NEMA power cords are essential in ensuring the safe functioning of many machines and devices in the current version of globalization, Whether it be setting up a data center, a device center, or even using an NREAT network. Along with all the applications and use cases, it comes with the NEMA power cords. We have devised a comprehensive guide to assist you with their use and application, ranging from their types, connectors, applications, and, most importantly, how to choose the NEMA power cord that best serves your requirements. Specifically, Let us delve into this guide and open the door to specialized knowledge to enable you to make the best decisions concerning NEMA power cords.

NEMA is an acronym for the National Electrical Manufacturers Association, which is responsible for setting standards for electrical components within the US. So, a NEMA power cord is simply a cable that uses NEMA connectors, standards set for different electrical components. NEMA cords, for instance, are made to provide safe and reliable connections by following specific configurations defined by the NEMA.

Different NEMA power cords are made for other purposes and serve unique functions. Cords are classified according to their NEMA connector types, which indicate what device and power socket a NEMA cord is suitable for. Most residential homes, business offices, factories, and locations that require plugging USC into AC power cords frequently use NEMA power cords.

Understanding NEMA power cords is crucial for compatibility, safety, and distribution. When choosing the best NEMA cord, you must always consider the NEMA voltage rating requirements, amperage ratings, connector requirements, and type of application. You can quickly and adequately decide what cord you need with knowledge about NEMA power cords and their specifications.

The National Electrical Manufacturers Association, also known as NEMA, is an organization in the United States responsible for developing standards regarding all electrical systems and equipment. Along with ensuring the appropriate power distribution, NEMA also focuses on compatibility and safety as key objectives. Furthermore, these standards outline a few requirements, such as voltage needs, ratings of amperes, and types of connectors suited for different electrical devices.

Depending on your requirements, it is essential to ensure that the correct NEMA power cord compliant with NEMA standards is selected. This entails choosing the proper NEMA connector type, voltage and amperage ratings, and then picking out the purpose of the power cord. Understanding NEMA standards and the specifications of KPI would help you make an appropriate decision regarding your power connectivity requirements.

It is essential to understand that these NEMA standards are more focused on the United States and are not universal. Local laws such as the IEC should also be considered when interacting with equipment from a different region.

In conclusion, it is vital to appreciate NEMA’s principles in safeguarding the efficient distribution of power, interoperability of devices, and security of electrical circuits. Following such regulations and obtaining the right NEMA power cords will guarantee a satisfactory power connection for the equipment.

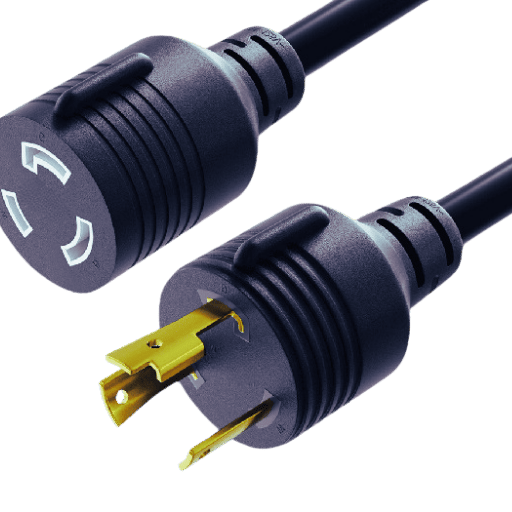

Including some Nema types of cords that might be used in different sites or tasks is just one of the available variants of power cords. Suggested below are some of the most utilized variants and their respective functions:

Factors such as voltage, current rating, connector type, and regional standards should be considered when determining the kind of power cord for a particular device. It is also prudent to evaluate the safety of electrical systems and consult with professionals. Also, always ensure that the cables meet the manufacturer’s requirements.

Standard Nema connectors and plugs can safely and reliably be used for electrical connections in various industries. Here is a list of Standard Nema connectors and plugs that are widely used:

More NEMA connectors and plugs are available; these are only a few. When determining what NEMA connector to use for electrical needs, referring to the manufacturer’s specifications and regional standards is advisable.

