Digital involvement has also required that data and transfer are managed reliably and efficiently, therefore increasing the demand for new advanced solutions related to networking. Among them, the use of fiber optic cables is one of the remarkable areas whereby large volumes of data can be transmitted with relatively little loss of the original signals, if at all, over large distances. This paper is concerned with OFNR cables (Optical Fiber Nonconductive Riser), which include the most widely used fiber optic cables that need to be installed in vertical orientations, such as riser systems within multi-story buildings. Thus, through explaining the applications, benefits, and technological specifics of OFNR cables, we expect that we have provided enough understanding, which, together with the recommendations provided, will present selection criteria for people’s wire needs. Most importantly, in today’s digital age, the growing importance of fiber optic technology necessitates sophisticated know-how to assist in advancements and innovations.

OFNR (Optical Fiber Nonconductive Riser) fiber refers to a kind of fiber optic cable that is meant to be used vertically in a building or a structure. It has a nonconductive sheath, which prevents any electrical interference, making it suitable for riser applications where cables have to be routed vertically from one floor to another. This construction guarantees that the requirements for safety are met and further enables the performance of data transmission. The transmission of high-speed data over relatively long distances is achieved by passing light signals through the core of the cable with greatly reduced signal loss. Its design features fire prevention measures and power durability, which is important for building regulations during a fire outbreak.

Optical Fiber Nonconductive Riser, in its acronym form OFNR, represents a type of fibre optic cable that has no metal components. Hence, such type of construction cannot be electrically conductive. Primarily utilized in the vertical riser shafts of cemented structures such cables are manufactured and built in accordance with the rigorous safety and standards requirements. Such type of cables is highly recommended due to their capability of transmitting voice, data, and video signals of up to 1,000 Mbit/s, along with low negligible electromagnetic interference.

The OFNR cables have various uses and applications. In the telecom sector, these cables are predominantly used for floor connections within the internal networks of multi-story office edifices. In an OFNR data center, the racks of servers and switches located within the various floors of the building are connected via OFNR cables. Such cables are important for the seamless integration of the building management system, which facilitates communication between heating, ventilation, air conditioning, securing, and smart devices. In addition, OFNR cabling is also found to be relevant in education and health sector institutions where access to the internet and wireless communication with advanced medical technology and devices operate core functions and clinical services. Their large market penetration indicates not only flexibility but also the general trend to provide more effective and safer in-building telecommunication systems.

The cable jacket of OFNR fiber optic cables serves to protect the inner fibers from environmental and mechanical stresses. The jacket is made of flame retardants, which also meet the building riser safety standards, including fire safety. Besides securing the fiber from physical moisture and chemical attack, the jacket also maintains flexibility for ease of installation. Also, the jacket being nonconductive increases the applicability of OFNR cables in places where interference by electric signals has to be minimal. The jacket is vital in the protection, safety, and performance of OFNR fiber optic systems.

Telecommunications OFNR cables can use nonconductive materials within their structures in OFNR cables and, in so doing, gain a basic advantage in performance and safety in certain applications. The most outstanding feature of nonconductive materials is the capability of electrical insulation, which is very crucial in environments such as riser locations where interference due to protrusion of electrical signals can be detrimental. Aramid yarns, as well as several plastics, are usually applied for this purpose at the cable construction level in order to avoid such circumstances from occurring. These fillers are also making the cable more robust by avoiding electrical shorts and enhancing the strength of the network as a whole. Furthermore, non-flammable materials ensure adherence to building regulations by ensuring that the fire tolerance of the cables in the required areas is achieved without the transmission of electricity through the cables. This is, therefore, apt for the riser parts of multi-store buildings, which necessitate the dual purpose of fire protection and electrical non-conductivity.

Optical Fiber Nonconductive Riser and Optical Fiber Nonconductive Plenum cables are both compatible with network infrastructures that contain fiber optic cables, however they have specific characteristics that best suit them to different environments. Following the description of the two types of cables is a detailed comparison of their key differences.

Application Environment:

Fire Resistance Standards:

Construction and Materials:

Cost:

Regulatory Compliance:

Being aware of all these distinctions is essential in assisting you in choosing the right type of cable which is based on the installation needs and the building regulations. When this awareness is provided it provides the opportunity to maximize the performance of the deployments while ensuring safety as well as regulatory obligations.

OFNP cables are predominantly used in plenum regions where there are very stringent requirements in relation to the materials used, in this case, those which greatly limit the spread of flames and the amount of smoke produced. Because these areas normally have a high air movement, they greatly enhance the degree of risk in the event of a fire which makes the additional protective features of OFNP cables absolutely necessary. Meet the requirements established by the NFPA-262 standard, which attests that these cables are designed to suit heavily regulated environments like hospitals, data centers, and commercial skyscrapers where the protection of life and critical assets is of utmost importance. On the other hand, OFNR cables are for the most part applied in less critical areas where such standards are more relaxed and less stringent.

