Power connectors and cables are also necessary in an office or industrial environment as they deliver electricity to various devices and systems effectively. Of the many power connectors utilized, the IEC 60320 C19 is notable for its strength and adaptability. This guide is devoted to the specific IEC C19 connector, its technical characteristics’ applications, and its advantages’ potential. Additionally, the guide will delve into the construction rules of the particular connector, the operational conditions of the connector, and the issues of bringing the particular connector into the electrical systems that are already in use. Regardless of whether one is a professional electric engineer or a beginner about power connectors, this IEC C19 guide will provide the absolute most necessary facts for the reader, enabling them to make appropriate considerations for the projects at hand.

What is an IEC C19 Connector?

Overview of IEC Standards

IEC (International Electrotechnical Commission) develops international standards in the field of electrical and electronic technology and its components, notably power connectors like the C19 and C20. This results in standardization, safety, and compatibility with all electrical circuits within the international systems. The IEC 60320 series deals with appliance couplers for use in households and similar use cases, and the part covering the IEC C19 is with high-current couplers, which is a part of Appliance inlet couplers. This means the technical documentation will include the profiles of the connectors’ design, their performance requirements as well as the requirements concerning their safety. Adopting IEC standards, manufacturers and engineers can be certain that power connectors such as the IEC C19 are designed to perform in different environments while remaining robust and dependable.

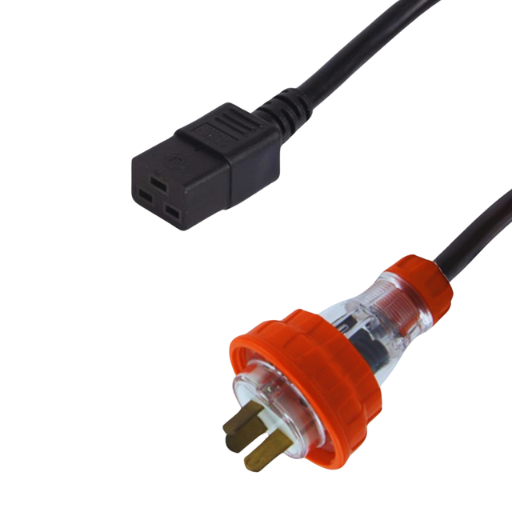

Features of IEC C19 and C20 Connectors

IEC C19 and C20 have high-voltage outlets, typically sustaining only 16 amps at as high as 250 volts AC. These sockets are unique in terms of pin configuration and stoutness. The C19 connector often applied in sockets resembles a rectangle with three horizontal pins. The C19 pin has a similarly shaped C20 inlet but rather three vertical slots.

Design features:

- Numerous connections are needed in the ZYX IEC c20 connector to allow the work of devices consuming mostly PDU Conventional type greater than 10Amp single-phase range up to 16Amp. The defined connectors can boast of higher currents 16A and thus can be used in heavy-duty roles, including in data centers engineering devices, and high computing devices.

- Tough Construction: The connectors utilize tougher materials that enhance their durability, considering that current technologies require the use of more than one operative at a given voltage level, and stable and continuous connectivity is paramount.

- Heat Resistance: The connectors’ nature allows them to resist temperatures, thus assuring that excessive electric current flow would not adversely affect performance.

- Safety Standards: C19 and C20 connectors conform to IEC 60320 standards helping to meet safety and performance standards as the connectors perform their intended action.

- Interchangeability: Due to use of standardized design even products by various manufacturers can be used interchangeably since the connectors and the PDUs can be used in any geographic region without problems of getting out of date.

With these robust characteristics, the IEC C19 and C20 connectors enhance safety, reliability, and performance in high-power applications.

Applications for IEC C19 Connectors

Simply put, IEC C19 connects were designed to be utilized in high-power usage situations most of the time. Here is how they are applied in brief:

- Data Centers: C19 connectors are widely used in data centers because they can support heavy electric currents. They connect high-power Servers, network switches, and Uninterruptible Power Supplies (UPS).

- Industrial Equipment: Another distinct application of C19 connectors is their ability to carry relatively high currents, which extends to industrial appliances and fabrication machines that require reliable and steady power connections.

- High-Power Computing Devices: The above connectors are also among the basic things to connect with high-power computing devices like enterprise servers and high-performance computing and mass storage solutions. Their high-temperature resistant nature facilitates use in high-performance intensive computing environments.

In this regard, C19 connectors are very important in achieving operational efficiency and reliability, not only in data centers but also in other areas that require intensive power utilization.

How to Choose the Right C19 Power Cord?

Understanding Power Cord Specifications

The selection of a C19 power cord should take into account factors such as current rating, type of load, and IEC 60309 compatibility since failure in either may lead to a hazard.

