————

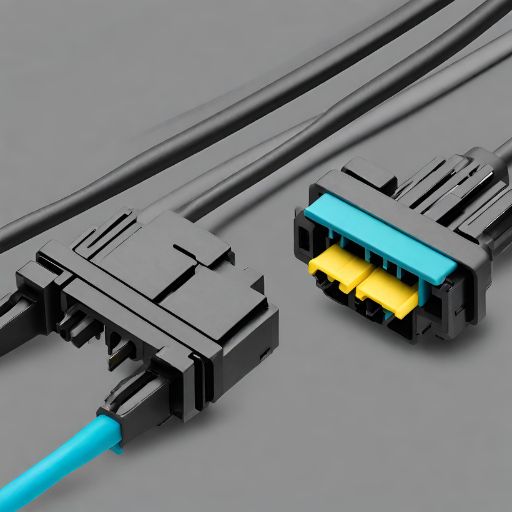

An MPO fiber connector is a high-density, multi-fiber connector that offers a scalable and flexible solution for high-speed data transmission.

The Multi-Fiber Push On (MPO) connector is a type of fiber optic connector that has been designed to accommodate multiple fibers in a single physical connector interface. It uses a high-density footprint to reduce space requirements and increase port density. The connector interfaces can hold up to 12, 24, 48 or even 72 fibers, making it ideal for high bandwidth applications.

While the terms MPO and MTP are often used interchangeably, they are not identical. MPO stands for Multi-fiber Push On, a term that refers to the type of connector. MTP, on the other hand, is a brand name for an improved version of MPO connectors, owned by US Conec. MTP connectors offer some enhancements over standard MPO connectors, including a floating ferrule to improve mechanical performance.

————

MPO fiber cables are integral to modern data transmission systems. They consist of various components that ensure high-speed, high-density connections.

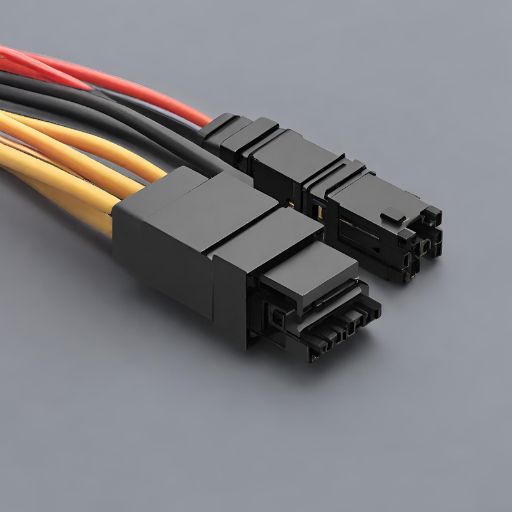

MTP connectors are an enhanced version of MPO connectors. MTP, standing for Multi-fiber Termination Push-on, is a specific brand of MPO connectors manufactured by US Conec. These connectors offer some technical advancements over standard MPO connectors, including a floating ferrule to improve mechanical performance. The use of MTP connectors in MPO cables ensures high-quality, reliable connections.

Breakout cables play a critical role in MPO cabling systems. These cables are designed to ‘break out’ the multi-fiber connector into individual simplex or duplex connectors. This allows the high-density MPO connectors to interface with standard equipment ports, facilitating flexibility in network design and simplifying cable management.

Polarity in MPO cables refers to the direction of the flow of the optical signal from one end of the cable to the other. There are three methods to maintain proper polarity:

The number of fiber strands in MPO cables can vary, typically from 12 to 72 fibers. The higher the fiber count, the greater the data capacity of the cable. However, a higher fiber count also means a larger diameter cable, which could impact installation considerations such as conduit size and bend radius.

MPO cables can be categorized based on several factors:

————

MPO fiber connectors play a crucial role in enhancing high-density cabling systems, providing streamlined solutions for data transmission.

MPO connectors are transformative for data center connectivity due to their high-density and high-performance characteristics. They allow the connection of multiple fibers using a single interface, significantly increasing port density and data throughput. This leads to a more efficient use of space within the data center, which is a critical consideration given the growing demand for data storage and processing capabilities.

Trunk cables form the backbone of a network, carrying data between different parts of a system. MPO connectors can optimize these cables by allowing multiple fibers to be carried within a single cable. This not only reduces the physical footprint of the network but also simplifies installation and maintenance, as fewer cables need to be managed.

In high-density settings, cable management can become complex and challenging. The use of MPO connectors can significantly simplify this process. By consolidating multiple fibers into a single connector, the number of individual cables required is reduced. This leads to fewer cables to manage, less clutter, and a lower risk of errors or faults occurring.

MPO connectors offer significant bandwidth and performance benefits in high-density cabling systems. By enabling the transmission of multiple data streams simultaneously, they increase the total data capacity of the system. This is particularly beneficial in applications that require high bandwidth, such as cloud computing, video streaming, and high-performance computing.

Multi-fiber Push-On (MPO) applications benefit greatly from the use of MPO connectors. These applications, which require the simultaneous transmission of multiple data streams, are well-suited to the high-density and high-performance characteristics of MPO connectors. By using MPO connectors, these applications can achieve higher data rates, better reliability, and more efficient use of space.

