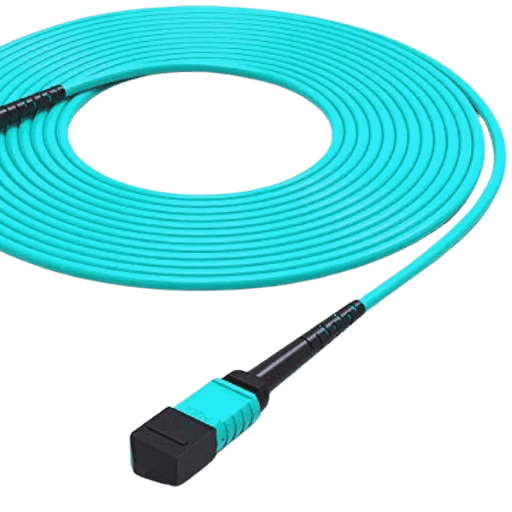

Effective and high-capacity data transmission is essential today. In modern data centers, multi-fiber push-on (MPO) cable assemblies are crucial to telecommunication networks and high-speed computing environments. This blog thoroughly explains MPO cable assemblies – their structural complexities, functional benefits, and significant role in supporting multi-fiber solid connectivity solutions. This paper aims to arm professionals with necessary information about optimizing network performance through technical aspects and practical applications of MPO cable assemblies, enabling them to meet ever-increasing data bandwidth demand.

In high-density fiber optic networks, multi-fiber connectors called MPO (Multi-Fiber Push On) and MTP (Multi-Fiber Termination Push-on) cables are used. The difference mainly lies in their branding and functionality. MPO is the generic name that complies with IEC-61754-7 as well as TIA-604-5 (FOCIS 5) standards. On the other hand, US Conec created MTP as a trademark for better optical and mechanical performance. Additional features like improved spring design, removable housing, and optimized ferrule polishing make it possible for MTP connectors to attain higher insertion loss and return loss characteristics than standard MPO connectors.

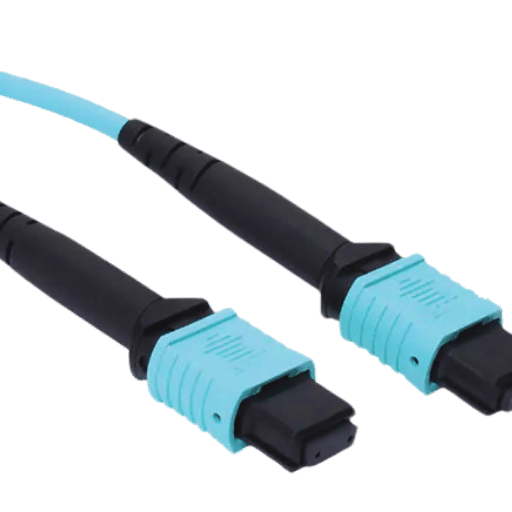

MPO connectors are available in different forms to meet various needs and applications. The two main types include:

Each type allows for a choice of 8, 12, 24, or more fibers, thereby allowing networks to be easily scaled as required.

There are a number of major benefits to using MPO cables in networking infrastructure, the most important being their high-density and high-performance features. First, let’s talk about how they can rapidly deploy fiber optic networks in small spaces. This is possible because MPO cables can put many fibers into one connector, which simplifies cable management and cuts down on installation time. In addition, these types of cables are scalable – you can increase network capacity without having to do much reconfiguration! It’s also worth noting that another great thing about them is that signal integrity is excellent while insertion loss is low – both factors being necessary for transmitting large amounts of data across longer distances at high speeds. Altogether, these properties result in lower costs overall so far as setting up advanced fiber optics networks goes, not to mention making them more efficient!

The fiber strands of MPO cables are one of the most important parts for their performance and functionality as a connector. In general, every single strand consists of an ultrathin, flexible glass or plastic thread that can transmit light signals with minimum loss over long distances in OS2 or other types of fibers. These strands are designed in such a way that they meet certain performance criteria like core diameter, numerical aperture (NA), and attenuation.