The significance of fire rating in the choice of OFNR and OFNP cables can only be determined if the baseline factors, such as the safety aspects and overriding rules specific to each, are known. Concerning those pitted against each other, the OFNR, although cheaper in those areas away from plenum zones, does, however, pose safety grievances in quarters where the risk of fire and smoke is high. This is in contrast to OFNP, which improves fire resistance and reduces combustion and smoke production, which is vital in the smoke zone during fire outbreaks. The higher classification of OFNP cables, however, meets the tough safety and building regulations, especially in environments where the lives of people and the physical structures are crucial. The need for such standards meets the physical composition of such environments. Hence, the specific environmental conditions that necessitate the installation of the cables determine the choice between OFFNR and OFNP cables.

Considering the jacket materials for OFNR cables, it is prudent to distinguish between the Polyvinyl Chloride (PVC) options and those made of Low Smoke Zero Halogen (LSZH) materials. PVC is inexpensive and is mechanically strong and flexible. It has good electrical insulation and fire retardance properties. However, pavements have been recognized as having one major drawback: when incinerated, they emit toxic gases as well as thick smoke, which can be energetically dangerous in the event of a fire.

On the contrary, LSZH materials possess the properties of low smoke emission and no halogenated chemicals if there is a fire. This makes LSZH a good candidate for locations looking to have higher requirements on safety as it lowers the potential of toxicity and protects the air quality in buildings. LSZH coverings are usually more expensive than PVC coverings since they cost more but tend to have enhanced flame-retardance properties and lower burn-off rates.

On the one hand, PVC offers material strength and cost-effectiveness, whereas LSZH variants are more focused on health and environmental safety. Research shows that if compared with ordinary PVC cables, LSZH cables are able to reduce the density of the smoke by up to 90% and are completely free of halogens. Therefore, to switch between LSZH and PVC jackets, one must take into consideration the specific safety measures that the installation area requires, the legal requirements, and the costs.

Numerous benefits come with a 2mm thick cable jacket in relation to optical fiber cables. First and foremost, the increased thickness increases the robustness of the cable and the mechanical protection provided for the cable, such as the abrasions that are presented by external forces. This is particularly useful in extreme conditions or fittings which require the cable to perform strongly. Furthermore, the insulation provided is even better due to the thicker jacket, therefore reducing the chances of electrical interference, and the signal loss is guaranteed to be reduced. It also helps secure structural stability during mounting or during hand movement, thus lessening the chances of bends and breaks. All in all, a 2mm jacket thickness maintains the cable ends more effectively and meets all set requirements of ensuring longevity of usage in harsh conditions with great cable efficiency.

In particular, Optical Fiber Nonconductive Riser (OFNR) applications demonstrate the superiority of single-mode fiber when compared to multimode fiber. These advantages are discussed in detail here:

For ONFR deployments, these advantages are reflected by improved performance of the network and the reliability of the network, making it possible to enhance the existing network in a cost efficient manner.

The OS2 classification is called an outdoor cable that is meant for reaching long-range and high data rates within single-mode optical fiber systems. OS2 fibers are designed for use across a wavelength range of 1310 nm to 1550 nm, which guarantees lower signal loss and dispersion over long distances. These types of fibers are most commonly used in the external parts of the telecommunications network as well as in underground applications where longer distances and faster speeds are needed. As noted in almost all major online sources, OS2 fibers gain significantly improved thermal and mechanical indices, which help them work in complex conditions. This type of fiber can be used in complex networking applications such as 40G and 100G Ethernet and will be viable in the years to come.

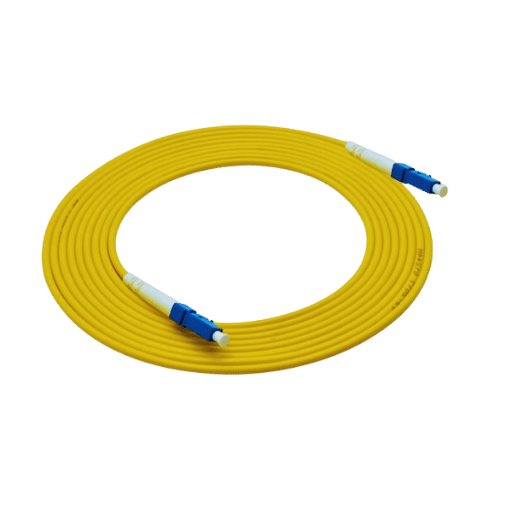

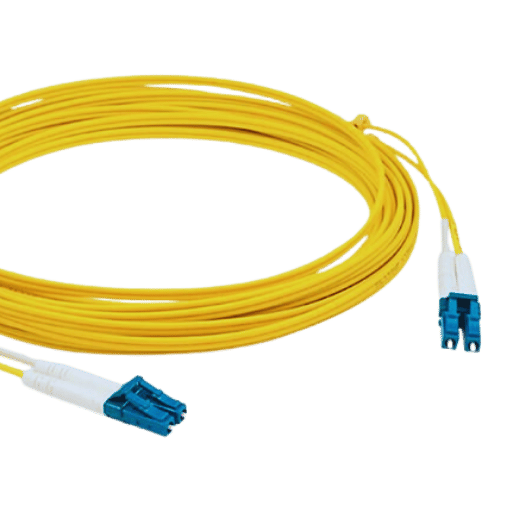

A number of crucial considerations must be reflected upon before making the final decision while choosing between simplex and duplex fiber optic cables, if optimal performance and cost efficiency are to be ensured.

