In the fast-paced world of telecommunications, fiber optic technology has become a necessary infrastructure for high-speed data transfer. Fiber optics cables and connectors are vital components that enable quick and reliable connectivity in this system. This article will focus on LC (Lucent Connector) fibers – one type among many others – which are known for their small size and great performance. Whether you want to understand more about network infrastructure or you’re a telecommunication professional pursuing further technical expertise, read on! This guide provides an all-inclusive review of LC fiber, discussing its design, where it is used most frequently, why people love it so much, as well as some disadvantages associated with deploying them over other types of cables within a wider range context of f.o networks, etcetera.

What is LC Fiber and How Does it Work?

Introduction to LC Fiber

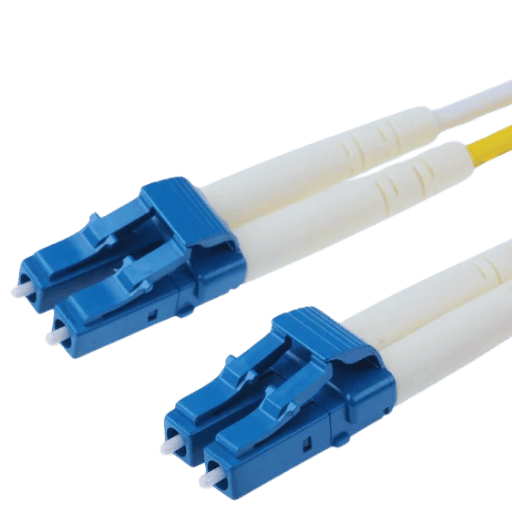

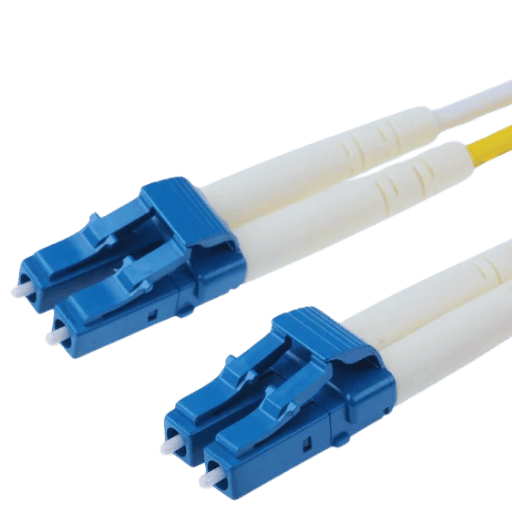

The LC fiber, or Lucent Connector fiber, is a small form-factor optic connector that was created to satisfy the requirements of telecommunications and data networks for compact cabling systems. The LC connectors come in various types based on different optical requirements, including single-mode duplex, multimode duplex, etcetera, which we will discuss later in this article. They are characterized by their compact size and push-pull latching mechanism, which are designed for reliable connection while taking up less space at the same time. With only 1.25mm ferrule (half size compared with SC/ST), higher density connections can be achieved on patch panels or other networking equipment where space is limited. This type of connector can be used with both multi-mode fibers and single-mode fibers, allowing them versatility across all network environments where they are needed most.

Operational Mechanism of LC Connectors

LC connectors operate by aligning precisely and connecting tightly. The ceramic ferrule of an LC connector has a diameter of 1.25mm, which allows for small tolerances and low insertion losses. They are easy to connect because they use a push-pull motion that can be done with one hand, making them less likely than other types of connectors to accidentally come unplugged while still providing a secure connection when mated together properly. This system involves lining up the holes in each end so their fibers touch before locking everything into place using something like our typical latch mechanism found on doors, etc., but only here does it snap closed instead. Because of this compactness feature alone, LC Connectors have been widely used throughout many different industries, especially those dealing with dense networks where space may be limited, such as data centers or telecommunications closets, among others. Also, the end face of the ferrule should be polished to allow for accurate light transmission, which is vital for maintaining network efficiency across long distances.