To achieve maximum light transmission efficiency, it is necessary to control the core diameter of fiber strands within MPO cables tightly. For example, singlemode fibers typically have cores with diameters ranging from 8 to 10 µm, which allows for very precise data transmission over large distances at extremely low levels of attenuation. Conversely, multimode fibers have much larger cores – usually 50 or 62.5 µm – which enables them to carry more bandwidth over shorter distances.

Another critical parameter influencing how much light can be collected into and transmitted through a fiber is its numerical aperture (NA). The NA is chosen so that it balances between gathering ability and signal loss minimization in MPO cables.

When talking about signal strength reduction with distance travelled by waves along optical paths – also known as attenuation – we say that these rates are kept very low by design during manufacture of fibre strands used in MPO cable assemblies; thus enabling them support even high speed transmissions without degradation across any required long haul length such as 0.35 dB/km at 1310 nm wavelength for single-mode fibres used in MPO cables.

In conclusion, strict specifications regarding the characteristics including but not limited too: core size/shape (diameter), entrance angle acceptance/exit beam divergence factor(numerical-aperture) and loss per unit length (attenuation rate) must be met by any given fiber strand meant for use within Multi-fiber Push On jumpers if they’re to provide modern networks with scalable, efficient means of transmitting data.

In fiber optic systems, it is important to have MPO polarity right so that the transmit and receive signals align correctly. The right alignment of signals sent by a transmitter at one end of the cable with the corresponding receiver at the other end is achieved through proper polarity, whether duplex or MTP fiber cables are used. Three major methods of polarity exist in MPO cables: Method A, Method B, and Method C. Method A utilizes a straight-through method where key-up to key-down adapters are used; method B uses a flipped configuration achieved by using key-up to key-up adapter while method C pairs employ transposed pairs where key-up to key-down adapters are used. Polarity understanding and correct selection are crucial as this will ensure that data is transmitted without any hitches while maintaining the performance of the system itself.

MPO cables are very important in today’s data centers because they can help manage a lot of connections and keep information organized. These types of wires are used for high-speed data transfer, like 40-gigabit or 100-gigabit Ethernet networks and fiber channel storage area networks (SANs). What makes them so great is that you can roll them out quickly and scale up easily when your data center starts to need more. Another thing MPO cables do is support modularity within a facility – this means we can maintain or upgrade parts without having any big shutdowns, which saves time and money. Also, since one connector can take many fibers at once, MPO cables cut down on the amount of space needed for cabling by consolidating everything into one place; this helps air move better around equipment racks so they stay cool without using as much power.

While comparing MPO cables to fiber cables, it is important to take into account several different points of performance. Multi-fiber push on (MPO) cables consist of multiple fibers within a single connector, unlike traditional fiber cables which have one fibre per connector. This dissimilarity in design has far-reaching implications for the overall cabling system.

Density and Number of Fibres:

Traditional fiber cords usually offer low density; they typically contain one or two fibers per connector requiring many connectors for large-scale deployments. Conversely, an MPO cable can house up to 12, 24 or even 72 strands into its compact body thus significantly increasing density and making better use of space in data centres.

Installation & Maintenance:

The installation process for traditional fiber optic lines is more intricate than that of MPOs since it involves managing a higher number of individual fibers and connectors. By reducing the number of connectors through which multiple fibres pass at once, time spent during installation is reduced with MPOS thereby simplifying cable management too. In addition, future upgrades or maintenance work can be done more easily due to its modular nature which reduces operational downtimes.

Performance and Data Transmission Rates:

High-speed applications like those demanding bandwidths above 40G or 100G require cabling systems capable of supporting such high data rates, thus making them suitable candidates for MPO usage where necessary. Although traditional fiber optics may also support these speeds, their installation complexity, together with lower infrastructure density as compared to any high-density solution like an MTP or even just a typical multimode duplex patch cord, makes this unfeasible most times since they will not achieve the same level as what can be realized using multi-mode plus parallel transmission offered by these types cables within modern-day data center environments.

