Many applications order industrial cables, which have become the lifeblood of electrical power, data, and signals throughout various machines and infrastructures. It is crucial to appreciate the different categories of industrial cables, their areas of use, and the intricate industrial cable solutions available in engineering, manufacturing, and technology industries. The objectives of this article are to show the existing interchange and interrelationships of processes present in shielding or bundling cables in industrial designs. It also focuses on emerging technologies and what they mean for industrial efficiency, safety, and performance. In this aggressive environment where better cables are increasingly required and produced, it is essential to keep up-to-date with new developments, new ideas, and concepts.

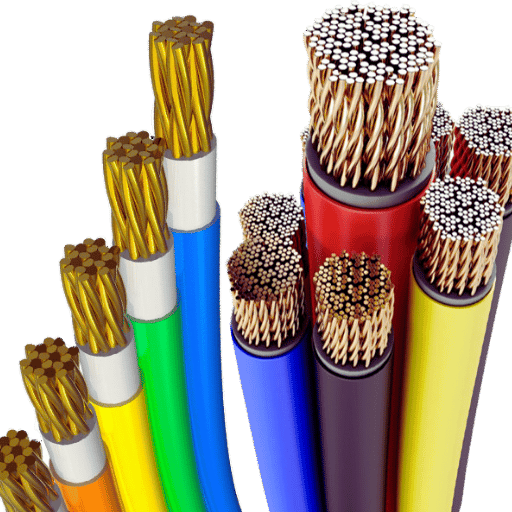

Industrial cables can be classified according to their use and requirements. These include power, control, data, and instrumentation cables. Power cables directly convey electrical energy and perform functions that involve high voltages. Control cables are always present in industrial applications and are mainly used to carry control signals to different parts of machines, aiding their functioning. Data cables, which include Ethernet, are used to transfer data at very high rates within production systems and communication networks. Such cables, known as instrumentation cables, are excellent for transmitting signals and interfacing processes and are usually used in automating processes involving various sensors and monitoring devices. As a rule, each cable type is manufactured from particular materials and configuration features, which should comply with the particular requirements relating to the performance and safety of the industrial use.

Standard types of industrial cable include various types meant for specific usable features. Out of these, power cables are made to accommodate high voltages and are effective in harsh conditions. Control cables carry signals that are necessary for the movement of heavy machines. Data cables such as Ethernet play important roles in fast and efficient data transmission in the working environment. Instrumentation Cables are required to transfer accurate signals for process control and automation since accuracy is critical. Each type has a material and design feature that assures high industrial performance and safety achievability.

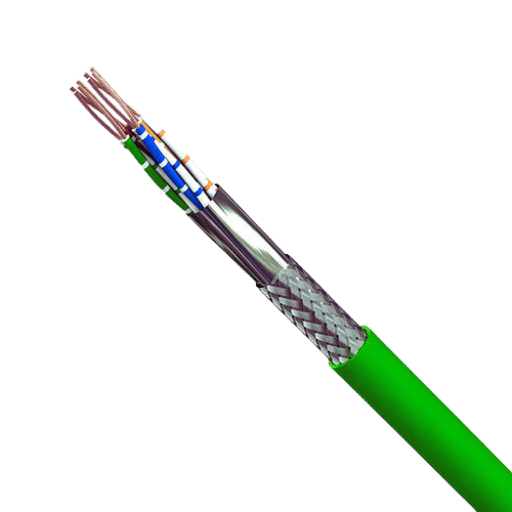

Thermal cables, fiber optical cables, and coaxial cables fall under specialized cables in the industrial sector, each with unique applications. Thermal cables are used in areas that constantly need to monitor high temperatures since these cables can withstand heat insulation and provide trustworthy heat solutions. Because fiber optic cables have higher bandwidth and no electromagnetic interference, they are especially used for long-distance communication of high data speeds, which is essential in today’s communications and networking functions. Coaxial cables are thick and strong and are mostly used by industries for video and RF signal transmission as they have low signal loss and high reliability. Each specialized cable is available to perform defined tasks under externally imposed limits to their performance and reliability.