Advantages of LC Fiber Optic Technology

There are many reasons why the LC fiber optic connector is considered one of the best choices for current data communication and networking systems. One reason is that it has a small form factor, which allows high-density cabling. This is very important for space efficiency in data centers and telecommunication hubs. Another advantage is its low insertion loss and high return loss, which helps to improve signal integrity, thus reducing transmission errors and enhancing the overall performance of the network. It also utilizes a push-pull latching mechanism that makes installation easy, hence saving time required during maintenance and cutting labor costs. This will also reduce downtime experienced while workers are fixing problems with connections. Additionally, being compatible with both single-mode and multi-mode fibers gives it flexibility in various applications such as LANs or enterprise networks, among others. All these features together ensure reliability, scalability, and efficiency based on different levels within a given network system.

How Does LC Fiber Compare to Other Fiber Connector Types?

LC vs SC Connectors

While you’re comparing LC connectors to SC connectors, there are a few important differences and performance measures you should know about. The SC (Subscriber Connector or Standard Connector) has a bigger form factor than the LC and uses a push-pull coupling mechanism in order to plug in or unplug easily.

Form Factor and Density:

- LC Connector: Being around 7mm x 4.5mm large, LC connectors can be configured for high-density which is necessary for modern data centers that need space saving.

- SC Connector: Measuring about 9mm x 9mm across, SC connectors generally take up more room than LC ones do and so they aren’t as good when it comes to being used in crowded areas where many ports are needed.

Insertion Loss:

- LC Connector: Typically ranging from 0.1 dB to 0.3 dB, these kinds of connectors have low values for insertion loss which means that they don’t attenuate signals much during transmission.

- SC Connector: Usually between 0.2 dB and 0.5 dB, although still relatively small, this value is slightly larger than what would be expected from an LC connector, causing some degradation in signal quality over long links.

Return Loss:

- LC Connector: Most LC connectors give back at least 50dB return loss which reflects back most of the light produced by laser diodes used as transmitters improving overall signal quality through reduced reflections from bad connections within fiber networks.

- SC Connector: In general about 40dB-50dB return loss can be achieved with these types thus making them less reflective then their counterpart but having higher figures compared to LC ones .

Ease of Use:

- LC Connectors: These things are easier to handle because they’re smaller and use a push-pull latching mechanism which makes them simple enough even if you have limited space or tight racks inside your cabinet where every millimeter counts!

- SC Connectors: Although this connector is bigger than other types, it still uses a push-pull system, so plugging should not require much effort on your side. However, sometimes, it may be difficult due to the high density of devices installed nearby.

Application Versatility:

- LC Connector: Due to being compatible with both single-mode and multimode fibers, LC connectors are used in many applications including telecoms, data centers or enterprise networks.

- SC Connector: In cable TV networks where high performance is required over long distances, such as metro area network (MAN) or passive optical network (PON), SC connectors will find their place as being more robust and reliable, though less versatile.

In conclusion, each type has its own strengths; however, considering its smaller form factor, lower insertion loss, and higher return loss, the LC connector would be a better option for densely populated areas with limited space availability and critical link performance requirements.

Comparing LC and ST Connectors

Insertion Loss:

- LC Connector: The insertion loss of LC connectors is usually between 0.1 and 0.3 dB, which is very low and ensures that the signal remains largely intact as it passes along the line.

- ST Connector: ST connectors have an insertion loss ranging from 0.2 to 0.5 dB, generally higher than LC connectors but still acceptable in most cases.

Return Loss:

- LC Connector: LC connectors have a high return loss— over 50 dB — which means they reflect less power back toward the source, resulting in better signal quality.

- ST Connector: It usually has a return loss of between 30 and 45 dB; this means that ST connectors are not as effective at preventing reflections compared to LC types.

Ease of Use:

- LC Connector: Designed with push-pull latching mechanism and small form factor for easy handling and installation especially in crowded network environments where space may be limited.

