Knowing the jargon of fasteners is necessary in manufacturing and construction today. An M2 screw boasts adaptability and precision that make it useful in a wide range of applications, from electronics to delicate machines. This manual offers a detailed account of all things M2 screws, specifications, kinds, uses, as well as key performance drivers, among others. Whether you are an engineer or just someone who loves doing things themselves around their homes, even if your profession involves building houses for a living, then this text will give you enough information about what this little thing does that can help guide decisions during project completion phases either personal or professional ones alike.

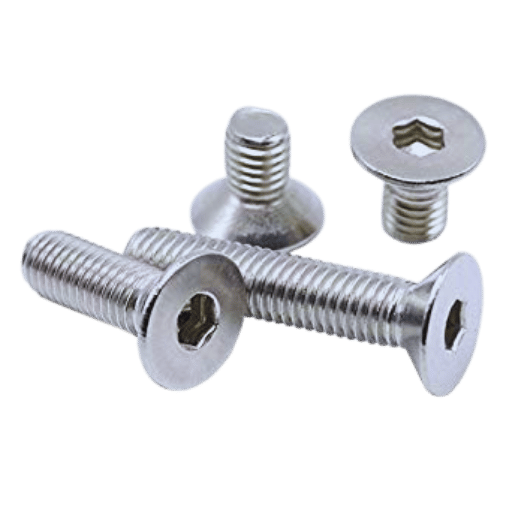

The diameter of a M2 screw is 2mm. The thread pitch can vary, and it is found in both fine and coarse threads, usually at 0.4mm for standard M.2 screw application. The length of an M2 screw is measured from where the head sits to the tip of the screw; it may range between a few millimeters up to 25 mm or more depending on what is required in specific situations. For M2 screws, there are flat, pan, roundhead, and countersunk head types designed for different applications, which offer either flush finishes or protruding heads that provide greater grip strength when necessary.

Screws M2 are used mainly in electronics and precision engineering. In the electronics industry, they can be employed for fixing circuit boards and connectors and tiny components found in mobile phones, laptops and other handheld devices like. These screws are also utilized in precision works such as fastening watch parts together or eyeglasses frames, or medical instruments where their small size and accurate threads come in handy too. Moreover, this type of screw is used during assembling hobby models or mini machines because it offers strong connections within limited spaces which need high accuracy measurements while putting things together tightly enough not to lose stability but without overdoing it either.

M2 screws and M2.5 screws are alike in many ways, but also contain important differences which affect their uses. Both types of screws are identified by their nominal diameters: 2 millimeters for the M2 screw and 2.5 millimeters for its counterpart. This slight increase in size with the M2.5 screw can provide additional strength as well as load bearing ability.

The thread pitch is another significant factor; typically, an M2 screw has a pitch of 0.4 millimeters, while an M2.5 screw commonly uses a pitch of 0.45 millimeters, so check if you’re using the right SSD screw kit when dealing with SSDs. Because of this difference in thread pitches between these two types of fasteners, it means that M2.5 screws can offer more stable and secure fastening, especially where additional mechanical stability is needed.

As far as application goes, microelectronic assemblies and precision engineering applications often prefer M2 screws due to their smaller size brought about by space constraints while slightly larger electronic devices or machinery may use a mix between m2 or m25 sizes depending on what best suits the machine both strong enough not break easily but small enough not take up much room either.

To sum it up, then, whether one should use an M-2 or an M-25 screw depends upon specific needs vis-a-vis diameter widths, thread pitches (strength), overall sizes (space requirements), etcetera that will vary from case to case but may be informed by considerations involving all these aspects at once.

When it comes to selecting what sort of material is best for M2 screws, there are a few things you should keep in mind:

To select the appropriate M2 screw material for a particular application, it is necessary to consider various factors, including strength requirements, resistance against corrosion, weight considerations (if any), electrical conductivity needs (if any), and tolerance levels toward different temperatures.