- Current and Voltage Rating: Ensure that you check the power cord’s current and voltage ratings, which are usually expressed in amps and volts, respectively. Ensure that these ratings align with your gadgets’ rated parameters to prevent overheating or electrical faults.

- Connector Type: There are many types of IEC connectors which should be understood. In case of high powered usage, make sure the power cord has a C19 connector on the equipment side and suitable plug on the power supply side.

- Wire Gauge: This is one of the last but very important selections made in that it signifies How much wire in AWG that cord set will be able to carry safely. Ensure that you select an appropriate wire gauge that will deal with the current state of your application, especially the one that comes with power extension cords.

- Cord Length: Choose the type of power cord whose length enables one to avoid unnecessary use of extra line and which gives the required length. Use longer cords when drop in voltage is not expected and shorter when more flexibility is anticipated.

- Temperature Rating: Similarly, the power cord must be rated for the useable operational temps applicable to the surrounding. High power applications tend to produce a lot of heat and thus low rated temperature cables may fail prematurely.

- Certifications: Seek out power cords with safety markings such as UL, CSA, VDE etc. These conformities are indicative of safe practices considering this equipment would function properly and safely.

By carefully examining the parameters, you will be able to choose the correct C19 power cord for the specific power requirements of your high-consumption applications.

Comparing 12 AWG vs. 16 AWG Cords

Current capacity and application requirements are additional factors to examine when choosing between 12 AWG and 16 AWG power cords.

12 AWG Cords:

- Current Capacity: Due to their thicker wire gauge, these cords can carry more current, typically at about 20 amps.

- Applications: This product is perfect for high-power equipment such as servers and large computers that use high current loads.

- Voltage Drop: They are low in resistance,, which means that there is very little loss of voltage even when the wires are long.

16 AWG Cords:

- Current Capacity: Because they have a thinner wire gauge, these cords carry lower current, usually up to 13 Amps.

- Applications: Good with regard to power consumption, for devices such as printers and smaller electronics that require an IEC C19 to C20 connector, is not use. However high ton files applications are not recommended.

- Flexibility: Thinner wire offers more flexible and easy-to-handle cords.

In conclusion, 12 AWG cords will be required for power-intensive equipment, including high-current applications, and where a low voltage drop is needed, while 16 AWG cords will be used for less powered and less demanding devices.

Importance of Temperature Rating and UL Certification

Rating and UL certification are essential factors to pay attention to when choosing power cords for high-demand applications.

Temperature Rating:

- Performance: The temperature rating describes the highest temperature at which the power cord insulation may be used operationally. This helps avoid extremely high temperatures that may lead to overheating and wear and tear that may worsen the product’s safety and efficiency.

- Durability: The dependence can also improve the lifespan of the cord because it raises the temperature level where the cord would otherwise break down, especially in high-heat conditions.

UL Certification:

- Safety Assurance: Underwriters Laboratories (UL) certification means that the power cord has been tested, scrutinized, and thoroughly assessed to prove its safety norms. Such cords are accurate and less prone to electrical or fire solutions in hazardous conditions since they can be relied on.

- Regulatory Compliance: There are many regulatory and standard requirements within the industry that prevent certain components from being installed that are incorrect, such as UL-certified components. The benefit of using such cords is that they help to follow the rules and technical conditions and avoid penalties for non-compliance.

One of the most crucial aspects of buying power cords is to ensure that they have the right temperature ratings and UL certification to ensure that your high-demand applications are safe, effective, and efficient.

What Are the Differences Between IEC 60320 Connectors?

Comparison of C13, C19, and C20 Connectors

C13 Connector:

- Applications: It is frequently used to provide power to computers or monitors.

- The current rating is important for knowing the dimension of the power extension connector electric wire so that personnel safety can be observed. It is usually applicable up to a 10amp rating.

- Shape and Size: It has a three-pin IEC connector nut, which is mainly used in low-power consumption devices.

C19 Connector:

- Applications: Configuration for high power-consuming devices such as servers and data center equipment.

- Current rating: Cost tends to be high being rated up to 16 amps making it perfect for tougher practices.

- Shape and Size: It is more thick than the C13 connector being rectangular in shape with 3 pin configuration.

C20 Connector:

- Applications are designed for high current applications and the output connector for c19 cables.

- Current rating: Also rated up to 16 amps.

- Shape and Size: It is similar in size and shape to a C19 connector, but this time, it is a female C19 connector.

Knowing the ratings of the current and how it is used, as well as the physical information or structure of the connector, enables you to know the type of connector to use and have it serve you well.

How IEC 60320 C19 and C20 Connectors Fit into Power Distribution

C19 and C20 socket connectors are especially significant in power distribution systems with high usage of electrical appliances. The C19 connector is rated at 16amps and is usually applied to servers and other networking devices in the data center and manufacturing environments. Their primary function is to connect the power supply and equipment to continuously power operations. As the female end of the C20 connector fills that of a C19 male connector, the male connector is typically the inlet for the power to which a power distribution unit is connected. C19 and C20 connectors perform better together in power distribution in highly demanding applications, enhancing the performance and stability of operations—ribution, supporting the operational stability and performance of critical high-power applications.

