The Optical Distribution Frame (ODF) serves as the backbone of sophisticated telecommunication and data center ecosystems, aiding in efficient fiber management. In this age of ever-increasing connectivity and data transmission reliability needs, the understanding of ODF functionality and construction is more critical than ever. This article on ODF components covers basic components, advantages, and uses of ODFs aimed at personnel and organizations wishing to enhance their network systems. This document is helpful for anyone who wants better to understand ODF design, installation, and maintenance, making it easier to make effective decisions about fiber optic infrastructure.

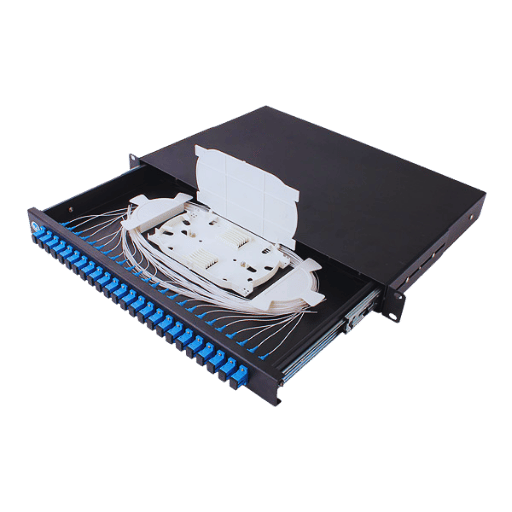

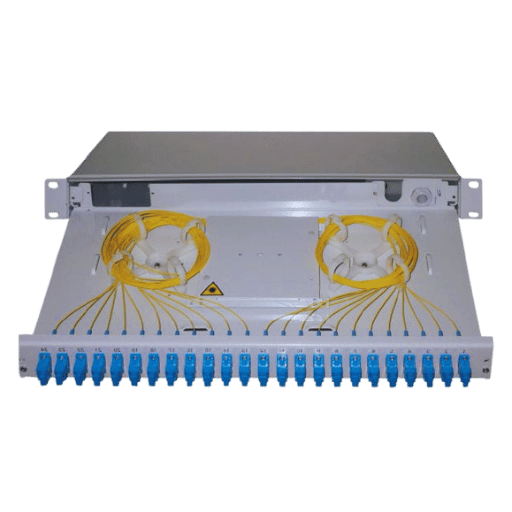

An Optical Distribution Frame (ODF) is an intelligent device in the fiber optic network that helps to organize and manage optical cables. It serves as a merging point for the optical fibers, where connections are consolidated and routed, thus minimizing signal attenuation. The ODF includes splicing, patching, and termination ports or panels, which allow for the interconnection and servicing of fiber optic cables. The ODF facilitates network system management. A high level of reliability and flexibility can be achieved with the aid of ODFs. Their primary application is in data centers and telecommunication hubs, as well as other essential infrastructures that require high-performance optical fiber connections, which can come in 12-core and 24-core configurations for higher-density regions.

Fiber optics technology allows data to be sent by transmitting light through thin, flexible strands of glass or plastic. It will enable data to be sent over long distances without loss in quality. It has become sophisticated as many modern devices rely on it for high-speed internet, cable television, and phone networks. Each fiber optic system has basic components, including a transmitter that converts data into light, a receiver that converts light back into data, and an optical fiber that transmits light signals. Signals transferred by light beams are faster than those sent through copper wires, as fiber optics are less affected by electromagnetic interference and electric signals.

All of these combined lead to the optimization of cable management, line of sight, and physical barriers, ensuring versatile control of optical fiber data networks.

The Optical Distribution Frame (ODF) serves fundamental purposes in the virtualization and administration of fiber optic networks. It serves as a focal point for the termination, connection, and distribution of fiber optic cables, which facilitates the precise propagation of signals. The ODF reduces signal loss and minimizes damage to sensitive components, appropriately mitigating these issues in 12-core and 24-core systems. Its design permits adaptability, ensuring network expansions can be integrated without compromising functional dependability, particularly in the presence of ODF fiber solutions. This guarantees optimal functioning and effortless maintenance in contemporary fiber optic networks, especially in rack-mount fiber systems.