Based on my survey of the most popular websites, there are several important reasons why stainless steel is highly recommended for use with M2 screws. First off, among them is the fact that stainless steel has high tensile strength, therefore making it capable of supporting heavy loads or pressures without bending or snapping, which suits it well for use in harsh conditions. Secondly, its corrosion resistance properties are quite significant especially when used in places with moisture content and chemicals involved; this helps to enhance their durability so that they can remain operational over a long period. Additionally, another reason why I think this material should be used is that these types of fasteners should work equally well at both low and high temperatures where extreme heat or cold might prevail as conductors since stainless steel does not lose its qualities under extreme heat or cold conditions. These few advantages show that many industries prefer using stainless steel instead of any other metal in making M2 screws considering different commercial environments also require various temperature ranges for operation purposes.

According to the three best websites on this topic, flat-head screws, and pan-head screws are used for entirely different things. Flat heads have a conical shape that allows them to be flush with the surface of whatever they’re screwed into; because of this, they’re perfect for places where you need something smooth, like cabinets or certain types of electronic enclosures. On the other hand, pan heads have round tops and more gripping area than most other screws do. This means that they work well when fastening metal objects together or if there’s nothing wrong with leaving part of the screw showing. Each kind has its own benefits, so which one to use usually depends on how something looks versus what it needs to do in any given situation.

To decide whether to go with a Phillips flat head screw or a socket head cap screw, you need to take into account the requirements of the specific application. These screws feature cross-shaped drive and countersunk heads that let them sit flush with or below the surface of an object. Because of this, they are perfect for achieving smooth finishes in woodworking or interior fixtures where fasteners should not be seen. In addition, their design allows for easy alignment during installation, which is handy when dealing with automated assembly processes.

On the other hand, socket head cap screws have cylindrical heads and are driven by means of an Allen wrench or hex key, thereby providing higher torque capacity as well as a more secure hold. This kind of screw is frequently used in mechanical assemblies where accurate torque application is required, while space may restrict the use of other types of fasteners. They are also strong enough to withstand heavy loads imposed on them by machinery subjected to vibrations like those found in automotive components.

In summary, whether you opt for Phillips flat head screws or socket head cap screws will depend on what is demanded mechanically and aesthetically by your project.

To choose a specialized kit for mounting screws on an SSD, it is important to ensure that the selected kit is compatible with the particular model of SSD as well as its mounting needs. The most common type of screw used in standard kits are M3 or 6-32 screws which can be employed when attaching these drives either directly onto chassis or onto brackets meant for holding them. High-end kits have multiple lengths of screws and required installation tools like screwdrivers necessary during easy and secure installations; furthermore, some also come with anti-vibration parts that protect against physical shocks and vibrations which would otherwise decrease the drive’s life span while at the same time slowing it down. For exact recommendations about products, one should check specifications & reviews posted on popular e-commerce websites or manufacturer sites.

For a PC build or any other electronic assembly, the use of a mounting screws kit cannot be overstated. These packages provide different types and sizes of screws that fit each component precisely, be it motherboards or SSDs, among others. In most cases, high, quality kits have screws made from strong metals that do not rust or wear out easily, thus creating a sturdy and long-lasting setup. Apart from that, they also come with special screws, which help to reduce noise as well as protect fragile parts from physical impact through vibration absorption. Therefore, without much ado about nothingness, all in all, we can say that such a simple thing like having some fasteners around really does make life easier when putting things together while at the same time reinforcing them so they won’t fall apart soon after completing the operation because this may lead to unnecessary expenses even if everything seems fine initially but breaks later on unexpectedly due to lack of support from below hence causing one loss financially besides wasting time too.

Mounting screw kits are created to be very compatible with different brands of motherboards which include ASUS, Gigabyte, ASRock, and MSI. These sets usually contain screws of the same size and type as those adopted by the industry so that they can fit into the pre-drilled holes on any motherboard made by these manufacturers securely. These screws that come with it have been designed in such a way that they can accommodate various form factors of motherboards like ATX, Micro-ATX, and Mini-ITX. The robustness provided by this kind of screwing is achieved through the use of high-quality materials; this means that you will get stable mounting, thereby keeping your system in its best operational state always and preventing any physical harm to it over time. To achieve the best outcome possible, always ensure that you have checked whether what the SSD screw kit manufacturer says about compatibility matches up against what your ASUS, Gigabyte, ASRock, or MSI motherboard specifications require from you.