Role of IEC 60320 in Data Centers

Data Center equipment, besides core computer servers and storage components, also uses IEC 60320 connectors. They include C19 and C20 connectors. However, changes are now being seen with the advancement of technology. Such universal power connectors are created to ease operation and boost safety at workstations, which numerous manufacturers produce. C19 and C20 electrical connectors are a level-up of standard three-pin plugs, usually meant for appliances that operate heavy duties such as internet servers, storage devices, and switching equipment. Features and structural robustness are crucial in ensuring a reliable attachment in power cords, a factor critical for uninterrupted functionality in data centers. Further, applying IEC 60320 standardized connectors allows power cord management improvement and replacement without power cuts, increasing the data center power distribution utility. Consequently, adopting IEC 60320 connectors offers a tool to promote power system performance, scale, and compliance with global standards in data center operation.

How to Properly Use C19 to C20 Power Cables?

Connecting C19 and C20 for Maximum Efficiency

There are practical steps that can be taken to enhance the connection between the C19 and C20 power cables for the best results:

- Verify Compatibility: Typically, C19 to C20 cable connectors are used with PDU and devices. Check the current and volt ratings to add safety and avoid overloading on the devices.

- Inspect Cables and Connectors: The cables and connectors should be free from wear, breakage, or defects. Using broken or low-standard cables can cause many risks or inconveniences.

- Secure Connection: Insert the C19 connector into the C20 inlet and press it until you hear a click. If the connector is not properly locked into position, it may lead to power sucking on the areas instructed by the false socket.

- Manage Cable Routing: Ensure that the wires are carefully arranged and managed so that the connectors are not twisted or pulled. Cluttered and accessible cables should be organized neatly with cable management accessories.

- Monitor Power Load: The power load should be checked periodically to verify that it does not exceed the specifications provided. Excessive loads on the connectors and equipment will make them hot.

Implementing these measures will improve workability and reliability within the C19 and C20 power connectors, ensuring the continuous smooth running of the data center.

Common Mistakes with C19 and C20 Connections

- Incompatible Equipment: C19 and C20 connectors that do not meet the equipment specifications are likely to be used, which will lead to an insufficient supply of power and a possible escalation of damage.

- Poor Inspection Practices: Properly assessing the cables and their respective connectors for wear and tear and defects is always possible. This can lead to unreliable connections and more electrical faults.

- Improper Insertion: The C19 connector is not pushed into the C20 inlet; that is, the connector cannot guarantee that it will click into place. As a result, cables are loosely plugged, which sometimes causes outages and even electrical shocks.

- Neglecting Cable Management: Cables that are not well-managed are liable to twine along with the power connectors, which applies physical strain and wear on the connectors, compromising the power supply.

- Ignoring Power Load Monitoring: Glaringly promoting monitoring power loads during grid operations can lead to power overload, which is likely to sell.

Neglecting these errors can protect the quality of functioning of C19 to C20 power connections, leading to better and safer operations.

Ensuring Safety with 20A 250V Power Cables

Important practices should be followed to guarantee the safe use of 20A 250V power cables. To begin with, on every occasion, only cables that have the proper specifications and have been reviewed for their quality and compliance should be used. Cables should also be checked from time to time for such damages as cuts or blisters; if such cables are discovered to be damaged, they should be replaced immediately. Cables should be appropriately managed; there is a need to cordon off the cables to prevent entanglement and also physical stress on the cables. Also, the power load to which a cable is being subjected should be monitored to avoid overloading the cable fastened below the recommended limits. Innovations from these steps will, in a significant way, limit the chances of electrical hazards occurring and enhance the safety features of the power connections.

What Are the Best Practices for IEC C19 and C20 Inlet Installation?

Step-by-Step Installation Guide for IEC C19 Inlet

- Gather Necessary Tools and Equipment: Ensure you have everything needed, such as a screwdriver, wire stripper, and the IEC C19 inlet.

- Power Down Equipment: Before installing, turn off all equipment and all electric connections.

- Prepare the Cables: Simply remove the cables’ covers, which will not harm the wires.

- Connect the Wires to the Inlet: Connect the conductors to the terminals as marked on the IEC C 19 inlet according to the wiring diagram: ‘L’ for live, ‘N’ for neutral, and ‘E’ or ‘GND’ for ground.

- Secure the Inlet: Use screws to hold the IEC C19 inlet to its mounting bracket. Ensure that it is tightened crisply to avert any shaking or looseness in the AC power connection.