- ST Connector: Utilizes twist-on mechanism which can take more time during setup; bulkier size also makes it unsuitable for high-density applications since connections are more complicated.

Application Versatility:

- LC Connector: Can be used widely across telecommunications, data centers, enterprise networks among others; supports both single-mode and multimode fibers thus flexible for different needs.

- ST Connector: Frequently found in industrial settings, some early network installations as well as military environments, but hasn’t gained much popularity lately due to its larger size compared with other connectors used today in modern high-density environments.

In conclusion, though both LC and ST connectors are good at what they do best, the low insertion loss offered by LC connectors coupled with high return loss together with compactness (small size) make them ideal for use in modern dense networking applications.

LC vs FC Connectors: Which is Better?

Comparing LC connectors with FC connectors requires taking into account a number of technical and practical factors to determine which is more suitable for a given application.

Insertion Loss: LC connectors have low insertion loss, typically around 0.1 dB, which is slightly better than FC connectors ranging from 0.3 to 0.5 dB commonly. This characteristic enables them keep the signal strength over long distances.

Return Loss: For this parameter both LC and FC connectors exhibit good results – over 50 dB – what allows reducing signal reflections and guaranteeing excellent signal quality.

Ease of Use: LC connectors are equipped with push-pull mechanism and have small form factor that makes them easy to handle as well as quick to install especially in dense network environments where there is limited space available while FC connectors use threaded coupling mechanism which can take more time during installation when dealing with high density applications it may also be inconvenient.

Application Versatility: As regards application versatility, LC connectors find wide applications in the telecommunications industry, including data centers and enterprise networks, being compatible with single mode or multimode fibers, whereas FC connectors are widely used in areas requiring high precision alignment stability, such as laboratory settings fiber optic instrumentation among others some types telecommunication networks.

Durability: When it comes to durability, therefore, robustness becomes an important aspect here because if something does not last longer, then we cannot rely on it completely; thus, the FC connector wins against the LC connector due to its threaded design feature that ensures a strong, stable connection even under heavy vibrations physical impacts so they are more rugged than other types but less so also at times.

To sum up, these days, people prefer using LC to any other type due to its ease of insertion loss and broad application versatility. On the other hand, when looking at the cost-benefit analysis between the two types, I would recommend going for fcs since they tend to be cheaper per unit compared with lcs. besides, FC offers a higher durability level.

What Are the Main Types of LC Fiber Cables?

