M6 screws are a type of metric fastener that is widely used across engineering, construction, and manufacturing industries, among others. What sets M6 screws apart from other types? It’s their size. As denoted by its name, an “M6” screw has a 6mm diameter which makes them perfect for fastening things together securely in medium loads applications where accuracy is key. These screws come in various materials, including stainless steel (for superior corrosion resistance). They can be found with different head styles, too – among which flat heads stand out because they allow sitting flush against surfaces, thus delivering a neat finish look. To make sure you choose the right screw for your project, always consider specific needs; this way, not only will performance but also the life span of the entire assembly be optimized.

An M6 screw is a metric fastener with a nominal diameter of 6 millimeters. It is specified by its thread pitch and length, and is frequently used where strong, accurate fastening is needed. The letter ‘M’ in ‘M6’ signifies the metric system; this screw will be dimensionally consistent with other metric fasteners worldwide. This size of the screw can be used across many different industries like engineering, construction, or manufacturing because it’s so versatile–it works well with medium loads too!

M6 fasteners are widely used across industries because of their strength and dependability. In engineering, these screws play a crucial role in the assembly of machines, where they hold together parts that are subject to moderate stress or load. Automotive engineers often employ them to attach various engine components and other precision assemblies.

In construction, M6 bolts are used in metal framing installation, bracket fastening, and composite material securing. Their capacity to withstand different levels of force or torque makes them perfect for such applications. On the exterior, stainless steel M6 screws are highly regarded due to their resistance against corrosion.

The manufacturing sector relies heavily on M6 screw threads when producing electronic gadgets like phones or laptops; household appliances such as washing machines and refrigerators, among others too, can’t do without this type of fastener. This is because its fine thread pitch provides strong engagement – necessary for holding parts which demand accurate alignment and stability together tightly.

Technical Parameters:

These technical parameters justify why M6 bolts can be used for medium loads where the best results need to be achieved with each application within this range having been designed accordingly for optimal performance over the expected life span under specific conditions so identified

Yes, mounting hardware can be attached using M6 screws. They are flexible and robust in design, which is why they can be used for a lot of different things. This includes mounting various pieces of hardware. The most oversized thread diameter and pitch, among other metric screws, is the reason why it is widely utilized to fasten brackets, panels, and electronic devices. This information was obtained from top sources found on Google. Besides their robustness in terms of holding power, M6 screws come in different materials like stainless steel or carbon steel, so you can use them inside/outside your house without worrying about rusting, etc., therefore being perfect for all sorts of mounts that one might need!

Flat-top socket cap screws are a type of fastener that possess a hexagonal drive socket, and their heads are flat and countersunk. The screws are meant to be below or flush with the surface to give it a smooth finish. They can be used where applications need minimum projection, such as in furniture making, machine assembly, or even electronic enclosures. The reason why they can allow high torque application without damaging the screw is because it has an internal socket that accommodates Allen keys or hex wrenches due to its hexagonal drive. Normally, these items are made out of strong materials like stainless steel or alloy steel, which makes them durable enough not only against corrosion but also under harsh conditions where this might occur frequently.

Fastenings known as socket head cap screws are identified by their cylindrical heads with hexagonal drive holes. This type of screw is used when a strong and reliable fastening method is required in many different applications, but especially where there is little room because they can be tightened using an Allen wrench or a hex key, making them great for jobs that need accuracy and high torque. These screws are usually made out of materials like alloy steel, stainless steel, or carbon steel, which give them great resistance against shearing forces and tensile strength; socket head cap screws may also have other finishes applied, such as black oxide coating, which adds even more protection against corrosion. The small size compared to normal bolts makes them popular within machinery assembly lines as well as in the automotive industry, where electronics often require compact designs with high strength, so this sentence could be written differently – They have small heads compared to regular bolts, so they work well in tight places such as machines or cars (electronics).