Before purchasing a NEMA cord, it is important to know the device’s specifications and requirements in terms of voltage and amperage. Voltage is the difference in potential energy measured in volts (V) across any two points in an electric circuit, and amperage is the rate of flow of electrical charge in the circuit, measured in amperes (A).

The manufacturer provides specifications that help you determine your device’s needs in terms of volts and amps. Usually, manufacturers provide this information in the device’s manual or other documentation. However, incorrect use of voltage or exceeding the rated amperage can damage the device, cause electric shock, and, in the worst case, cause an electric fire.

It needs to be noted that a NEMA cord can only work perfectly with the right supply voltage, and therefore, one should pay close attention to the voltage requirement while purchasing the device. For instance, most American households use 120 volts, while some commercial or industrial regions require 240 or 208 volts instead. For the device to operate seamlessly, it is necessary to consider the voltage ratings.

The amp rating of any electrical device is determined by its electrical load and the kind of device that is connected. Usually, devices requiring more power typically have a higher amperage, as they need to conduct the electric current safely. A NEMA cord must always be carefully selected to meet or exceed the required amperage of the equipment being used so as not to cause overheating, which would subsequently damage the equipment.

Once again, knowing the voltage and amperage your particular electrical application requires helps you decide which NEMA cord will be best suited to safely and reliably connect the power source.

One aspect of international standards compatibility that needs to be considered is the compatibility of NEMA cords with IEC systems and power supply systems worldwide. While in the United States, NEMA cords have become commonplace, in other countries, NEMA, based on IEC specifications, is not widely used; other standards are often adopted. Still, a point that requires emphasis is that NEMA cords can interface with IEC systems using proper adapters or converters.

Concerning power supply systems, it is necessary to know the voltage and frequency requirements of the country or the region within which the equipment will be used. Regions may have different volts and hertz ratings and, therefore, distinct standards for the power supply. The requirements for the varying nurtures of NEMA cords to these nurtures have to be meticulously observed.

When choosing a NEMA cord for use in a particular country for international business or when using alongside the IEC systems, one ought to seek the advice of local electrical experts or reference the documents to ensure that the country’s Power Supply is well within the limits. In this way, a dependable and safe power connection can be established without breaching the legal stipulations of the area.

Factors related to the firmness and reliability of NEMA (National Electrical Manufacturers Association) connectors need to be considered in determining their quality and suitability. Knowing these factors will help decision-making regarding NEMA connector selection for particular application requirements.

The assessment of NEMA connectors must consider the materials, that is, the structure and the components joining these connectors. The best connectors are made of durable thermoplastic or non-corrosive metals. Such materials guarantee the connectors will last long and be used under normal day-to-day conditions.

Apart from the materials, the engineering aspects of the connectors must also be analyzed. Look for connectors with accurately molded products, well-designed contact pins, and locking parts. These design features enhance the connectors’ strength and reliability, providing steady and secure power connectors.

In assessing NEMA connectors, it is essential to consider any applicable compliance standards and certifications. Examine if any given connectors have UL or CSA approvals since these are indicators that the connectors have been subjected to relevant safety and performance requirements. These allow the easy assurance of the necessary electrical safety compliance.

Moreover, seeking customer reviews, industry views, and experts’ views about NEMA connectors can help attain the proper reputation and performance for any specific NEMA connector. This will allow them to find connectors with known measurable reliability and durability in a particular context.

As analyzed above, the NEMA connectors appear to have different qualities and durability. Therefore, practitioners can make informed choices and possess connectors that serve their purposes in meeting the power connection needs of their applications.

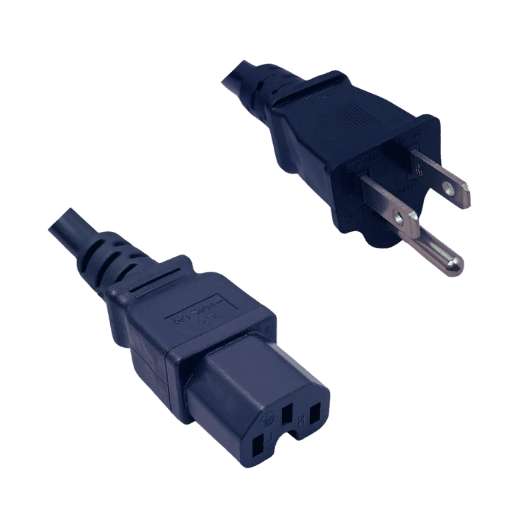

The NEMA 5-15p connector has its formal designation standard in North American countries. Sufficient supply and plug of the connector make it suitable for different applications. A description is listed below alongside its features:

Thanks to its versatility, safety features, and international compatibility, the NEMA 5-15p connector is suitable for residential, commercial, and industrial use.