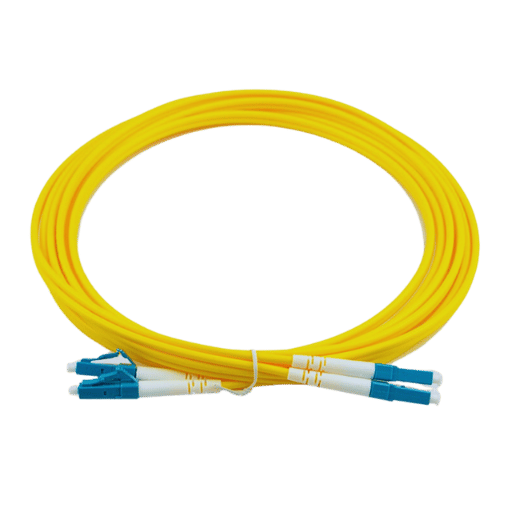

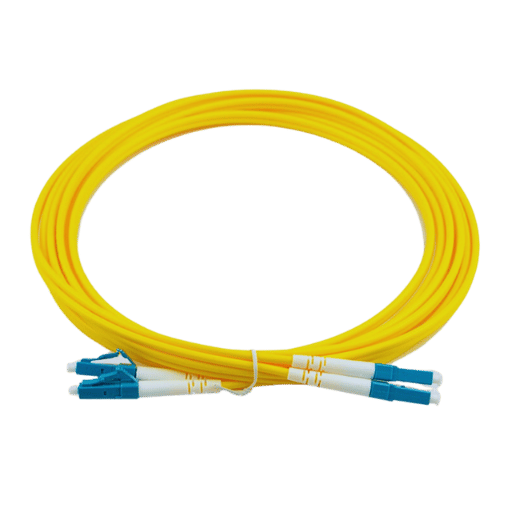

Introduction to Single Mode LC Fiber

High-precision communications over long distances are the domain of single-mode LC fibre cables. With a small core of about 9 µm in diameter, this type of cable allows for data transmission across large areas with low signal loss. When light is sent directly down the fibre by these narrow cores, dispersion and attenuation are reduced resulting in wider bandwidths and lower latencies at greater ranges.

Technical Specifications:

- Core Diameter: 9 µm.

- Cladding Diameter: 125 µm.

- Wavelength: 1310 nm and 1550 nm.

- Distance Capability: Up to 40 km or more depending on use case and equipment.

- Loss Performance: Typically about 0.35 dB/km at 1310 nm; around 0.20 dB/km at 1550 nm.

Applications:

Single-mode LC fibers are used extensively where there is a need for fast connections over large distances between data centers (DCs) that serve different continents. They also play an important role in intercontinental undersea cables, long-haul terrestrial networks, and metropolitan area networks (MANs). Furthermore, these cables form part of backbone networks within large enterprise DCs and telecommunications infrastructure – providing strong, reliable communication channels that are hard to interfere with or degrade signals on them.

In the short term, then, single-mode LC fiber cables provide great performance for high-fidelity data transfer over long ranges, so they should never be missing from any modern-day network that aims to be reliable and efficient.

