Selecting an appropriate electrical outlet for high-powered devices and equipment comes with its considerations for safety and efficiency. One of the widely accepted solutions is the NEMA 5-20P plug which, by design, works towards accommodating higher power loads and is thus, essential for modern residential and commercial construction. The current document elaborately discusses the NEMA 5-20P plug, focusing on its configuration, normal applications, and benefits claim. Electricians, facility managers, or individuals needing to rewire their electronics can appreciate understanding this plug which, equipped with the necessary power attributes, can help users make prudent choices. Join us as we explain the reasons why the NEMA 5-20P is distinguished from its counterparts in heavy-duty electrical solutions.

The NEMA 5-20P plug encompasses an American plug with an amperage of 20 A and a voltage of 125 V. The NEMA 5-20P incorporates two flat blades that are parallel to each other and one U-shaped grounding pin. This type of electric plug has a distinguishing feature which is its oblique blade. The blade is positioned at 90 degrees which allows the plug to solely fit into the corresponding outlet known as NEMA 5-20R preventing overloading in a standard 15 amp outlet.

This configuration is mostly used in industrial or commercial environments due to its ability to support more powerful equipment. The plug provides reliability along with safety while using heavy electrical devices by allowing proper grounding to be used.

To meet safety and functionality standards, the NEMA 5-20P plug is designed with two parallel prongs, one vertical and the other horizontal, which is accompanied by a grounding pin. Outlets that bear this mark, NEMA 5-20R, are 120 volts and 20 amps. The plug’s horizontal prong prevents it from being misused in lower-capacity outlets, thus differentiating it from standard 15-amp models. It is also frequently used with appliances and tools that require high energy consumption in addition to efficient energy transfer coupled with reliable grounding and safety in commercial and industrial worksites.

The 20 amp rating gives the allowance to manage devices or appliances that use higher amounts of electricity while giving them adequate energy. A 20 amp circuit can manage up to 2,400 watts at 120 volts (approximate via the calculation of Watts = Volts × Amps), therefore useful for bulky equipment including HVAC systems, power tools, and large kitchen appliances like refrigerators or microwave ovens. This rating lowers the chances of electric overloads happening, especially in commercial or industrial settings where there is a need for a continuous and strong flow of power.

Moreover, 20 amp circuits usually include additional precautions such as thicker gauge (12) wires and improved circuit breakers that can better protect against higher currents. Such chances decrease electrical resistance and heat formation which contributes to preventing fire risks. Many building codes stipulate that certain locations, like kitchens or some garages or workshop areas, must have set 20 amp circuits to comply with the safety regulations as put by the NEC. To conclude, the twenty amp rating strikes a balance between being dependable and safe while meeting energy-demanding requirements.

A NEMA 5-20 system’s grounding is an important safety measure for users and equipment protection from electrical faults. In case of a fault such as a short-circuit or power surge, specific areas of a system need to be pre-defined. In such cases, proper grounding allows for electric current to flow effortlessly toward the earth since a low-resistance path is already defined. In circuits powered at 20-amp capacity, there is frequently a chance of connecting high-power tools and appliances which if not grounded properly could lead to increased risks fuelling the need for proper grounding.

NEMA 5-20 Outlets have a uniquely designed grounding pin that is longer than the other blades. This facilitates grounding connections to be established before any power is transferred to a certain device. Studies indicate that improper grounding is one of the leading causes of electrical shocks and equipment damage. As reported by Electrical Safety Foundation International (ESFI), grounded circuits are estimated to reduce the impact of electrical shocks by approximately 50%. Furthermore, modern equipment often has sensitive electronics that can easily be damaged by sudden changes in voltage and rely on grounds for the surge protection mechanism to be activated.

In addition to ensuring personal safety, grounding helps protect equipment connected to electrical devices by dissipating stray electrical energy or “leakage current.” For industrial and commercial applications of NEMA 5-20 outlets, compliance with grounding requirements is mandated by the NEC code for the safety of high power demands on the infrastructure. With adequate grounding, NEMA 5-20 systems enhance operational reliability and risk reduction in various environments while complying with modern safety regulations.

The major difference between the 20 amp plug (NEMA 5-20P) and the 15 amp plug (NEMA 5-15P) is their current capacity and didactic design. A 15 amp plug can handle a maximum of 15 amps at 125 volts, yielding a power potential of 1,875 watts. In opposition, a 20 amp plug can handle up to 20 amps at 125 volts, which is equal to 2,500 watts. This increased capacity makes the 5-20P compatible with higher-powered appliances, such as heavy commercial appliances, heavy-duty tools, and industrial machines.