It is ever more apparent that there is a need for more flexible and armored cable materials to be developed to cope with the peculiarities of different working environments. The construction of flexible cables is particularly reinforced to withstand wear from motion since frequent motion is required in such applications. These cables are indispensable in active industrial applications, including but not limited to factory floors where industrial robots or mobile equipment are used. Armored cables are entirely different in that they assist in harsh conditions by protecting the internals of the conductors from physical damage. These types of cables come in handy in underground wiring or areas where heavy machinery is operated since such cables are designed to be impact and weather-resistant. Flexible and armored cable solutions are manufactured, observing the required industrial standards for the performance and security of either one or both under consideration.

The role of industrial cables in operations and connectivity cannot be overstated, especially in the machinery and the processes that involve automation. Such cables are manufactured to overcome the harsh conditions of automated systems and industrial machines. Machinery requires industrial power cables to be connected to electric power sources, whereas control cables provide operational signals to the machines, enhancing their productivity. High-speed broadband Ethernet and data cables will connect equipment for fast communication and data transfer required for process automation and portable equipment use. Some cables are built with oil-login-competitive-couples-chemicals-and-extreme-temperatures materials for functioning properly and long-lasting. Moreover, shielded wires help in reducing electromagnetic interference, improving the transmission of signals in areas with many distractions. Such Cables are very useful for increasing industrial production and process reliability in the automation environment.

Electric wire and cable products are used in several ways within the industry, especially as a part of this structure, developing supporting systems for power, information, and control. As many experts report, these products’ performance is also designed to withstand industrial application conditions. In general, industrial cables can be classified into three s- power cables, control cables, and data cables, each best suited for its application. Power cables are insulated enough to remain safe even when carrying high voltage. Control cables must transmit all signals necessary for controlling the operable functions of the equipment. In contrast, data cables connect devices in such a manner as to provide all necessary conditions for real-time communication. The use of such materials and even special forms are often manufactured to the application’s specific requirements, enhancing the employment of such cables to extreme temperatures, oils, and chemicals to enhance performance and safety.

It is only natural that the cables are made and designed for extreme environments while ensuring uninterrupted operation in the heat and coarse industrial atmosphere. Such replacement cable jackets are usually made from silicone, Teflon, and fiberglass, and high heat resistance comes with them. Depending on the material capabilities and design, the maximum serviceable temperature can be more than 200°C. In addition, anti-abrasion, anti-chemical, and oil and moisture resistant treatments are applied or present to the outer protective sheaths of these cables which are normally used in hostile environments. Using modern shielding methods reduces EMI, which is fundamental to the signal’s integrity and security of action. To respond to such conversions in the industry, new developments in cable technology are aimed at providing and maintaining the supply of both power and data under adverse conditions.

Certain factors come into play when determining industrial cable solutions’ voltage and power requirements. First of all, decide on the voltage rating that will work for the application so that the cable does not get overloaded and fails. This encompasses knowing the environment of operation and the highest voltage the system may be subjected to during its operation. Secondly, the thickness of the wire should cope with the load demand given the available space while considering some power spikes occurring on hardwearing cable assemblies. A cable’s material and construction attributes affect its practical current carrying ability. Thirdly, the distance that the power has to reach the load, in some instances, due to long distances, the cable has to be designed to carry less resistive losses. Considering all these aspects helps ensure that the selected cable solution will perform accurately upon being deployed for the intended purpose and will not compromise the performance parameters or the system’s safety.

