The advent of the 800G optical communication era and the AI-driven acceleration of computing power infrastructure construction indicate a surge in demand for optical modules – foundational components in data transmission.In this context, data centers, now major energy consumers, require upgraded optical module technologies that balance high-speed performance, low power consumption, and cost efficiency.

Consequently, LPO (Linear-drive Pluggable Optics) technology has emerged as a pivotal development direction for the optical module industry in building next-generation computing infrastructure.

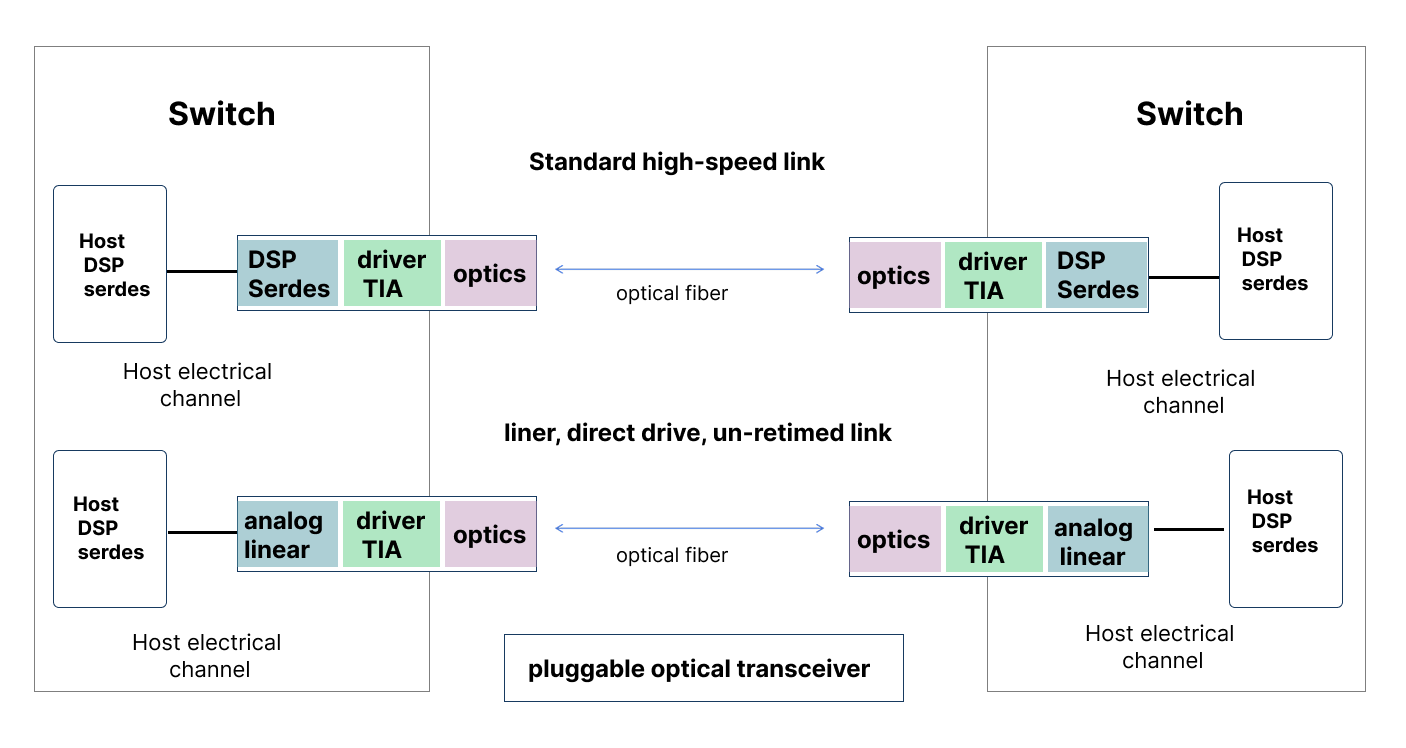

LPO (Linear-drive Pluggable Optics) refers to a pluggable optical module that uses only linear analog components in the data link, eliminating the need for DSP or CDR chips.