A black oxide coating has many advantages for mounting screws in PC builds. First, it offers a protective layer that improves corrosion resistance by preventing contact between the screws and moisture or other environmental agents, thus increasing their life span. Secondly, this finish also provides higher resistance to wear, which minimizes the chances of damaging them when being assembled or disassembled many times – something important if you want your fasteners to stay strong through several rounds of taking apart and putting back together again. In addition to these functional benefits, blackening with an oxide gives a sleek look thanks to its dark matte appearance while making sure that different parts blend well together within most computer case designs. Last but not least, lubricants stick better on this surface, so it would be easier to insert or remove such fasteners, thereby speeding up the assembly process.

To search for dependable distributors of M2-0.4 x 6 mm screws, please consult the following sources:

Using these major suppliers will guarantee access to top-quality screws, timely delivery services, and professional support during the purchase process.

To choose between buying M2 screws online or offline, one must consider convenience, availability, cost and support when buying things like SSD screw kits. Online vendors such as McMaster-Carr, Grainger and Fastenal offer a wide range of options as well as detailed specifications with the added advantage that you can order from anywhere at any time. What is more? Typically there are reviews left by other customers along with competitive prices which means you can make an informed decision about what to buy and also save some money if you are purchasing many units of an SSD screw kit.

Even though it may not have access to everything due to limited local stock; one great thing about making purchases in person is that they can be obtained instantly then examined physically before paying for them. Local hardware stores offer friendly customer service which may come in handy for troubleshooting unique cases or obtaining professional advice.

Ultimately online shopping proves best when it comes down to being convenient, having a variety of choices and affordability whereas offline transactions win because they allow immediate possession and hands on evaluation of goods purchased. You should therefore use both methods so that only the most appropriate M2 screws for your application are acquired.

Boot Up and Configure: Plug your computer back into the wall socket and turn it on. Go to BIOS/UEFI settings to check if new ssd storage device is recognized by system.Finally, format partition new disk using operating system’s built in tools like disc management or third party software like partition magic etc.

A: M2 screws are also called SSD screws. They belong to the family of machine screws with a nominal diameter of 2 mm, which can be used together with other types of fasteners like an SSD screw kit. These small-sized fasteners are common in electronic devices and some other places where big screws cannot fit, for example, laptops, notebooks, and M.2 SSD mounting screw kits.

A: It should be noted that M2 refers to screws whose diameters measure only two millimeters across, making them ideal when it comes down to precision or delicate systems. These kinds usually find their way into electronic devices in addition to being part of ASUS or Gigabyte motherboard packs containing different sizes such as M3 or even bigger ones like (M4) countersinks, etcetera.

A: Most commonly, stainless steel metric is chosen as the primary material, out of which M 2 nuts, bolts, washers, etc., can be produced for better durability against corrosion in various applications, including computers, DIY projects, etcetera.

A: There exist many diverse options when we talk about head types since there might be hex socket head cap Phillips Panhead countersunk, among others, so this gives you freedom on what kind would work best for your specific needs – all these varieties come under one size – m 2 screw thread diameter being same throughout its length

A: Computers often require different parts to be connected using them as connectors; For instance, attaching” .”0″ solid state drives onto motherboards necessitates the utilization of these tiny fasteners known as m.two ssd mounting kit, which should always accompany ASUS or Gigabyte boards during assembly since any other type might not fit well with those devices’ designs. Additionally, it’s essential that you know where precisely each should go, so read instructions carefully before starting anything

A: Yes, you can buy kits with M2 screws. Different retailers, such as amazon.com, sell M.2 SSD mounting screw kits and screw assortment kits. Such kits may consist of various sizes and types of M2 screws, washers, and standoffs, which makes them versatile for use in a wide range of applications.

A: For you to ensure that you acquire the proper size of an M2 screw, measure the diameter and length needed for your specific application. There are many specifications available, like DIN or ISO standards which will guide you in selecting suitably sized screws. You can also refer to product manuals or component manufacturer specs from your motherboard or other parts used to determine what size should be used.

A: Yes, indeed, there are various kinds under this category; they include DIN as well as ISO, among others. Each has its own set rules covering dimensions, materials employed during the manufacturing process, etcetera, so if one follows these guidelines, then his projects would be compatible with others.

A: While dealing with electronic devices, it is vital to take into account electrical conductivity, corrosion resistance, mechanical strength, i.e., things that affect their performance over time when exposed to various environmental conditions, especially those involving moisture concentration levels, etcetera; therefore, if possible always go for stainless steel ones