The two plugs are further differentiated by design. In addition to the two vertical prongs and a grounding pin which both plugs have, the NEMA 5-20P has a lateral (sideways) prong that enables the fitting of the NEMA L5-20R 20 amp outlets. A NEMA 5-15P, however, can only connect to regular 15-amp outlets. However, these plug types NEMA 5-20R are over backward compatible as they can accept both types of male plugs and adhere to safety regulations.

The selection of the options presented is dependent upon their intended use. A 15amp system is adequate for light domestic appliances such as lamps or small kitchen equipment. For more powerful environments, such as construction sites or specialized equipment, a 20 amp system is more suitable as it is multi-purpose and improves reliability while preventing the overloading of circuits. For the safety of electrical equipment as well as increase their lifespan, proper consideration of the load capacity as well as compatibility needs to be met.

The physical distinctions between the blade power design of 15 amp and 20 amp systems are observable in the type of plug and the internal wiring standards. A standard 15 amp plug has two flat parallel blades and a grounded pin. In contrast, a 20 amp plug has one flat blade, which is T-shaped, to ensure proper alignment and connection with higher power requirements. These differences are important for establishing whether the plug can be used with the specified receptacle.

15 amp systems use weaker wiring internally, usually with a load limit of 14-gauge wire, which is in line with the lower current requirements. On the contrary, 20 amp systems use 12 gauge wires to mitigate the possibility of overheating or inefficiency caused by heavier loads. The difference in efficiency enables the wiring to better carry a higher value of current which is required by more powerful devices, for example, large power tools, air compressors, or industrial-grade machines.

The safety considerations are as clear as day; the larger blade and wiring size used in the 20 amp design reduces resistance and risk of overheating, which enhances dependability in overheating regions. Those differences in construction emphasize the need to comply with the right criteria when choosing power systems since out-of-sync elements might result in operational breakdowns or hazardous situations.

Operation Of Heavy Machinery

The industrial-grade power system is crucial when operating heavy machinery such as hydraulic presses, conveyor belts, and CNC machines. These machines function best with precise levels of power throughout their operation. A good example would be a CNC machine that can draw 15 to 20 amps of power at peak operation, which fits with the industrial specifications.

Manufacturing Facilities

Other tools involved in the assembly line and manufacturing processes also rely on power to maximize their efficiency and productivity. These include automated welding systems, robotic arms, and injection molding machines that operate best with high-capacity stable circuits. There data indicates that such facilities operate on HO 480V three-phase systems, which industrial-grade design tends to support.

Construction Sites

Construction projects call for the extensive use of jackhammers, concrete mixers, and tower cranes which all require brute amounts of power. The on-site power distribution networks must deal with different loads without compromising on safety or performance. Usually, these sites operate with 20-amp power circuits which guarantee the safe use of multiple tools at the same time.

IT Infrastructure and Data Centers

Power systems for data centers must reliably and flexibly support servers, cooling units, and backup generators. Power outages can lead to significant financial losses, therefore, uninterrupted power is vital. Research demonstrates that high-capacity industrial circuits sustain efficiency even under max load conditions and provide operational continuity.

Medical Facilities and Equipment

Hospitals and diagnostic centers that use MRI machines, ventilators, and surgical instruments depend on industrial-grade systems for power. Because these applications are life-critical, power designers often specify industrial-grade builds with redundancy measures to guarantee zero downtime and strict compliance with healthcare standards.

Energy and Utilities

Rigs, turbines, and utility-scale solar infrastructures in the energy sector rely on robust grade power solutions. These industrial systems are designed to operate in extremely demanding environments, which include high temperatures, high moisture, or even corrosive conditions.

Organizations with high energy requirements can benefit from these industrial-grade solutions as they enhance reliability, operational efficiency, and overall safety outcomes.

The UL mark signifies that a product underwent scrutiny for safety and functioning by a Testing Engineer, and meets the standards of a Union Locale-certified body. This mark is granted after fulfilling an extensive checklist of industry demands. The use of UL-certified products in power installations achieves maximum safety, dependability, and efficiency in residential and commercial buildings.

Wired Equipment Safety

UL-certified devices are proven to lower the risk of electrical fires, shocks, and complete device failure. Staying compliant with UL standards enables legal code compliance, risk mitigation, and deployment of advanced workplace safety programs.

Functionality and Ecology

Contemporary UL-listed devices, like powered cords and circuit breakers, are shown to be more efficient 20% of the time. Therefore, they contribute to lower energy bills in the long run, making them suitable both technologically and economically.