It replaces traditional DSP with linear direct-drive technology, reducing system power consumption and latency.Primarily applied in high-speed optical modules for short-distance scenarios like data centers.

Current mainstream 200G/400G/800G products rely on PAM4 technology and DSP chips for high-speed signal modulation, transmission, and recovery. LPO differs from traditional optical modules by using linear drive and pluggable design, supporting hot-swappability to simplify fiber cabling and equipment maintenance.

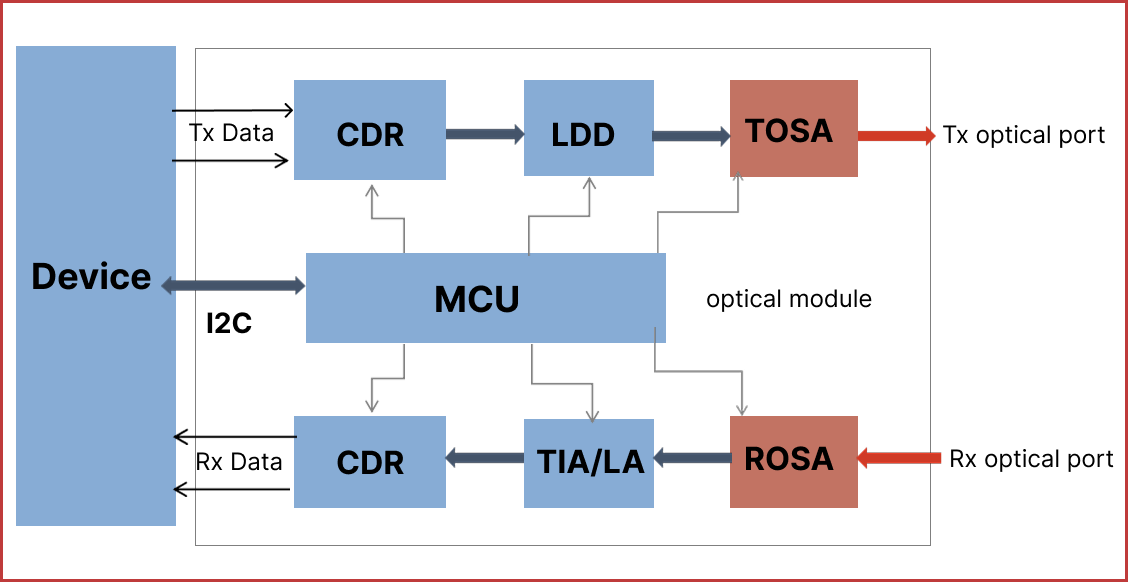

Optical module transmission involves converting electrical signals to optical signals and vice versa. At the transmitter side, the digital signal is converted into an analog signal via a DAC (Digital-to-Analal Converter), while at the receiver side, the analog signal is transformed back into a digital signal through an ADC (Analog-to-Digital Converter).

The core electronic components in optical modules include DSP (Digital Signal Processor), laser driver (LDD), transimpedance amplifier (TIA), limiting amplifier (LA), and CDR (Clock and Data Recovery) circuits, which collectively enable high-speed electro-optical signal conversion and signal integrity management.

Components of Traditional Optical Modules

Although DSP (Digital Signal Processor) offers advantages like digital clock recovery and chromatic dispersion compensation, enabling signal restoration with low bit error rates, it comes with significant power consumption and cost implications.

For instance, in 400G optical modules, the 7nm DSP consumes approximately 4W of power – accounting for about 50% of the module’s total power usage. From a cost perspective, the DSP contributes 20-40% to the BOM (Bill of Materials) cost of a 400G optical module.

To address power consumption and cost challenges while meeting demands for high-speed, high-density optical connectivity along with network flexibility and upgradability, LPO (Linear Drive Pluggable Optics) has emerged as an innovative solution.