————

MPO fiber connectors are essential for high-density cabling solutions. However, their application requires adherence to certain best practices for optimal performance.

Proper polarity is crucial in MPO cabling to ensure that data transmission occurs correctly from the transmitting end to the receiving end. The three methods of maintaining polarity – Method A, Method B, and Method C, each have different configurations and uses. Additionally, proper positioning of fibers within the connector is essential for correct alignment and data transmission.

The choice of MPO connector should be based on the specific requirements of the application. This includes the number of fibers needed (12, 24, 48, or 72), the type of cable (single-mode or multi-mode), and the physical environment where the cable will be installed. Careful consideration of these factors will ensure that the chosen connector meets the performance and reliability requirements of the application.

Multiple fiber connections in MPO cabling can pose challenges such as increased complexity in cable management and potential signal loss due to misalignment or damage to the fibers. These challenges can be addressed by using high-quality connectors, implementing proper cable management practices, and regular inspection and maintenance of the cabling system.

MPO connectors should be compatible with the equipment they are connecting to, and interchangeable to allow for flexibility in system design and expansion. This involves ensuring that the connectors are of the same type (MPO or MTP), have the same number of fibers, and are of the same polarity type. Compatibility and interchangeability are crucial for the long-term viability and scalability of the cabling system.

Effective cable management is essential for maintaining the performance and reliability of MPO connectivity. This includes proper routing of cables to avoid physical damage, labeling of cables for easy identification, and regular inspection and maintenance. Additionally, the use of cable management solutions such as cable trays, racks, and panels can help organize cables and protect them from physical damage.

————

Installing and maintaining MPO fiber cabling requires a solid understanding of various technical aspects, from installation configurations to ongoing maintenance procedures.

The installation of MPO cables in data center environments necessitates careful planning and precise execution. The first step involves determining the cable length, fiber count, and polarity method. Once these are established, the MPO cables can be installed according to the specific configuration of the data center. This includes proper routing of the cables to avoid physical damage and ensure optimal performance.

Maintenance and testing of MPO connectivity are key to ensuring long-term performance and reliability. Regular inspection of the cables and connectors for physical damage, as well as testing for signal loss, should be part of any maintenance routine. It’s also recommended to use proper cleaning tools and techniques to keep the connectors free from dust and debris that can affect signal quality.

As data centers continue to evolve towards higher density and faster speeds, the role of MPO fiber connectors is expected to grow. They offer the ability to connect multiple fibers in a single interface, significantly increasing port density and data throughput. By staying up-to-date with advancements in MPO technology, organizations can ensure they are prepared for future demands.

Adherence to best practices is critical when deploying and managing MPO cables. This includes maintaining correct polarity, choosing the right connector type for the application, implementing effective cable management solutions, and ensuring compatibility and interchangeability of connectors. By following these practices, organizations can maximize the performance and lifespan of their MPO cabling systems.

MPO fiber connectors have a significant impact on network infrastructure. By enabling high-density, high-speed connections, they allow for more efficient use of space within data centers and other network environments. Additionally, they simplify cable management and reduce the risk of errors or faults. Understanding these impacts can help organizations make informed decisions about their network infrastructure design and management.

————

A: MPO (Multi-Fiber Push-On) fiber connectors are compact, high-density fiber optic connectors that can house up to 12 or 24 fibers. Their primary use is in data centers and high-speed telecommunications due to their proficiency in optimizing the cabling infrastructure and boosting connectivity.

A: MPO connectors advance high-density cabling by permitting simultaneous connection of multiple fibers. This decreases the cabling quantity needed and eases cable management in high-density settings, leading to efficient space usage and better airflow.

A: MPO fiber connectors support multi-fiber connections and are known for their high-density design. They are compatible with both multimode and single-mode fiber optics. They offer various polarity types and can be utilized with fiber breakout cables.

A: OM3 and OM4 are types of multimode optical fibers. Compared to OM3, OM4 fibers offer higher bandwidth and support longer transmission distances. OM4 fibers are preferred in the context of MPO connectors for high-speed data transmission and applications needing higher performance.

A: Yes, MPO connectors and MTP connectors can be exchanged. MTP is a brand name for an MPO connector. They can mate with each other without any issues.

A: An MPO trunk cable is a high-density fiber optic cable fitted with MPO connectors at both ends. This configuration allows for swift and reliable connections between MPO-enabled equipment. These cables are frequently used in data centers and high-speed networking applications.

A: A fiber breakout cable has multiple fibers within a single sheath that can be split into individual fibers for connection. MPO connectors use fiber breakout cables to distribute individual fibers to diverse equipment or devices, providing flexible connectivity options.

A: Polarity type in MPO connectors concerns the proper alignment and connectivity of fibers in the connector. Correct polarity type ensures the successful transmission and reception of signals across the cabling infrastructure. It is essential for seamless data transmission.

A: LC connectors are small form-factor fiber optic connectors for single-mode and multimode fiber connections. They are often paired with MPO connectors, enabling a smooth integration between high-density backbone cabling and individual equipment connections.

A: MPO connectors are beneficial for 12-fiber applications due to their high-density design. They can accommodate multiple fibers within a single connector, simplifying cable management, improving space utilization and reducing cabling complexity, making them perfect for 12-fiber connectivity requirements in data centers and telecommunications environments.

————