer cord distances.

Insertion and withdrawal of cords too many times can also result in weakening of the cable. In many of the technical articles it is recommended that reinforcement in material composition and strain-relieve designs be utilized in order to prolong the life span of the cable. Connectivity drops on the other hand tend to occur quite frequently due to poor configuration of the network or the materials used. If cables are utilized with better shielding to eliminate electromagnetic disruption and proper installation aspects are maintained, the rate of connection disintegration can be greatly reduced.

Moreover, the complexity of the setup makes it hard for the customers to deal with the cable clutter. Patch cords that are of different lengths and color coded are said to be the best option as they help with cable organization and repair while reducing setup time, as reported by the industry. Taking into account such issues and implementing appropriate fixes allow the users to improve the reliability of their networks.

A: In most situations, a cable that’s orange would be identified as being multicolored in optical reception. This means that it is utilized in areas where large data transfer is handled over short distances. This separates it from the singlemode fiber, which is predominantly yellow in color.

A: The core diameter in mm of a multi-mode fiber optic cable is usually 50 or 62.5 and allows for a range of light modes. It is also ideal for short distances and is commonly orange in color. In contrast, singlemode fiber has a narrower core, preferably used in long-distance communication.

A: An LC to LC OM3 fiber optic patch cable is called a multimode duplex cable; it has LC connectors on both ends, and om3 is a cable type. It has an aqua color, which stands out. It was also created using fiber optics. This device can easily handle 10GB Ethernet connections.

A: In case of data rates of about 10 Gbps, OM1 multimode patch cords with a core of 62.5 microns are used for networking purposes on shorter distances which are mainly located between buildings or within the data centers.

A: Such members provide structural reinforcement in optical fibers used together with copper wire by preventing physical deformation without electricity conduction, rendering them suitable for use in places where electricity wiring or conductivity is a concern.

A: The lengths and the configurations of fiber optic cables are contingent upon the characteristics of the network to be interconnected and the fact that it is part of an infrastructure configuration. It is also worthwhile to note how far data needs to be transmitted, as well as the type of environment the cables are to be placed in, as these factors do influence the successful configuration of the cables.

A: The term “corn” in the context provided does not seem to connect in any way with fiber optic cable production. It could be included as a metaphoric or an industry jargon not connected with the basic workings of a fiber optic cable.

A: The National Electrical Code outlines several safety objectives that guide the installation of fiber optic cables in a bid to help mitigate risks such as cable faults and arcing by ensuring a particular way of usage compliance with both materials and methods to be used.

A: The first construction material to offer several advantages over copper wiring is fiber optic cables, which possess higher bandwidth capabilities, longer distances without degradation of signal transmission, electromagnetic immunity, and lighter and thinner construction, allowing for easier installation.

A: It is a patch cable with LC plugs at each end. It is intended for interconnecting network devices and supports a maximum of 10Gbps. Its purpose is primarily for high-speed data communication within a data center, and it is offered at various lengths to meet customers’ standards.