The LPO architecture employs linear direct-drive technology by replacing DSP with high-linearity drivers and TIAs (Trans-Impedance Amplifiers), integrating CTLE (Continuous Time Linear Equalization) and EQ (Equalization) functionalities respectively.

This design approach achieves significant reductions in both power consumption (typical power under 2W) and signal latency (sub-nanosecond level), while maintaining error rates below 1E-5 through advanced analog compensation techniques.

Comparison of Technical Principles between Traditional Optical Modules and LPO Optical Modules

LPO demonstrates compelling advantages in low power consumption and cost-effectiveness, positioning it as a potential mainstream solution for next-generation optical networks.

By eliminating DSP chips, LPO optical modules achieve dramatic power reduction, cutting energy consumption by approximately 50% compared to traditional pluggable modules while achieving near parity with CPO in power efficiency.

This optimization is consistently demonstrated in Arista’s comparative analysis of photonic platforms: adopting linear-drive technology reduces power draw by around 50% across diverse implementations including Silicon Photonics, VCSEL, and Thin-Film Lithium Niobate (TFLN) architectures.

Eliminating DSP chips (which account for 20-40% of BOM costs) drives significant savings in LPO systems. While integrating EQ (Equalization) capabilities into drivers and TIAs introduces marginal cost increments, the overall cost structure shows net reductions.

For 800G optical modules, LPO implementations achieve~8% total cost reduction(approximately $50-60/module), with production scalability expected to further amplify savings through photonic-electronic co-optimization.

Removing DSP chips (20-40% of BOM costs) cuts costs significantly in LPO systems. While adding EQ to drivers and TIAs slightly raises expenses, overall costs still drop. For 800G modules, LPO achieves ~8% total cost savings (~$50-60 per module), with future scalable production and photonic-electronic co-optimization boosting savings further.

Removing DSP reduces a processing step in the optical module, lowering data transmission latency. This benefit is especially critical for AI and supercomputing applications.

The LPO solution maintains standard pluggable form factors with hot-swappable interfaces, enabling tool-free module replacement that streamlines field operations. This design simplifies fiber cabling and equipment maintenance, improving system manageability and maintainability.

LPO technology removes the DSP chip, integrating its functions into the switch chip while retaining only the driver and transimpedance amplifier (TIA) chips. The improved performance of TIA and driver chips in LPO modules enhances linearity.

However, LPO compromises system bit error rate (BER) and transmission distance, making it suitable only for short-range applications, such as links between data center servers and top-of-rack (TOR) switches.

TIA and driver chips cannot fully replace DSP. Removing DSP increases the system’s bit error rate (BER), thereby reducing transmission distances.

The industry widely acknowledges that LPO is only suitable for specific short-range applications, such as intra-rack server-to-switch connections and inter-rack links within data centers.

Currently, the lack of mature standards may cause compatibility issues in cross-vendor or cross-platform implementations.

Adopting LPO requires enterprises to have technical capabilities to define specifications and solutions, explore device-module boundary conditions, and conduct extensive integration and interoperability testing.

Experts also note that LPO poses challenges for electrical channel design on the system side. While current mainstream SerDes specifications are 112G, the industry is rapidly transitioning to 224G. However, LPO struggles to meet the requirements of 224G SerDes, limiting its compatibility with next-generation high-speed interfaces.

LPO offers advantages such as low power consumption, cost efficiency, low latency, and easy maintenance, making it the most promising technology for the 800G era.

