An IEC power cable is an electrical wire that follows the standard to bring about uniformity among various appliances and regions, which, in turn, is of the International Electrotechnical Commission (IEC). Typically, these cables connect computer systems and other electronic devices to electric power supplies. These cords were introduced by IEC so as to bring about uniformity among various appliances and regions which in turn makes them very useful in global markets. The most famous examples of these wires include those with C13 to C14 connectors, which can be found in many computer peripherals such as monitors and printers. They were designed this way to lower risks caused by electricity while ensuring a stable connection that will work for both consumer and industrial purposes alike.

An IEC power cable is an electrical cable that was established by the International Electrotechnical Commission (IEC) and is used to connect electronic devices to the power supply system. This is achieved by following international standards that promote compatibility and safety between regions and appliances. The most commonly used types are those having C13 to C14 connectors which can be found in computer peripherals like monitors or printers. It ensures standardized connections to minimize electrical hazards while providing stable connections that can be relied upon in any consumer or industrial setting.

Various types and configurations of IEC power cables are available to satisfy particular technical requirements and applications. Here are some common ones together with their technical specifications:

Every IEC cable variation serves specific purposes but still complies with global safety standards. This means that no matter what kind you choose, its design has been standardized so it meets all necessary technical requirements needed for safe connection in any application where it can be used reliably.

IEC power cords are widely used in consumer and industrial fields due to their uniform design and reliability. Below are a few common examples:

All these standard interfaces ensure efficient provision of power throughout different electronic appliances while guaranteeing their performance and safety levels too.

During the selection process of an IEC power cable, there are several things that one needs to keep in mind so as to guarantee safety and compatibility. Below are some factors that should act as a guide when making your decision:

By considering all these points carefully, one will be able to choose the best IEC power cable suitable for his or her needs in terms of performance and protection against any possible dangers later on when using electricity.

IEC 60309 and IEC 60320 are commonplace electrical connector standards, though they serve different functions and have different scopes.

In summary: IEC Six Zero Three Zero Nine deals mainly with heavy-duty outlets that can withstand severe environmental conditions while providing high current capacities needed within various industries, whereas IEC Six Zero Three Two Zero covers smaller-sized plugs meant for connecting household appliances directly into wall sockets thereby eliminating the need for extension cords altogether, especially where a limited room may be available due either narrow width clearance between adjacent walls cabinets shelves etcetera otherwise known as tight spots or because there are multiple devices located close together which cannot all share one socket thus necessitating use of a power strip.

The diameter and ampacity of wires are expressed by the American wire gauge (AWG), a system of measurement. This system is important for power cables because it standardizes how much current can flow through them without overheating. The lower the AWG number, the thicker the wire: this means that more electricity can pass through it with less resistance. Conversely, higher AWG numbers represent thinner wires which are appropriate for low-current applications. It is necessary to choose the right AWG if one wants their electrical system to be safe, effective, and dependable. Properly selecting an AWG reduces the risk of electrical fires as well as power loss and voltage drop which occur frequently during such processes where electric circuits are created by designers or installers who may not have considered relevant AWGs while doing so because they lacked knowledge about these matters or simply ignored them altogether