Space & Cooling:

One advantage offered by having many fibres within a small space is reduced physical footprint hence leading to improved air flow as well as cooling efficiency within the DC. On the contrary, conventional fibre cables require more cabling which can restrict air flow and cause higher cooling costs due to possible overheating problems.

Cost Considerations:

MPOs may have higher initial costs compared to traditional fibres because of better features but they often save money in the long run through reduced installation time and complexity during maintenance as well as lower cooling expenses. However, although conventional ones might be cheaper at first glance, over time, their higher overall expenditures arising from increased numbers needed together with associated support requirements such as those related to frequent repairs would make these less cost-effective options when considering large-scale implementations involving extensive infrastructure.

To sum it up, MPO provides far more benefits than standard fiber cables particularly where there is need for dense environments or high-speed data centers. This allows consolidation of multiple fibers into one connector which simplifies installation and saves time among other advantages.

To ensure that they work well and are compatible, one should consider some factors when choosing MPO cables for data center environments:

Fiber Counts:

The number of fibers contained in an MPO cable can be anything between eight and one hundred forty four. Generally, the choice of a particular fiber count depends on how much data transmission is needed at present as well as plans for future scalability in the data center. When you have 12-fiber or 8-fiber MTP cables, they offer more redundancy options because higher fiber counts allow them to support larger amounts of data throughput.

Polarity:

This refers to getting all the multi-fiber connectors’ fibers aligned properly with their orientation so that signals can flow through correctly. If polarity is not kept consistent, there will be signal losses and connection failures. There are three methods in common use among most MPO systems, namely Method A, Method B, and Method C, which have different configurations for managing signal transmission directionality.

Trunk Cable Types:

In other words, backbone cabling within networks connects different patch panels or distribution areas; these cables are commonly known as trunks and come with varying features such as mode type (single-mode or multi-mode) depending on application needs vis-à-vis distance requirements, among others. It is also crucial to choose an appropriate jacket material together with proper cable diameter size, mainly when space is limited within buildings while still considering toughness under different environmental conditions.

Data centers can achieve the highest levels of efficiency and reliability in their MPO cabling infrastructure by taking into account such aspects like: fiber counts; polarity; trunk cable types.

To choose between singlemode and multimode MPO cables, it is important to know their unique features and uses:

Singlemode MPO Cables:

These types of MPO cables have a smaller core (usually 8-10 microns) which allows light to be transmitted straight down the fiber for extended distance data transmission that can go up to 10 km or more. They are best suited for high-speed and long-haul applications like telecoms and data centers with large coverage areas. Generally, single-mode fibers possess higher bandwidths than multimode ones while having lower signal attenuation rates, thereby making them suitable for future scaling-up purposes and creating superfast networks.

Multimode MPO Cables:

On the other hand, multimode MPO cables use larger cores (50 or 62.5 microns), enabling many light modes to travel at once, although this may lead to higher signal attenuation over longer distances. Such cables are commonly employed in LAN systems where short links of about 550 meters are required under certain specifications; they can also be found in data centers, among other places where there is a need for high data rates over shorter ranges. Cost efficiency reigns supreme when deploying multi-mode fibers within close proximity since they still provide enough bandwidth capacity, as demanded by most modern-day server farms.

To sum up, one would consider using singlemode MPO cables if they want a greater amount of bandwidth for long distance connections whereas multimode should be chosen when dealing with cost effective solutions over short distances.

It is possible to optimize network performance for reliable high-speed data transmission if these typical problems are identified early enough during careful observation coupled with regular upkeep programs.

MPO cable assemblies of high density were invented to cope up with the growing demand for increased data transfer speeds and wider bandwidths in data centers. These assemblies use connectors with many fibers, which reduces cable size and improves air circulation, leading to better utilization of space within the facility as well as its cooling system.

Characteristic Features of MPO Cables with High Density

Applications

Considerations

A good knowledge base about this technology, coupled with its adoption by organizations, will lead them towards building scalable networks with efficient flows characterized by higher capacities.