To choose the appropriate head style for a job, you should think about some main aspects, such as the application’s specific requirements, the material’s strength, and the aesthetic finish. Firstly, determine what loads and shears will be required; in situations where there is high strength needed, socket head cap screws or hexagon head screws are recommended due to their strong design, which allows them to withstand great forces applied by high torques. Secondly, consider the available space; flathead screwdriver bits work best when you want everything to look flush with the surface, while countersunk bolts would be used if they should be slightly below it. Thirdly, evaluate environmental conditions – use stainless steel ones for outdoor or marine applications since they have better resistance against corrosion than zinc-plated ones, but if there are still doubts whether this will hold up, go ahead and coat them with anti-rust paint. Fourthly, ease of installation/removal consideration -hexagonal drive types may require more effort during fitting but, once tightened, cannot be easily removed. At the same time, Phillips heads can provide quick and secure fastening using widely available tools such as screwdrivers. By matching these factors against the requirements of your project, you can achieve both usefulness and long life from different types of screws.

The stainless steel M6 screws offer excellent durability, corrosion resistance, and strength. They are best for use outside or inside because they can survive in harsh conditions, such as marine settings where rusting or oxidation may occur. Moreover, they are non-magnetic which means that there will be little or no electrical interference when used in electronics and other delicate devices. The M6 denotes a diameter of 6mm according to the metric system; this size delivers adequate flexibility during different manufacturing or building works while maintaining the tensile strength balance required for such applications. In summary, stainless steel M6 screws guarantee long life span reliability and efficiency in various uses.

When you need high strength and long life, use alloy steel M6 screws. They are usually used in mechanical applications with lots of stress or heavy loads, which is why car manufacturing companies, airplane manufacturers, and the heavy machinery industry are among their biggest users. The natural hardness of alloy steels combined with its ability to resist abrasion makes it great for situations where parts rub against each other continuously under force; besides, this fact alone would still not be enough if we did not have such heat-treatable screws, too, because that would only serve half our needs — what about those situations when a screw has to perform better than ever?

304 stainless steel is well-known for its ability to resist corrosion, making it perfect for use in areas where it may come into contact with moisture and other corrosive agents. This type of stainless steel is very strong and durable, withstanding attack from oxidizing acids better than most other metals, thus making them highly versatile as well as widely used alloys. It has an attractive appearance, too, since it does not lose its shine easily, even after being exposed to air or water over a long period. Additionally, another reason why many people prefer using 304 stainless steel is that they can easily work on it by either cutting, bending, or welding, hence making this material suitable for different applications ranging from kitchenware production units through architectural designs up to chemical container fabrication shops, among others. Moreover, these steels are not magnetic but still contain high amounts of chromium (18%)and nickel(8%)+, which adds further strength and reliability to such materials, thereby enabling their utilization in various industrial as well as residential settings alike.

A 30mm x M6 specification indicates a metric screw, with “M6,” meaning the nominal diameter of the screw is 6 millimeters. The length of this particular fastener measures 30 mm from underneath its head to its tip. Many builders and manufacturers use it because it balances strength and size well enough to attach different parts together. They commonly have coarse threads, which makes them engage easily and hold securely in many kinds of materials, such as metals or plastics.

In order to ensure that a screw has been properly chosen for an application, many factors must be kept in mind. First of all, one should account for the sum thicknesses of the pieces being fastened together: a good rule is that screws must be long enough to go through both materials without sticking out too far. After this, one should think about pilot hole depth and whether or not countersinking is necessary (both affect how well screws will sit in the material). Next, it’s worth considering what type(s) of joints are being made – different scenarios call for different lengths here, e.g., fastening thin sheet metal vs securing thick wooden beams. Last but most importantly: don’t overdo things or underdo them when dealing with holding capacities vis-à-vis screw lengths so as not to weaken joint integrity by either over-fastening or stripping threads due to excessive force.