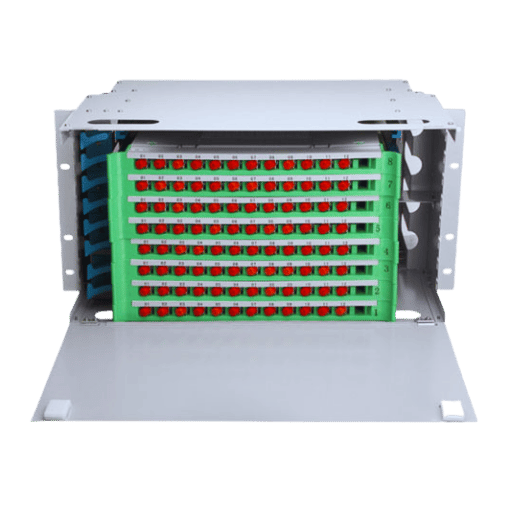

High-density Optical Distribution Frame (ODF) solutions are designed to optimize fiber optic connection capacity in a space-efficient manner. Such systems are best suited for areas where space is constrained, such as data centers or telecommunications centers. They enhance cable management, minimize the potential risk for cable damage, and simplify network expansion. Furthermore, high-density ODFs are modular, and as such, they are easy to configure and maintain. Their use improves the system’s operational performance while reducing the spatial and functional restraints of both the system and its environment.

The main distinction between 1U and 2U rack mount options is their physical dimensions and capacity. Space-constrained environments will particularly benefit from 1U rack mounts, which are 1.75 inches in height. 2U rack mounts, on the other hand, have almost double the height at 3.5 inches, which provides more space for additional hardware or more efficient cooling solutions.

Less technologically sophisticated devices are generally best housed in 1U options. At the same time, 2U models are best used with more powerful machinery that requires higher levels of electricity or cooling, such as those with rack mount fiber. The decision on which version to choose is primarily dictated by the use case, alongside the system’s operational needs in terms of space, performance, and future expansion capabilities.

Cable management in Optical Distribution Frame (ODF) systems directly influences efficient operation, maintenance, and reliability. From an engineering perspective, properly organized cables minimize the risk of physically damaging the fibers and reduce signal degradation, thus improving data transmission quality. Well-managed systems also help the components to cool down by improving airflow within equipment racks, which prolongs system life, reduces costly downtime, and mitigates maintenance expenses.

Marked and well-routed cables accelerate troubleshooting, system reconfiguration, and upgrades, significantly minimizing downtime. Industry reports cite that organized cable management allows drastic improvements in the productivity of technicians in blended management methods—reaching up to 50%—resulting in cost-effective measures and faster response times in repair and adjustment o network services.. Beyond functional advantages, aesthetically appealing cable systems also help mitigate workplace accidents by reducing tripping hazards while also adhering to international standards for cable installation. These factors emphasize the need for sophisticated cable management for ODF deployments.

To guarantee operational effectiveness and system dependability in Optical Fiber Distribution Frame (ODF) setups, effective cable management practices are crucial. These practices consist of:

The longevity, enhanced safety, and performance of the infrastructure can be achieved with these practices.

These tools provide adequate and safe cable organization, which improves performance while reducing the need for maintenance tasks.

Optimizing network performance with an ODF rack mount entails a precise physical arrangement, reducing signal degradation, and allowing for adequate later modification adaptability. To enhance optical cable management, try to organize optical cables to reduce clutter. Implement frequent, spasmodic monitoring of the signal on the rack mount to detect potential issues before they escalate by actively looking for possible problems. To sustain reliability and performance, use compatible, dependable grade parts with the rack mount. Furthermore, implement foresight for later modification adaptability by employing modular designs that allow circumvention of disruptions during operations and provide unobstructed future alterations. These measures guarantee that the ODF rack mounts function within a resilient and seamless network infrastructure.

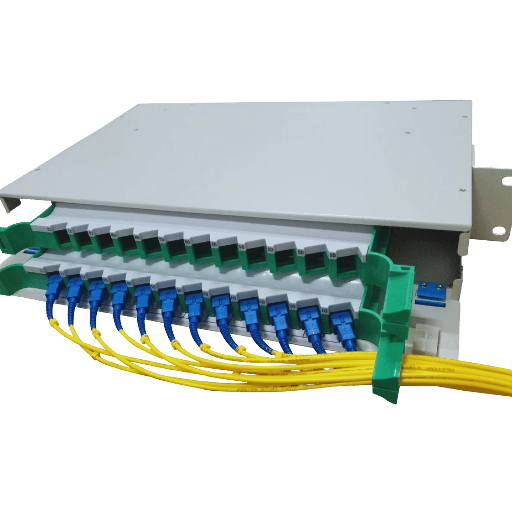

A fiber optic patch panel serves as a basic connection interface within a network, allowing for the safe and orderly connection of individual optical cables via its ports. It also simplifies cable management and speeds up reconfiguration and troubleshooting processes.