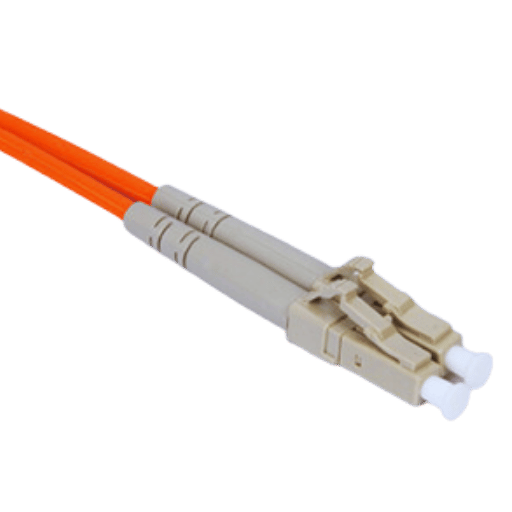

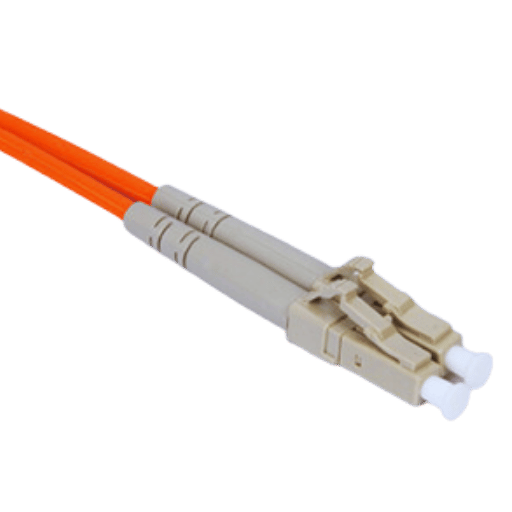

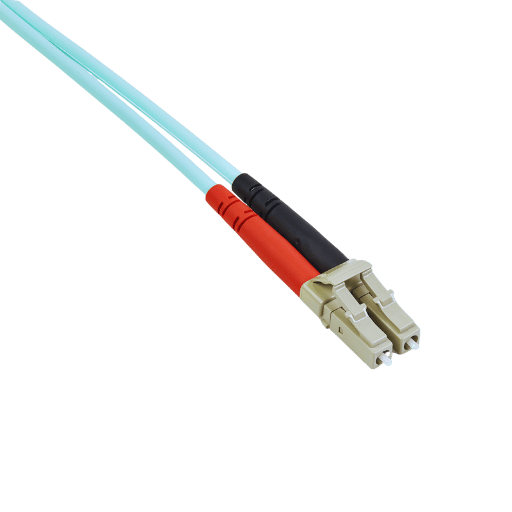

Understanding Multimode LC Fiber Cables

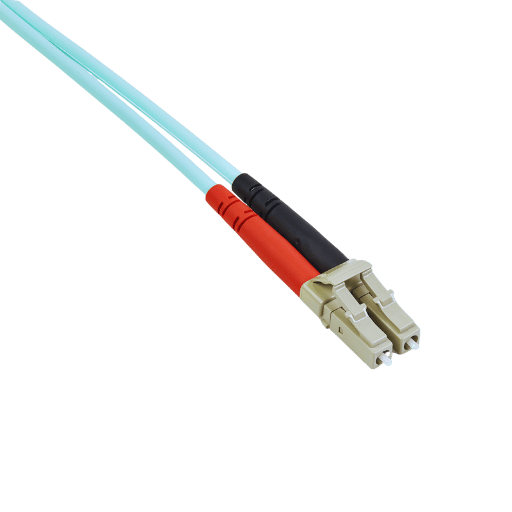

The reason behind creating multi-mode LC fiber cables is to cater to short-range communication, which can only be achieved by high bandwidth. To enable propagation of many light modes, these cables come with a bigger core diameter, usually 50µm or 62.5µm while at the same time. Thus there exists what is called modal dispersion that limits the usability distance of such fibers mainly. However, they still have their advantages in places where space is limited and very fast data transfer rates are needed like LANs(local area networks) and data centers.

Technical Specifications:

- Core Diameter: 50 µm or 62.5 µm.

- Cladding Diameter: 125 µm.

- Wavelength: 850 nm and 1300 nm.

- Distance Capability: Typically up to 550 meters for 10 Gbps transmission, varying with specific fiber types and equipment.

- Loss Performance: Approximately 2.5 dB/km at 850 nm and 0.7 dB/km at 1300 nm.

Applications:

Short-haul is the primary utilization area for multimode LC fibers; they are commonly used within campus networks where there may be a need for high bandwidth backbone links between different buildings situated on the same campus or even different floors within one building. Their low cost and easy installation features make them suitable in environments requiring shorter connection lengths, especially when compared to single-mode fiber optic cables.

In summary, multimode LC fiber optics are important components of any short-range high-speed data link system connecting devices installed within buildings or closely located adjacent sites not further apart than a few miles where distance coverage provided by long-haul single-mode fibers would be unnecessary due to cost considerations.

Plenum Duplex LC Fiber Patch Cables Explained

Cables called Plenum Duplex LC Fiber Patch are created to be used in plenums. A plenum is a space in a building used for air circulation that also often contains communication and electric cables. They have an outer layer that resists fire which reduces the amount of smoke and toxic fumes given off during a fire, thus increasing safety. The name “Duplex” refers to the fact that these cables consist of two fibers that can transmit data simultaneously in both directions, which is necessary for most fast networks.

Main Features:

- Resistant to Fire: These wires meet strict codes regarding flammability by incorporating materials designed not only to limit smoke production but also to reduce toxicity upon combustion, thereby ensuring compliance with safety regulations governing cable usage inside plenums.

- Type of Connector: The connector type used on this cable is LC (Lucent Connector) connectors, which are smaller than their competitors, making them more space efficient and especially useful within densely populated network environments where every square inch counts towards reducing clutter caused by excessive numbers rack mounted switches side by side panels patching cords etcetera while still maintaining high levels connectivity performance across all nodes within such network topologies.