When choosing the appropriate cable insulation and its degree of durability, more specific factors about environmental conditions and structural loads should also be considered. Regarding insulation options in cable sub-assemblies assembly, priorities such as temperature range, chemical exposure, and flexibility should be considered. For example, polyethylene and cross-linked polyethylene are very well known for their great thermal resistance and ability to withstand environmental pressure. At the same time, strain relief structures are also exposed to wear due to bending and rubbing, which is possible with some jackets or grease-resistant materials that feature great mechanical resistance, such as PU. Moisture and UV stamina are also important to the longevity of the insulation, hence the outer shell in an industrial setting, especially outside or in factory work. Chemical and mechanical protection is necessary to withstand industrial exposure and conditions when selecting insulations and jackets for the cables.

It is necessary to determine not only the electrical specifications but also the environmental conditions in which the device would be used to suit a particular industry’s application. These include electrical specifications like voltage, current rating, and frequency, which should correspond to the system’s operational requirements and be capable of performing the intended function. Moreover, the casing must be compatible with its environmental conditions, such as the temperature range, exposure to corrosive substances, and humidity and UV exposure. Mechanical compression deformation must also be considered, such as bending, flexing, and vibrations, to which the cable may be subjected in the intended wire harnessing industrial environment. With the help of choosing the right cable for the right industrial use case, reliable functioning and regulatory compliance means meeting applicable industry standards and safety requirements are achieved. These parameters can be investigated, and once these components or other components meeting standard requirements are incorporated, compatibility and efficiency in the industrial field can be enhanced.

While considering the best industrial cable manufacturers, several companies stand out regularly owing to their range and quality. One of the prominent manufacturers is Prysmian Group, which is well renowned for its diversified assortment of cables and systems. A diverse range of solutions is provided by Prysmian’s, which are used not only for telecommunications but for energy as well, and works well under harsh conditions. Nexans is another dominant name in this industry as it specializes in technology and sustainability, offering the latest cable products aimed at improving efficiency and curbing carbon footprint. Finally, Southwire stands out due to the wide variety of power cables, persistent customer-focused strategies, and enhanced safety and innovation. Such companies remain leaders in the market of this product by rejuvenating to the market’s needs and raising the threshold of the cable technology and its dynamic characteristics.

Finding and selecting the best industrial cable suppliers can dramatically improve the performance and dependability of many industrial activities. Such suppliers A, B, and C are always mentioned for well providing their services and having a wide variety of products that range from:

These suppliers are acknowledged for quality, contribution to innovation, and customer care, which means they are able to deliver on the growing and changing needs of the industrial sector.

When a particular cable manufacturer or distributor is sought, several important aspects should be considered for industrial purposes.

Engaging this way allows deriving extensive information on these factors that will enable appropriate decision-making, which ultimately will lead to operational improvements and better equipment maintenance.

The above practices aim to achieve the best performance from industrial cables while increasing their durability and reducing downtimes for better operational effectiveness.

The storage and treatment of industrial wire and cable must be carried out properly, as these factors determine their quality and performance levels. Industry leaders like Southwire and Belden assert that industrial cables should prevent deterioration by keeping them in a clean and dry area. Cables should be picked up by racks rather than the ground as the latter will lead to damage caused by building moisture as they could be put in a pile or otherwise jumbled together with others. For example, heavy-duty equipment is used to lift such items as reels, and it is ideal for use on hard surfaces and not cables, which get damaged easily from dragging. Failure to do this means trouble to the longevity and reliability of the cables for the companies in question, which in turn leads to higher operational costs due to increased maintenance needs.

The first thing to look for when diagnosing common problems for cables intended for industrial use is any signs of damage or abrasion of any parts. Experts like those at Allied Wire & Cable and Anixter note that the most common issues include the insulation becoming damaged, connector failure, and conductors breaking. Wires and cables with insulation that is worn out, cracked, or appears burnt can cause short circuits or unpredictable contact with electrical live parts. Connector failures can often be diagnosed by either abnormal connections or a complete signal loss, which can require repair or replacement of the connector. It can be ascertained using continuity tests, as copper conductors sometimes break due to excessive bending or too much mechanical strain. Troubleshooting of cables and their associated circuitry has been aided by using cables that can utilize diagnostic tools such as multimeters. Cables and connectors ought to be regularly checked, the installation of cables should be appropriately done, and the cables used should be suitably protected from environmental factors to minimize these occurrences, enabling the system to work satisfactorily.