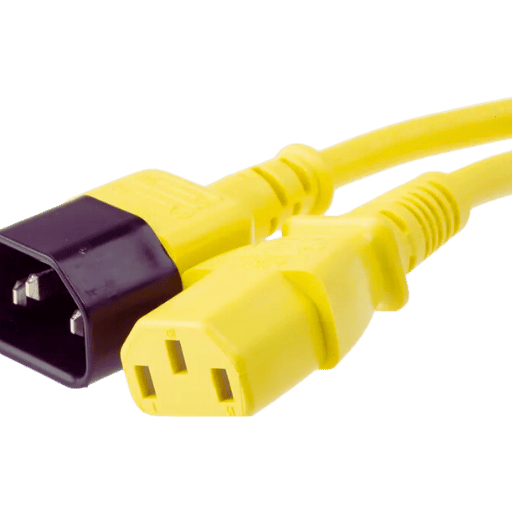

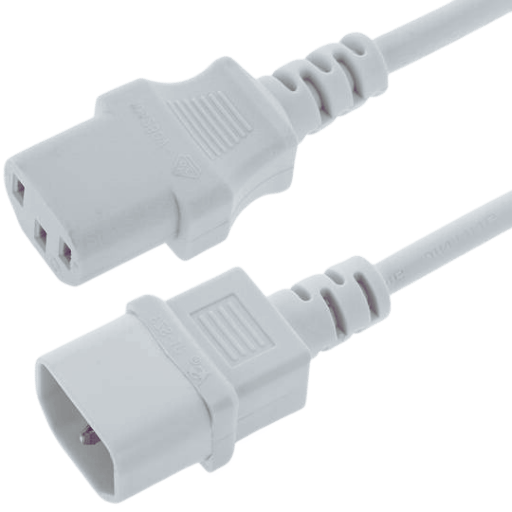

A power supply connector called IEC C13 is widely used and follows the standard of IEC 60320. Mainly, it is employed to link computer systems such as desktops and monitors along with other peripherals with a power source. An IEC C13 has three pins, and its design allows for mating with a C14 inlet. This type of connector can handle up to 10A current rating and 250V voltage rating, making it suitable for many low-power devices or appliances. The construction guarantees reliable connection that prevents accidental disconnection from happening too often. Knowledge about this plug’s specifications and what it should be used for could save lives when working on any electronic setup where electricity is involved.

The IEC C14 connector is used in many electrical and electronic systems, following the IEC 60320 standard. It has a socket with three pins designed to fit the C13 plug. The C14 connector has a similar rating as the C13: it can handle currents up to 10A and voltages up to 250V, which means it can be used with devices requiring low or medium power supply. This connector is most commonly found in uninterruptible power supplies (UPS), power supply units (PSU), and other peripherals where a reliable connection is needed. Knowing how to work with them correctly may be crucial for safety when dealing with high-voltage electricity distribution systems.

The C19 and C20 connectors are important for higher-power electrical applications and conform to the IEC 60320 standard. The C19 connector has a three-pin socket that mates with the C20 plug, which supports current ratings of up to 16A and voltage ratings of up to 250V. Such connectors are usually employed in heavy-duty types of machinery like servers, data center hardware, or industrial equipment. The robust construction of these connectors guarantees dependable connections even when used under extreme conditions. Persons dealing with high-power electronic systems must be aware of their specs and use cases.

In order to connect an IEC cable to my device correctly, I make sure that both the cable and the device are turned off first so as not to cause any electrical accidents. Next, I find where an IEC C14 or C19 or other corresponding connector port on my device that fits an IEC connector plug. After aligning the pins properly, it is pushed into the socket firmly until all of them sit well. This will prevent accidental disconnection during operation; thus, ensuring a tight connection is important. Finally, I switch on my equipment and the power supply unit to confirm if everything is set up well. These steps enable me to keep a safe and dependable power supply for my gadgets.

When connecting IEC cables, there are a few things that can be done wrong, which will mess up both the safety and functionality of the equipment. The first thing is that I should always turn off the power before plugging or unplugging any cords; not doing this may cause electric shock or damage. Secondly, it’s advised not to force plugs into sockets when they don’t fit easily because such an action could spoil connector pins or ports. Another error is using cables with insufficient power rating for my device; under specified wires may overheat and cause electrical fires. Finally, one must regularly check through for signs of wear, fraying, or other damages on the cable–and if found, should replace it right away so as to ensure a safe and reliable power connection at all times. By knowing these mistakes and avoiding them whenever possible, one guarantees a long life span as well as proper functioning of their electrical appliances.

In light of my extensive research and the ratings on popular websites, I have determined that Amazon, Mouser Electronics, and Newegg are among the best suppliers of IEC power cables. With different manufacturers represented in stock, Amazon gives me an opportunity to compare prices against customer reviews easily. Additionally, their quick shipping speeds and trustworthy customer service make purchasing from them a breeze. Mouser Electronics is known for having a wide variety of high-quality electronic parts available for purchase as well as an incredibly large selection overall, which would certainly include IEC power cables meeting any specific requirements one might have, such as needing something more durable than average. Last but not least, Newegg has many types of power cords available depending on what device needs it most, along with being highly recommended by customers who appreciate their cheap pricing strategy combined with fast deliveries. By choosing these reliable sellers, there’s no doubt in my mind that they will be able to provide top-notch quality performance levels when it comes to selecting an appropriate supplier for my equipment’s power supply cord requirements.