- Inspect connections regularly to ensure the integrity of the IEC 320 system: All the connectors should be inspected to establish their tightness and fastened accordingly. There should be no wires hanging freely in the air.

- Reconnect Power Supply: After making sure all connections are tight and the inlet is safe on its place, turn on the power supply and switch on the equipment.

- Test Introduction: Check the installation by testing the performance of the equipment with a newly installed IEC C19 inlet. Make sure there is no problem with power supply.

Choosing the Right Power Supply Cord for C19 and C20 Inlets

What criteria can be identified when choosing a power supply cord?

- Voltage and current ratings: Check that the cord satisfies the applicable voltage and equipment’s current conditions.

- Compliance: Risk and other significant safety and regulatory requirements related to the cord should be addressed.

- Length: Briefly specify the distance from the power supply to the place of the equipment.

- Environment: Pick a cord appropriate for working conditions like heat and humidity.

- Plug type: The type should fit the power outlet and the equipment.

What is the effect of not matching the voltage and current ratings?

- Prevents overheating

- Creates a reliable performance

- Minimizes chances of an electrical fire

Maintaining IEC Connectors for Longevity

However, several best practices must be followed to use IEC connectors for many years. The first is the achievable care of the connectors through regular reviews of the connectors for physical and/or chemical wear, damage, or corrosion. This helps diagnose the issues that can become sufficient to lead to a breakdown of the equipment. The next step I undertake is to periodically remove dirt and dust from the connectors’ surfaces with proper cleaning agents for proper contact. The third one is that I ensure the connections are tight but do not pull too much on the cable connections, as this can cause wear and tear on the connectors in the long run. Additionally, when the connectors are not being used, I also make sure that they are stored in a safe place that is not moist or too warm in order to avoid other factors speeding up the degradation process. Adhering to these requirements, I can quite increase the working life of my IEC connectors, which include the IEC C20 power cables, and keep them in good working order.

Reference Sources

Power cord

Electrical connector

International Electrotechnical Commission

Frequently Asked Questions (FAQs)

Q: Could you briefly explain the C19 connector and C20 inlet, after which you can describe the differences?

A: The C19 connector and C20 inlet are part of the group of connectors as per the IEC 60320 standard for power connectors. The C19 is a female connector, so it is generally installed on devices, while the C20 is a male inlet, which is present on power supplies or PDUs. C19/C20 systems are higher-current versions rated for use up to 16A at 250V.

Q: What is a C20 to C19 power cord, and what is the application area of such cord?

A: A C20 to C19 power cord has one end with a C20 male connector and another with a C19 female connector. This type of cord is mainly used in a server or UPS as well as a networking console to PDU/power in data center and industrial applications

Q: Is there any expansion for SJT in the Context of power cables?

A: SJT means Service Junior Thermoplastic, which denotes a flexible cord, usually with thermoplastic covering, used for power cords, extension cords, etc. SJT cables are light to medium-duty cables often found with computers, appliances, and electrical devices.

Q: What is interesting about the 12AWG on power cords?

A: The term 12AWG (American Wild Gauge) concerns dimensional wire from the power cord system. 12AWG is a comparatively thick gauge of wire, so it carries higher currents. It is used in C19/C20 power cords, which are rated for higher amperage, hence better power supply and efficiency on high-power appliances.

Q: Compare the C13 connector and C14 inlet to C19 and C20.

A: C13 and C14 inlets are analogous to C19 and C20 connectors and inlets, except that they are intended for low-power usage. C13/C14 are usually rated for 10A at 250V, while C19/C20 are rated for 16A at 250. C13/C14 is more utilized in desktop PCs and monitors, while C19/C20 is utilized in high-end power devices such as servers and networking devices.

Q: What is a PDU, and how does it fit with connectors C19 and C20?

A: A power distribution unit (PDU) is a signification of a PDU. This device is designed to share electric energy among a number of devices and is common equipment in data centers and server rooms. In many instances, PDUs with C19 receptacles are used to power high-current devices, and C20 inlets are present for connecting to power lines, so C19 and C20 connectors make sense in how power is used in these facilities.

Q: Do IEC C19 and C20 connectors comply with RoHS?

A: Affirmative. Most of the current IEC C19 C20 connectors and power cords are made in compliance with the ROHS (restriction of hazardous substances) directive. Remaining compliant means simply looking at these components and making them free of specified hazardous materials like lead, mercury, and cadmium, making them safer and more environmentally friendly.

Q: Is it safe to connect a C14 plug to a C19 receptacle using a C20 to C19 C14 adapter?

A: Although there are C20 to C19 adapters, it is not advisable to use one to connect a C14 plug to a C19 wall socket. This is because C19 receptacles are intended for devices using high currents, and such an adapter will work at the risk of overloading either the C14 plug or the device fitted into it. Pay attention to the fact that your power connections always meet the demands of the corresponding equipment being used.

Post Views: 11,760