An Optical Distribution Frame (ODF) serves as a more complete structure used not only for organizing cables, but also for splicing, terminating, and managing a multitude of fiber optic cables within a network. Unlike a patch panel, an ODF often integrates additional components, such as splice trays and storage for slack cables.

Both devices serve the purpose of structured cabling systems, but patch panels are more sought after for smaller or more specific scope works. At the same time, ODFs are used in large-scale meticulous deployments with stringent high-density cable management requirements.

In Fiber to the Home (FTTH) networks, fiber optic patch panels serve as the main point for organizing, connecting, and distributing cables, thereby patching together diverse networks. Patch panels ensure proper termination and provide precise connections for incoming and outgoing fibers. Also, patch panels enable easy maintenance and troubleshooting of network faults by providing organized access to specific fibers. Their design minimizes signal loss while still enabling effortless scalability, making them vital to performance-driven FTTH systems.

Patch panels provide physical protection for patch panel fibers and offer mechanical protection by organizing and securing the optical fibers within a guarded enclosure. They avoid physical damage to the delicate fibers, signal interference, and consistent performance degradation over time. Patch panels ensure ease of access and organization, which simplifies network management while preserving the order and structure of the fiber network. Proper utilization of patch panels is essential for reducing maintenance efforts and prolonging the lifespan of the optical connections.

A: An Optical Distribution Frame (ODF) is used as a frame to connect cables between communication facilities. It is critical for the overall management of middle fiber optic cable connections and terminations, as well as fiber sorting and organizing within a network.

A: The main functions of a space management or fiber optic distribution frame include containing the fiber optic splice and patching assembly, restructuring and filing of fiber cables, performing patching and splicing, providing control and distribution of signals through the frame, and assisting in proper filing of the fiber optic infrastructure.

A: Fiber patch panels are parts of the ODF structure. They permit an orderly file of all the fiber optic cables, fiber terminations and connections, and optical cables linkages that are configured to several nodes or endpoints within the network.

A: The commonly used optical connectors in OD Fs include LC, SC, FC, and ST. These connectors make it easy to join and terminate optical cables in the frame.

A: A fiber splice blends two pieces of fiber optic wires. Its contribution to the system is ensuring low signal loss, even with as little as 0.1% distortion, to achieve adequate distribution and use of the signal within a fiber optic system.

A: Fiber termination within an ODF is done using different optical connectors and adapters to use fiber optic patch cables effectively. To achieve proper termination, the signal must be as expected: neither lower nor higher than the required signal.

A: This is a tray specifically designed to hold and organize spliced optical fibers within an optical distribution frame (ODF). Equilibrium in the order of splicing is attained during protection against hot air and cold air through enclosures, which lead to the maintenance of distribution.

A: High-density fiber optic distribution frames, for example, those of 144 cores, are the type that enable the use of high volumes of fiber optic connections over a smaller space. This is highly rated for data centers since it saves space while still providing good connections and managing cable congestion.

A: Fiber optic adapters play an essential role within ODFs as they interface between two optical cords for connection. They provide an adequate interface between various fiber optic connectors of the so-called Adaptive Fiber Interface Types.

A: ODFs incorporate air-blown fiber solutions, as they allow for aggregate or incremental addition to the existing fiber infrastructure. This technique involves injecting lightweight fiber-optic cables into microtubes or microducts, which increases flexibility in network architectures, such as FTTH or data centers, and offers straightforward expansion capabilities.

1. Diffusion Phantom Study of Fiber Crossings at Varied Angles Reconstructed with ODF-Fingerprinting (Filipiak et al., 2023, pp. 23–34)

2. Use of Laser Diode Coupled Optical Diffusing Fiber (ODF) in Optical Camera Communication and Rolling Shutter Image Sensor (Tsai et al., 2022, pp. 16069–16077)