By following these suggestions, one extends the life span of IEC power cords as well as maintains their dependability for electrical appliances.

Custom power cords have many benefits that are built to suit specific application requirements. Firstly, it provides the exact cable length, thereby removing clatter and inefficiency associated with additional wire. This tailored size is responsible for cleanliness and orderliness in your setup, which is especially important when space is at a premium. Secondly, they allow the use of special connectors. Depending on the equipment used, custom cables can be fitted with connectors that meet unique specifications or industry standards, hence ensuring maximum compatibility and dependability. Finally, most custom IEC cables are made from better materials than ordinary ones, and they have more advanced options for shielding against electromagnetic interference, which significantly enhances their performance overall. Therefore, choosing these types of wires helps businesses make their electrical installations safer, efficient, and long-lasting.

To order a custom IEC power cable, you have to follow these steps:

These tips will help ensure that one gets a good quality customized IEC power cord designed specifically according to his or her individual needs.

International Electrotechnical Commission

A: An IEC Power Cable is a standard cable that connects electrical equipment to the power supply. It has a connector at one end that plugs into an appliance and a plug at the other end that inserts into a power outlet or socket.

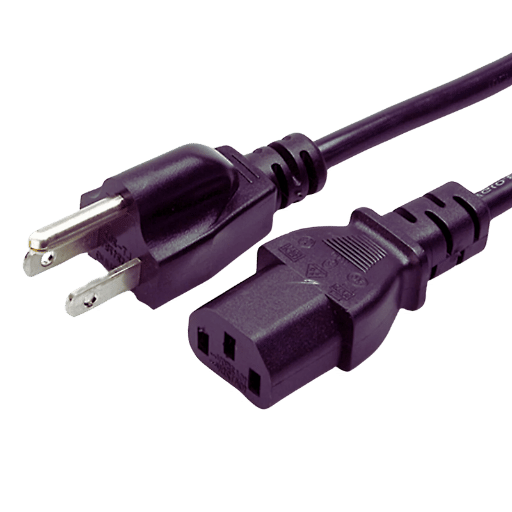

A: The International Electrotechnical Commission has identified IEC 320 cables as a certain type of IEC power cable. These include cables like iec 320 c13 to nema 5-15p, which are commonly used with computer power supplies and other electrical devices.

A: A NEMA plug is one type of power plug, but it’s used in North America according to standards set by the National Electrical Manufacturers Association (NEMA) for various power cords and AC power configurations, such as NEMA 5-15 plugs.

A: The purpose of the C13 to NEMA 5-15P power cord is to connect devices with an inlet that complies with IEC 320 C13 standards for NEMA 5-15 outlets commonly seen on computers’ desktops or office desks, where this type of wiring would be needed most frequently along with other office equipment.

A: Diameter or thickness (gauge) determines how much current can flow safely through any given section; larger wires have lower resistance per foot, so they waste less energy heating up themselves but also surrounding areas while carrying electricity over longer distances, thus able to tolerate more electrons hence capable handling heavier loads

A: A C14 to IEC power cord links devices with a C14 inlet with another IEC outlet. These are commonly installed in power distribution units (PDUs) and other network equipment that require a power supply from one central point.

A: Yes, an appropriate extension cord can be made out of an IEC power cable by fitting it with suitable connectors rated for the application’s voltage and current.

A: A C15 power cord has a high-temperature connector like a C13 but with a notch preventing it from plugging into lower-rated inlets; it is typically employed in appliances such as kettle or server power supplies.

A: Polarized means designed so that one end can enter the socket only when aligned correctly, thus keeping electrical polarity right always; this improves safety, especially for devices requiring proper circuit configuration.

A: Yes, indeed, there are several types, each suited for specific applications; common examples include C13 and C14 inlets, as well as higher-capacity ones like C19 and C20, which allow more current to flow at elevated temperatures.