- Performance: These cables can support bandwidth-intensive applications and are often rated at 10 Gbps data rates, optimized for short-haul transmissions over multimode fiber optic links.

- Applications: Office buildings, campuses, or even data centers where there may be a need for routing through ducts connected with air handlers could benefit from using them because, apart from being ruggedly built, they can also withstand exposure.

The Plenum Duplex LC Fiber Patch Cables offer strong solutions for current networking infrastructures as they comply with safety requirements and provide reliable high-speed data transfer capabilities.

How to Choose the Right LC Fiber Patch Cable?

Single Mode vs Multimode LC Fiber Patch Cables

The core diameter of the single mode is a rough estimate of 8 to 10 microns.

Laser

- Transmission Distance: Long Haul (more than 100 km).

- Bandwidth: Higher possible bandwidth.

- Applications: It is suitable for telecommunications networks and long-distance data transmission.

Multimode:

- Approximate Core Diameter: 50-62.5 micrometers.

- Light Source: LED/ Laser.

- Transmission Distance: Short or Medium distances (up to two kilometers).

- Bandwidth: High Speed, Small Range Data Transfer.

- Applications: The most common use is in LANs, data centers, and intra-building connections.

Key Features to Look for in LC Fiber Patch Cables

To guarantee the best performance and to make sure it is compatible with your networking environment, there are some key factors that should be considered when selecting an LC fiber patch cable:

- Connector Type: You must ensure that the cable uses LC connectors since they are small-sized as well as high performing especially in places where density of network equipment is high.

- Cable Jacket Rating: Check whether it conforms to fire-retardant standards such as plenum-rated (CMP) or riser-rated (CMR) depending on where it will be installed.

- Core And Cladding Diameter: Go for what suits either single mode(about 8-10 microns) or multimode(approximately 50-62.5 microns) applications in terms of core diameter.

- Insertion Loss & Return Loss: Always choose cables having low insertion loss coupled with high return loss because this helps in maintaining good signal quality thus minimizing errors during data transmission.

- Strength/Reliability/Flexibility : Ensure that its construction is strong enough while at the same time being flexible so as not only survive physical stresses associated with bending but also continue performing optimally under such conditions.

- Bandwidth/Data Rates: Make sure that these support required bandwidths along various speeds of data transmission, especially when dealing with higher rates, such as 10 Gbps or more.

- Length: Choose a cable whose length matches your needs without leaving too much slack, which can result in signal attenuation.

- Environmental Suitability: Take into account its temperature ranges within which it can operate and also how resistant it is to different surroundings in order to achieve consistent performance regardless of variations.

Comparing Different Duplex LC Fiber Patch Cables

To match unique attributes with different duplex LC fiber patch cables, one need to measure the products against some important factors. Typically, there are three brands that most reputable websites rank highly:

Corning ClearCurve® OM4 Duplex Fiber Optic Cable:

- Operation: Corning has always been known for its low-loss optical fibers, which offer better signal integrity and less dispersion.

- Build: With bend-insensitive fiber being used in its construction, even when routed tightly, the performance of ClearCurve® cable remains excellent.

- Application: Designed for use in data centers and high-speed networks where it supports 10Gbps as well as 40Gbps data rates with a core diameter of 50 microns.

Leviton Opt-X™ Unity 40/100G Multimode OM4+ Duplex Patch Cable:

- Operation: Leviton’s OM4+ cables can reach up to 550 meters at 10Gbps, which is longer than standard OM4 cable types, besides having higher bandwidth.

- Build: Ultra-low loss connectivity as well improved connector durability are among key features that make up this series called Opt-X™ Unity by Leviton.

- Application: It should be used when there is need for transmitting large volumes of information rapidly within limited spaces since it ensures minimum insertion loss plus superior return loss as well thus perfect for environments requiring high density and speed data transmission.

Panduit Opti-Core® 50/125μm OM4 Duplex Fiber Optic Patch Cord:

- Operation: Panduit’s Opti-Core® OM4 cables have very good signal performance over long distances due to the high modal bandwidth provided (4700 MHz*km).