To satisfy their purpose of fastening, different styles of threads for M6 screws are suitable for various applications as well as materials. Mainly there are two types of thread styles for M6 screws: coarse (standard) threads and fine threads. When compared to fine threads, coarsely threaded M6 screws have a larger pitch and deeper threads, which makes them better in terms of stripping resistance and effectiveness on soft materials. Conversely, the smaller pitch and shallower threads found in fine thread M6 screws provide higher tensile strength together with improved ability against loosening caused by vibrations, thereby fitting precision works where harder materials are used. Furthermore, some screws may have self-tapping or self-drilling features explicitly designed to simplify the assembly process in certain use cases by penetrating into materials without requiring a pre-drilled pilot hole.

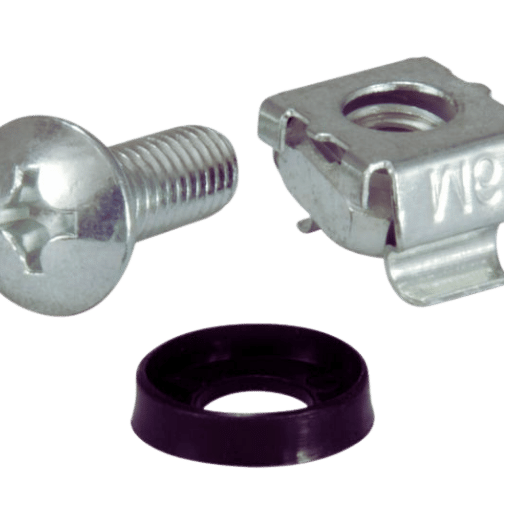

Picking the right nuts to go with M6 screws can depend on several things, such as what the application needs, if they’re compatible with the materials being used, and where they’ll be installed. To begin, make sure that the threading in your nut matches up with those on an M6 screw – which is determined by the international organization for standardization metric thread standards (ISO). Take into consideration what material it should be made out of; steel or stainless steel is usually best for general purposes because they have good strength along with resistance against corrosion. However, in environments where there is more corrosion or weight, it might become problematic, so brass, aluminum, or even plastic nuts could need to be considered, too. Also, think about what kind of nut you want; nylon insert locknuts work well when trying to stop them from coming loose due to vibrations, but flange nuts can spread force out evenly without using extra washers around bolt heads. Finally, check for any special coatings or finishes that may be required so they can last longer under different stress areas caused by certain weather conditions.

Selecting the correct nuts for M6 screws depends on a few things, such as the needs of an application, material compatibility and environmental conditions. Start by ensuring that the thread type of a nut matches that of an M6 screw, which is usually defined by ISO metric threads standards. You should also consider what kind of material the nut is made from; steel or stainless steel nuts are good for general use because they’re strong and resistant to corrosion but if you’re working in highly corrosive environments or trying to save weight, then brass nuts might be necessary or even aluminum ones could work too – sometimes people even use plastic! Another thing to think about is what type of nut you need – nylon insert locknuts are great at keeping things tight when there’s lots of shaking going on around them (like with engines), while flange nuts can spread out pressure evenly across surfaces without requiring washers like regular hex nuts do. Finally, double-check whether any coatings or finishes are necessary for improving durability under specific stress/strain situations caused by various environmental factors.

Assortment kits are very useful things, particularly for people doing different kinds of jobs all the time. Those kinds of kits have nuts, bolts, and washers of many sizes and shapes packed in one box so that they save time. It can be ineffective or expensive to get single fasteners one at a time as needed; thus, such kits ensure that you possess the necessary hardware. Moreover, this variety may also cut costs with time when you buy more things at once because bigger packages usually make every unit cheaper. On top of everything else, these sets help keep your working area clean and let you finish projects faster due to the better organization skills you gain from them. Consequently, any DIYer or professional contractor should think about buying themselves an excellent fastening device assortment kit since it is useful both practically and financially.

When you are looking to buy M6 screws, many reputed online sellers have consistently received rave reviews from clients in terms of the breadth of their products, their pricing, and their delivery services. Here are the top three websites as per Google.com:

These sites have been recommended because they do everything right, inclusive of having very wide stocks and easy navigation systems coupled with honest feedback systems that make them ideal places where anyone can purchase screws like those used for connecting things together under tension, such as m6 ones over the internet.