In view of these considerations and a careful evaluation of particular requirements of the network, the businesses are able to identify the appropriate type of cable to deploy for effective completion of tasks and cut on costs involved that are not essential.

While considering the installation of simplex and duplex cables in vertical runs, Burn Keyort emphasizes factoring in specific elements relevant to these scenarios. He elaborates further by stating that it is necessary to understand the physics of the system being designed and integrated, internal applications, and the building’s code. Riser spaces serve the dual purpose of air space and a cavity in building construction, mandating that one complies with national building codes, A level above its scope. Although this provides immediate short term solutions, it begs the question as to whether up shower alone fulfills the requirements of the target audience and further becomes the only solution employed. The key questions remain concerning immediate application requirements and the architectural development focus encompassing the integration of the building systems.

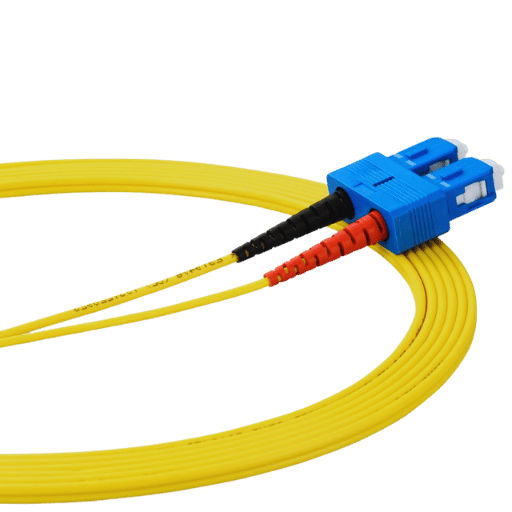

When it comes to picking the right LC connector for a specific purpose, one must take into consideration some crucial factors, namely transmission, compatibility, and durability. Based on several sources, LC connectors are widely used in such environments as data centers that require high density and high bandwidth because of their small size, which helps to increase the amount of fibers in the coupler or installation. They are mostly used in telecommunication and data communications; LC connectors are made to be used with singlemode and multimode fibers with minimal insertion loss as well as lower return loss, thus ensuring quality performance. For a particular LC connector to be effective it is important to check that it will not be at odds with any hardware that is currently in use, also ensure that the environmental and mechanical tolerances required are satisfactory so that it will deliver the expected results and service even in harsh conditions. Also, the types of polishing, UPC or APC, should also be taken into consideration when deciding on how much reflection signal loss is acceptable.

A: An OFNR fiber cable represents a type of fiber optic technology designated for communication. The term OFNR stands for Optical Fiber Non-conductive Riser and such types of cabling is also used in between floors considering the cable is designed to be used in vertical spaces. Besides, such cables are also non-metalllic which makes them less susceptible to electric interference as well as being non-dangerous.

A: The major difference between Optical Fiber cables and all other kinds of cables is the use of light transmission in the former, this leads to greater bandwidth and transmission velocity, when compared to copper cables. These are made up of three components that are a fiber core, cladding, and outer jacket that protects the core fibers from damage. Further, while conductive cables are, by definition, made of conductive materials, optical fibers are not, meaning they are much safer and more effective for long-distance communication.

A: Cables with lower ratings are unsuitable for applications designed for higher-rated cables due to their non-fire-barring properties. Besides, a substantially lower rating suggests that the cables fail to secure some applications, such as space between floors, and even violate legal fire codes.

A: The outer jacket or sheath of a fiber optic cable acts as a layer of protection that prevents any harm from happening to the fiber core and the cladding due to outside interference or environmental factors. It is customary then to see that a jacket is color-coded to identify if it is singlemode or multimode regardless of compliance with UL and IEC standardization.

A: A singlemode OS2 cable allows for long-distance transmission of data using minimal digital signals on a single light path or mode. A tighter tolerance is maintained right from the core of the fiber, thus enabling its use in both telecom and fiber-to-the-home FTTH applications. Multimode cables such as OM3 or OM4 tubes have a yellow jacket color exclusively for singlemode tubes.

A: Tight buffers help increase the tensile strength of the fiber core by coating it and the cladding with more fibers. This, in turn, makes the fiber much more durable and flexible, enabling it to be better suited for environments where it would be too rough, such as those in simplex configurations for fiber optics.

A: Yes, a higher-rating application can be used in lower-rating applications, making it easier to replace one with the other if work permits. This means that lower-rated cables can be avoided altogether; as such, compatibility issues will be minimal when implemented in an area where higher-rated cables are required for installation.

A: AFL is a company that specializes in the manufacture and provision of fiber optic products such as cables, connectors, and testing equipment. It develops modern fiber optic technology and highly competitive products that meet qualification requirements for performance and safety, thus strengthening communication networks.

A: No, cables marked with OFNR cannot be installed in plenums. Plenum applications have a higher air circulation requirement and therefore require cables such as OFNP which emit minimal fumes and have a higher fire rating. Plenum-rated cables satisfy the requirements of the NEC.