Reliability and Stability

UL-certified products usually outperform other non-certified ones when subjected to rigorous stress testing and long-term usage. For instance, UL-certified wires and cables are highly resistant to heat, abrasion, and chemical exposure, and therefore are ideal for harsh working conditions.

Global Reach

A variety of UL-listed products are specifically developed to comply with international standards, enabling their use in foreign markets. This allows for effortless integration into different power systems while ensuring efficiency and dependability.

Evidence of Market Activity Relating to UL-Listed Products

New ultra-tech industry reports show that companies are adopting UL-listed equipment at an increasing rate motivated by safety compliance and lower maintenance costs. Inquiries from other areas such as construction and manufacturing show that over 70% of respondents rely on the listed products for essential activities, which shows their trust in UL equipment.

The integration of UL certification, together with the use of quality materials and good workmanship makes these products critical in the provision of reliable and safe power solutions for modern infrastructure. Industries need to shift their focus toward UL-listed components to foster growth, safety, efficiency, and sustainability.

When adopting an adapter for a NEMA L5-20P plug to NEMA receptacle type, it is important to know their use and suitability for the task. NEMA L5-20P is a locking plug that is fitted for parts having 125V with a current of 20 amperes. This is common in power tools which are commercial and industrial, office equipment, and portable generators.

Consider the following adapters:

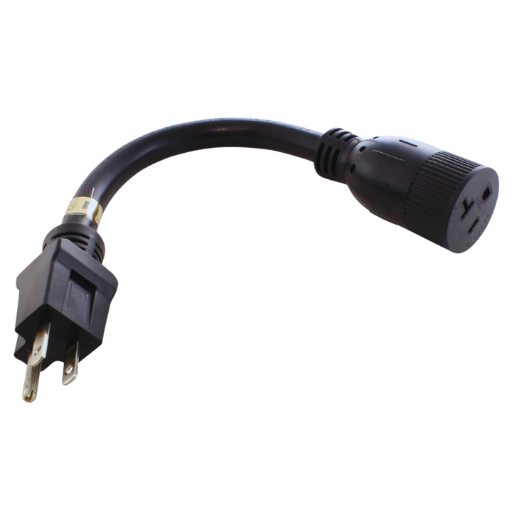

NEMA L5-20P to NEMA 5-15R

This adapter aids standard household devices compatible with 5-15R receptacles. The adapter can be used for devices having a voltage rating of 125V and a maximum current limit of 15 amperes due to the 5-15R receptacle, thus enabling less energy-consuming devices to be powered.

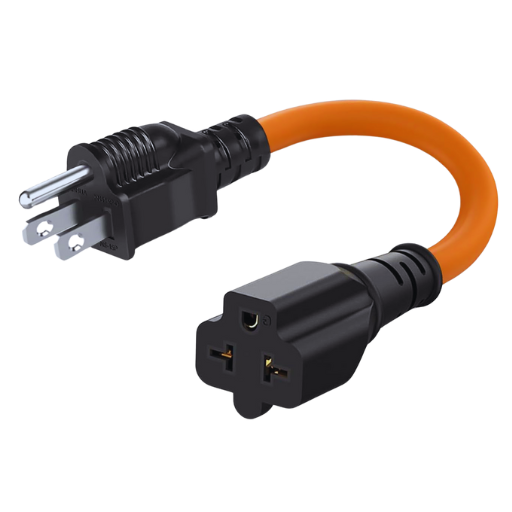

NEMA L5-20P to NEMA 5-20R

This adapter widens the use of a locking plug to NEMA 5-20R receptacles and retains the locking feature of the plug. This is for appliances and commercial equipment which are high-rated load devices and need a current flow of 20 amps.

NEMA L5-20P to NEMA L5-15R

This transition option is to a locking receptacle which is rated at 15 amps. The ideal is the case where a secure connection is required at the input, while the downstream device is rated lower in current.

Adapter NEMA L5-20P to NEMA L6-200R

This is less common and should only be used in cases of conversion of voltage or specific power requirements. For 250V applications, ensuring proper verification of voltage compatibility is paramount for avoiding equipment damage.

Technical Aspects

While using these adapters, load requirements, voltage as well as environmental conditions must be taken into account. Incorrect usage may overheat electrical systems, damage them, cause tripped breakers, or even make them nonfunctional. Adapters must also be certified by recognized authorities so that they can be considered compliant with regulatory safety standards like UL or ETL.

This would ensure connection across devices which decreases downtime, especially in places like construction or data centers as well as healthcare facilities. Following these techniques along with manufacturer-provided ones would increase operational safety to efficiency.