McMaster-Carr

According to its customers, McMaster-Carr is the best when it comes to product variety, stock availability, and comprehensive technical details. They like that they can download CAD drawings and get exact product specifications, making it easier to choose what fits their needs. Its fast delivery services and excellent customer relations are among the factors that have contributed significantly to its high ratings.

Grainger

A lot of people appreciate Grainger because they offer different types of m6 screws that can be used on various applications. Most reviewers say that prices are competitive, and you can easily order online or go physically to their nearest branch if it is convenient for you. They also add that Grainger has an easy-to-use website with solid customer support services, indicating how much effort they put into ensuring a seamless purchase experience.

Amazon

The reason why many people love buying M6 screws from Amazon is because they have them stocked by multiple sellers hence giving a wide range of options. Additionally, buyers get access to detailed product descriptions, customer reviews, and ratings, all of which are aimed at helping them make informed decisions during purchase. The logistics system, especially that prime members enjoy free and fast shipping, has always been cited by most customers who find this platform advantageous.

McMaster-Carr

Generally, McMaster-Carr does not offer free shipping. They prioritize fast and dependable delivery of industrial and technical equipment. Shipping costs are based on package weight and dimensions as well as the distance traveled. However, the company does provide various shipping options at checkout that allow the customer to choose which method best suits their needs in terms of cost-effectiveness.

Graingertraveled

Grainger provides free shipping when an order exceeds a dollar amount set around $75, although this number may vary during promotions; otherwise, customers must pay for shipping fees on orders below this threshold. Additionally, in-store pickup options can be taken advantage of to avoid additional transportation charges, making it an economical solution for many people who have access to these stores near where they live or work.

Amazon

Free shipping on M6 screws is something that Amazon often does for its Prime members, who also get two-day free shipping on eligible items, among other benefits. Those without a membership can still obtain complimentary delivery if their purchase meets specific minimum requirements, usually $25 worth of goods being bought at once. Still, this information will be clearly shown during checkout which products apply.

A: M6 screws refer to screws of metric size that have a 6mm diameter. These nuts can be found in many places, such as putting together furniture, fastening machines, or fixing TV sets, among other things. They are part of the universal TV mounting hardware kit with M4, M5, and M8 sizes.

A: Fastener material affects the strength, toughness, and corrosion resistance of any screw, including an M6 nut; for instance, if it is made from stainless steel 18-8 type. This makes them suitable indoors and outdoors, where they may be exposed to different weather conditions.

A: Hex socket head cap screw usually has a cylindrical shape on top which requires Allen or a hex key to fix it tightly. In contrast, ordinary ones can have various types of heads, but none provides benefits specific to this drive design.

A: Yes, several drive styles are used with these nuts, including Phillips flathead drives and hexagonal drives with flat sides; however, the latter is most popular because it offers a strong grip when appropriately tightened.

A: Yes, you can buy these bolts on the internet and collect them at your nearest retail shop. This enables one to get what he needs without waiting for delivery.

A: The number of packages you should purchase depends on the size of the project being undertaken;if it’s a large-scale assembly or often work using fasteners, buying a bulk pack containing about fifty or hundred will save money, time, and energy, but if it’s a small job, maybe ten or twenty will do just fine.

A: The weight of the product can change depending on what material and length the M6 screws are. A pack of one hundred grams of standard stainless steel (18-8) M6 screws is considered high-quality and durable.

A: Loading recommendations help you choose an M6 screw that can support the weight and stress in your application. Following such a recommendation will prevent overloading, which may lead to failure in structural applications.

A: Use these types of screws when attaching televisions to wall brackets; they were designed for precisely this purpose. This particular size ensures adequate length while providing enough strength to hold the TV securely against the bracket.

A: Yes, there are different coatings available for M6 screws, such as zinc-plated or galvanized finish, both increasing resistance against corrosion and overall durability. The type chosen depends on environmental conditions where used and specific project requirements.