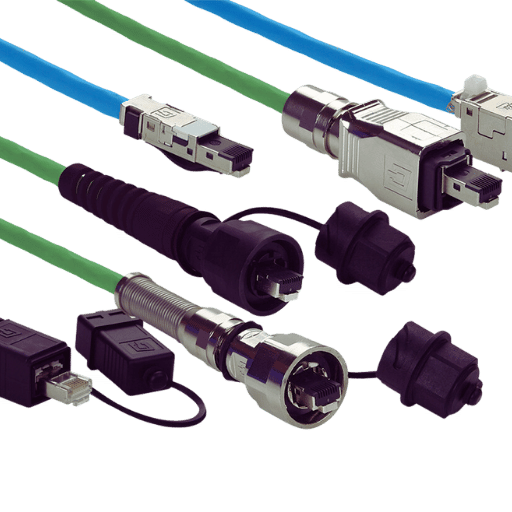

A: Ethernet cables, fiber optic cables, and fieldbus cables form the main types of industrial network cables within a strong line of industrial solutions. These cables are manufactured to operate in adverse industrial conditions and allow data transmission for industrial control and automation systems. Each type has specific applications and benefits depending on the needs of the industrial environment.

A: Industrial cables can withstand extreme conditions within an industrial environment. They are typically stronger, more chemical resistant, and can operate on extreme physical loads. In contrast to ordinary cables, electric wire and cable solutions for industrial use are specially designed to be cut-proof, temperature-resistant, and industrial chemical resistant. This makes them ideal for application in extreme conditions, such as power and manufacturing plants.

A: Control cables are a specific type of industrial cable used to communicate control functions in industrial applications. They are common in production lines, control and automation systems, and, of course, measuring or control instruments. Control cables have internal properties that protect them against mechanical pressure and electrical disturbances, ensuring effective communication every time in an industrial setup.

A: Flex cables are very useful in the industrial sector, especially where movements and flexibility are required. These cables are made such that they can be bent and flexed several times without any changes in their performance or structure. Such features are useful in robotic arms, moving machines, and any feature where cabling has to be mobile most of the time. Flex cables assist in stabilizing proper connections even in active working industrial conditions.

A: Armored industrial cables are resistant to any physical or environmental influences. Armoring, whether steel or aluminum, occurs when the mechanical layer is added to the cable, making its usage possible even in harsh industrial conditions. The use of durable cables further includes durability, crush and impact resistance, and rodent proofing. Armored cables are commonly used for underground wiring, heavy equipment, and areas prone to cable destruction.

A: Industrial cables are essential in the industrial network infrastructure to ensure good and fast data transmission. Such cables are made to endure the unfavorable working conditions typical of manufacturers, such as electromagnetic interference, extreme heat, and chemicals. They provide easy communication among various devices, machines, and control systems for operations in industrial automation, aiding production activities in factories, electric grids, and other industries.

A: Many factors must be considered when selecting cables for welding applications. The most important are the cable’s ampacity, flexibility, strength, and heat and spark resistance. A welding cable must have many strands so that it can be very flexible and not burnt or damaged easily due to the impact of a welding operation. Furthermore, where electrical cables are encapsulated in insulating materials, these insulating materials would be resistant to flames and withstand the effect of slag and other welding waste in the cable constructions.

A: Custom cables are an answer to the unique industrial applications that have to meet specific requirements. They can be manufactured to resist certain environmental factors, support certain signals or voltages, or connect to customized sockets. Custom cables assist industries in solving problems that off-the-shelf solutions cannot address, such as extreme ranges of temperatures, particular chemicals, specific bendability issues, and many others. Various engineers can customize cables for particular industries by collaborating with the manufacturers of these cables.