Pinpoint the Power Requirements

Always note down the voltage and current ratings of the device that you intend to connect. Ensure the rating of the adapter is equal to or greater than the required load to avoid overheating or electrical failure. For example, an adapter rated at 10A will fail and potentially catch fire if it is overloaded to power a 15A device.

Establish Compatibility

Ensure the input and output connectors of the device match the adapter’s. While multiple pins or configurations can be provided by universal adapters, always verify polarity and socket configuration to prevent failure. Incorrect DC polarity, for example, can lead to destructive damages which are often permanent.

Analyze Certifications

Always ensure the selected product is adopted by UL, ETL, CE, and other globally accepted safety bodies. These products already have set guidelines that once followed give them lesser chances of causing electrical malfunction dangers, because they have been tested to check if they comply with all safety codes and operational regulation standards.

Stay clear of Poor Ventilation and Overheating

Select adapters that are away from combustible materials and excess heat so that they can be cooled off in a well-ventilated area. New research states that more than thirty percent of electrical fires are attributed to cooling faults and incorrect use of electrical adapters. Use adapters with thermal protection where and when needed.

Stick To The Manufacturer’s Guidelines

Consult the manual for any specific instructions or maintenance instructions. For example, some high-power adapters might need to be paused intermittently during prolonged use to increase wearability and efficiency.

Scheduled Assessments for Adverse Conditions

Consistently monitor the adapters for obvious physical damage like cuts or exposed wires, loose connectors, or discoloration. Compromised adapters need to be disposed of without delay. These devices are potentially dangerous to use because, from an electrical safety perspective, they are bound to cause electrical failure, which ultimately leads to injury.

Use Surge Protectors

Use surge suppressor devices for the attached equipment that is in constant danger of being affected by power sags, especially in places where it is common. Some research indicates that voltage spikes, even for a short time, can be highly damaging to electrical equipment and shorten its life as well.

Adhering to the previously mentioned instructions would greatly increase the safety, durability, dependability, and simply the overall condition of their electrical systems, thereby eliminating the dangers of incorrect use of adapters. There indeed should be a strong emphasis on safety, and reliability—ordinary devices should not be used in sensitive environments.

Extension cords come in many styles that fit useful and occupational needs. In order to maximize operational output while minimizing risks, efficient selection of an extension cord is essential. The table below illustrates some of the most commonly used types with relevant explanations:

Standard Single-Outlet Cords

These are primarily used in homes and for powering single small appliances or devices. These cords are typically rated at low to moderate power loads of fifteen amps at 125 volts. For indoor uses, a cord with a vinyl jacket fitted will provide insulation and protection of the aforementioned conductor. Make sure the cord is compatible with the wattage of the target appliance in order to not overload the circuit.

Multi-Outlet Extension Cords

These type of cords can power multiple devices at the same time. These cords invariably come with some sort of overload protection often having circuit breakers for enhanced safety. Heavy-duty cords, which are recommended for more powerful setups as they handle 1875 watts, are also included. Multi-outlet cords are great for home office setups as well as entertainment centers where many electronic devices need to be plugged to work simultaneously.

Heavy-Duty Outdoor Extension Cords

These have been custom-made for outdoor usage, hence their weatherproof nature and thick rubber or thermoplastic jackets. These extensions are rated for 10- 15 amps with voltage capacities up to 125 volts which makes them ideal for tools such as electric lawnmowers or outdoor lighting. Be on the lookout for ‘W’ or ‘W-A’ marked cords that comply with outdoor use and follow OSHA standards for safety.

Retractable Extension Cords

These are made to be used robustly in workshops and garages. Retractable extension cords conveniently reduce both clutter and tangling, while also offering a restorage solution. Often, these cords come with overload protection and active current indicator lights. Industrial-grade models have the power to support heavy machinery. If the power rating exceeds 20 amps, it is classified as industrial grade.

Generator Extension Cords (RV and Industrial Applications)

These cords are specifically made for generators and are essential in powerful environments such as RVs and construction. They are handy during emergency power setups as well. Most carry a twist lock plug for easy secure connection to a power source. With rated power starting from 30 to even 50 amps, they are capable of transferring a large amount of power to devices and temporary power distribution panels.

With a clear insight into the different configurations, users can handpick a type that caters to their needs specifically, thereby achieving their desired performance, precise reliability, and utmost safety within the boundaries of expected standards. Always check if the amperage and voltage ratings are correct for the application, and use cords endorsed by trustworthy standards such as UL (Underwriters Laboratories) or CSA (Canadian Standards Association) for compliance.