- Build: These cords were designed with flexible yet rugged jackets so they can withstand various installation conditions without compromising their strength or reliability according to different user requirements.

- Application: This particular type would be suitable within telecommunication rooms; enterprise networks; data center installations etc., because it works well with many types of high-speed networking applications.

From what has been said about the aforementioned top-ranked products made by Corning, Leviton, and Panduit, it is clear that all these three brands offer strong solutions for high-performance network environments, albeit having slightly different bandwidths, construction features, and suitability for use cases.

How do you properly install and maintain LC fiber connectors?

Step-by-step Guide to Installing LC Fiber Connectors

Required Tools and Materials

- These can be LC fiber connectors.

- Then, fiber optic cables.

- A precision fiber cleaver.

- Fiber optic stripper.

- Some isopropyl alcohol and lint-free wipes.

- Epoxy glue or anaerobic adhesive.

- Crimp tool.

- Heat oven (if using heat-curing epoxy).

The Installation Steps are:

Fiber Optic Cable Preparation:

- Use the fiber optic stripper to remove the outer jacket of the fiber optic, exposing the core and cladding.

- Strip about 2-3 inches of the buffer coating from the fiber, being careful not to break or damage the fiber strand.

Cleaning The Fiber:

- Clean off any dust particles, dirt, or oil by rubbing down with isopropyl alcohol and a lint-free wipe. Ensure that no contaminants remain on any part of the fiber end face.

Fiber Cleaving:

- Using a precision fiber cleaver, cut the fiber at the correct length, ensuring a clean perpendicular end face. For optimal connector performance, it is important to get an accurate cleave.

Gluing Process:

- If using epoxy glue, insert some into the connector ferrule. Anaerobic adhesive should be applied directly onto the glass fiber itself.

- Ensure that every microfiber surface fits well into its corresponding fitting within its housing cavity.

Adhesive Curing:

- Then if you use heat curing epoxy put assembled connector in heat oven according to adhesive manufacturers specifications(typically around 100-120°C for 5-10 min).

- Anaerobic Adhesive Allowance: Allow it some time to set up until it is completely hardened as guided by the manufacturer’s instructions for that particular type of adhesive used here.

Connector Crimping:

- The crimp tool can be used to fixate and hold the optical fibers by compressing/connecting them with this device’s main body; you need to do this properly so that there will never be a chance of any movement happening.

Polishing The Connector End Face:

- Polish the fiber end face using polishing films and a polishing puck. Start with a rougher grit and progress to finer grits to achieve a smooth and flat surface.

- The polished end face should be wiped down with isopropyl alcohol, then inspected under a microscope to ensure there are no scratches or imperfections.

Connector Testing:

- Test the connector for insertion loss and return loss using an optical power meter and light source to ensure performance meets industry standards.

Technicians must be careful in adhering strictly to these steps so as to enable them install LC fiber connectors that guarantee maximum signal transmission efficiency and long term serviceability. For this reason, proper installation is necessary for high speed data communication and network reliability.

Essential Maintenance Tips for LC Fiber Optic Systems

In order to attain the highest performance levels and longest lifespan possible, it is vital to maintain LC fiber optic systems properly. These are some of the most important suggestions:

Regular Cleaning:

- Make use of appropriate cleaning tools and solutions for fiber optics so that you can clean connectors and ports often. Any contaminants will severely impair signal quality.

- Use lint-free wipes together with isopropyl alcohol to clean connector end faces before making any connection.

Inspect Connections:

- Aim an inspection microscope specially designed for fiber optics at connector end faces in order to check for damage or dirt; doing this on a regular basis will help discover problems sooner than later.

Monitor Performance:

- Check insertion loss as well as return loss by periodically testing the network using optical power meters and light sources. Performance indicators should be monitored over time for trend identification purposes.