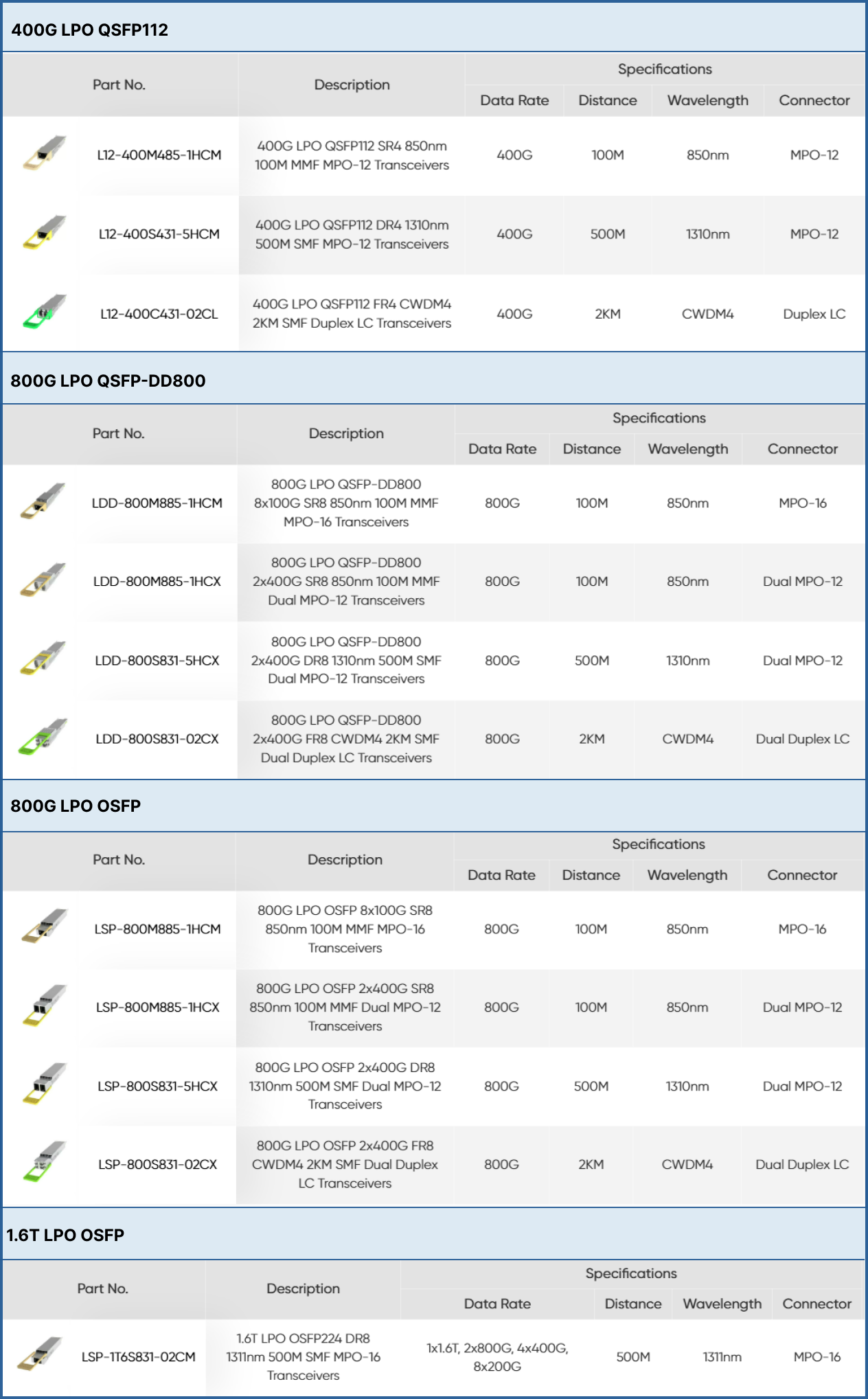

AscentOptics has already invested in R&D, launching short-reach components compatible with LPO optical modules. These products support optical modules with transmission rates ranging from 40G to 800G, aiming to build higher-performance computing power networks.

AscentOptics LPO Product Series

As DSP chips evolve from 7nm to 5nm process nodes, their design and manufacturing costs continue to rise. In contrast, the LPO solution significantly reduces power consumption and latency while offering cost advantages. Although LPO suffers from higher bit error rates (BER) and shorter transmission distances, these drawbacks are mitigated in short-distance AI computing scenarios. As a result, LPO is poised to dominate the vast market of internal data center switching networks in the near future.

1. Title: 800G LPO: The Most Promising Technical Route in the AI Era

2. Title: LPO Optical Modules