Because of its adaptability and compatibility, the NEMA 5-15p connector is commonly employed in various settings in the United States and abroad. Below are some key areas where the NEMA 5-15p plug is used on a larger scale.

Moreover, certain applications may differ between regions and industries. Following the respective country’s electrical codes and regulations when using NEMA power cables for particular purposes or in other jurisdictions.

In the PCI (Power Cable Interface), It is central to understand the electrical functional properties of NEMA power cables, which focus on the NEMA 5-15P plug alongside offering some comparisons with other NEMA plugs that have similar properties, for example:

Analysts suggest that one must follow the working parameters of any Machine’s Electric Motor, as there are requirements set for NEMA-rated plugs, models, voltage, current, and more. Moreover, seeking professional advice in the industry will ensure electricians can safely and effectively connect power equipment.

NEMA power cables are the backbone of IT infrastructure and data centers’ power connections. They provide solutions for safely integrating high-voltage equipment, which is very important for server environments. These cables allow servers, networking components, and other data center devices to receive the proper amount of electricity, facilitating the effective management of present operational power needs.

In most data centers, NEMA power cables assist in the smooth functioning of servers, storage equipment, and networking devices by delivering electricity to them. These cables can energize data center equipment that requires high voltages, with power levels being sent constantly and preventing potential fluctuations or failure. These NEMA power cables are designed and made to be used in data centers, so they require little effort to install or service.

NEMA power cables are vital in powering the IT structure’s computers, monitors, printers, networking devices, and control cables. They assist with integration and ensure there are no faults with the power output spare in the IT system, ensuring the smooth running of all operations.

NEMA power cables are widely used in data centers and IT infrastructure and are considered dependable and standardized for power connections. To appropriately choose, install, and maintain NEMA power cables in these sensitive areas, it is pertinent to seek professional assistance and comply with industry guidelines.

Uninterrupted and practical electricity usage is imperative in both commercial and residential spaces. One needs to understand and implement essential power connections for electrical systems to function efficiently and securely. Power connections are significant in providing homes and businesses with the electricity necessary for compliance with various devices and appliances.

Power connections in a residence deliver electricity to various electrical devices and accessories, including lighting. Common household items include refrigerators, televisions, ACs, and computers. Effective power connections in the household promote the smooth running of the devices and ensure that the users are safe from any electrical inefficiencies and hazards.

In an industrial setting, utilizing a wide variety of electrical devices and equipment comes in handy. This includes equipment such as office machinery, industrial equipment, data storage, various individualized appliances, and much more. Ensuring that one has appropriate power connections in a commercial organization reduces idle time and promotes efficiency while also prioritizing the safety of personnel and equipment.

The safety and reliability of power connections can only be guaranteed if industry standards and best practices are followed. Adhering to electrical codes, choosing suitable and relevant power cables and connectors, proper installation, and, thereafter, maintenance are all encompassed in it. Consulting with experts and electricians who are well versed in power connections is very helpful in ascertaining the correct selection, installation, and maintenance of power connections within residential and commercial settings.

Remember that all electrical systems will be secure and valuable only if proper power connections are made. Individuals and businesses take all necessary measures to ensure that there is uninterrupted delivery of power, minimal chances of electrical faults are experienced, and the electrical systems in residential and commercial areas function effectively.

Extensions and adapters are essential parts of electrical systems as they add convenience and options for supplying power. An overview is given below:

Also, when using extension leads and adapters, extensions, and adapters such as NEMA 5-15P to C13, the following should be done:

After comprehending the correct application of extension cords and adapters, one can use them efficiently and safely in any electrical work.