Proper Handling:

- Avoid bending, pulling or twisting fiber cables too much since such physical stress can easily break their delicate fibers.

- All connections must be solidly made without subjecting them to unnecessary tension.

Documentation and Record-Keeping:

- Every activity carried out during maintenance needs to be recorded in detail alongside test results plus any incidents noted down – such documentation aids troubleshooting efforts while also providing future planning reference points for subsequent similar undertakings.

Training and Procedures:

- Train all staff involved in maintaining fiber optic systems adequately so they follow standardized procedures which promote consistency as well as quality throughout their work execution process.

By following these important maintenance tips, your LC fibers will operate more effectively, thereby supporting high-speed data transmission within robust network performance.

Common Problems and Solutions for LC Fiber Connector Installations

Contamination:

- Issue: Dust, oil, or another substance on the ends of fibers may increase loss of insertion and return.

- Solution: Regularly clean connectors with lint-free wipes and isopropyl alcohol. Check that no contaminants are present on the connector before making any connection.

Improper Handling:

- Problem: If fiber optic cables are bent too far, pulled too hard or twisted excessively they get damaged physically and degrade signals.

- Solution: Be gentle when handling them keeping in mind recommended bending radiuses so as not to put unnecessary strain on fibers; manage cable routes effectively using protective tubing and supports.

Faulty Connections:

- Problem: Loose connections or those which were not seated properly could lead to poor performance within a network as well as intermittent connectivity problems.

- Solution: Ensure all connectors have been firmly mated together and locked into place where applicable. Inspect connection points regularly using an optical microscope for alignment correctness and seating adequacy alike.

These simple troubleshooting steps will go a long way towards improving reliability and performance in your LC fiber connector installations.

Reference Sources

Optical fiber connector

Optical fiber

Patch cable

Frequently Asked Questions (FAQs)

Q: What is an LC fiber optic connector?

A: A Lucent Connector, commonly called an LC fiber optic connector, holds a single core fiber with a 1.25mm ceramic ferrule due to its small size and high performance.

Q: How does a multimode fiber cable differ from a single-mode fiber cable?

A: Multimode fibers have larger diameters, which allow light to travel through multiple paths or modes; hence, they are ideal for short distances. Conversely, single-mode fiber cables are designed for long-distance communication and have smaller cores that enable only one mode of light propagation.

Q: What are the advantages of using an LC duplex connector?

A: Some benefits associated with LC duplex connectors include their small size, high density, and reliability in performance; they connect two fibers at once, thus facilitating bidirectional communication.

Q: What is the purpose of a fiber jumper?

A: Fiber jumpers, also known as patch cables, are used to connect different network devices such as switches, routers, or patch panels together. They typically have connectors on both ends, like LC to SC or LC to LC.

Q: Why is a plenum duplex fiber patch cable important for certain installations?

A: Plenum duplex fiber patch cables are made with special fire-retardant jackets, which makes them suitable for installation in air handling spaces like plenums where fire safety may be a concern.

Q: What is an optical fiber connector, and why is it important?

A: An optical fiber connector is a device that links two optical fibers together so that light can pass through them. It plays a very significant role in maintaining the whole system of the optic fiber networks.

Q: What are the different types of LC armored duplex fiber patch cables available?

A: There are several different kinds of LC–armored duplex fiber patch cables; some include standard LC to LC fiber, others are LC plenum duplex fiber patches and stronger ones like LC armored duplex fiber patch, which provides additional protection against damage for the fibers.

Q: Can you explain the role of a fiber adapter in fiber optic networks?

A: A Fiber adapter connects two similar or dissimilar kinds of connectors, this device allows fast and easy connecting/disconnecting of optical fibers therefore enabling scalability as well as flexibility within networks.

Q: What is the significance of using an LC to SC connector configuration?

A: With an LC/SC configuration, one can connect devices with different connector types, such as older devices having ST connections while newer ones come with SC connectors, thus integrating both technologies into a single network infrastructure.

Post Views: 4,962