There are a number of ways to shift from 40G to 100G networks using MPO technology. The first is to make use of the existing MPO backbone infrastructure. To ensure a seamless upgrade, it is important that one uses MPO connectors that can support both 40G and 100G applications – such as the MTP®/MPO 24-fiber connector – which can cater for several 10G lanes aggregated into a higher-speed link of 100G commonly implemented in MTP fiber for scalability convenience and high-density deployments.

Secondly, parallel optics should be employed because this technique allows data transmission over multiple fibers simultaneously thereby multiplying throughput capacity considerably. Also, it is crucial that transceivers are compatible with the MPO assembly; hence QSFP28 type which works well with MPO connectors designed specifically for them should be used without any problems arising.

Lastly, testing and certification must be done correctly so as to validate the performance of the upgraded network. With an MPO tester, among other tools, at their disposal, every fiber strand can be checked to see if it operates properly, ensuring that data integrity plus reliability standards set by the industry are met by the entire system. Following these strategies will enable enterprises to transition smoothly into 100G, thus improving their networks’ capabilities and performances.

Several upcoming trends promise to further improve network capabilities as far as Multi-Fiber Push On (MPO) cable technology is concerned in the future. The initial trend is the need for higher data rates, which pushes for 400G and even 800G MPO solutions. These developments call for new designs like MPO-16 and MPO-32 connectors that can support increased fiber counts as well as bandwidth requirements. Moreover, MTP fiber connectors may allow high-density installations.

Secondly, there has been an increased focus on automation and intelligence in network infrastructure lately. This means that more intelligent MPO Cable Systems with built-in diagnostic and management abilities are being used than before. Such smart systems help optimize network performance by enabling real-time monitoring while making maintenance work easier through automated troubleshooting.

Lastly, flexible modular MPO solutions have started gaining popularity, too. With modular MPO cassette systems, it becomes easier to scale up or reconfigure them so that they can meet today’s dynamic data centers’ needs better. Also, bend-insensitive fibers are being used more widely nowadays, making the physical flexibility and robustness of these cables better, ensuring their ability to withstand harsh environments of high-density areas without compromising performance.

These trends point out how much MPO cable technology keeps evolving, thus continuing to enhance network reliability and performance levels beyond limits.

A: An MTP® cable assembly, or Multi-Fiber Push-On, is a particular type of high-density fiber-optic cable that employs numerous optical fibers, frequently either 12 or 8 fibers, into one connector for fast and efficient fiber applications.

A: Various types of MPO cables include 8-fiber, 12-fiber, and 16-fiber assemblies that can be pre-terminated with different connector types, such as MTP®, LC, etc., depending on the application requirement.

A: OM3 and OM4 are both multimode fibers, but OM4 has higher bandwidth and better performance over longer distances than OM3. It is often used in high-speed data centers and parallel fiber applications.

A: A breakout cable, also known as a fanout cable, splits a multi-fiber MPO assembly into individual fibers with different types of connectors on one end, such as LC or SC. This allows easy connection to endpoints like switches or panels.

A: High-density MPO cables provide efficient connectivity in data centers by saving space and increasing port density. They usually come with low smoke zero halogen (LSZH) jackets meeting safety requirements for confined spaces besides having mtp® connectors.

A: These high-density fiber connectors can be used interchangeably with other multi-fiber connectors, such as maps, ensuring multiple connections at once. They have been designed to work effectively under harsh environmental conditions requiring high-performance levels.

A: MPO cables with OFNP (Optical Fiber Nonconductive Plenum) or low smoke zero halogen (LSZH) jackets are safe for installation in plenum spaces that meet fire safety regulations.

A: An LC breakout cable splits the fibers of an MPO assembly into single-fiber connections with LC connectors. This allows flexibility in fiber patch panels and other high-density solutions where devices require individual fiber strands to be connected.

A: A Type B polarity refers to a particular fiber mapping within an MPO cable, whereby the first fiber position on one end aligns with the last fiber position on the other end. This simplifies and ensures the correct connection between MTP® connectors.