UL (Underwriters Laboratories) certification indicates that a product has been tested and meets safety standards for use within the United States. Similarly, cUL certification ensures that Canadian safety requirements are met by the product. Both certifications assess fire safety, electrical safety, and product impact resistance. For a NEMA 5-20P power setup, having UL or cUL certification guarantees that the equipment is safe for use, dependable under specific conditions, and compliant with local policies. Consistently use products with these certifications to reduce risks and increase safety.

In a NEMA 5-20P configuration, I emphasize the use of UL or cUL-approved power cords. I also check to make sure that all connections are tight, take the load of the circuit within safety tripping and overheating levels, and ensure the equipment and the environment meet wear and safety guidelines to maintain optimal performance and reliability.

A 3-prong grounding system is an important aspect of safety measures while working with electrical equipment. With the use of a hot wire, neutral wire, and ground wire with ground wire enabling low-resistance routing for fault currents towards the earth’s surface, this system is much safer to use. Grounding prevents scenarios where electric shocks are administered, damage to equipment is caused, or fires are sparked due to the presence of stray currents.

An important maintenance step to ensure the safety of a 3-prong grounding system is confirming that all electrical outlets are grounded. Current safety measures show holes for mounting 3-prong outlets have effective resistance levels below 25 ohms. Moreover, a receptacle tester or multimeter can be used regularly to detect malfunctioning within open grounds or reverse wiring.

While not in the forefront of one’s mind, an important step is checking all screw terminal grounding connections to ensure they do not have any signs of corrosion or damage. Indoor and outdoor settings as well as industrial setups can be compromised due to moisture or wear and tear factors over time. For bringing the systems in alignment with safety measures, upgrading older 2-prong outlets to 3-prong ones is a necessary step.

Conducting inspections regularly and following the standards outlined in ANSI/NFPA 70, also known as the National Electrical Code (NEC), will make sure the dependability of 3-prong grounding systems is sustained. This will reduce interruptions to the system, while still shielding both infrastructure and workers from potential electrical dangers.

A: A NEMA 5-20P plug is an industrial-strength male plug that is rated for 125v, and 20a. It is used in industrial settings to power machinery, large appliances, and any other equipment that draws more power than a standard 15a outlet provides. Its design allows for reliably high-power connections on devices that require it.

A: The most important distinction is that a NEMA 5-20P plug is rated for 20 amps at 125 volts, and a NEMA 5-15P is rated for 15 amps at 125 volts. The 5-20P has a T-shaped neutral blade unique to this type of plug, as opposed to two parallel blades on the 5-15P. Because of this design, the 20A plug cannot be inserted into a 15A receptacle.

A: Yes. A NEMA 5-20P plug is intended to be used with a 5-20R receptacle. 5-20R is a receptacle rated for 125-volt and 20-amp which can take in both 5-20P and 5-15P plugs, hence it can accommodate multiple power requirements.

A: A NEMA 5-20P plug is usually recommended to be wired with a 12 AWG (American Wire Gauge) wire. This particular wire gauge will be able to carry the recommended 20 amps and will allow for the safe use of the power cable or heavy-duty extension cord.

A: Yes, there are several power cord adapters available with different configurations. For instance, there are specific NEMA 5-20P to C19 adapters for use with certain computers. However, safety dictates that any adapter used should have the right voltage and amperage rating.

A: Of course, a broken NEMA 5-20 P plug can be changed. These plugs are sold in stores, and if you have the right tools and skills, you can change the ends of the extension cords. On the other hand, if you think you can accomplish this safely on your own, you should instead go get help from an electrician.

A: The NEMA 5-20P Plug has an important T-shaped neutral blade made for heavy-duty work and is a three-prong male plug. Like many other plugs, it is also labeled 20 A 125 V, but unlike many other plugs, it is frequently found on industrial-grade power cords. The NEMA 5-20 P Plug belongs to the straight blade family of connectors, so it is wider than the commonly found NEMA 5-15P household plugs, which makes it easy to identify.

A: NEMA standards are commonly found in use in North America, but some other countries which also have similar electrical standards might have use of NEMA 5-20P plugs. A word of caution, many other countries use other types of plugs along with differing standards of voltage for all more, which is why it is always advisable to check local standards before traveling or importing goods.

1. Optimal Urban Traffic Model Predictive Control for NEMA Standards

2. Omni Legend 32 Performance Evaluation as a New Generation Digital Bismuth Germanium Oxide PET/CT System does indiscriminately violate NEMA NU 2-2018 Standards.

3. Evaluation of PET/CT: National Electrical Manufacturers Association NU2-2018 Standards versus American Association of Physicists in Medicine Task Group 126