Ensuring NEMA cord sets’ safe and optimal utilization entails adhering to specific recommendations. Here are a few I endorse as a reliable practitioner in this area, along with those related to installation and upkeep:

Following these sound installation and use practices allows the continued safe and dependable use of NEMA cord sets for many applications. Always remember that safety comes first when working with electrical apparatus.

As an electrician, I can help identify power issues and their solutions. A systematic approach is important when dealing with power-related conflicts. Here are some easy steps to diagnose and resolve power issues.

As long as these steps are taken to discuss issues and also when problems arise with power, smooth functionality and the usual operation of electric devices are ensured. Safety should always be given the most importance when working with electricity.

In my professional opinion, I highly recommend the practice of using grounded plugs for electrical equipment. Grounded plugs, referred to as three-prong plugs, are critical in that they help safeguard you and your devices from electric shocks. The grounding pedal, the third pedal in the set, prevents electric shocks by redirecting the current whenever there is a fault or a short circuit, reducing the chances of starting an electrical fire. This situation prevents plugged-in equipment from suffering damage. The use of grounded plugs ensures that there is proper grounding, thus providing a safe electrical environment. Always remember that removing or altering the third prong of a plug constitutes a safety hazard and increases the risk of electric accidents.

A: NEMA, the National Electrical Manufacturers Association, controls the standards worldwide for NEMA cables. NEMA power cords are necessary because they follow international standards for configuring plugs and receptacles, enabling devices to connect to power sources without harm, such as further NEMA receptacles. Such cords are generally used in the USA and countries that endorse NEMA regulations.

A: NEMA 5-15P refers to the powered end of the cord that goes into the wall socket, and NEMA 5-15R refers to the socket or wall outlet itself. For the cord type, P means plug, and R means receptacle. For example, a NEMA 5-15P to NEMA 5-15R cord would usually be simply an extension cord, connecting a standard wall socket to a piece of equipment or another power strip.

A: C13 and C19 are IEC 60320 connector types with which Nema plugs are often used. C13 is in most of the female connectors of many computer power cords, whereas C19 is the more robust version. Such connectors can be attached to the appliance side of the power supply cord, leaving the other side with a Nema plug 5-15P that would connect to a wall socket.

A: The difference in the amperage rating distinguishes Nema 5-15 from Nema 5-20. NEMA 5-15 allows 15 amps, and Nema 5-15 standards are Thomas Edison plug sockets applicable to most household equipment. 5-20 is Nema 5-20, rated to allow 20 amps and applied in high-powered devices. Plugs are configured differently to avoid accidentally inserting a 20-amp device into a 15-amp socket.

A: The NEMA 6-15 and NEMA 6-20 are 250-volt configurations, while the NEMA 5 series is a 125-volt configuration, which is most used. NEMA 6-15 is rated at 15 amps, and NEMA 6-20 is rated at 20 amps. This is essentially used for larger devices or machinery that need higher voltages.

A: A C5 connector is smaller than a C13, known as a cloverleaf connector. It is typically found in laptop power cords and other smaller electronics. Power cords “5-15 to C5” are less common, but they are used with laptop power adapters and have a NEMA 5-15P plug on one end and a C5 connector on the other.

A: When choosing the appropriate NEMA power cord, consider the following: your device’s regulatory specs regarding voltage and amperage, the type of wall plug outlet in your wall (e.g., NEMA 5-15R), and the type of connector needed by your device (C13, C19, C5). The cords’ ratings should be at least equal to or greater than the device’s rated power and follow the NEMA or IEC standards for safety.

A: NEMA 1-15 is an outdated model with two ungrounded prongs that have a more straightforward design, while NEMA 5-15 is an up-to-date model with three grounded ends that are more complex. As NEMA 5-15 offers more safety, it is the most common connection for modern applications. Most currently available devices have NEMA 5-15P plugs, which are much safer; however, some devices still have NEMA 1-15P plugs as a backward compatibility option.

1. The options available for transforming sound power levels to sound pressure levels at a distance of 3 feet

2. Evaluation of DOE Motor And Drive Shows That Power Drive Systems Are More Energy-Saving

3. A New Strategy for MPPT Based on Impedance Matching Involved Non-Isolated DC-DC Converters In A Solar PV System